check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2717 of 3000

PS–6POWER STEERING – POWER STEERING FLUID

PS

POWER STEERING FLUID

BLEEDING

1. BLEED POWER STEERING SYSTEM

(a) Check the fluid level (See page PS-2).

(b) Jack up the front of the vehicle and support it with

stands.

(c) Turn the steering wheel.

(1) With the engine stopped, turn the steering

wheel slowly from lock to lock several times.

(d) Lower the vehicle.

(e) Start the engine.

(1) Run the engine at idle for a few minutes.

(f) Turn the steering wheel.

(1) With the engine idling, turn the steering wheel

left or right to the full lock position and keep it in

that position for 2 to 3 seconds, then turn the

steering wheel to the opposite full lock position

and keep it there for 2 to 3 seconds.

(2) Repeat this procedure several times.

(g) Stop the engine.

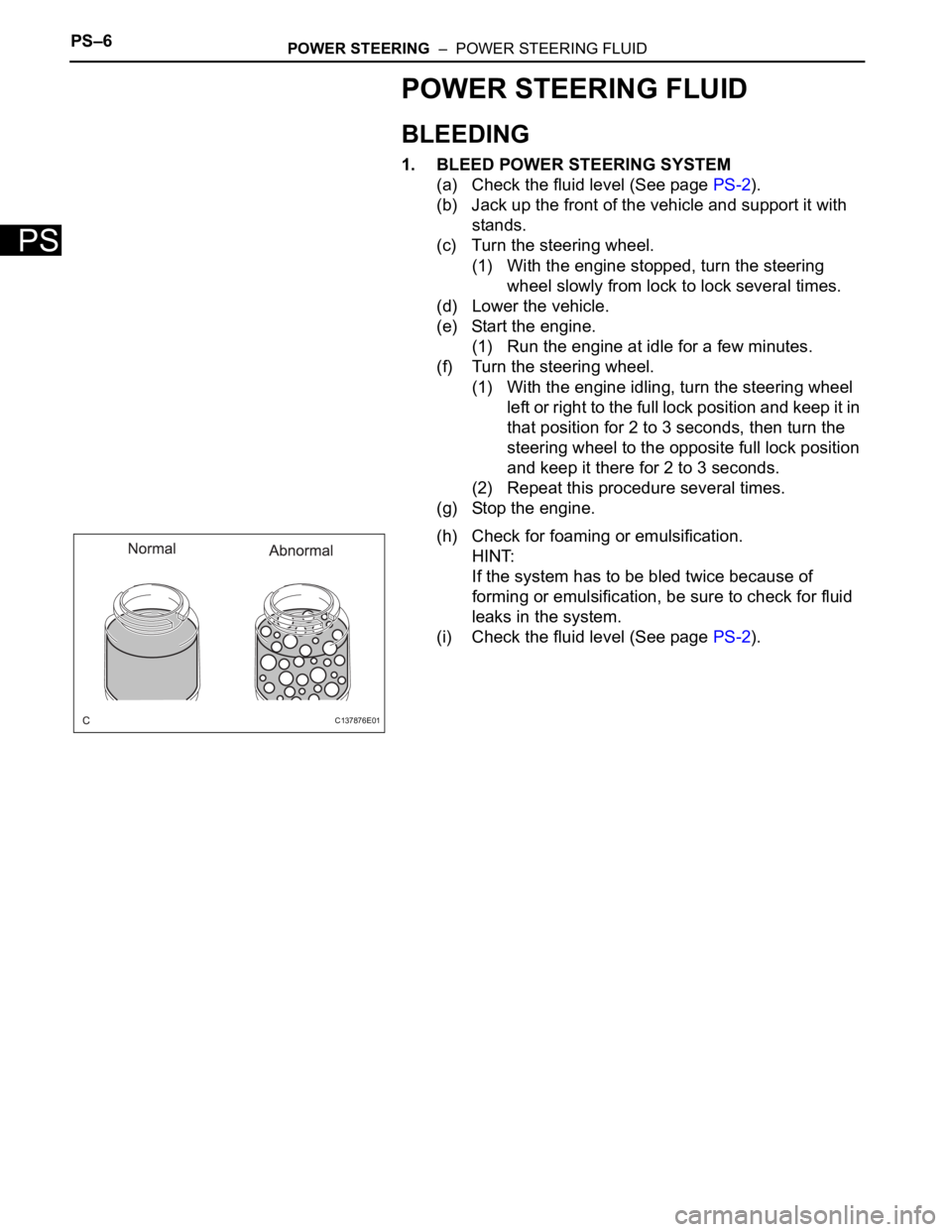

(h) Check for foaming or emulsification.

HINT:

If the system has to be bled twice because of

forming or emulsification, be sure to check for fluid

leaks in the system.

(i) Check the fluid level (See page PS-2).

