throttle body TOYOTA SIENNA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 866 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–49

EM

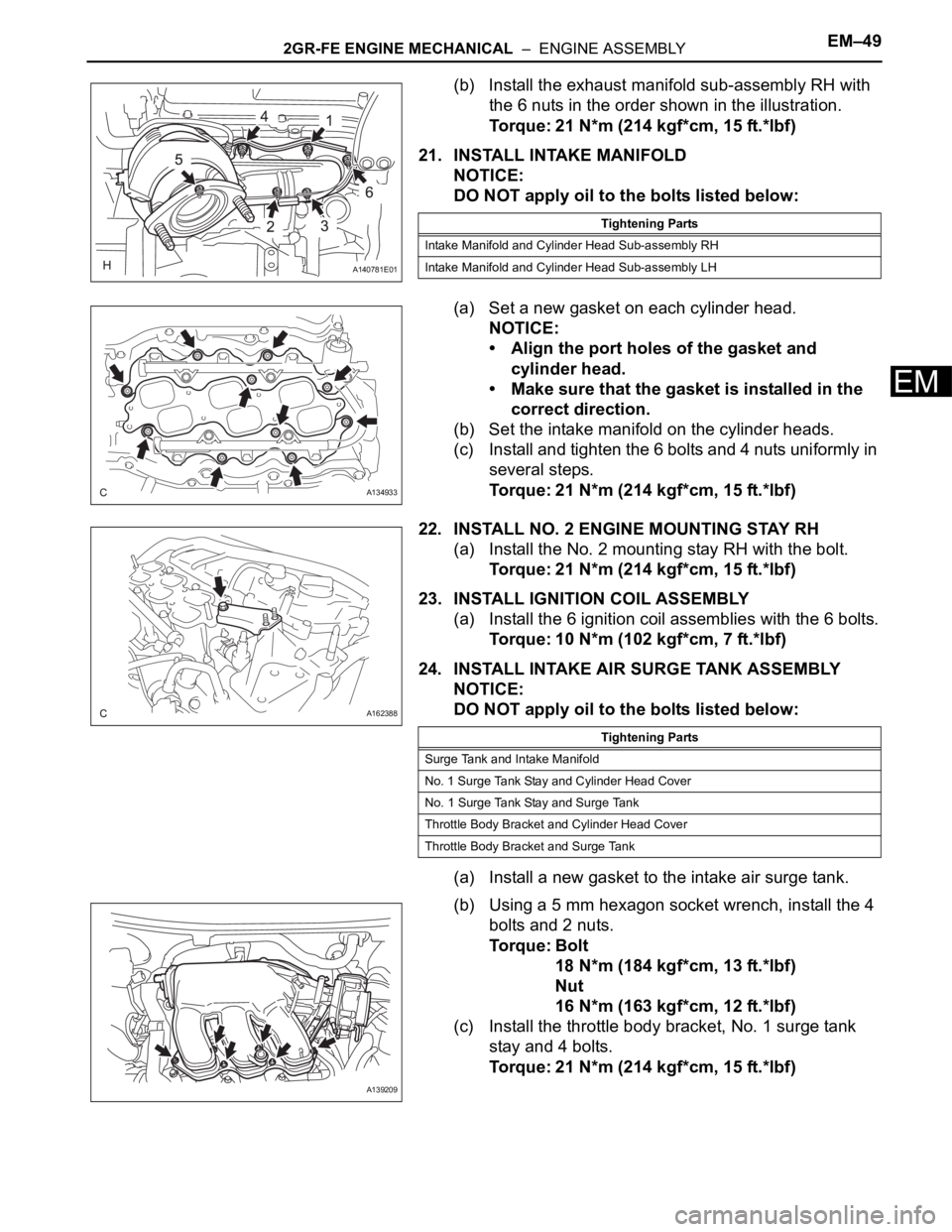

(b) Install the exhaust manifold sub-assembly RH with

the 6 nuts in the order shown in the illustration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

