check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1772 of 3000

AX–100U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(g) According to the display on the tester, read the "DATA LIST".

HINT:

• SPD (NC) is always 0 while driving:

Open or short in the sensor or circuit.

• SPD (NC) is always more than 0 and less than 300 rpm while driving the vehicle at 50 km/h (31 mph)

or more:

Sensor trouble, improper installation, or intermittent connection trouble of the circuit.

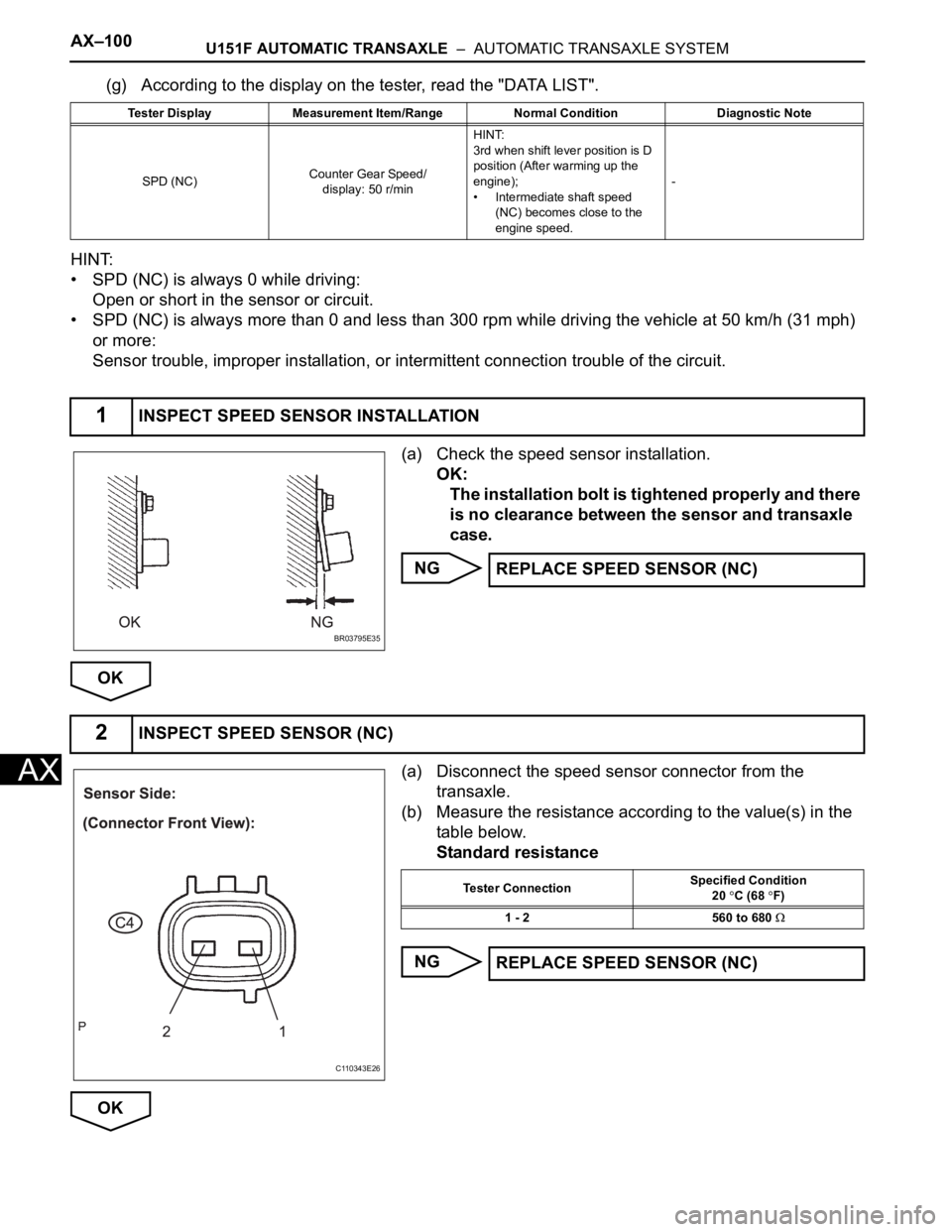

(a) Check the speed sensor installation.