C137876E01

Page 2791 of 3000

AC–48AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

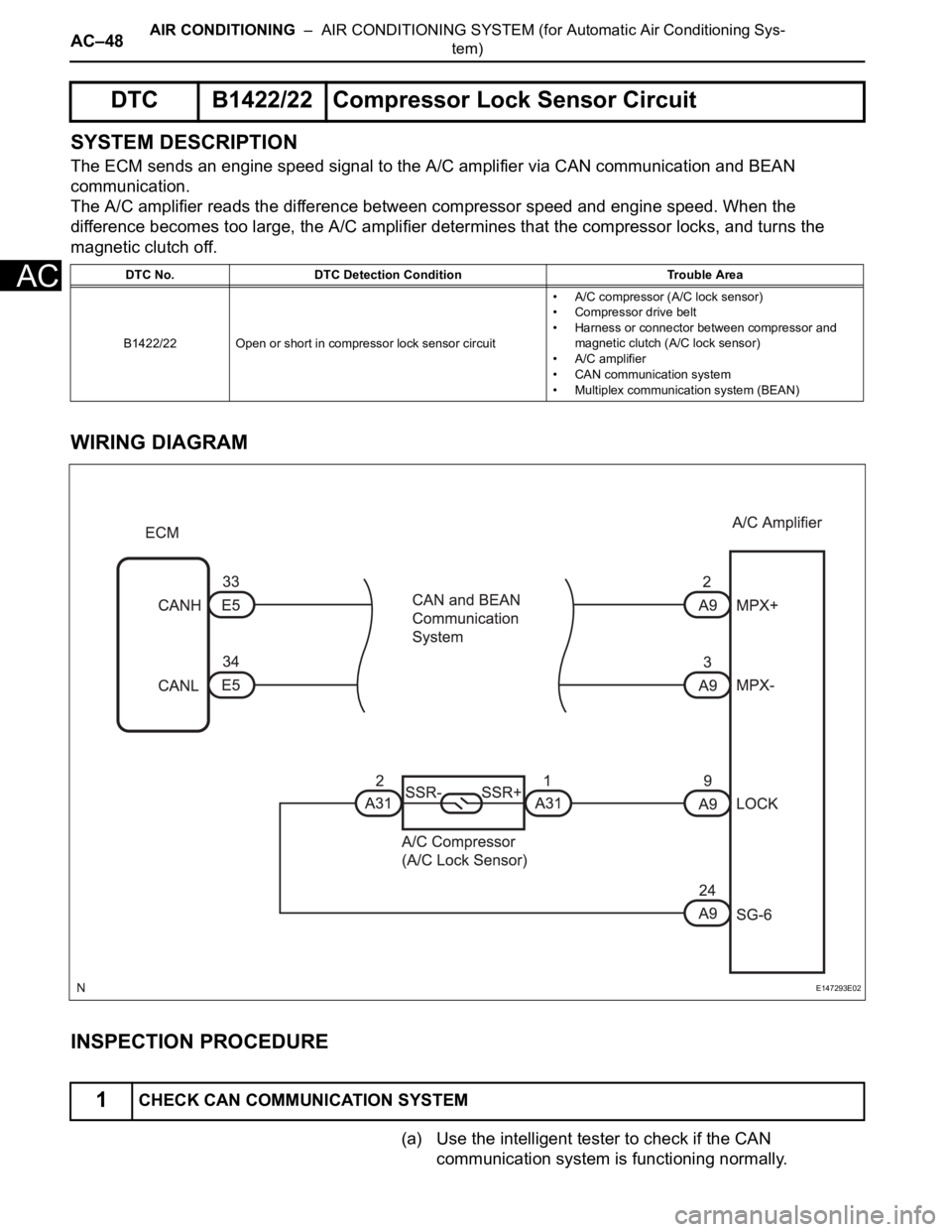

SYSTEM DESCRIPTION

The ECM sends an engine speed signal to the A/C amplifier via CAN communication and BEAN

communication.

The A/C amplifier reads the difference between compressor speed and engine speed. When the

difference becomes too large, the A/C amplifier determines that the compressor locks, and turns the

magnetic clutch off.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Use the intelligent tester to check if the CAN

communication system is functioning normally.

DTC B1422/22 Compressor Lock Sensor Circuit

DTC No. DTC Detection Condition Trouble Area

B1422/22 Open or short in compressor lock sensor circuit• A/C compressor (A/C lock sensor)

• Compressor drive belt

• Harness or connector between compressor and

magnetic clutch (A/C lock sensor)

• A/C amplifier

• CAN communication system

• Multiplex communication system (BEAN)

1CHECK CAN COMMUNICATION SYSTEM

E147293E02

Page 2792 of 3000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–49

AC

Result

B

A

(a) Use the intelligent tester to check if the multiplex

communication system (BEAN) is functioning normally.