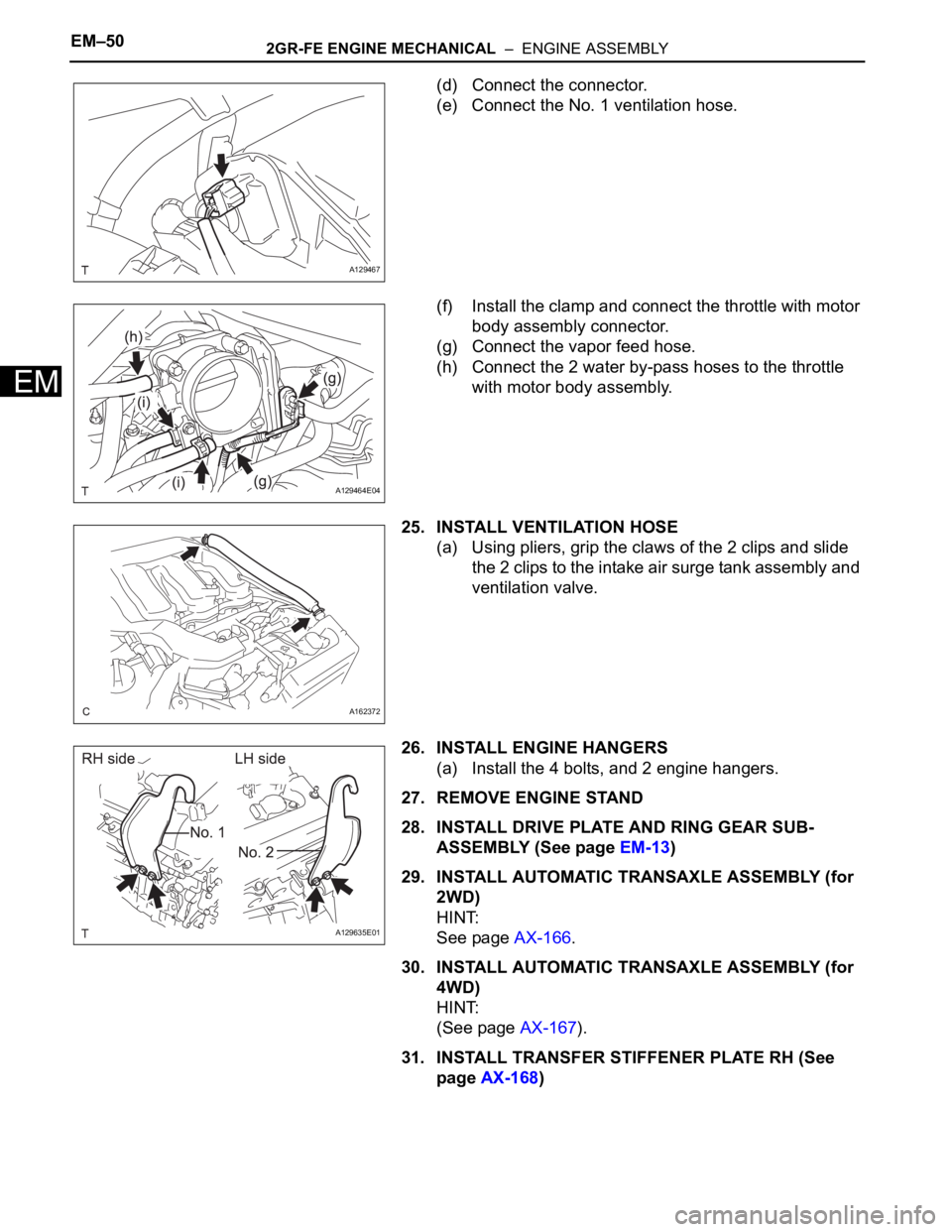

21. INSTALL INTAKE MANIFOLD

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Set a new gasket on each cylinder head.

NOTICE:

• Align the port holes of the gasket and

cylinder head.

• Make sure that the gasket is installed in the

correct direction.

(b) Set the intake manifold on the cylinder heads.