OK:

The installation bolt is tightened properly and there

is no clearance between the sensor and transaxle

case.

NG

OK

(a) Disconnect the speed sensor connector from the

transaxle.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

SPD (NC)Counter Gear Speed/

display: 50 r/minHINT:

3rd when shift lever position is D

position (After warming up the

engine);

• Intermediate shaft speed

(NC) becomes close to the

engine speed.-

1INSPECT SPEED SENSOR INSTALLATION

BR03795E35

REPLACE SPEED SENSOR (NC)

2INSPECT SPEED SENSOR (NC)

C110343E26

Tester ConnectionSpecified Condition

20 C (68 F)

1 - 2 560 to 680

REPLACE SPEED SENSOR (NC)

Page 1776 of 3000

AX–104U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to perform ACTIVE TEST allows relays, VSVs, actuators and other items to be

operated without removing any parts. This non-intrusive functional inspection can be very useful because

intermittent operation may be discovered before parts or wiring is disturbed. Performing ACTIVE TEST

early in troubleshooting is one way to save diagnostic time. DATA LIST information can be displayed while

performing ACTIVE TEST.

1. PERFORM ACTIVE TEST

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the intelligent tester together with the CAN VIM (controller area network vehicle

interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / SHIFT".

(g) According to the display on the tester, perform the "ACTIVE TEST".

HINT:

While driving, the shift position can be forcibly changed with the intelligent tester.

Comparing the shift position commanded by the ACTIVE TEST with the actual shift position enables you

to confirm the problem (See page AX-30).

HINT:

• This test can be conducted when the vehicle speed is 50 km/h (31 mph) or less.

• The shift position commanded by the ECM is shown in the DATA LIST/SHIFT display on the intelligent

tester.

(a) Connect the intelligent tester together with the CAN VIM

(controller area network vehicle interface module) to the

DLC3.

(b) Turn the ignition switch to the ON position and turn the

OBD II scan tool or the intelligent tester main switch ON.

(c) When you use intelligent tester:

Select the item "DIAGNOSIS / ENHANCED OBD II /

DTC INFO / CURRENT CODES".

(d) Read the DTCs using the OBD II scan tool or the

intelligent tester.

Result

Tester Display Test Part Control Range Diagnostic Note

SHIFT[Test Details]

Operate the shift solenoid valve and set the each

shift position by yourself.

[Vehicle Condition]

• IDL: ON

• Less than 50 km/h (31 mph)

[Others]

•Press "

" button: Shift up

•Press "" button: Shift down1st/2nd/3rd/4th/5thPossible to check the

operation of the shift

solenoid valves.

1CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0796)