Result

B

A

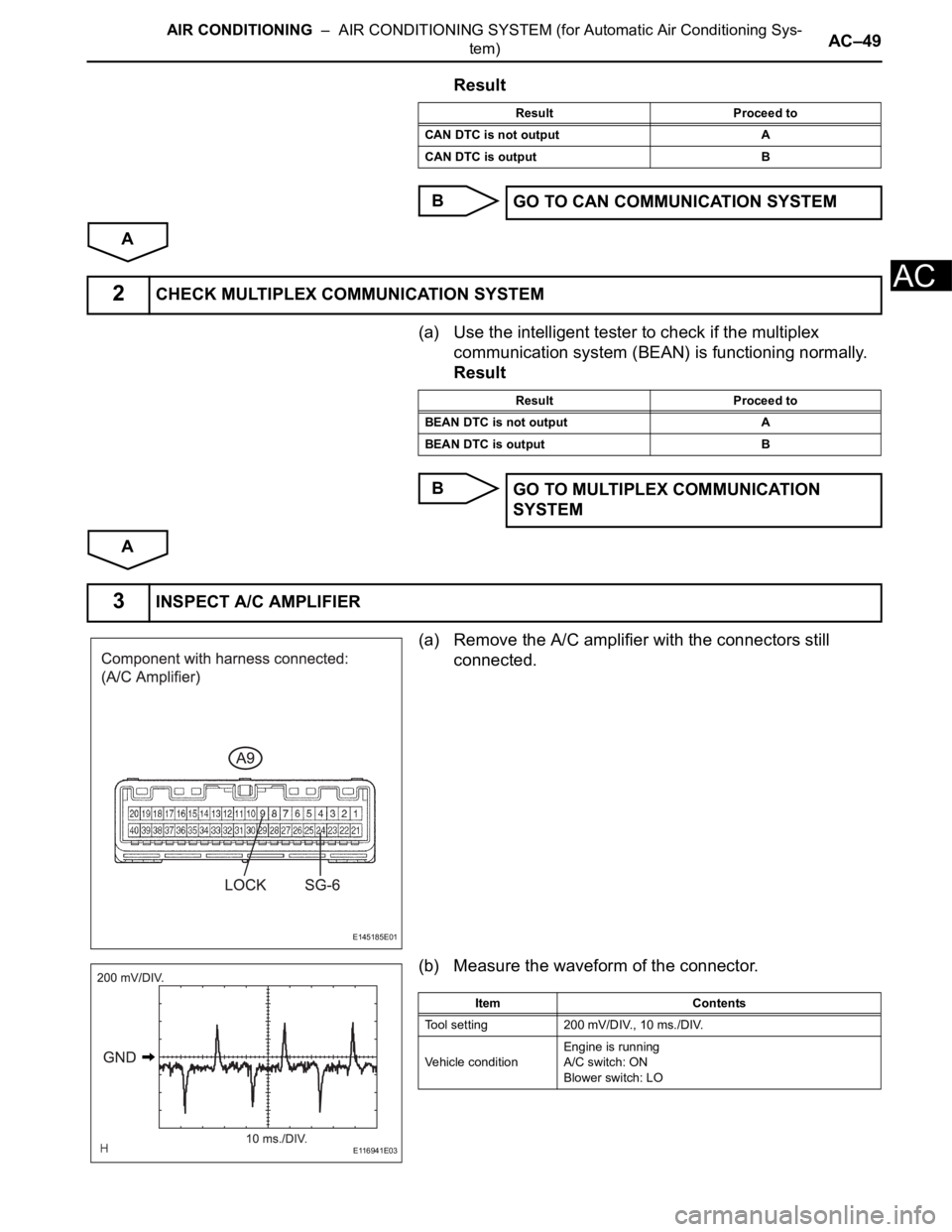

(a) Remove the A/C amplifier with the connectors still

connected.

(b) Measure the waveform of the connector.

Result Proceed to

CAN DTC is not output A

CAN DTC is output B

GO TO CAN COMMUNICATION SYSTEM

2CHECK MULTIPLEX COMMUNICATION SYSTEM

Result Proceed to

BEAN DTC is not output A

BEAN DTC is output B

GO TO MULTIPLEX COMMUNICATION

SYSTEM

3INSPECT A/C AMPLIFIER

E145185E01

E116941E03

Item Contents

Tool setting 200 mV/DIV., 10 ms./DIV.

Vehicle conditionEngine is running

A/C switch: ON

Blower switch: LO

Page 2805 of 3000

AC–62AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

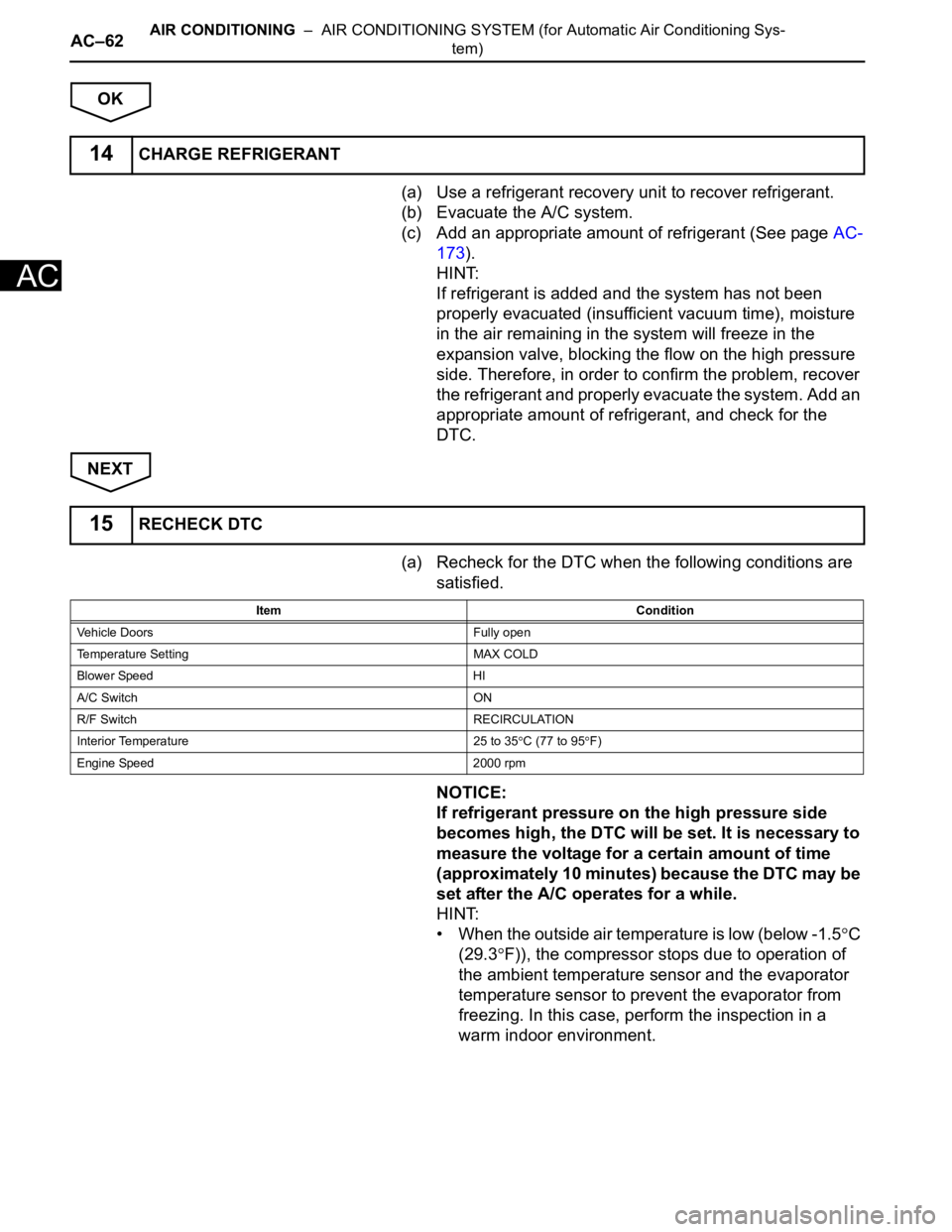

OK

(a) Use a refrigerant recovery unit to recover refrigerant.

(b) Evacuate the A/C system.

(c) Add an appropriate amount of refrigerant (See page AC-

173).