(c) Install and tighten the 6 bolts and 4 nuts uniformly in

several steps.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

22. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the No. 2 mounting stay RH with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

23. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coil assemblies with the 6 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

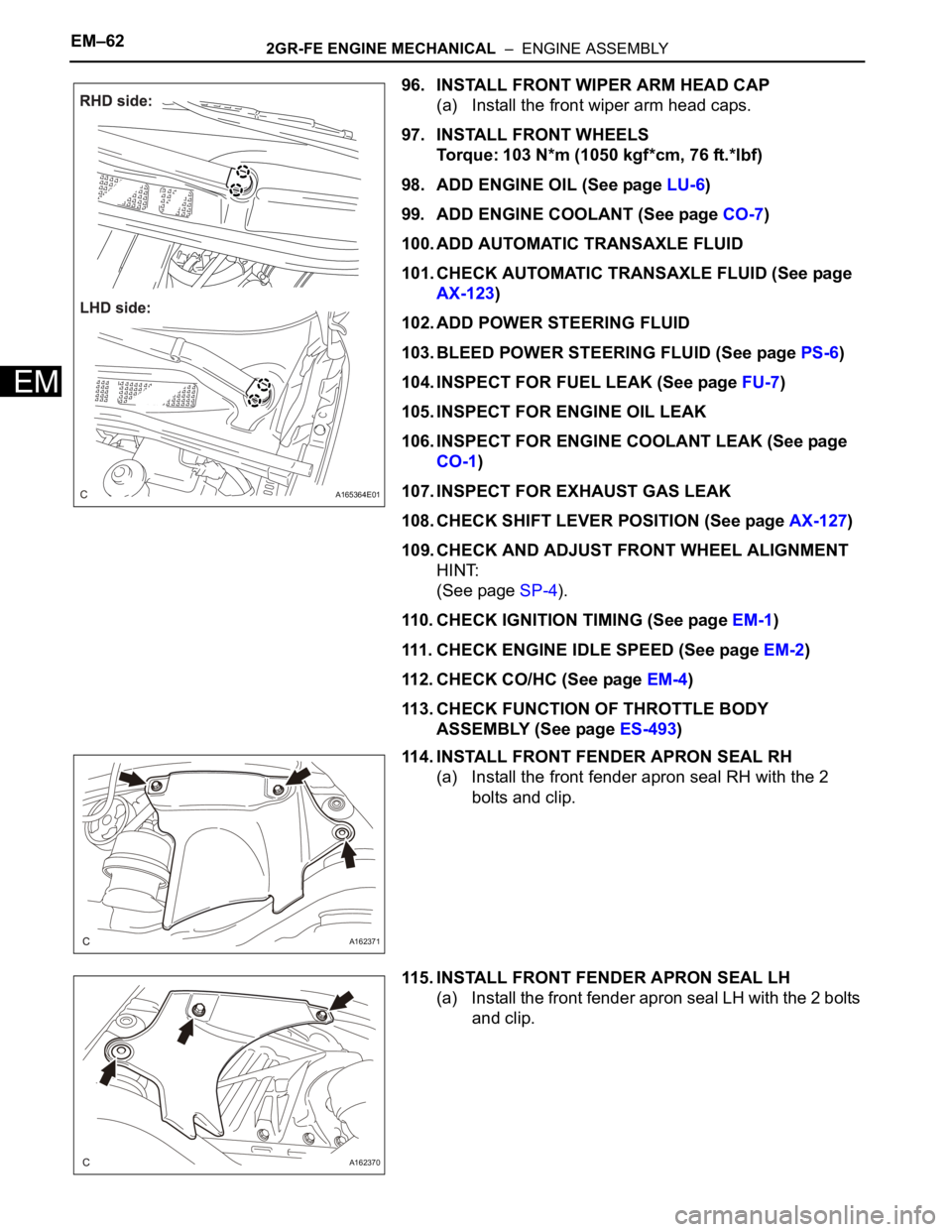

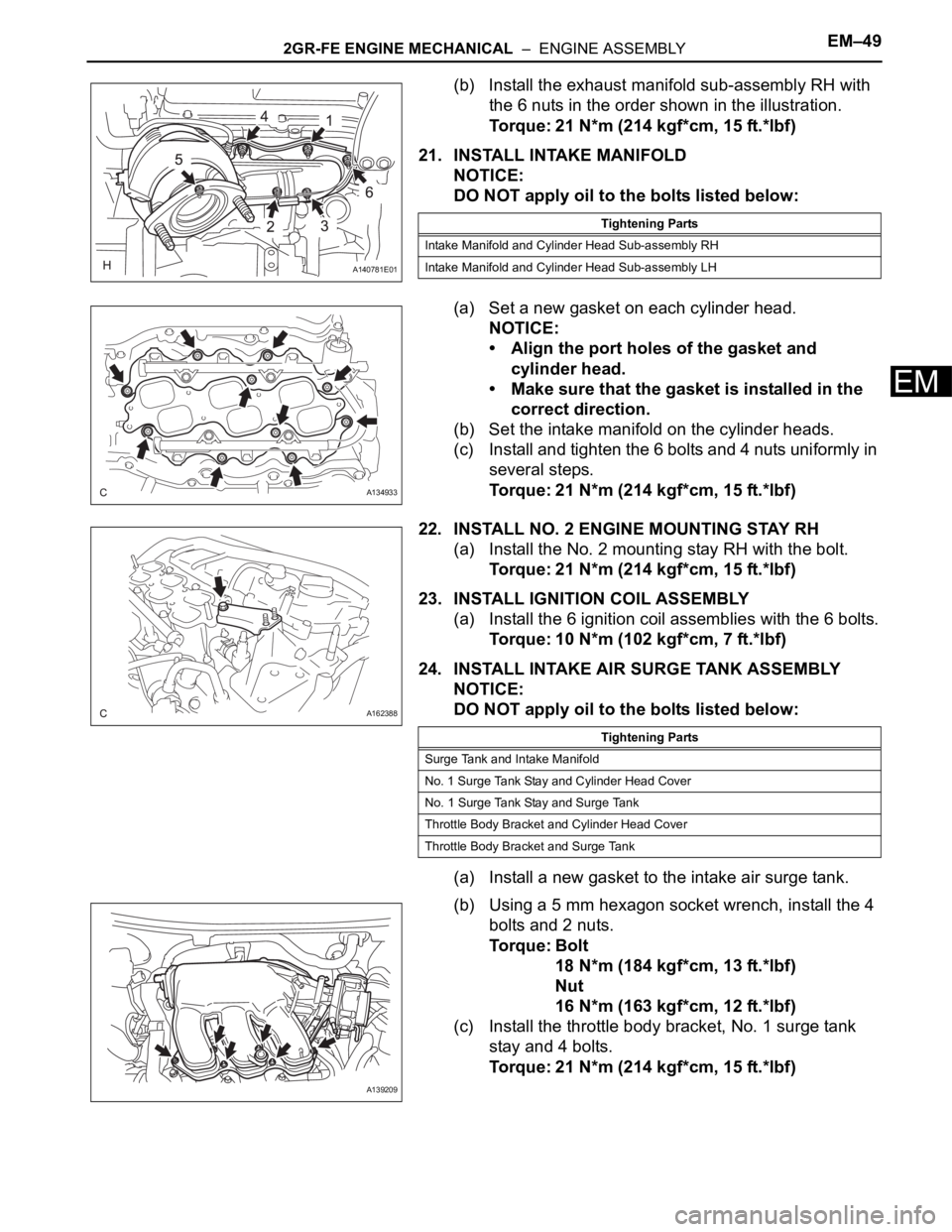

24. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts and 2 nuts.

Torque: Bolt

18 N*m (184 kgf*cm, 13 ft.*lbf)

Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

(c) Install the throttle body bracket, No. 1 surge tank

stay and 4 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A140781E01

Tightening Parts

Intake Manifold and Cylinder Head Sub-assembly RH

Intake Manifold and Cylinder Head Sub-assembly LH

A134933

A162388

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Cylinder Head Cover

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Cylinder Head Cover

Throttle Body Bracket and Surge Tank

A139209

Page 867 of 3000

EM–502GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(d) Connect the connector.

(e) Connect the No. 1 ventilation hose.

(f) Install the clamp and connect the throttle with motor

body assembly connector.

(g) Connect the vapor feed hose.

(h) Connect the 2 water by-pass hoses to the throttle

with motor body assembly.

