check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2577 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–37

BC

(a) Install the ABS 2 fuse.

(b) Disconnect the skid control ECU connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

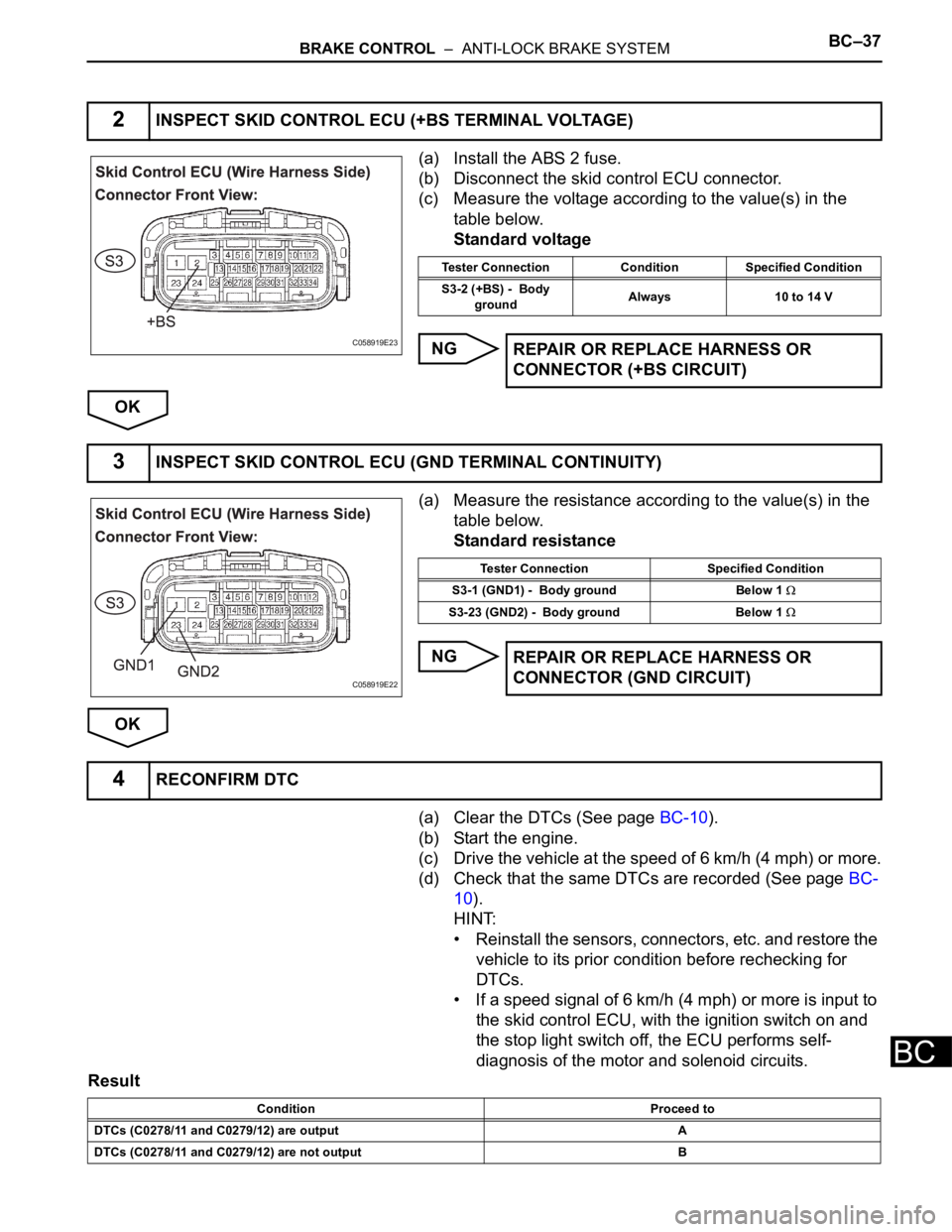

2INSPECT SKID CONTROL ECU (+BS TERMINAL VOLTAGE)

C058919E23

Tester Connection Condition Specified Condition

S3-2 (+BS) - Body

groundAlways 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (+BS CIRCUIT)

3INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

4RECONFIRM DTC

Condition Proceed to

DTCs (C0278/11 and C0279/12) are output A

DTCs (C0278/11 and C0279/12) are not output B

Page 2583 of 3000

BC–40BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

NG

OK

(a) Remove the ECU-IG fuse from the driver side J/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Install the ECU-IG fuse.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the DATA LIST mode on the intelligent tester.

ABS:

(f) Measure the voltage output from the ECU displayed on

the intelligent tester.

OK:

"Normal" is displayed.

