check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2514 of 3000

BC–152BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

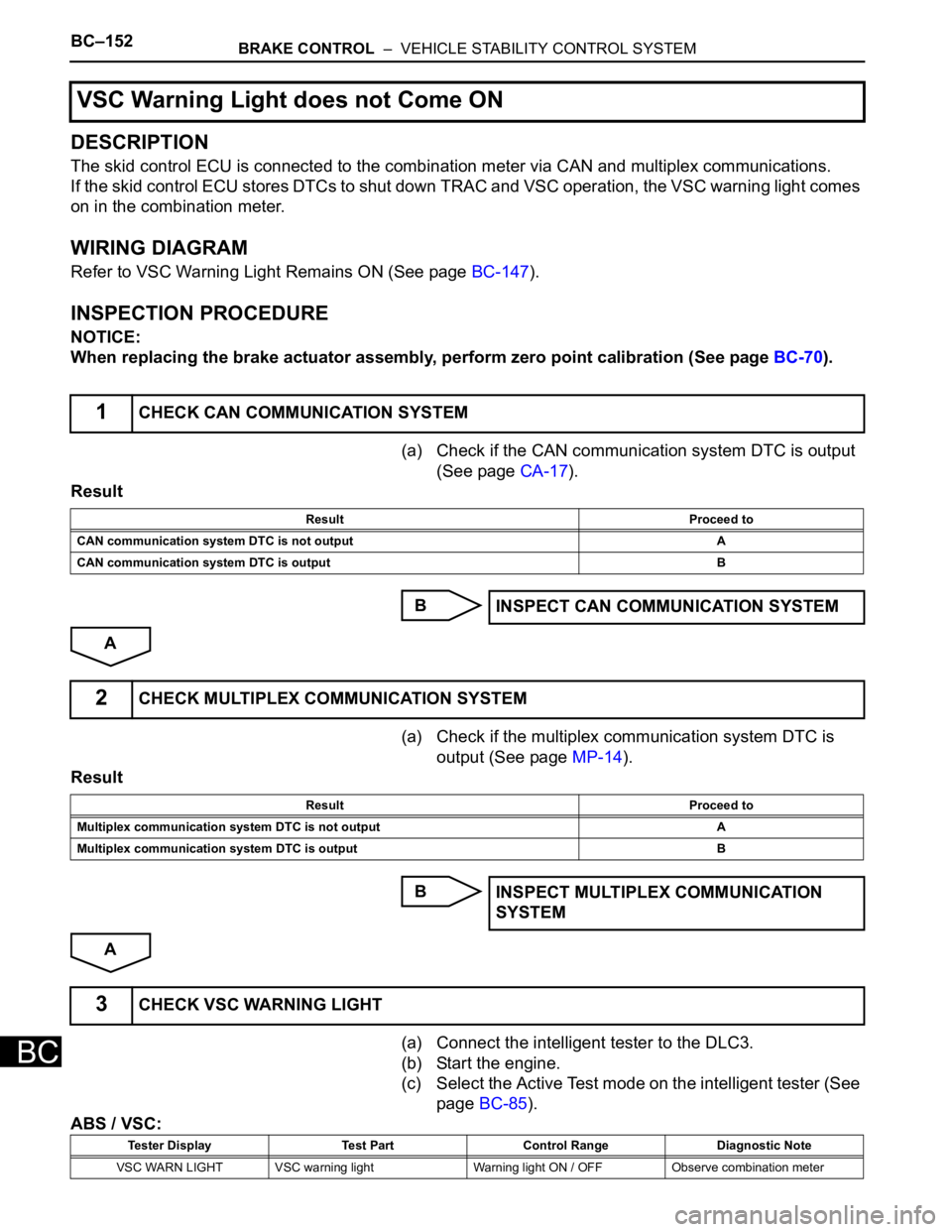

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and multiplex communications.

If the skid control ECU stores DTCs to shut down TRAC and VSC operation, the VSC warning light comes

on in the combination meter.

WIRING DIAGRAM

Refer to VSC Warning Light Remains ON (See page BC-147).

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Check if the CAN communication system DTC is output

(See page CA-17).

Result

B

A

(a) Check if the multiplex communication system DTC is

output (See page MP-14).

Result

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the Active Test mode on the intelligent tester (See

page BC-85).

ABS / VSC:

VSC Warning Light does not Come ON

1CHECK CAN COMMUNICATION SYSTEM

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

INSPECT CAN COMMUNICATION SYSTEM

2CHECK MULTIPLEX COMMUNICATION SYSTEM

Result Proceed to

Multiplex communication system DTC is not output A

Multiplex communication system DTC is output B

INSPECT MULTIPLEX COMMUNICATION

SYSTEM

3CHECK VSC WARNING LIGHT

Tester Display Test Part Control Range Diagnostic Note

VSC WARN LIGHT VSC warning light Warning light ON / OFF Observe combination meter