HINT:

If refrigerant is added and the system has not been

properly evacuated (insufficient vacuum time), moisture

in the air remaining in the system will freeze in the

expansion valve, blocking the flow on the high pressure

side. Therefore, in order to confirm the problem, recover

the refrigerant and properly evacuate the system. Add an

appropriate amount of refrigerant, and check for the

DTC.

NEXT

(a) Recheck for the DTC when the following conditions are

satisfied.

NOTICE:

If refrigerant pressure on the high pressure side

becomes high, the DTC will be set. It is necessary to

measure the voltage for a certain amount of time

(approximately 10 minutes) because the DTC may be

set after the A/C operates for a while.

HINT:

• When the outside air temperature is low (below -1.5

C

(29.3

F)), the compressor stops due to operation of

the ambient temperature sensor and the evaporator

temperature sensor to prevent the evaporator from

freezing. In this case, perform the inspection in a

warm indoor environment.

14CHARGE REFRIGERANT

15RECHECK DTC

Item Condition

Vehicle Doors Fully open

Temperature Setting MAX COLD

Blower Speed HI

A/C Switch ON

R/F Switch RECIRCULATION

Interior Temperature 25 to 35

C (77 to 95F)

Engine Speed 2000 rpm

Page 2806 of 3000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–63

AC

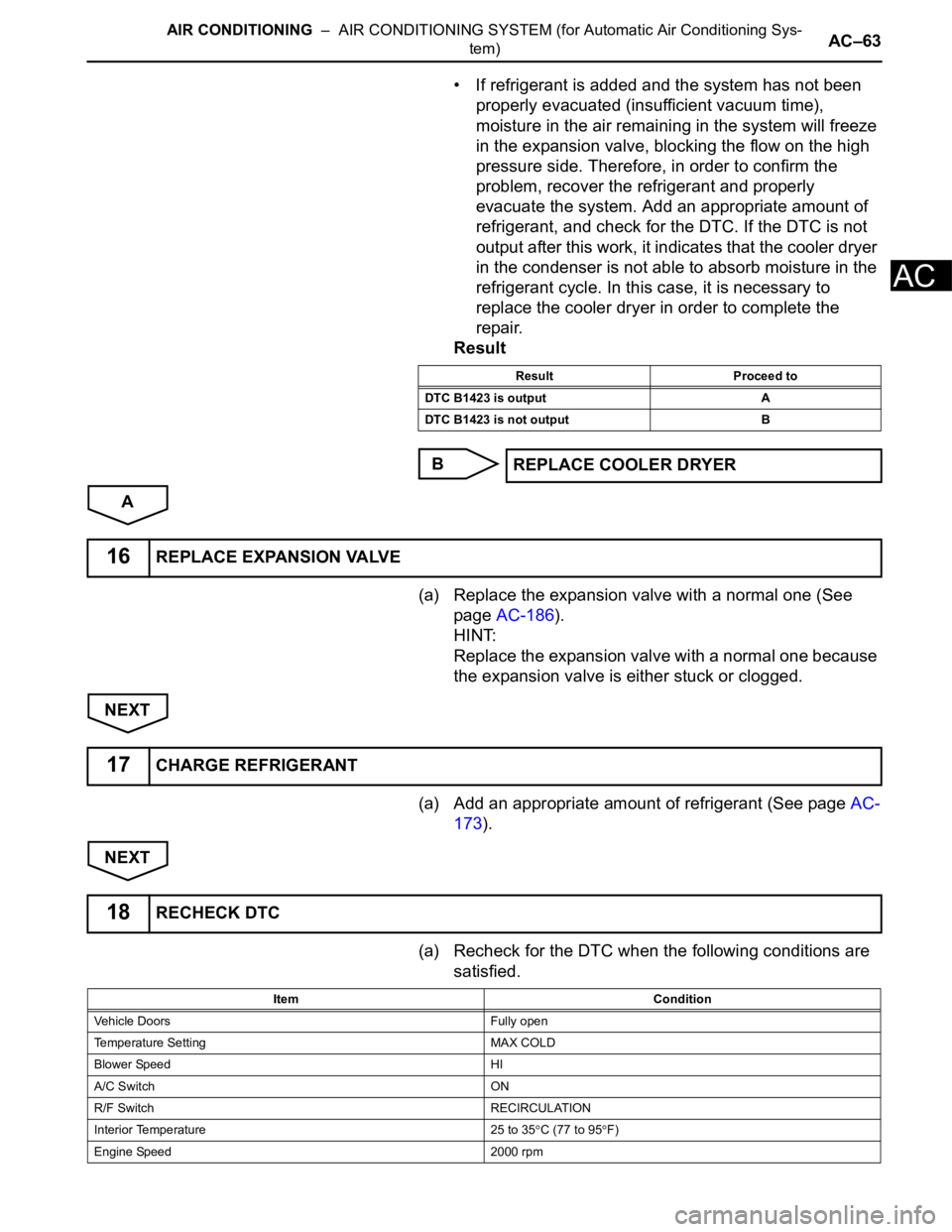

• If refrigerant is added and the system has not been

properly evacuated (insufficient vacuum time),

moisture in the air remaining in the system will freeze

in the expansion valve, blocking the flow on the high

pressure side. Therefore, in order to confirm the

problem, recover the refrigerant and properly

evacuate the system. Add an appropriate amount of

refrigerant, and check for the DTC. If the DTC is not

output after this work, it indicates that the cooler dryer

in the condenser is not able to absorb moisture in the

refrigerant cycle. In this case, it is necessary to

replace the cooler dryer in order to complete the

repair.

Result

B

A

(a) Replace the expansion valve with a normal one (See

page AC-186).

HINT:

Replace the expansion valve with a normal one because

the expansion valve is either stuck or clogged.

NEXT

(a) Add an appropriate amount of refrigerant (See page AC-

173).

NEXT

(a) Recheck for the DTC when the following conditions are

satisfied.