Result Proceed to

P0796 A

P0796 and other DTCs B

Page 1795 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–123

AX

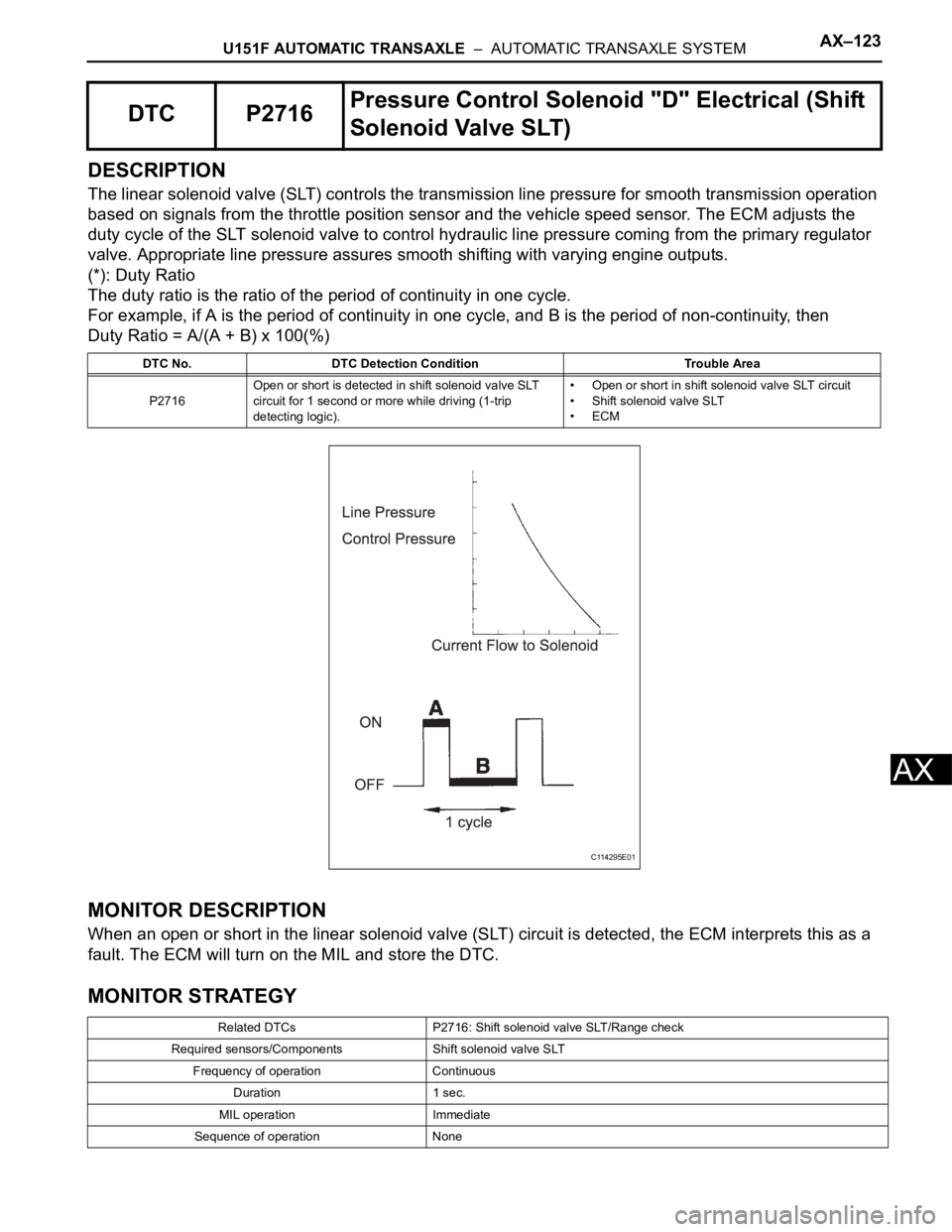

DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the

duty cycle of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator

valve. Appropriate line pressure assures smooth shifting with varying engine outputs.

(*): Duty Ratio

The duty ratio is the ratio of the period of continuity in one cycle.

For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, then

Duty Ratio = A/(A + B) x 100(%)

MONITOR DESCRIPTION

When an open or short in the linear solenoid valve (SLT) circuit is detected, the ECM interprets this as a

fault. The ECM will turn on the MIL and store the DTC.

MONITOR STRATEGY

DTC P2716Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

DTC No. DTC Detection Condition Trouble Area

P2716Open or short is detected in shift solenoid valve SLT

circuit for 1 second or more while driving (1-trip

detecting logic).• Open or short in shift solenoid valve SLT circuit

• Shift solenoid valve SLT

•ECM

Related DTCs P2716: Shift solenoid valve SLT/Range check

Required sensors/Components Shift solenoid valve SLT

Frequency of operation Continuous

Duration 1 sec.