Page 2517 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–155

BC

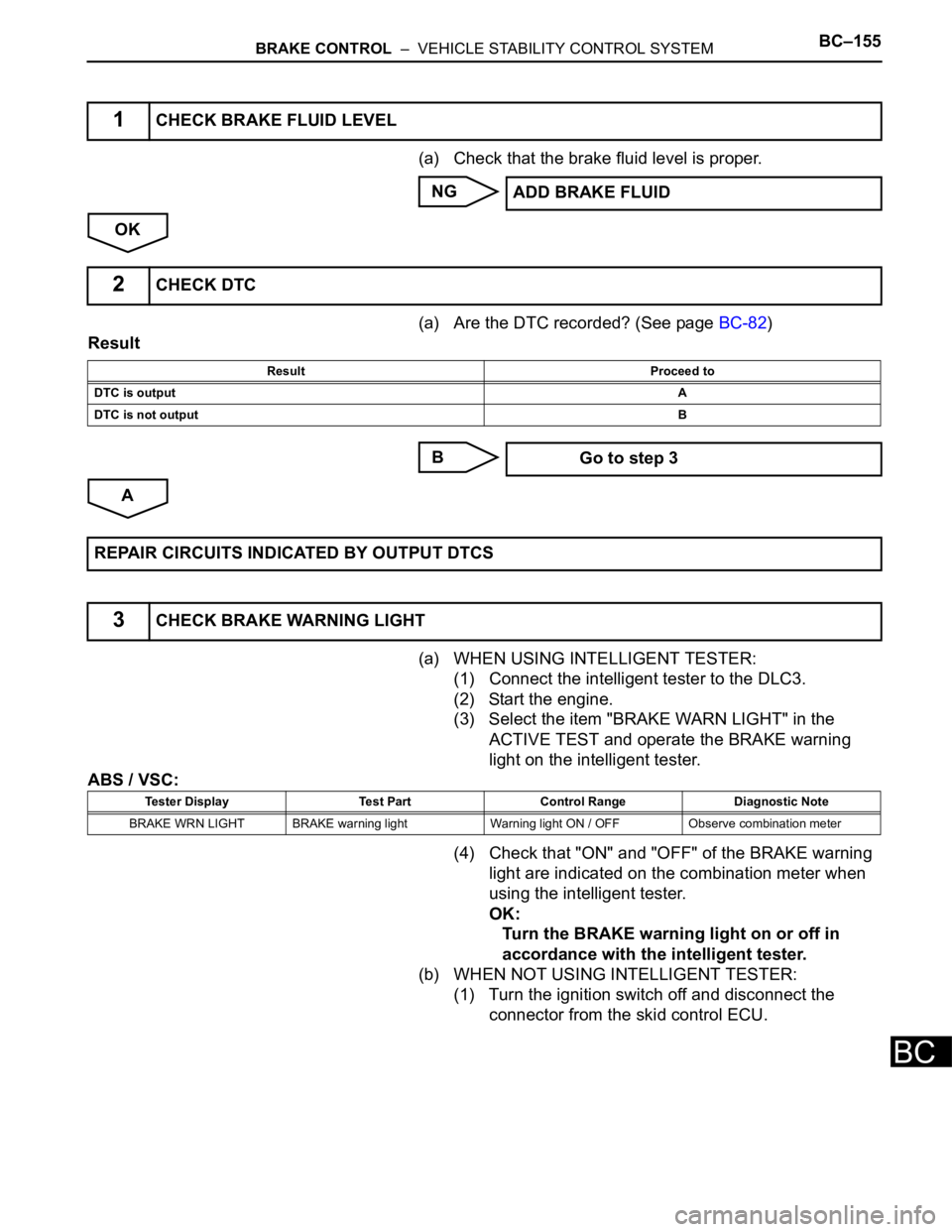

(a) Check that the brake fluid level is proper.

NG

OK

(a) Are the DTC recorded? (See page BC-82)

Result

B

A

(a) WHEN USING INTELLIGENT TESTER:

(1) Connect the intelligent tester to the DLC3.

(2) Start the engine.

(3) Select the item "BRAKE WARN LIGHT" in the

ACTIVE TEST and operate the BRAKE warning

light on the intelligent tester.

ABS / VSC:

(4) Check that "ON" and "OFF" of the BRAKE warning

light are indicated on the combination meter when

using the intelligent tester.

OK:

Turn the BRAKE warning light on or off in

accordance with the intelligent tester.

(b) WHEN NOT USING INTELLIGENT TESTER:

(1) Turn the ignition switch off and disconnect the

connector from the skid control ECU.