Result Proceed to

DTC B1423 is output A

DTC B1423 is not output B

REPLACE COOLER DRYER

16REPLACE EXPANSION VALVE

17CHARGE REFRIGERANT

18RECHECK DTC

Item Condition

Vehicle Doors Fully open

Temperature Setting MAX COLD

Blower Speed HI

A/C Switch ON

R/F Switch RECIRCULATION

Interior Temperature 25 to 35

C (77 to 95F)

Engine Speed 2000 rpm

Page 2849 of 3000

AC–106AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

A

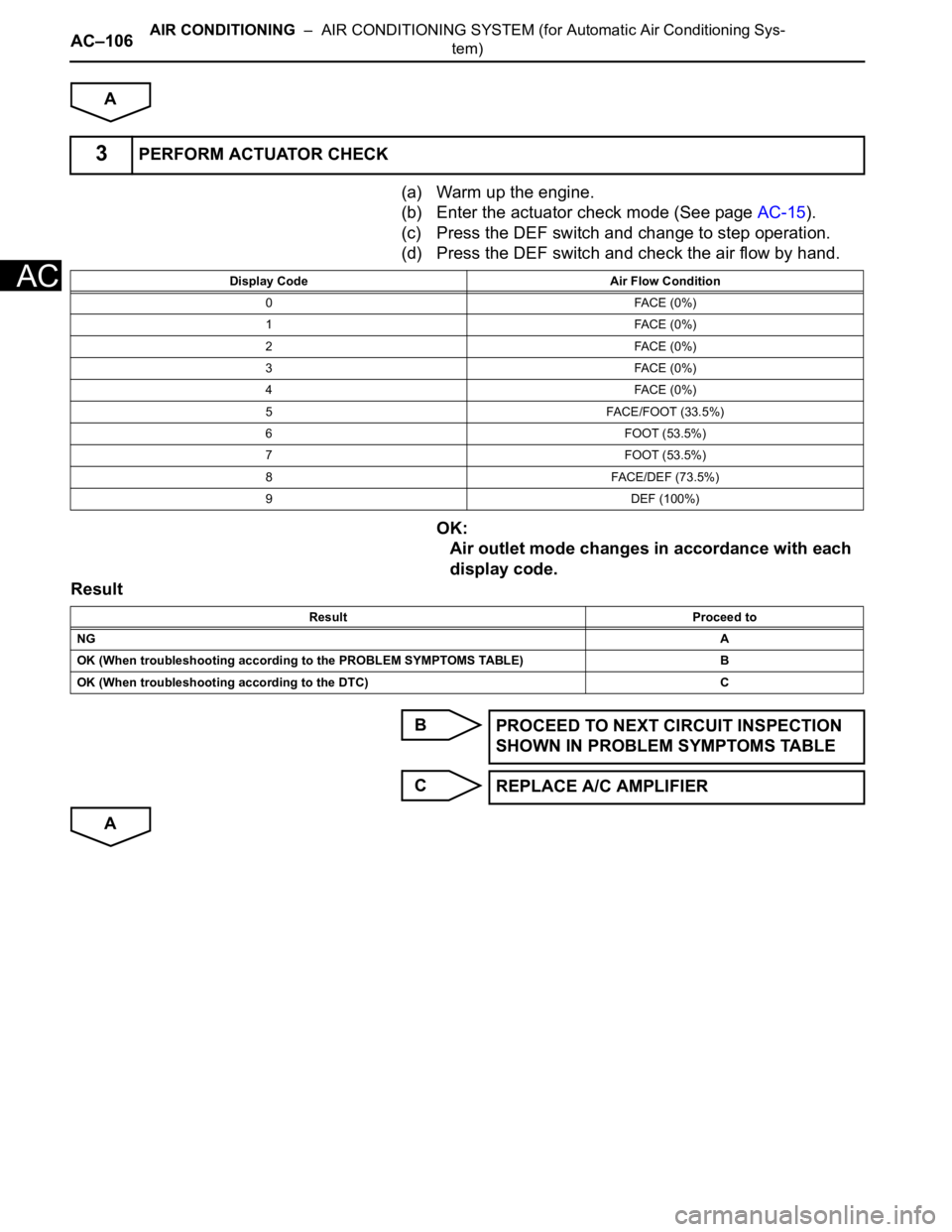

(a) Warm up the engine.

(b) Enter the actuator check mode (See page AC-15).

(c) Press the DEF switch and change to step operation.

(d) Press the DEF switch and check the air flow by hand.

OK:

Air outlet mode changes in accordance with each

display code.

Result

B

C

A

3PERFORM ACTUATOR CHECK

Display Code Air Flow Condition

0 FACE (0%)

1 FACE (0%)

2 FACE (0%)

3 FACE (0%)

4 FACE (0%)

5FACE/FOOT (33.5%)

6 FOOT (53.5%)

7 FOOT (53.5%)

8FACE/DEF (73.5%)