MIL operation Immediate

Sequence of operation None

C114295E01

Page 1799 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–127

AX

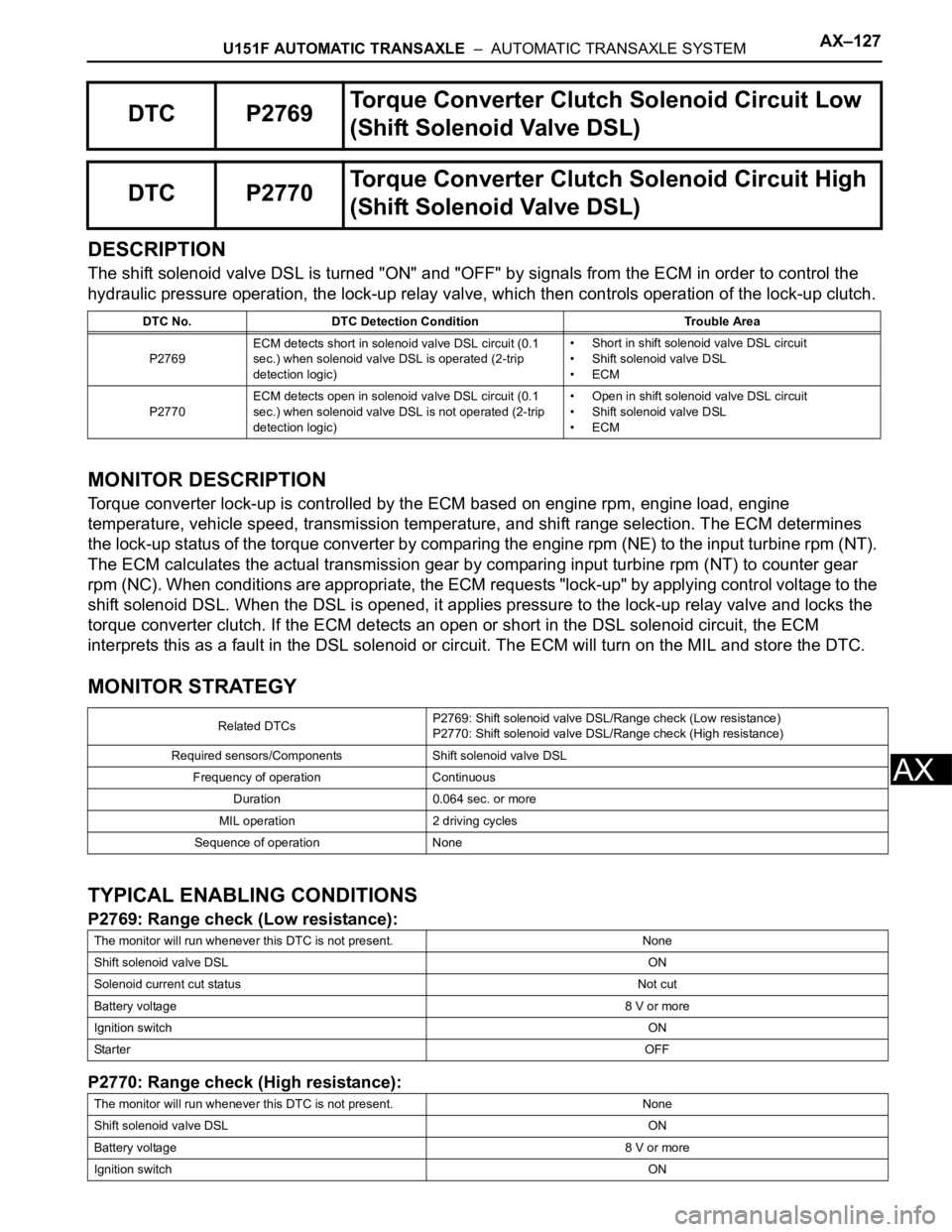

DESCRIPTION

The shift solenoid valve DSL is turned "ON" and "OFF" by signals from the ECM in order to control the

hydraulic pressure operation, the lock-up relay valve, which then controls operation of the lock-up clutch.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on engine rpm, engine load, engine

temperature, vehicle speed, transmission temperature, and shift range selection. The ECM determines

the lock-up status of the torque converter by comparing the engine rpm (NE) to the input turbine rpm (NT).