1CHECK BRAKE FLUID LEVEL

ADD BRAKE FLUID

2CHECK DTC

Result Proceed to

DTC is outputA

DTC is not outputB

Go to step 3

REPAIR CIRCUITS INDICATED BY OUTPUT DTCS

3CHECK BRAKE WARNING LIGHT

Tester Display Test Part Control Range Diagnostic Note

BRAKE WRN LIGHT BRAKE warning light Warning light ON / OFF Observe combination meter

Page 2526 of 3000

BC–164BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

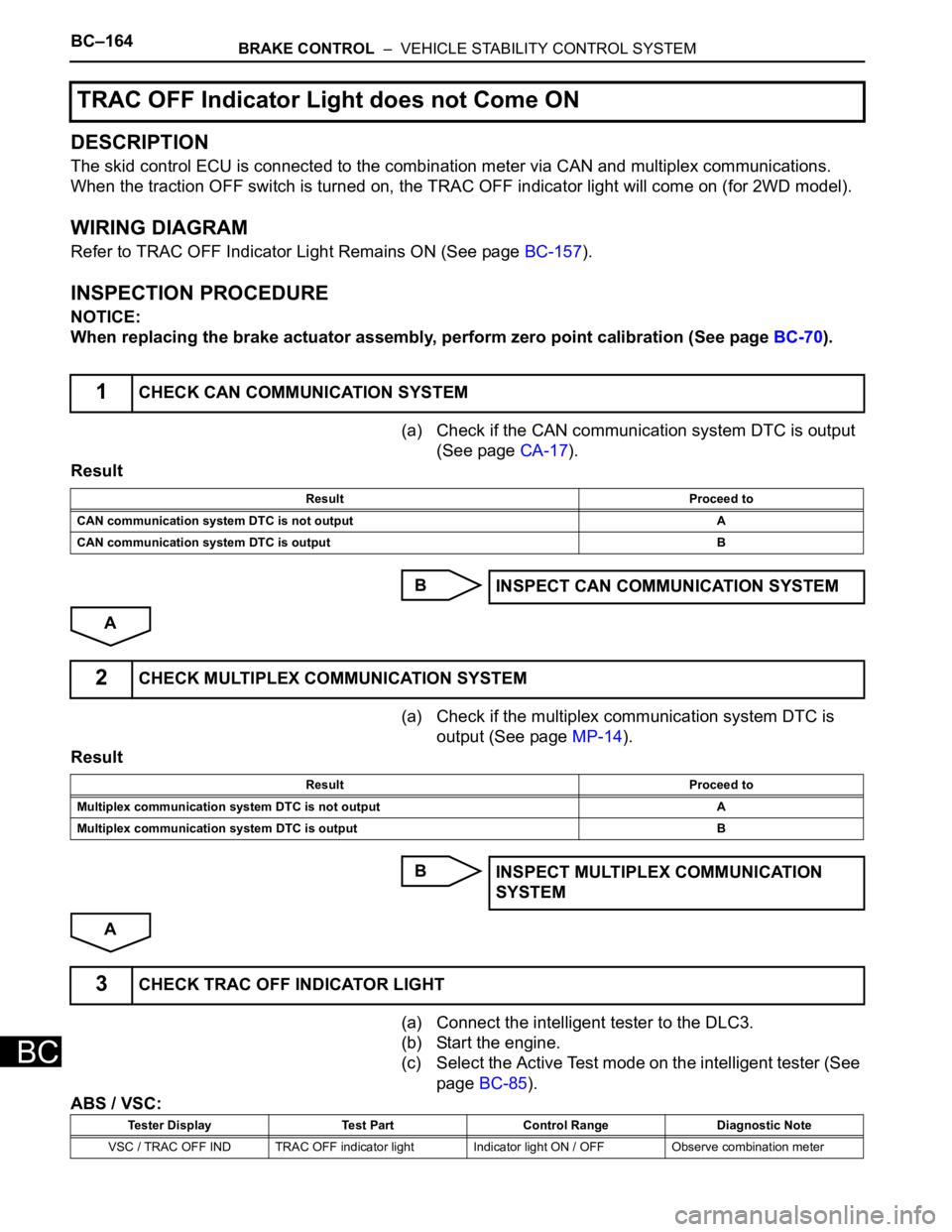

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and multiplex communications.

When the traction OFF switch is turned on, the TRAC OFF indicator light will come on (for 2WD model).

WIRING DIAGRAM

Refer to TRAC OFF Indicator Light Remains ON (See page BC-157).

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Check if the CAN communication system DTC is output

(See page CA-17).

Result

B

A

(a) Check if the multiplex communication system DTC is

output (See page MP-14).

Result

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the Active Test mode on the intelligent tester (See

page BC-85).

ABS / VSC:

TRAC OFF Indicator Light does not Come ON

1CHECK CAN COMMUNICATION SYSTEM

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

INSPECT CAN COMMUNICATION SYSTEM

2CHECK MULTIPLEX COMMUNICATION SYSTEM

Result Proceed to

Multiplex communication system DTC is not output A

Multiplex communication system DTC is output B

INSPECT MULTIPLEX COMMUNICATION

SYSTEM

3CHECK TRAC OFF INDICATOR LIGHT

Tester Display Test Part Control Range Diagnostic Note

VSC / TRAC OFF IND TRAC OFF indicator light Indicator light ON / OFF Observe combination meter