NG

OK

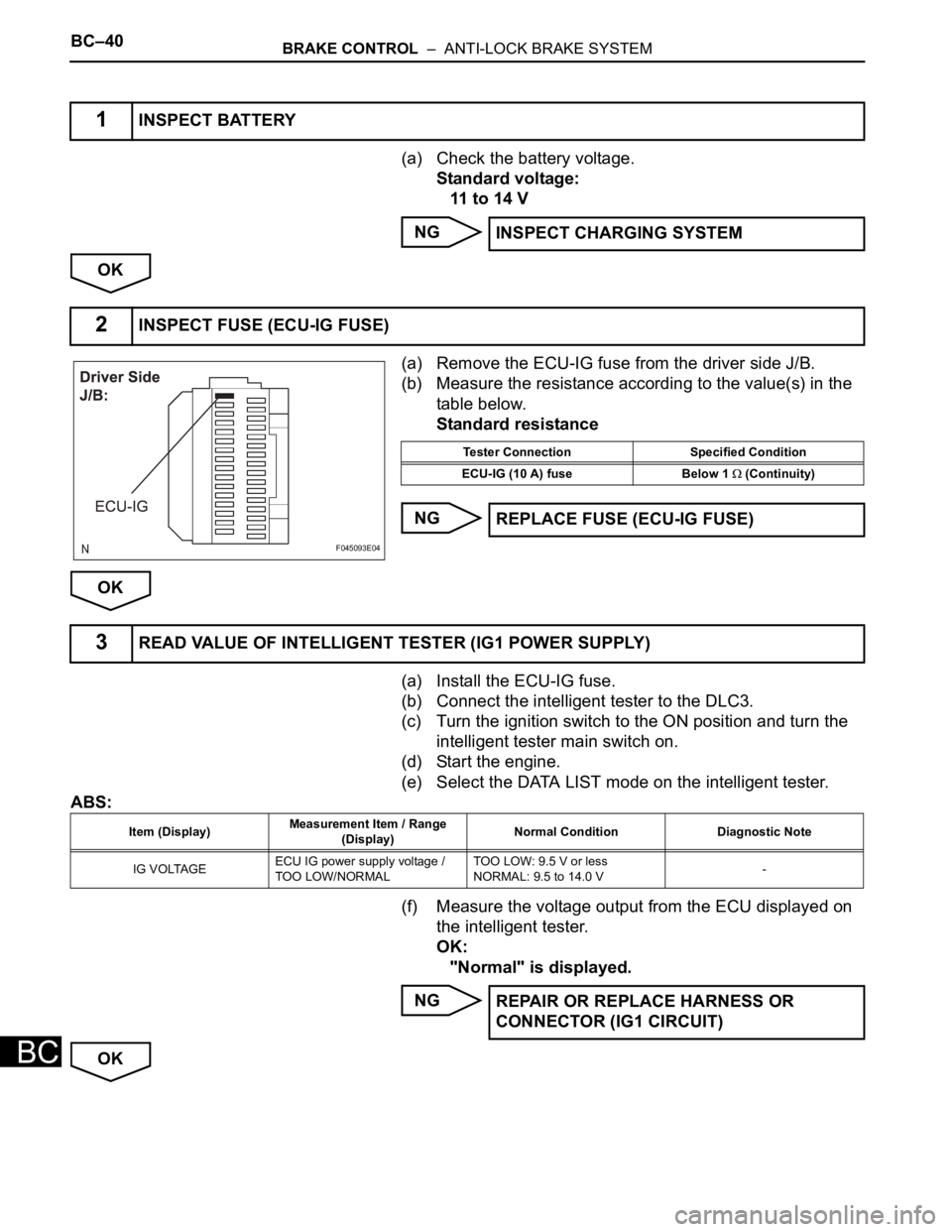

1INSPECT BATTERY

INSPECT CHARGING SYSTEM

2INSPECT FUSE (ECU-IG FUSE)

F045093E04

Tester Connection Specified Condition

ECU-IG (10 A) fuse Below 1

(Continuity)

REPLACE FUSE (ECU-IG FUSE)

3READ VALUE OF INTELLIGENT TESTER (IG1 POWER SUPPLY)

Item (Display)Measurement Item / Range

(Display)Normal Condition Diagnostic Note

IG VOLTAGEECU IG power supply voltage /

TOO LOW/NORMALTOO LOW: 9.5 V or less

NORMAL: 9.5 to 14.0 V-

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

Page 2600 of 3000

BR–22BRAKE – BRAKE BOOSTER

BR

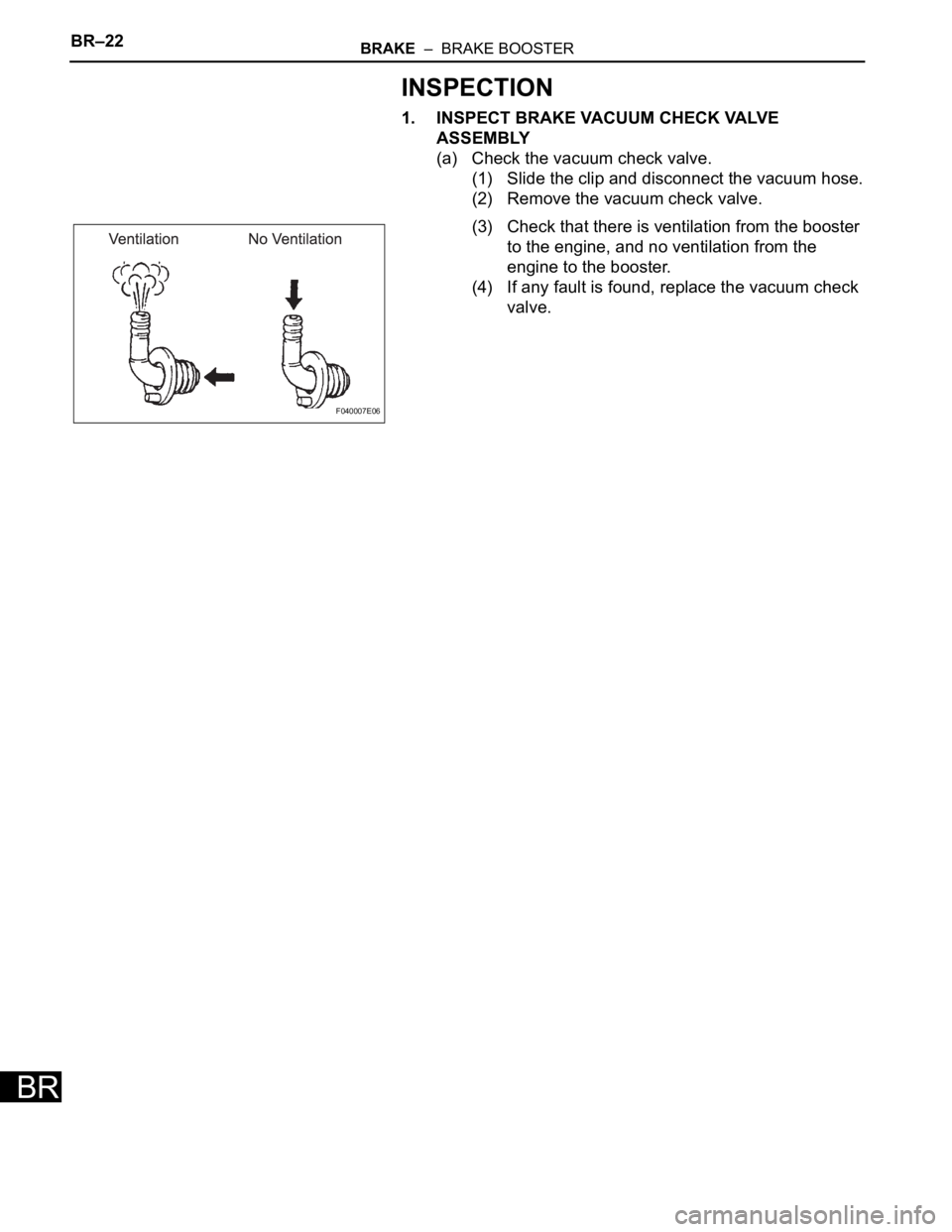

INSPECTION

1. INSPECT BRAKE VACUUM CHECK VALVE

ASSEMBLY

(a) Check the vacuum check valve.