The ECM calculates the actual transmission gear by comparing input turbine rpm (NT) to counter gear

rpm (NC). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to the

shift solenoid DSL. When the DSL is opened, it applies pressure to the lock-up relay valve and locks the

torque converter clutch. If the ECM detects an open or short in the DSL solenoid circuit, the ECM

interprets this as a fault in the DSL solenoid or circuit. The ECM will turn on the MIL and store the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

P2769: Range check (Low resistance):

P2770: Range check (High resistance):

DTC P2769Torque Converter Clutch Solenoid Circuit Low

(Shift Solenoid Valve DSL)

DTC P2770Torque Converter Clutch Solenoid Circuit High

(Shift Solenoid Valve DSL)

DTC No. DTC Detection Condition Trouble Area

P2769ECM detects short in solenoid valve DSL circuit (0.1

sec.) when solenoid valve DSL is operated (2-trip

detection logic)• Short in shift solenoid valve DSL circuit

• Shift solenoid valve DSL

•ECM

P2770ECM detects open in solenoid valve DSL circuit (0.1

sec.) when solenoid valve DSL is not operated (2-trip

detection logic)• Open in shift solenoid valve DSL circuit

• Shift solenoid valve DSL

•ECM

Related DTCsP2769: Shift solenoid valve DSL/Range check (Low resistance)

P2770: Shift solenoid valve DSL/Range check (High resistance)

Required sensors/Components Shift solenoid valve DSL

Frequency of operation Continuous

Duration 0.064 sec. or more

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Shift solenoid valve DSLON

Solenoid current cut status Not cut

Battery voltage8 V or more

Ignition switchON

Sta r t e rOFF

The monitor will run whenever this DTC is not present. None

Shift solenoid valve DSLON

Battery voltage8 V or more

Ignition switchON

Page 1802 of 3000

AX–10U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the ATF temperature 50 to 80

C

(122 to 176

F) in the normal operation.

(a) D position test:

Shift into the D position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that 1

2, 2 3, 3 4 and 4 5th up-

shifts take place, and that the shift points

conform to the automatic shift schedule (See

page SS-31).

HINT:

5th Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 80 km/h (176

mph) or less.

• ATF temperature is -2

C (28F) or less.

4th Gear Up-shift Prohibition Control

• Coolant temperature is 47

C (117F) or less

and vehicle speed is at 55 km/h (34 mph) or

less.

5th and 4th Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Coolant temperature is 60

C (140F) or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3, 3

4 and 4 5th up-shifts.

(3) Check for abnormal noise and vibration.

Drive in the D position lock-up or 5th gear, and

check for abnormal noises and vibration.

HINT:

The check for the cause of abnormal noise and

vibration must be done very thoroughly as it

could also be due to loss of balance in the

differential, torque converter clutch, etc.

(4) Check kick-down operation.

Check that the possible kick-down vehicle speed

limits for 2nd to 1st, 3rd to 2nd, 4th to 3rd, 5th to

4th kick-downs conform to those indicated on

the automatic shift schedule while driving

through all gears with the shift lever in the D

position (See page SS-31).

(5) Check abnormal shock and slip at kick-down.

Page 1803 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–11

AX

(6) Check the lock-up mechanism.

• Drive in D position (5th gear), at a steady

speed (lock-up ON).

• Lightly depress the accelerator pedal and

check that the engine speed does not change

abruptly.

HINT:

• There is no lock-up in the 1st and 2nd gear.

• 4th lock-up operates while uphill-downhill

control is active in D position.

• 3rd lock-up operates while uphill-downhill

control is active in D position.

• ATF temperature is 120

C (248F) or more.

• If there is a big jump in engine speed, there is

no lock-up.

(b) 4 (O/D OFF) position test:

Shift into the 4 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2, 2 3 and 3 4 up-shift

take place and that the shift point conforms to

the automatic shift schedule (See page SS-31).

HINT:

There is no 5th up-shift in the 4 position.