9 DEF (100%)

Result Proceed to

NGA

OK (When troubleshooting according to the PROBLEM SYMPTOMS TABLE) B

OK (When troubleshooting according to the DTC) C

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

REPLACE A/C AMPLIFIER

Page 2864 of 3000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–121

AC

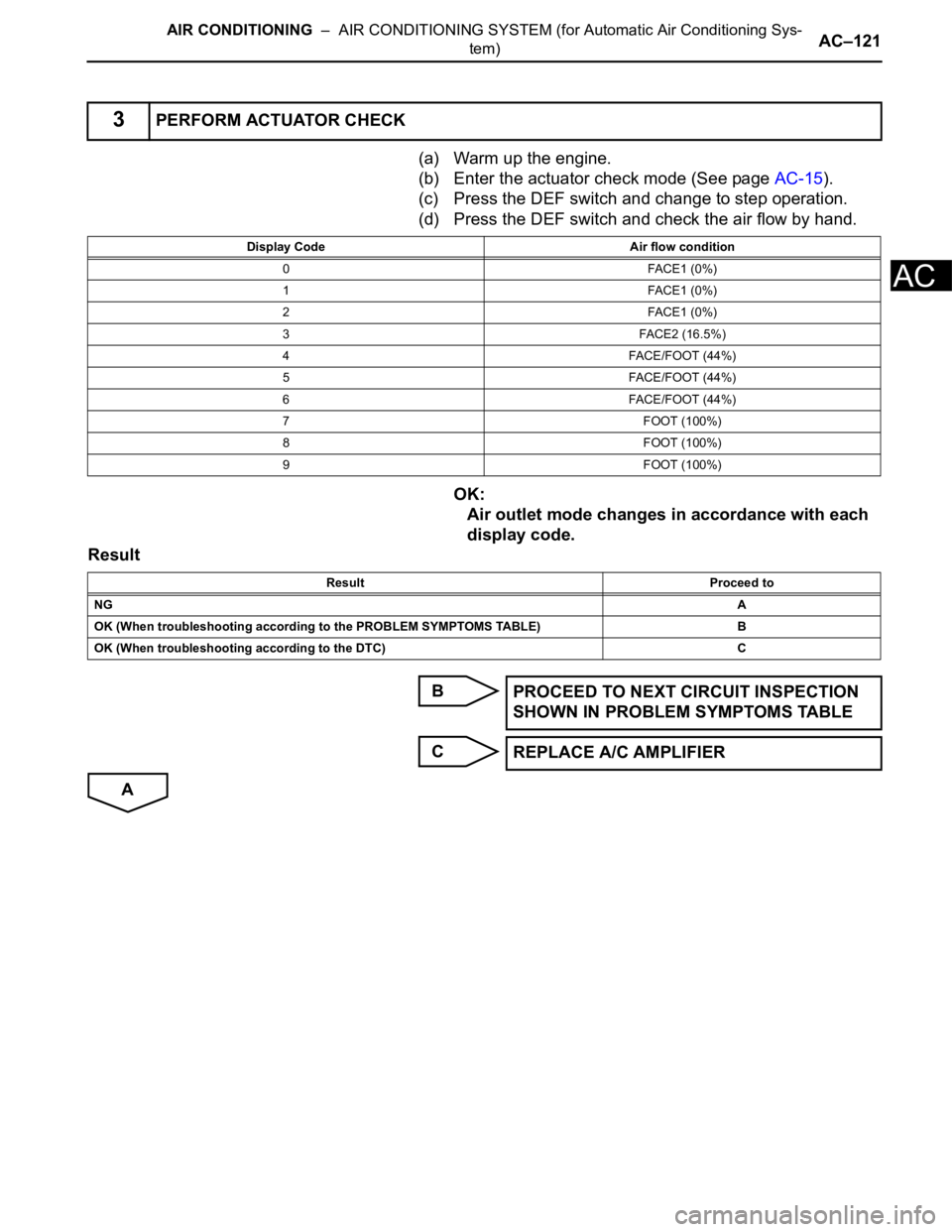

(a) Warm up the engine.

(b) Enter the actuator check mode (See page AC-15).

(c) Press the DEF switch and change to step operation.

(d) Press the DEF switch and check the air flow by hand.

OK:

Air outlet mode changes in accordance with each

display code.

Result

B

C

A

3PERFORM ACTUATOR CHECK

Display Code Air flow condition

0FACE1 (0%)

1FACE1 (0%)

2FACE1 (0%)

3 FACE2 (16.5%)

4 FACE/FOOT (44%)

5 FACE/FOOT (44%)

6 FACE/FOOT (44%)

7FOOT (100%)

8FOOT (100%)

9FOOT (100%)