(1) Slide the clip and disconnect the vacuum hose.

(2) Remove the vacuum check valve.

(3) Check that there is ventilation from the booster

to the engine, and no ventilation from the

engine to the booster.

(4) If any fault is found, replace the vacuum check

valve.

F040007E06

Page 2605 of 3000

BR–10BRAKE – BRAKE PEDAL

BR

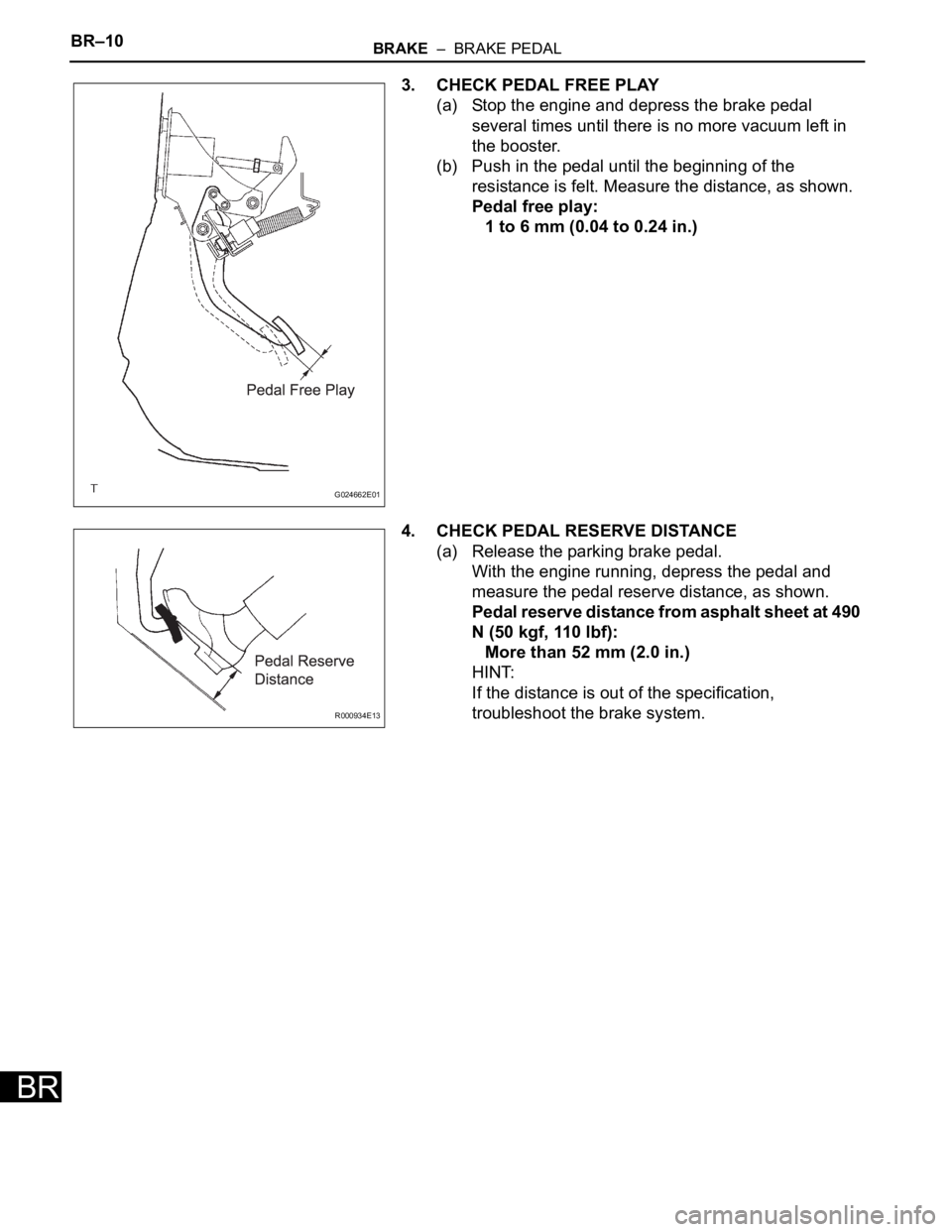

3. CHECK PEDAL FREE PLAY

(a) Stop the engine and depress the brake pedal

several times until there is no more vacuum left in

the booster.

(b) Push in the pedal until the beginning of the

resistance is felt. Measure the distance, as shown.

Pedal free play:

1 to 6 mm (0.04 to 0.24 in.)

4. CHECK PEDAL RESERVE DISTANCE

(a) Release the parking brake pedal.

With the engine running, depress the pedal and

measure the pedal reserve distance, as shown.

Pedal reserve distance from asphalt sheet at 490

N (50 kgf, 110 lbf):

More than 52 mm (2.0 in.)

HINT:

If the distance is out of the specification,

troubleshoot the brake system.