(2) Check engine braking.

While driving in the 4 position and 4th gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(c) 3 position test:

Shift into the 3 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 and 2 3 up-shift take

place and that the shift point conforms to the

automatic shift schedule (See page SS-31).

HINT:

There is no 4th up-shift and lock-up in the 3

position.

(2) Check engine braking.

While running in the 3 position and 3rd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

Page 1804 of 3000

AX–12U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(d) 2 position test:

Shift into the 2 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 up-shift takes place and

that the shift point conforms to the automatic

shift schedule (See page SS-31).

HINT:

There is no 3rd up-shift and lock-up in the 2

position.

(2) Check engine braking.

While running in the 2 position and 2nd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(e) L position test:

Shift into the L position and fully depress the

accelerator pedal and check the following points.

(1) Check no up-shift.

While running in the L position, check that there

is no up-shift to 2nd gear.

HINT:

There is no lock-up in the L position.

(2) Check engine braking.

While running in the L position, release the

accelerator pedal and check the engine braking

effect.

(3) Check for abnormal noise during acceleration

and deceleration.

(f) R position test:

Shift into the R position and fully depress the

accelerator pedal and check for slipping.

CAUTION:

Before conducting this test ensure that the test

area is free from people and obstruction.

(g) P position test:

Stop the vehicle on the grade (more than 5

) and

after shifting into the P position, release the parking

brake. Then, check that the parking lock pawl holds

the vehicle in place.

(h) Uphill/downhill control function test:

(1) Check that the gear does not up-shift to the 4th

or 5th gear while the vehicle is driving uphill.

(2) Check that the gear automatically down-shifts

from 5th to 4th or from the 4th to 3rd gear when

brake is applied while the vehicle is driving

downhill.