Result Proceed to

NGA

OK (When troubleshooting according to the PROBLEM SYMPTOMS TABLE) B

OK (When troubleshooting according to the DTC) C

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

REPLACE A/C AMPLIFIER

Page 2893 of 3000

AC–150AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

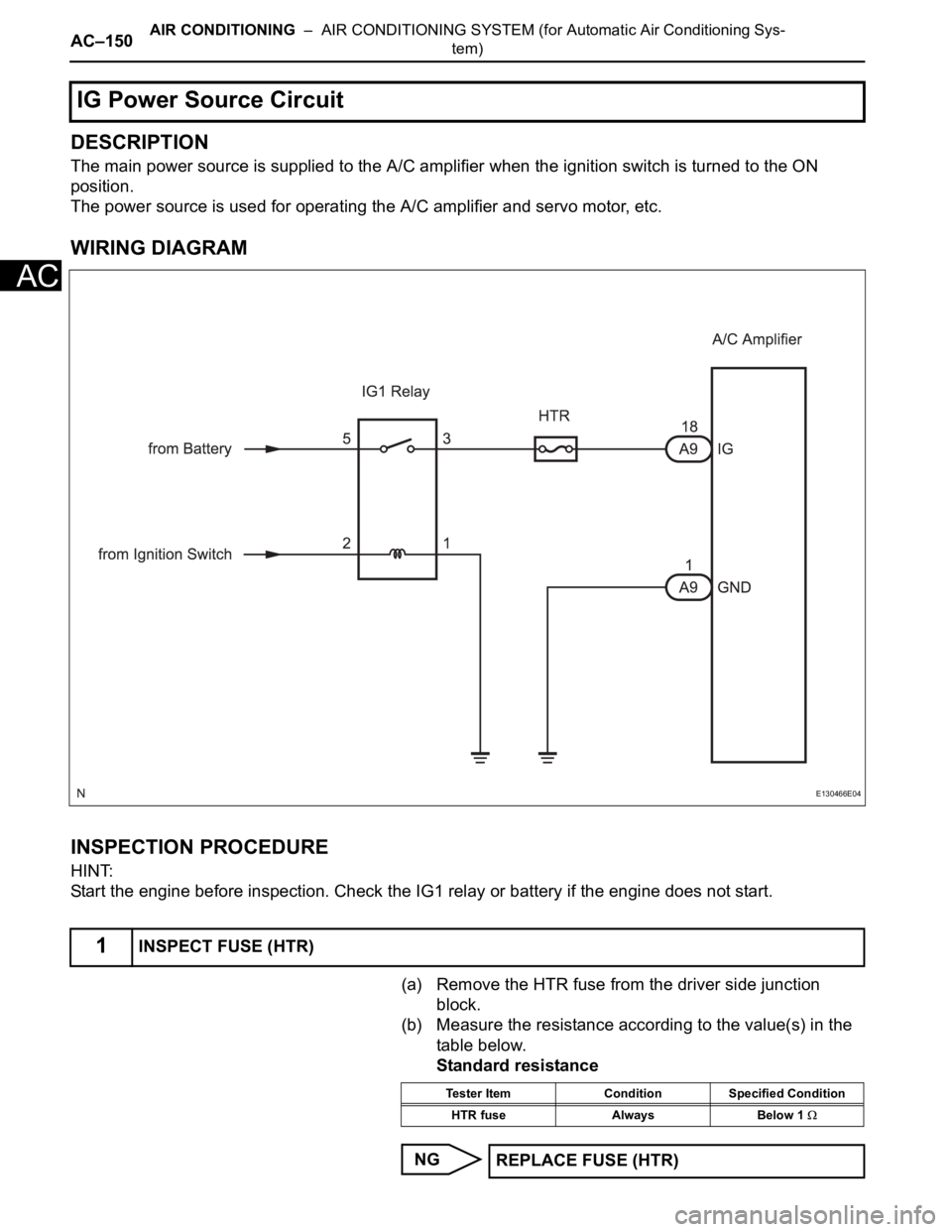

DESCRIPTION

The main power source is supplied to the A/C amplifier when the ignition switch is turned to the ON

position.

The power source is used for operating the A/C amplifier and servo motor, etc.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Start the engine before inspection. Check the IG1 relay or battery if the engine does not start.

(a) Remove the HTR fuse from the driver side junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

IG Power Source Circuit

1INSPECT FUSE (HTR)

E130466E04

Tester Item Condition Specified Condition

HTR fuse Always Below 1

REPLACE FUSE (HTR)

Page 2903 of 3000

AC–14AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

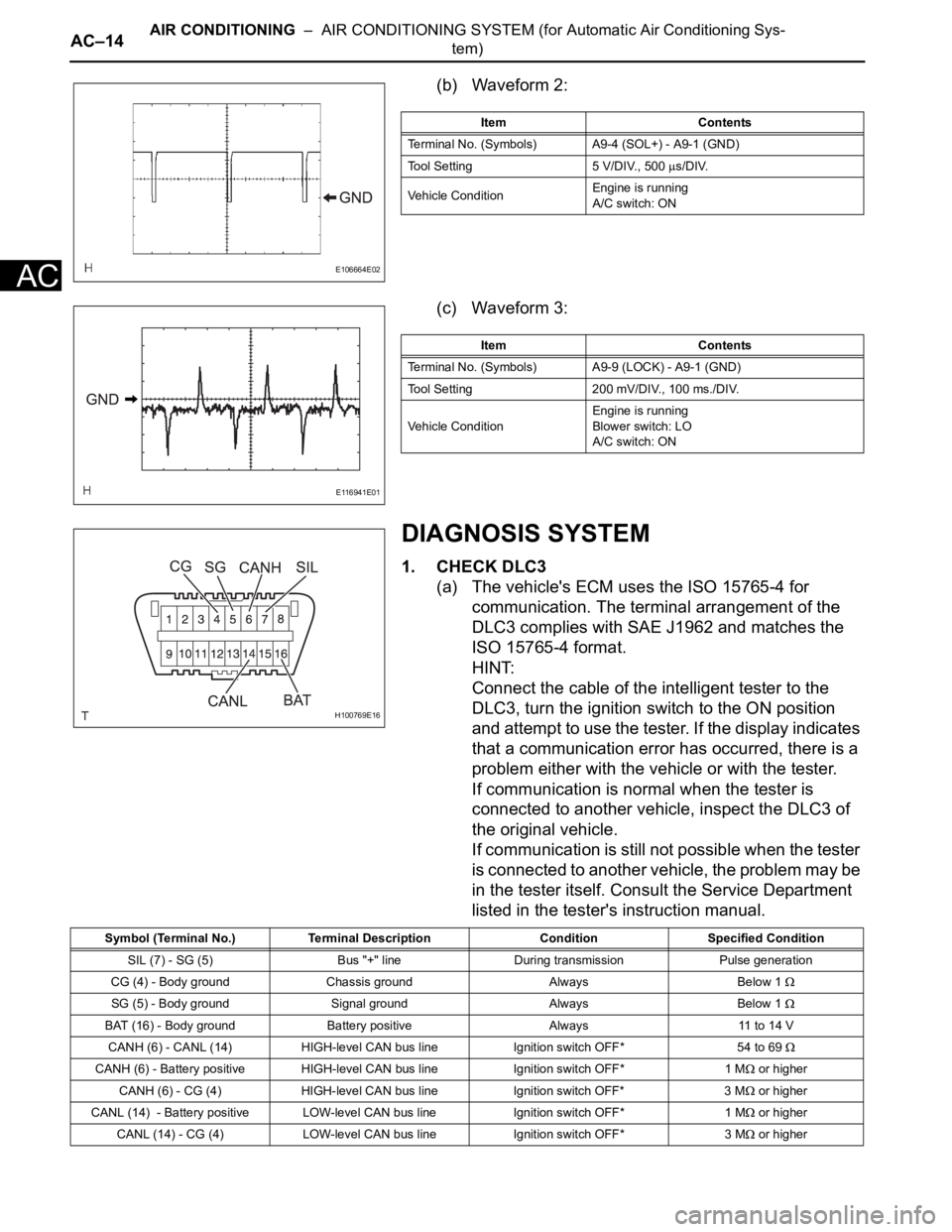

(b) Waveform 2:

(c) Waveform 3:

DIAGNOSIS SYSTEM

1. CHECK DLC3

(a) The vehicle's ECM uses the ISO 15765-4 for

communication. The terminal arrangement of the

DLC3 complies with SAE J1962 and matches the

ISO 15765-4 format.