G024662E01

R000934E13

Page 2615 of 3000

BRAKE – BRAKE BOOSTERBR–19

BR

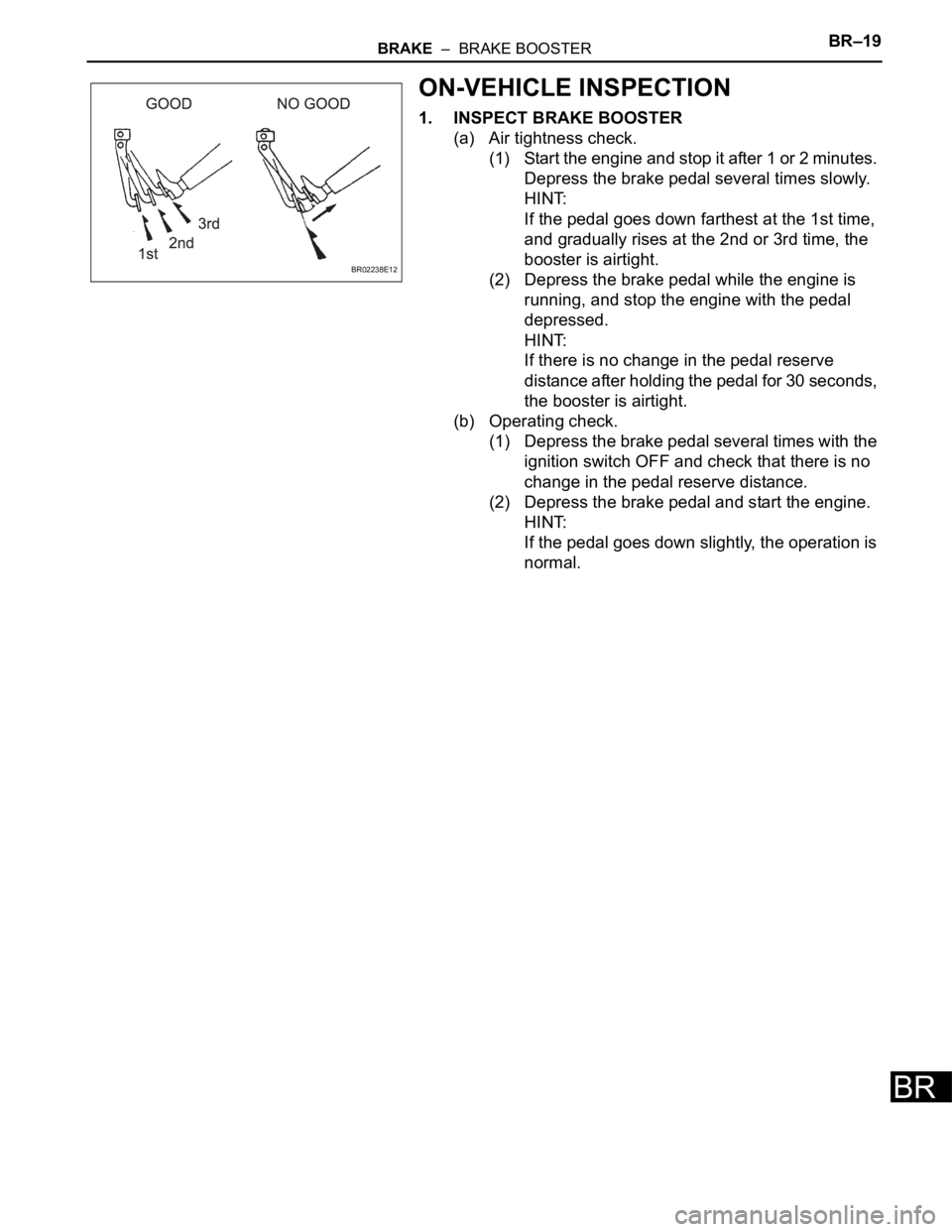

ON-VEHICLE INSPECTION

1. INSPECT BRAKE BOOSTER

(a) Air tightness check.

(1) Start the engine and stop it after 1 or 2 minutes.

Depress the brake pedal several times slowly.

HINT:

If the pedal goes down farthest at the 1st time,

and gradually rises at the 2nd or 3rd time, the

booster is airtight.

(2) Depress the brake pedal while the engine is

running, and stop the engine with the pedal

depressed.

HINT:

If there is no change in the pedal reserve

distance after holding the pedal for 30 seconds,

the booster is airtight.

(b) Operating check.

(1) Depress the brake pedal several times with the

ignition switch OFF and check that there is no

change in the pedal reserve distance.

(2) Depress the brake pedal and start the engine.

HINT:

If the pedal goes down slightly, the operation is

normal.