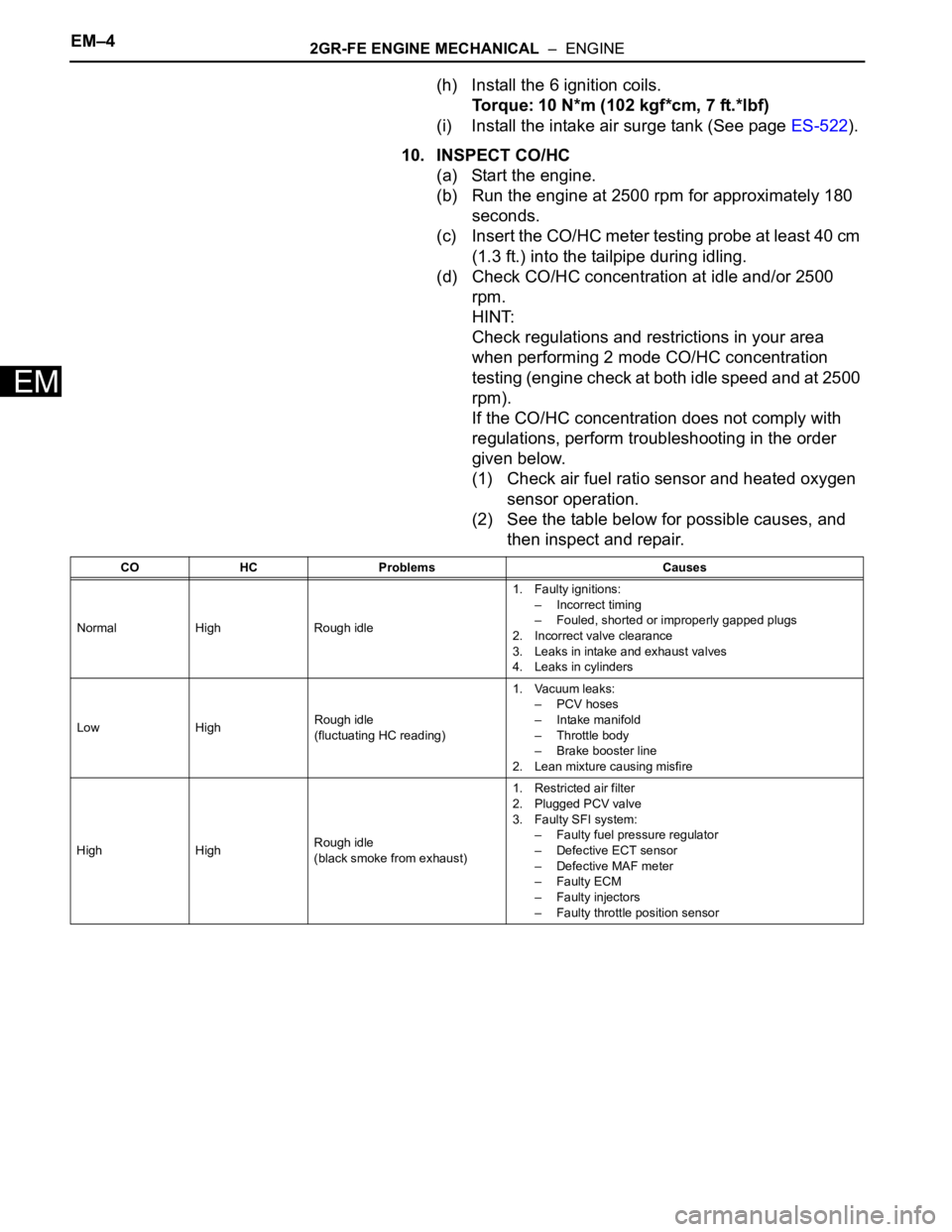

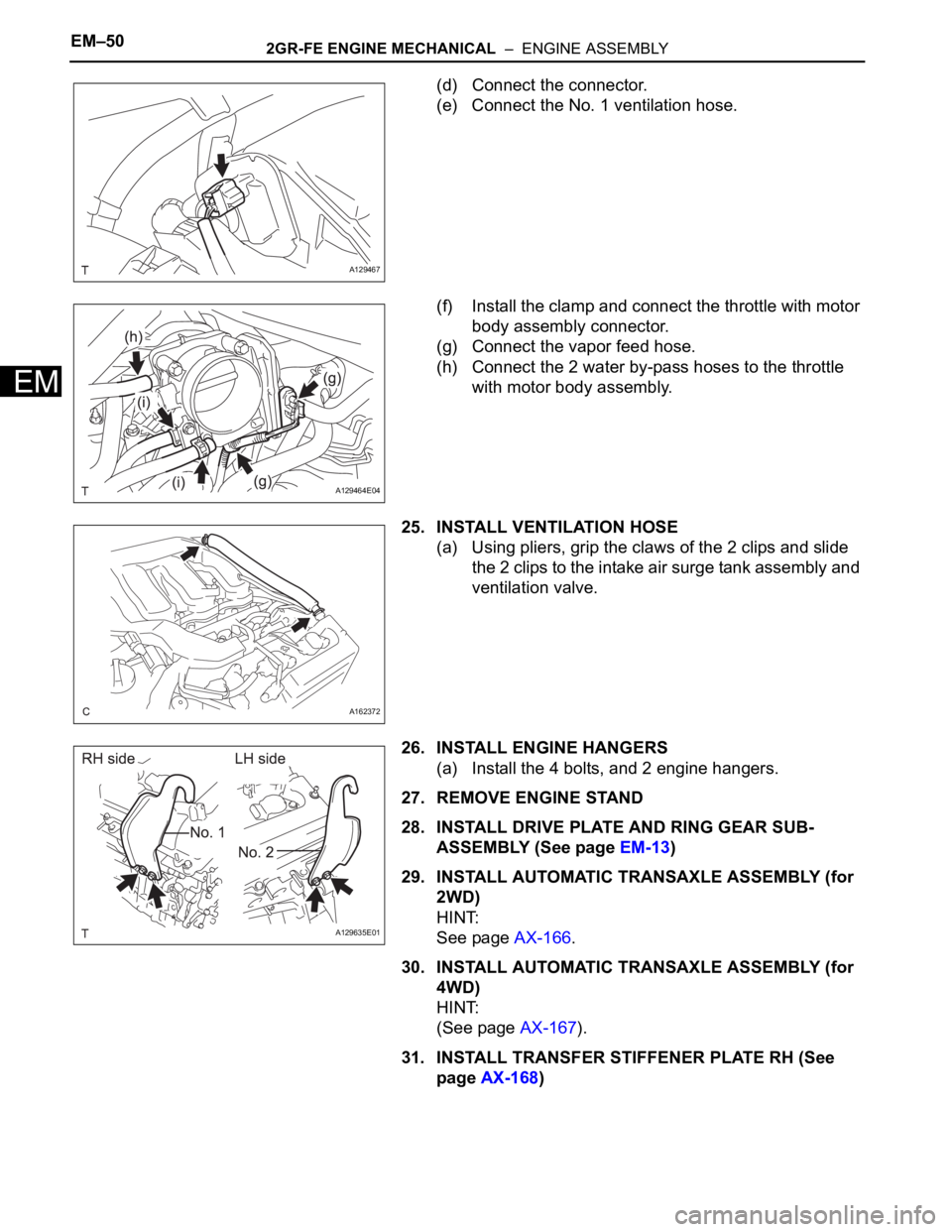

25. INSTALL VENTILATION HOSE

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to the intake air surge tank assembly and

ventilation valve.