Page 2531 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–169

BC

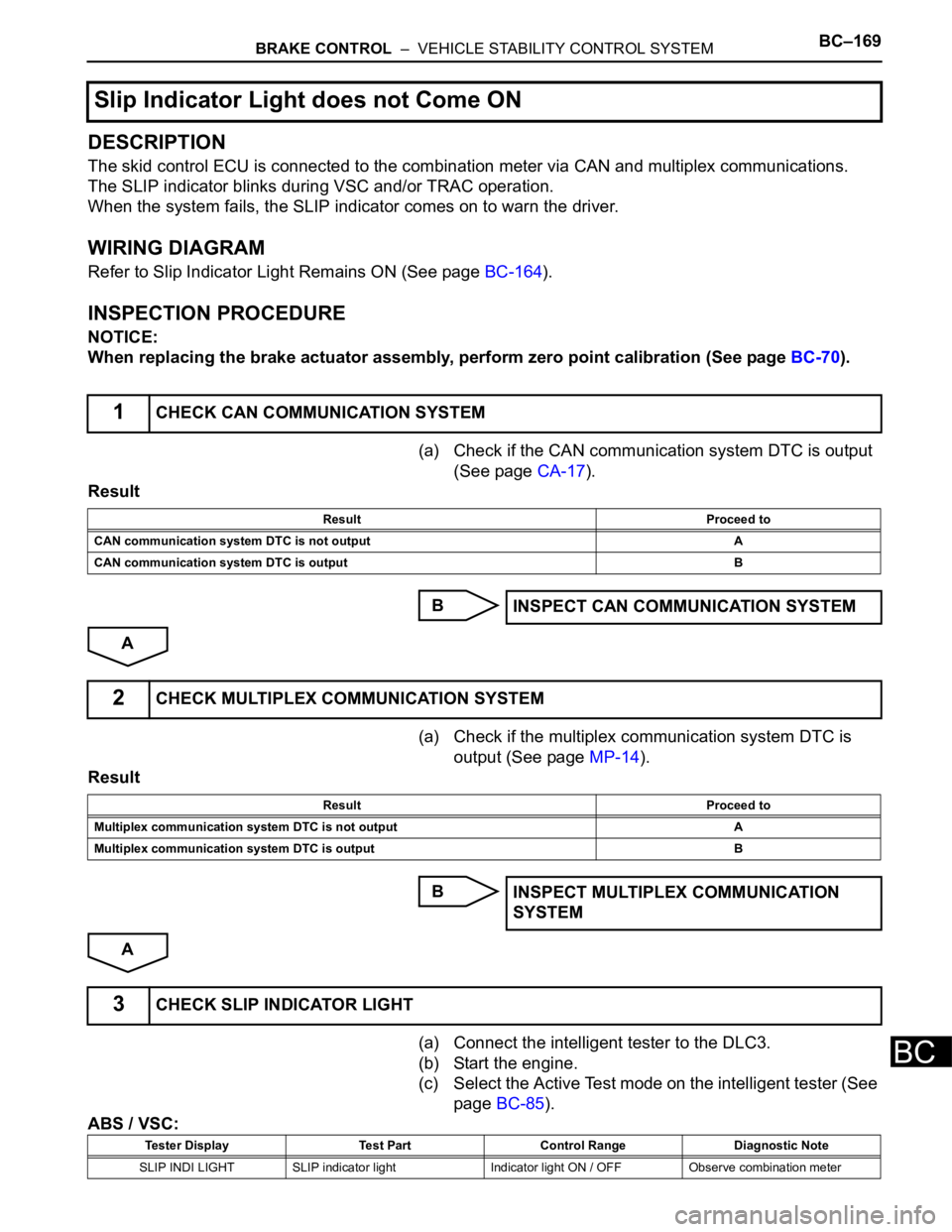

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and multiplex communications.

The SLIP indicator blinks during VSC and/or TRAC operation.

When the system fails, the SLIP indicator comes on to warn the driver.

WIRING DIAGRAM

Refer to Slip Indicator Light Remains ON (See page BC-164).

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Check if the CAN communication system DTC is output

(See page CA-17).

Result

B

A

(a) Check if the multiplex communication system DTC is

output (See page MP-14).

Result

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the Active Test mode on the intelligent tester (See

page BC-85).

ABS / VSC:

Slip Indicator Light does not Come ON

1CHECK CAN COMMUNICATION SYSTEM

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

INSPECT CAN COMMUNICATION SYSTEM

2CHECK MULTIPLEX COMMUNICATION SYSTEM

Result Proceed to

Multiplex communication system DTC is not output A

Multiplex communication system DTC is output B

INSPECT MULTIPLEX COMMUNICATION

SYSTEM

3CHECK SLIP INDICATOR LIGHT

Tester Display Test Part Control Range Diagnostic Note

SLIP INDI LIGHT SLIP indicator light Indicator light ON / OFF Observe combination meter