BR02238E12

Page 2674 of 3000

SR–10STEERING COLUMN – STEERING COLUMN ASSEMBLY

SR

REASSEMBLY

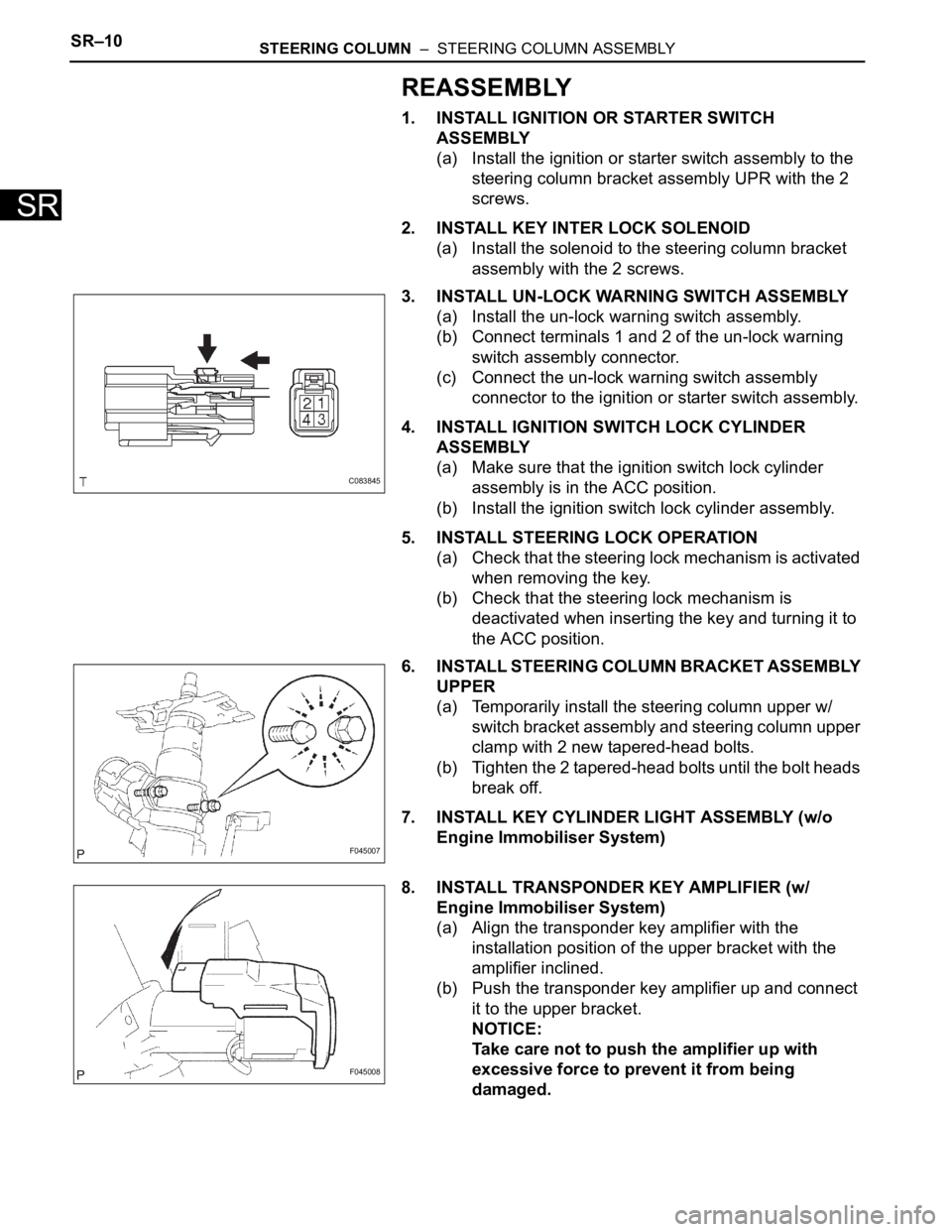

1. INSTALL IGNITION OR STARTER SWITCH

ASSEMBLY

(a) Install the ignition or starter switch assembly to the

steering column bracket assembly UPR with the 2

screws.

2. INSTALL KEY INTER LOCK SOLENOID

(a) Install the solenoid to the steering column bracket

assembly with the 2 screws.

3. INSTALL UN-LOCK WARNING SWITCH ASSEMBLY

(a) Install the un-lock warning switch assembly.

(b) Connect terminals 1 and 2 of the un-lock warning

switch assembly connector.

(c) Connect the un-lock warning switch assembly

connector to the ignition or starter switch assembly.

4. INSTALL IGNITION SWITCH LOCK CYLINDER

ASSEMBLY

(a) Make sure that the ignition switch lock cylinder

assembly is in the ACC position.

(b) Install the ignition switch lock cylinder assembly.

5. INSTALL STEERING LOCK OPERATION

(a) Check that the steering lock mechanism is activated

when removing the key.

(b) Check that the steering lock mechanism is

deactivated when inserting the key and turning it to

the ACC position.

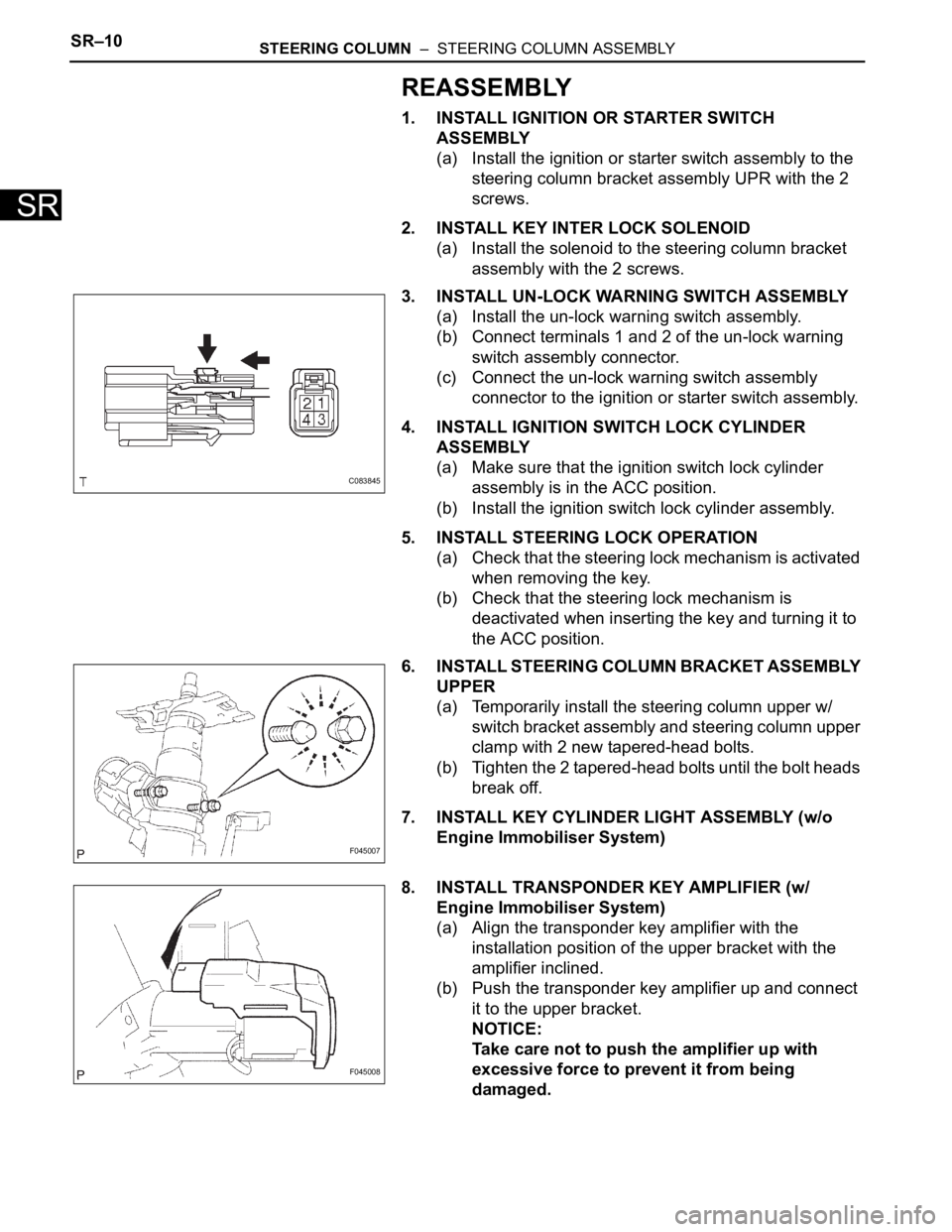

6. INSTALL STEERING COLUMN BRACKET ASSEMBLY

UPPER

(a) Temporarily install the steering column upper w/

switch bracket assembly and steering column upper

clamp with 2 new tapered-head bolts.