HINT:

Connect the cable of the intelligent tester to the

DLC3, turn the ignition switch to the ON position

and attempt to use the tester. If the display indicates

that a communication error has occurred, there is a

problem either with the vehicle or with the tester.

If communication is normal when the tester is

connected to another vehicle, inspect the DLC3 of

the original vehicle.

If communication is still not possible when the tester

is connected to another vehicle, the problem may be

in the tester itself. Consult the Service Department

listed in the tester's instruction manual.

E106664E02

Item Contents

Terminal No. (Symbols) A9-4 (SOL+) - A9-1 (GND)

Tool Setting 5 V/DIV., 500

s/DIV.

Vehicle ConditionEngine is running

A/C switch: ON

E116941E01

Item Contents

Terminal No. (Symbols) A9-9 (LOCK) - A9-1 (GND)

Tool Setting 200 mV/DIV., 100 ms./DIV.

Vehicle ConditionEngine is running

Blower switch: LO

A/C switch: ON

H100769E16

Symbol (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1

SG (5) - Body ground Signal ground Always Below 1

BAT (16) - Body ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) HIGH-level CAN bus line Ignition switch OFF*54 to 69

CANH (6) - Battery positive HIGH-level CAN bus line Ignition switch OFF* 1 M or higher

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch OFF* 3 M

or higher

CANL (14) - Battery positive LOW-level CAN bus line Ignition switch OFF* 1 M

or higher

CANL (14) - CG (4) LOW-level CAN bus line Ignition switch OFF* 3 M

or higher

Page 2904 of 3000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–15

AC

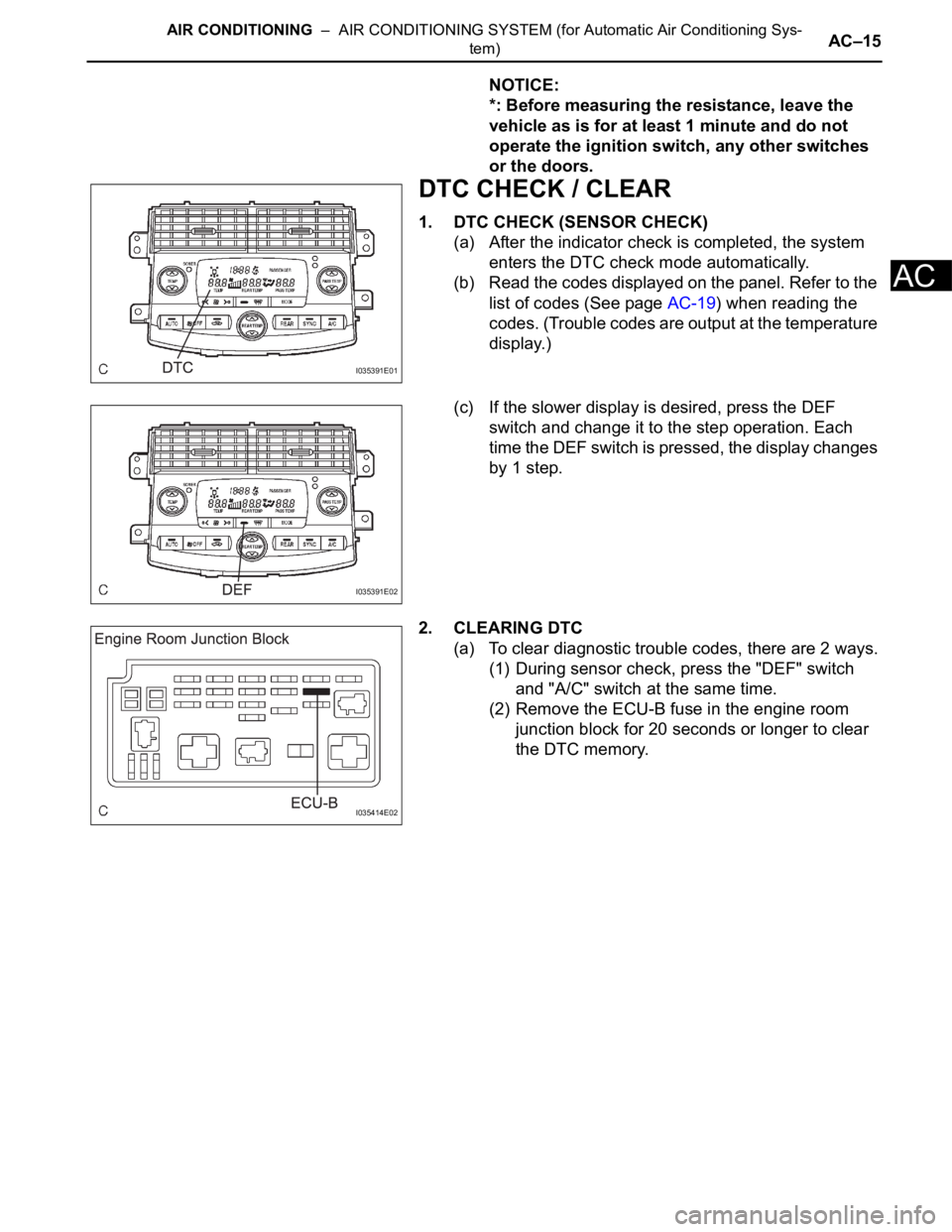

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the doors.

DTC CHECK / CLEAR

1. DTC CHECK (SENSOR CHECK)

(a) After the indicator check is completed, the system

enters the DTC check mode automatically.

(b) Read the codes displayed on the panel. Refer to the

list of codes (See page AC-19) when reading the

codes. (Trouble codes are output at the temperature

display.)

(c) If the slower display is desired, press the DEF

switch and change it to the step operation. Each

time the DEF switch is pressed, the display changes

by 1 step.

2. CLEARING DTC

(a) To clear diagnostic trouble codes, there are 2 ways.

(1) During sensor check, press the "DEF" switch

and "A/C" switch at the same time.

(2) Remove the ECU-B fuse in the engine room

junction block for 20 seconds or longer to clear

the DTC memory.

I035391E01

I035391E02

I035414E02