Page 2533 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–171

BC

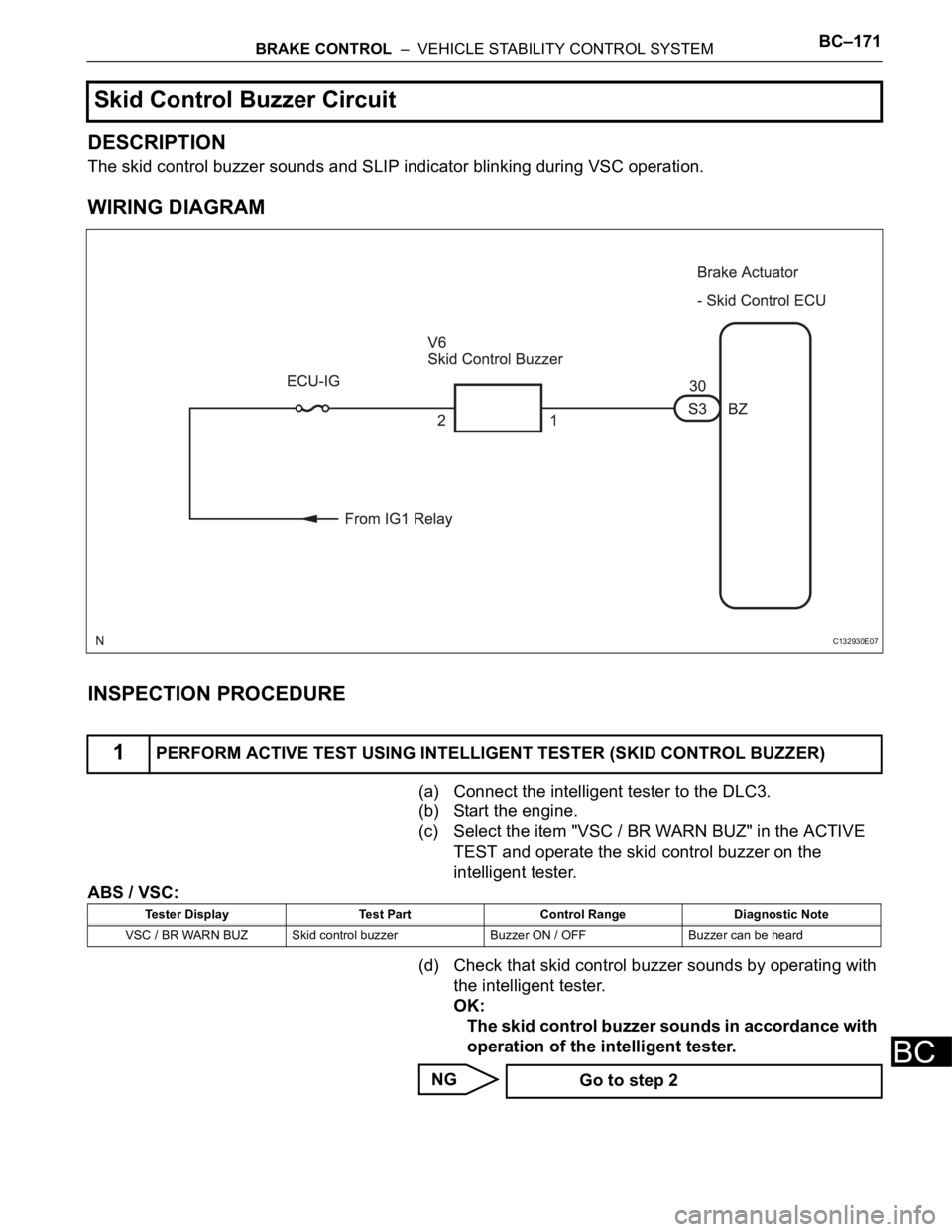

DESCRIPTION

The skid control buzzer sounds and SLIP indicator blinking during VSC operation.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the item "VSC / BR WARN BUZ" in the ACTIVE

TEST and operate the skid control buzzer on the

intelligent tester.

ABS / VSC:

(d) Check that skid control buzzer sounds by operating with

the intelligent tester.

OK:

The skid control buzzer sounds in accordance with

operation of the intelligent tester.

NG

Skid Control Buzzer Circuit

1PERFORM ACTIVE TEST USING INTELLIGENT TESTER (SKID CONTROL BUZZER)