(b) Tighten the 2 tapered-head bolts until the bolt heads

break off.

7. INSTALL KEY CYLINDER LIGHT ASSEMBLY (w/o

Engine Immobiliser System)

8. INSTALL TRANSPONDER KEY AMPLIFIER (w/

Engine Immobiliser System)

(a) Align the transponder key amplifier with the

installation position of the upper bracket with the

amplifier inclined.

(b) Push the transponder key amplifier up and connect

it to the upper bracket.

NOTICE:

Take care not to push the amplifier up with

excessive force to prevent it from being

damaged.

C083845

F045007

F045008

Page 2683 of 3000

SR–10STEERING COLUMN – STEERING COLUMN ASSEMBLY

SR

REASSEMBLY

1. INSTALL IGNITION OR STARTER SWITCH

ASSEMBLY

(a) Install the ignition or starter switch assembly to the

steering column bracket assembly UPR with the 2

screws.

2. INSTALL KEY INTER LOCK SOLENOID

(a) Install the solenoid to the steering column bracket

assembly with the 2 screws.

3. INSTALL UN-LOCK WARNING SWITCH ASSEMBLY

(a) Install the un-lock warning switch assembly.

(b) Connect terminals 1 and 2 of the un-lock warning

switch assembly connector.

(c) Connect the un-lock warning switch assembly

connector to the ignition or starter switch assembly.

4. INSTALL IGNITION SWITCH LOCK CYLINDER

ASSEMBLY

(a) Make sure that the ignition switch lock cylinder

assembly is in the ACC position.

(b) Install the ignition switch lock cylinder assembly.

5. INSTALL STEERING LOCK OPERATION

(a) Check that the steering lock mechanism is activated

when removing the key.

(b) Check that the steering lock mechanism is

deactivated when inserting the key and turning it to

the ACC position.

6. INSTALL STEERING COLUMN BRACKET ASSEMBLY

UPPER

(a) Temporarily install the steering column upper w/

switch bracket assembly and steering column upper

clamp with 2 new tapered-head bolts.

(b) Tighten the 2 tapered-head bolts until the bolt heads

break off.

7. INSTALL KEY CYLINDER LIGHT ASSEMBLY (w/o

Engine Immobiliser System)

8. INSTALL TRANSPONDER KEY AMPLIFIER (w/

Engine Immobiliser System)

(a) Align the transponder key amplifier with the

installation position of the upper bracket with the

amplifier inclined.

(b) Push the transponder key amplifier up and connect

it to the upper bracket.

NOTICE:

Take care not to push the amplifier up with

excessive force to prevent it from being

damaged.