Page 1805 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE FLUIDAX–123

AX

AUTOMATIC TRANSAXLE FLUID

ON-VEHICLE INSPECTION

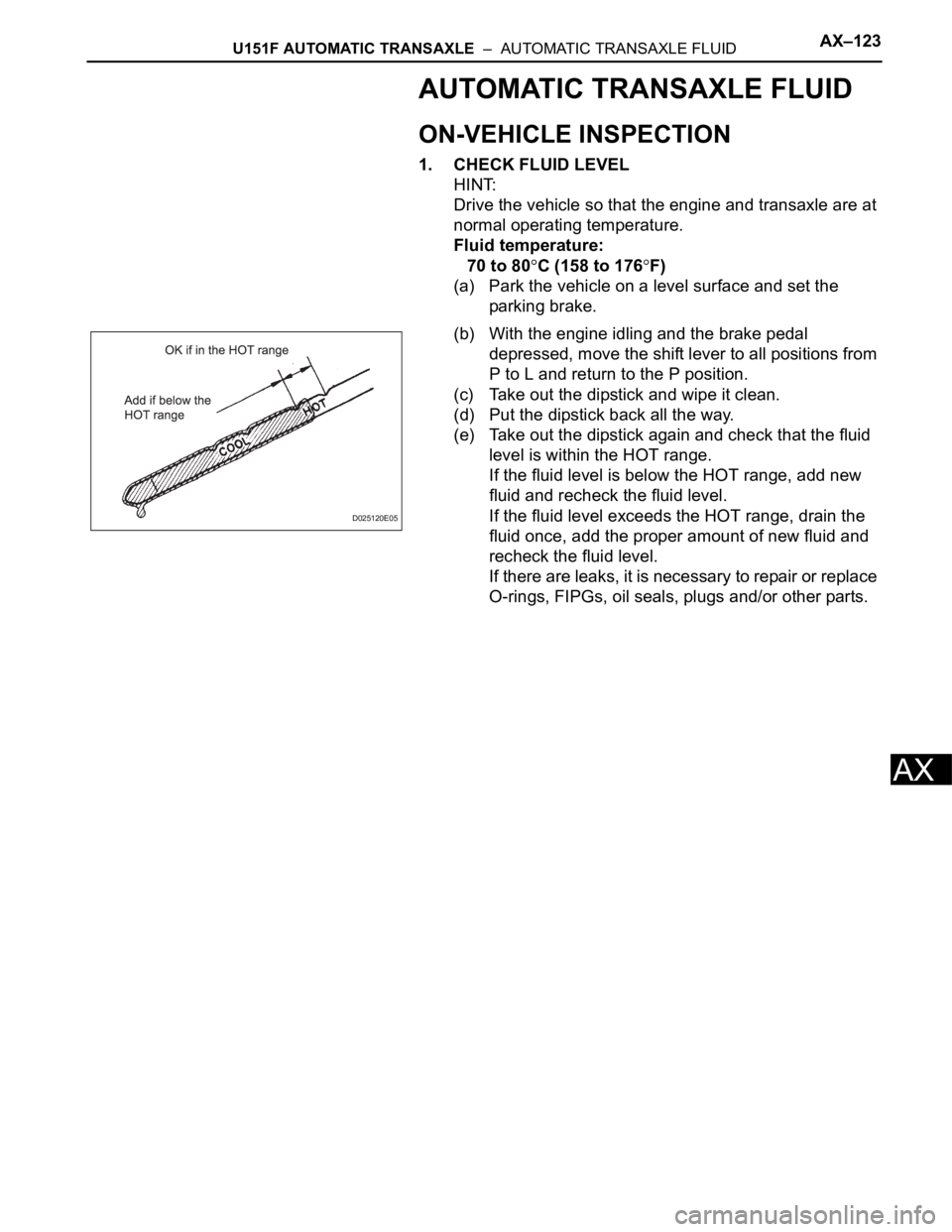

1. CHECK FLUID LEVEL

HINT:

Drive the vehicle so that the engine and transaxle are at

normal operating temperature.

Fluid temperature:

70 to 80

C (158 to 176F)

(a) Park the vehicle on a level surface and set the

parking brake.

(b) With the engine idling and the brake pedal

depressed, move the shift lever to all positions from

P to L and return to the P position.

(c) Take out the dipstick and wipe it clean.

(d) Put the dipstick back all the way.

(e) Take out the dipstick again and check that the fluid

level is within the HOT range.

If the fluid level is below the HOT range, add new

fluid and recheck the fluid level.

If the fluid level exceeds the HOT range, drain the

fluid once, add the proper amount of new fluid and

recheck the fluid level.

If there are leaks, it is necessary to repair or replace

O-rings, FIPGs, oil seals, plugs and/or other parts.

D025120E05

Page 1806 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,600 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1807 of 3000

AX–14U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(b) Measure the time lag.

(1) When the shift lever is shifted while the engine is

idling, there will be a certain time lapse or lag

before the shock can be felt. This is used for

checking the condition of the clutch and brake.

NOTICE:

• Perform the test at the normal operating

ATF (Automatic Transmission Fluid)

temperature: 50 to 80

C (122 to 176F).

• Be sure to allow 1 minute interval between

tests.

• Perform the test three times, and measure

the time lags. Calculate the average value

of the three time lags.

• When conducting stall test, do not

continue more than 10 seconds.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Start and warm up the engine and check idle

speed.

Idle speed:

approx. 700 rpm (In N position and A/C

OFF)

(5) Shift the lever from N to D position. Using a stop

watch, measure the time from when the lever is

shifted until the shock is felt.

Time lag:

N

D less than 1.2 seconds

(6) In the same way, measure the time lag for N

R.

Time lag:

N

R less than 1.5 seconds

Evaluation (If N

D or N R time lag is longer than the specified):

Problem Possible cause

N

D time lag is longer• Line pressure is too low

• Forward clutch worn

• No.1 one-way clutch is not operating properly

• U/D (Underdrive) one-way clutch is not operating

• U/D (Underdrive) brake worn

N

R time lag is longer• Line pressure is too low

• Reverse clutch worn

• 1st and reverse brake worn

• U/D (Underdrive) brake worn