C132930E07

Tester Display Test Part Control Range Diagnostic Note

VSC / BR WARN BUZ Skid control buzzer Buzzer ON / OFF Buzzer can be heard

Go to step 2

Page 2538 of 3000

BC–176BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

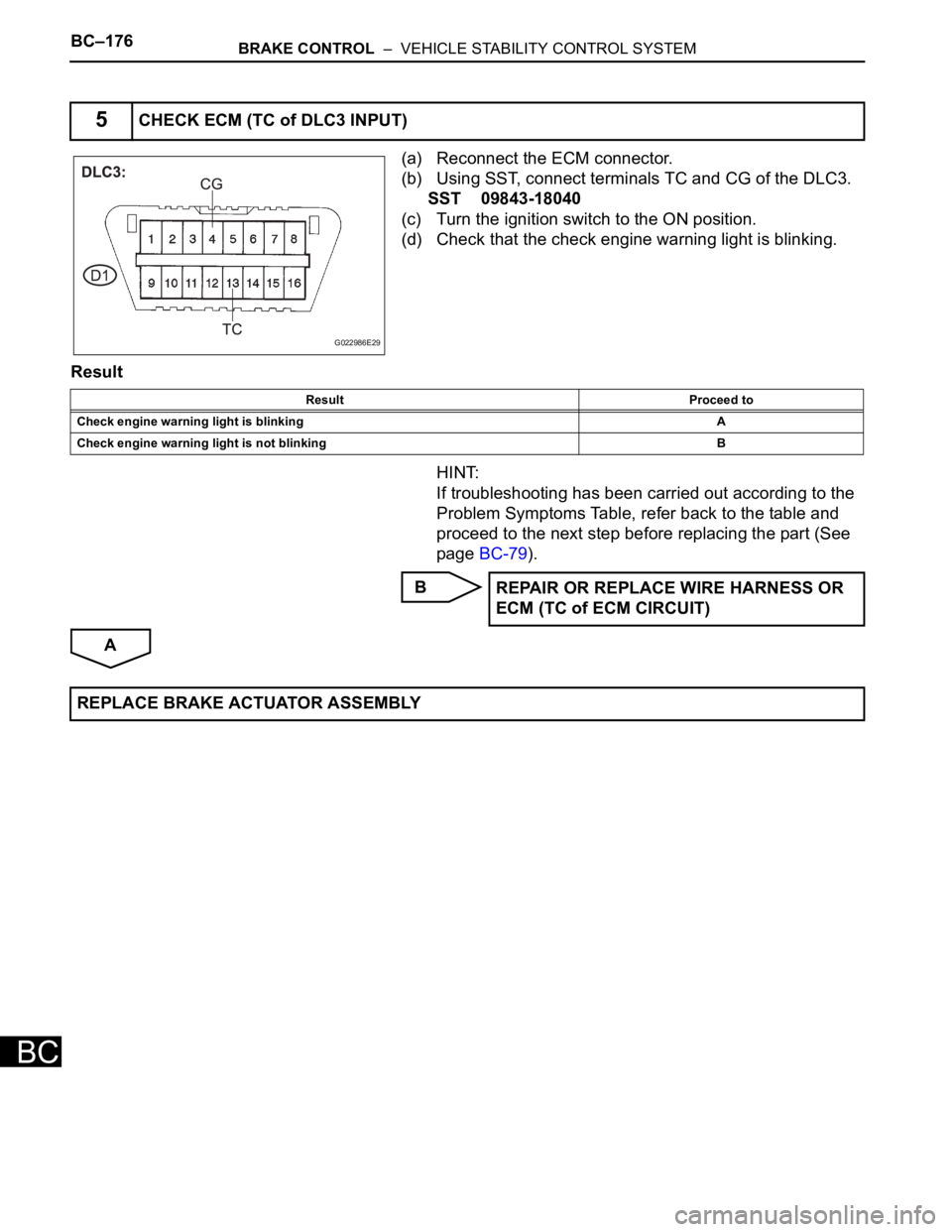

(a) Reconnect the ECM connector.

(b) Using SST, connect terminals TC and CG of the DLC3.

SST 09843-18040

(c) Turn the ignition switch to the ON position.

(d) Check that the check engine warning light is blinking.

Result

HINT:

If troubleshooting has been carried out according to the

Problem Symptoms Table, refer back to the table and

proceed to the next step before replacing the part (See

page BC-79).

B

A

5CHECK ECM (TC of DLC3 INPUT)

G022986E29

Result Proceed to

Check engine warning light is blinkingA

Check engine warning light is not blinking B

REPAIR OR REPLACE WIRE HARNESS OR

ECM (TC of ECM CIRCUIT)

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2544 of 3000

BC–178BRAKE CONTROL – BRAKE ACTUATOR (w/ VSC)

BC

ON-VEHICLE INSPECTION

1. CONNECT INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and run at idle.

(c) Select the ACTIVE TEST mode on the intelligent

tester.

HINT:

Please refer to the intelligent tester operator's

manual for further details.

2. INSPECT ACTUATOR MOTOR OPERATION

(a) With the motor relay on, check the actuator motor

operation noise.

(b) Turn the motor relay off.

(c) Depress the brake pedal and hold it for

approximately 15 seconds. Check that the brake

pedal cannot be depressed.

(d) With the motor relay on, check that the pedal does

not pulsate.

NOTICE:

Do not keep the motor relay turned on for more

than 5 seconds continuously. When operating it

continuously, set an interval of more than 20

seconds.

(e) Turn the motor relay off and release the brake

pedal.

3. INSPECT RIGHT FRONT WHEEL OPERATION

NOTICE:

Never turn on the solenoids in a manner different to

those described below.

(a) With the brake pedal depressed, perform the

following operations.

(b) Turn the SFRH and SFRR solenoids on

simultaneously, and check that the pedal cannot be

depressed.

NOTICE:

Do not keep the solenoid turned on for more

than 10 seconds continuously. When operating

it continuously, set an interval of more than 20

seconds.

(c) Turn the SFRH and SFRR solenoids off

simultaneously, and check that the pedal can be

depressed.

(d) Turn the motor relay on, and check that the pedal

returns.

NOTICE:

Do not keep the motor relay turned on for more

than 5 seconds continuously. When operating it

continuously, set an interval of more than 20

seconds.

(e) Turn the motor relay off and release the brake

pedal.