C083845

F045007

F045008

Page 2713 of 3000

POWER STEERING – POWER STEERING SYSTEMPS–3

PS

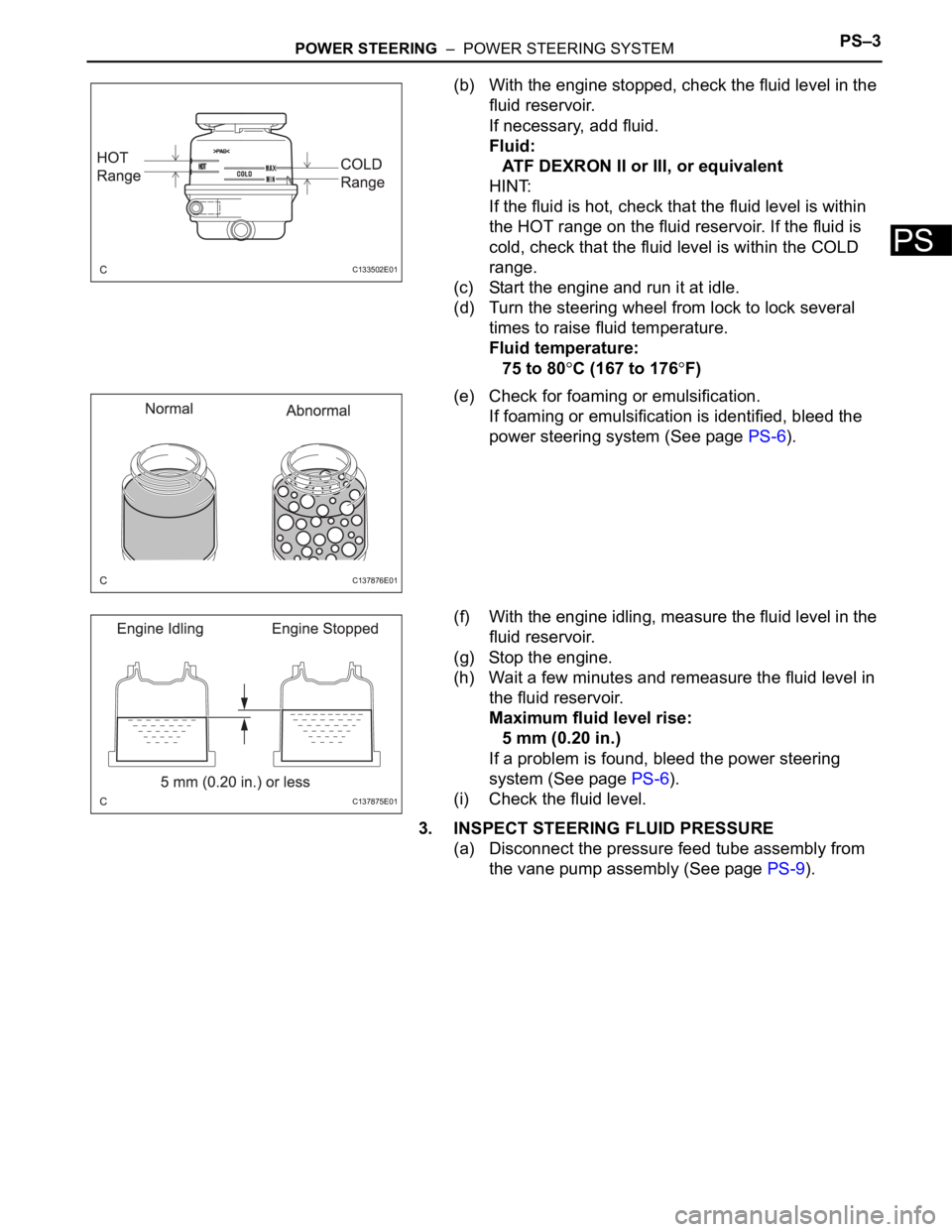

(b) With the engine stopped, check the fluid level in the

fluid reservoir.

If necessary, add fluid.

Fluid:

ATF DEXRON II or III, or equivalent

HINT:

If the fluid is hot, check that the fluid level is within

the HOT range on the fluid reservoir. If the fluid is

cold, check that the fluid level is within the COLD

range.

(c) Start the engine and run it at idle.

(d) Turn the steering wheel from lock to lock several

times to raise fluid temperature.

Fluid temperature:

75 to 80

C (167 to 176F)

(e) Check for foaming or emulsification.

If foaming or emulsification is identified, bleed the

power steering system (See page PS-6).

(f) With the engine idling, measure the fluid level in the

fluid reservoir.

(g) Stop the engine.

(h) Wait a few minutes and remeasure the fluid level in

the fluid reservoir.

Maximum fluid level rise:

5 mm (0.20 in.)

If a problem is found, bleed the power steering

system (See page PS-6).

(i) Check the fluid level.

3. INSPECT STEERING FLUID PRESSURE

(a) Disconnect the pressure feed tube assembly from

the vane pump assembly (See page PS-9).

C133502E01

C137876E01

C137875E01

Page 2714 of 3000

PS–4POWER STEERING – POWER STEERING SYSTEM

PS

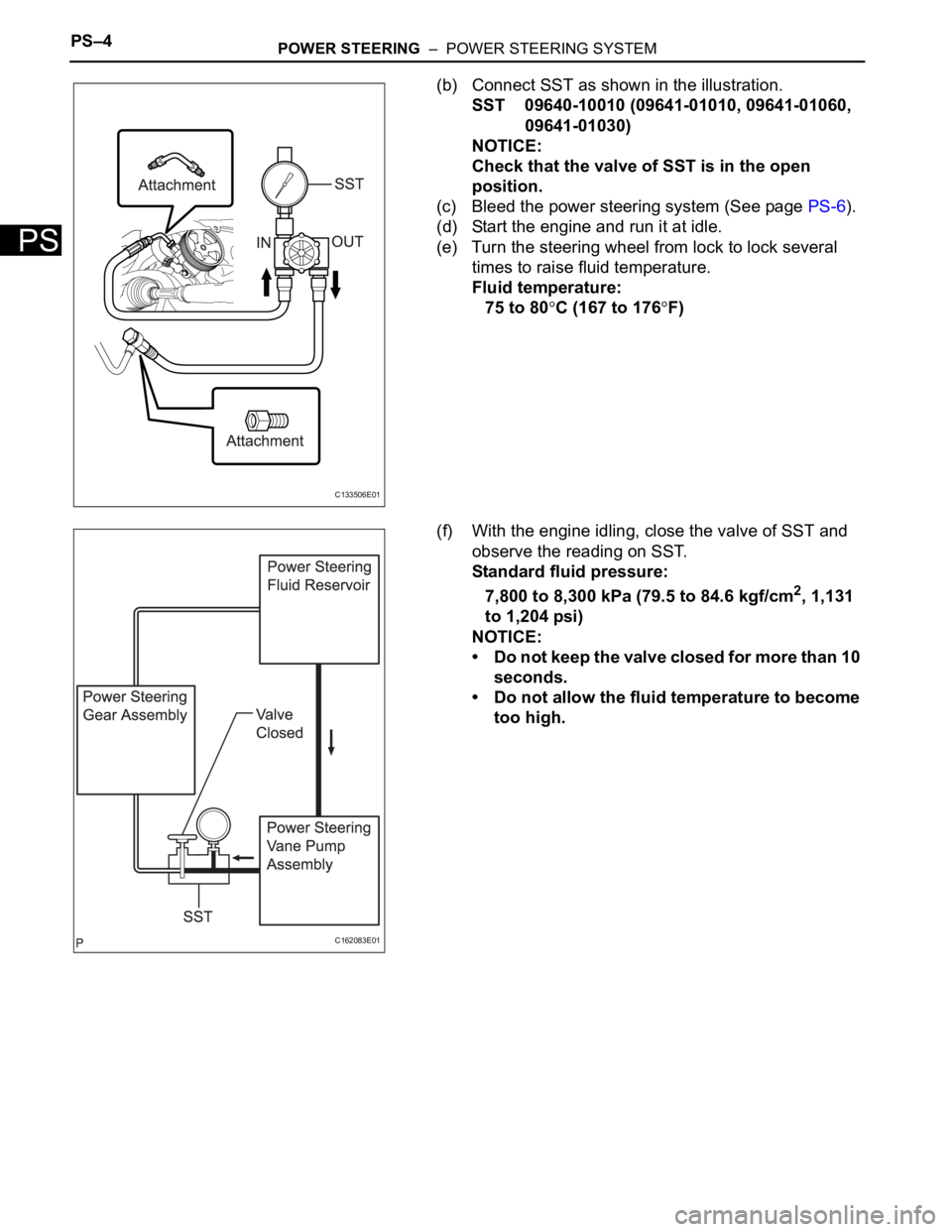

(b) Connect SST as shown in the illustration.

SST 09640-10010 (09641-01010, 09641-01060,

09641-01030)

NOTICE:

Check that the valve of SST is in the open

position.

(c) Bleed the power steering system (See page PS-6).

(d) Start the engine and run it at idle.

(e) Turn the steering wheel from lock to lock several

times to raise fluid temperature.

Fluid temperature:

75 to 80

C (167 to 176F)

(f) With the engine idling, close the valve of SST and

observe the reading on SST.

Standard fluid pressure:

7,800 to 8,300 kPa (79.5 to 84.6 kgf/cm

2, 1,131

to 1,204 psi)

NOTICE:

• Do not keep the valve closed for more than 10

seconds.

• Do not allow the fluid temperature to become

too high.

C133506E01

C162083E01

Page 2715 of 3000

POWER STEERING – POWER STEERING SYSTEMPS–5

PS

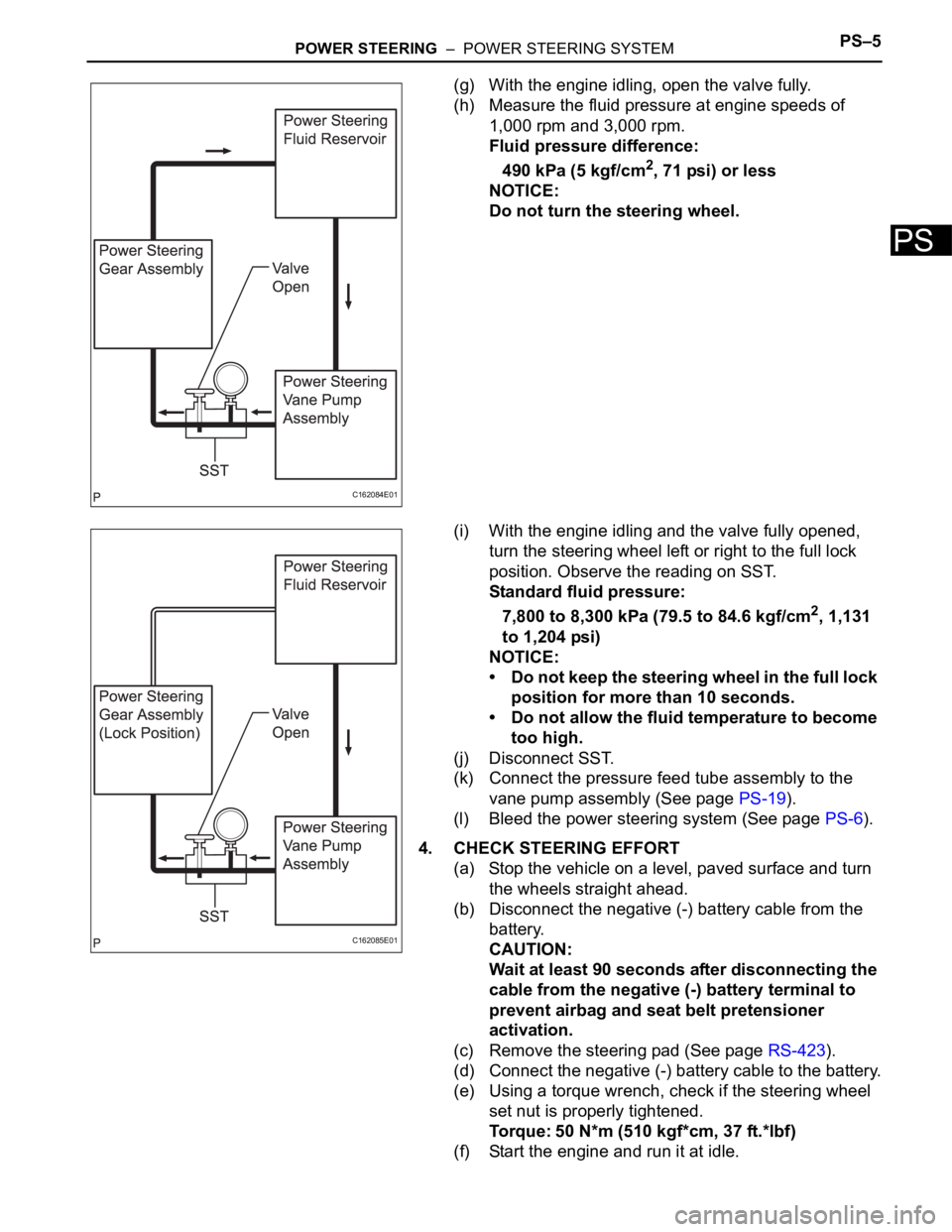

(g) With the engine idling, open the valve fully.

(h) Measure the fluid pressure at engine speeds of

1,000 rpm and 3,000 rpm.

Fluid pressure difference:

490 kPa (5 kgf/cm

2, 71 psi) or less

NOTICE:

Do not turn the steering wheel.

(i) With the engine idling and the valve fully opened,

turn the steering wheel left or right to the full lock

position. Observe the reading on SST.

Standard fluid pressure:

7,800 to 8,300 kPa (79.5 to 84.6 kgf/cm

2, 1,131

to 1,204 psi)

NOTICE:

• Do not keep the steering wheel in the full lock

position for more than 10 seconds.

• Do not allow the fluid temperature to become

too high.

(j) Disconnect SST.

(k) Connect the pressure feed tube assembly to the

vane pump assembly (See page PS-19).

(l) Bleed the power steering system (See page PS-6).

4. CHECK STEERING EFFORT

(a) Stop the vehicle on a level, paved surface and turn

the wheels straight ahead.

(b) Disconnect the negative (-) battery cable from the

battery.

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner

activation.

(c) Remove the steering pad (See page RS-423).

(d) Connect the negative (-) battery cable to the battery.

(e) Using a torque wrench, check if the steering wheel

set nut is properly tightened.

Torque: 50 N*m (510 kgf*cm, 37 ft.*lbf)

(f) Start the engine and run it at idle.

C162084E01

C162085E01