A080036E03

Page 2555 of 3000

BRAKE CONTROL – BRAKE ACTUATOR (w/o VSC)BC–183

BC

ON-VEHICLE INSPECTION

1. CONNECT INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and run at idle.

(c) Select the ACTIVE TEST mode on the intelligent

tester.

HINT:

Please refer to the intelligent tester operator's

manual for further details.

2. INSPECT ACTUATOR MOTOR OPERATION

(a) With the motor relay on, check the actuator motor

operation noise.

(b) Turn the motor relay off.

(c) Depress the brake pedal and hold it for

approximately 15 seconds. Check that the brake

pedal cannot be depressed.

(d) With the motor relay on, check that the pedal does

not pulsate.

NOTICE:

Do not keep the motor relay turned on for more

than 5 seconds continuously. When operating it

continuously, set an interval of more than 20

seconds.

(e) Turn the motor relay off and release the brake

pedal.

3. INSPECT RIGHT FRONT WHEEL OPERATION

NOTICE:

Never turn on the solenoids in a manner different to

those described below.

(a) With the brake pedal depressed, perform the

following operations.

(b) Turn the SFRH and SFRR solenoids on

simultaneously, and check that the pedal cannot be

depressed.

NOTICE:

Do not keep the solenoid turned on for more

than 10 seconds continuously. When operating

it continuously, set an interval of more than 20

seconds.

(c) Turn the SFRH and SFRR solenoids off

simultaneously, and check that the pedal can be

depressed.

(d) Turn the motor relay on, and check that the pedal

returns.

NOTICE:

Do not keep the motor relay turned on for more

than 5 seconds continuously. When operating it

continuously, set an interval of more than 20

seconds.

(e) Turn the motor relay off and release the brake

pedal.

A080036E03

Page 2568 of 3000

BC–32BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

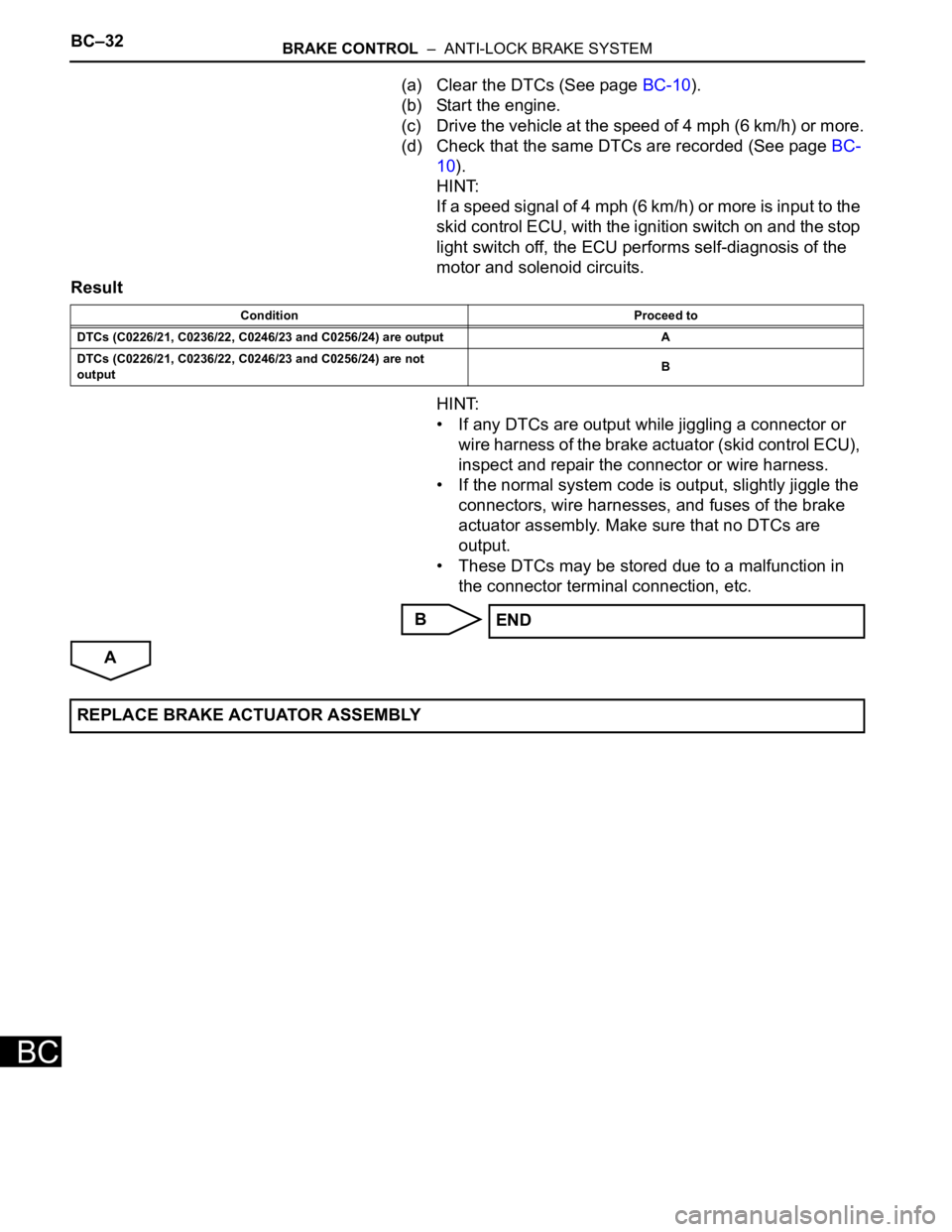

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 4 mph (6 km/h) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

If a speed signal of 4 mph (6 km/h) or more is input to the

skid control ECU, with the ignition switch on and the stop

light switch off, the ECU performs self-diagnosis of the

motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

A

Condition Proceed to

DTCs (C0226/21, C0236/22, C0246/23 and C0256/24) are output A

DTCs (C0226/21, C0236/22, C0246/23 and C0256/24) are not

outputB

END

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2573 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–35

BC

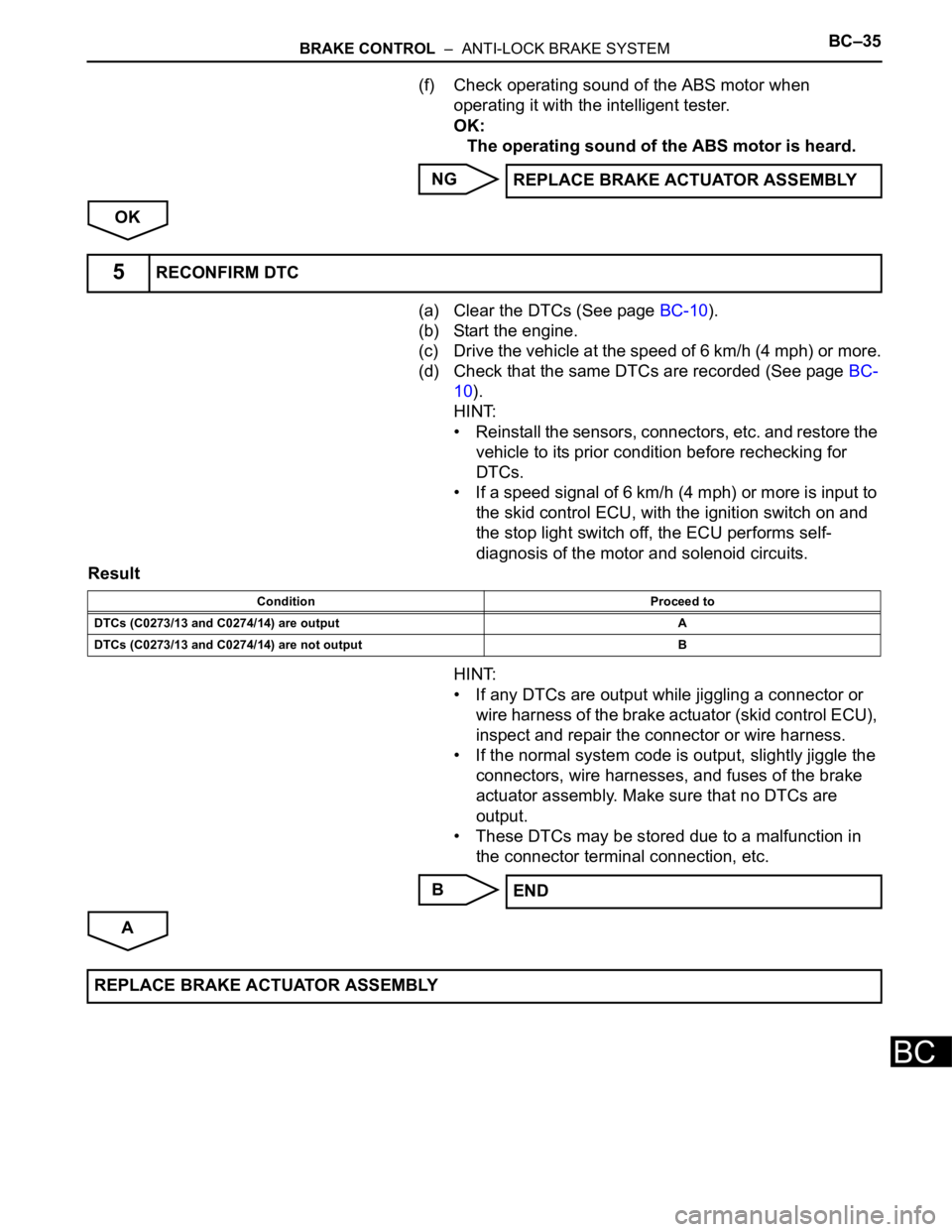

(f) Check operating sound of the ABS motor when

operating it with the intelligent tester.

OK:

The operating sound of the ABS motor is heard.

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

AREPLACE BRAKE ACTUATOR ASSEMBLY

5RECONFIRM DTC

Condition Proceed to

DTCs (C0273/13 and C0274/14) are output A

DTCs (C0273/13 and C0274/14) are not output B

END

REPLACE BRAKE ACTUATOR ASSEMBLY