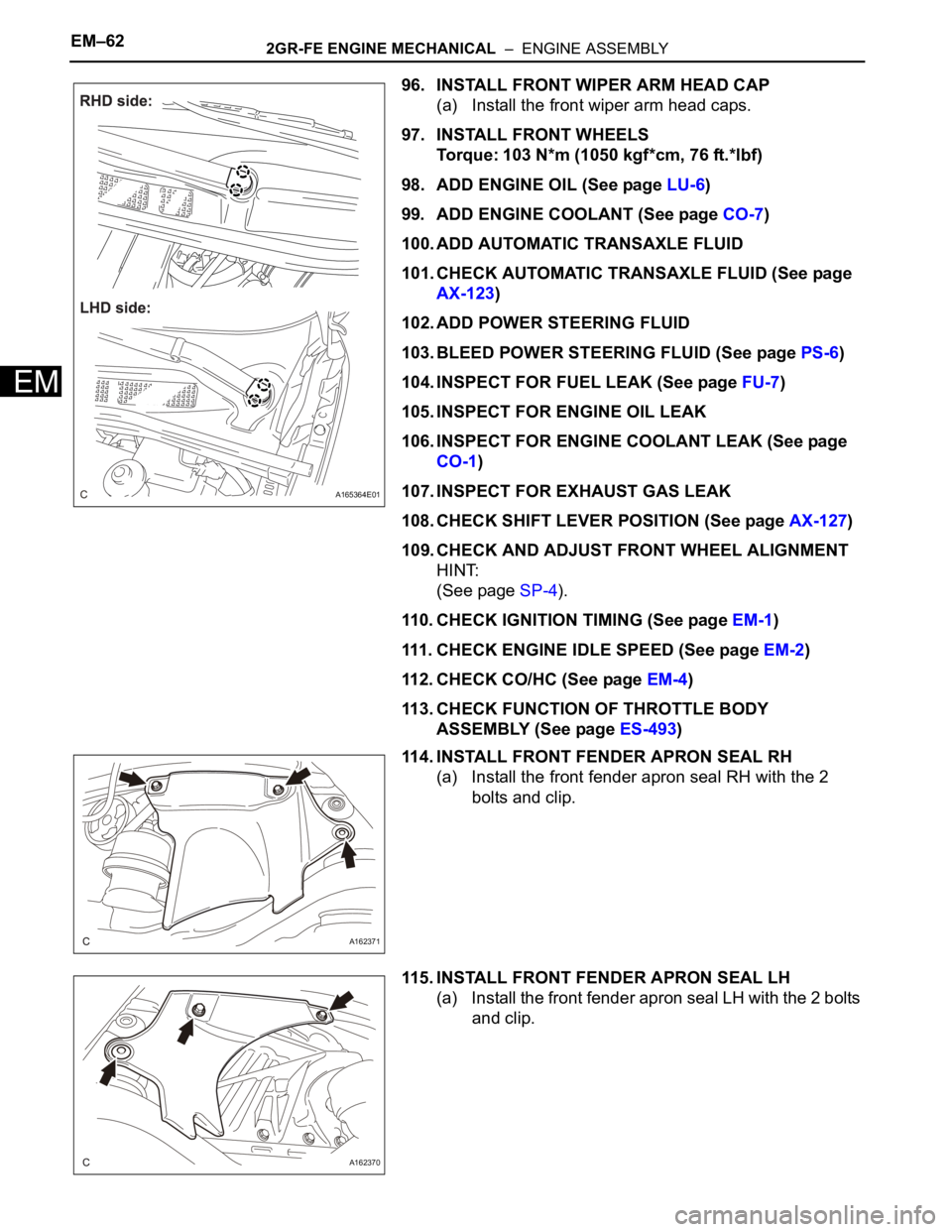

26. INSTALL ENGINE HANGERS

(a) Install the 4 bolts, and 2 engine hangers.

27. REMOVE ENGINE STAND

28. INSTALL DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY (See page EM-13)

29. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-166.

30. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

(See page AX-167).

31. INSTALL TRANSFER STIFFENER PLATE RH (See

page AX-168)

A129467

A129464E04

A162372

A129635E01

Page 879 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 934 of 3000

EM–42GR-FE ENGINE MECHANICAL – ENGINE

EM

(h) Install the 6 ignition coils.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(i) Install the intake air surge tank (See page ES-522).

10. INSPECT CO/HC

(a) Start the engine.

(b) Run the engine at 2500 rpm for approximately 180

seconds.

(c) Insert the CO/HC meter testing probe at least 40 cm

(1.3 ft.) into the tailpipe during idling.

(d) Check CO/HC concentration at idle and/or 2500

rpm.

HINT:

Check regulations and restrictions in your area

when performing 2 mode CO/HC concentration

testing (engine check at both idle speed and at 2500

rpm).

If the CO/HC concentration does not comply with

regulations, perform troubleshooting in the order

given below.

(1) Check air fuel ratio sensor and heated oxygen

sensor operation.

(2) See the table below for possible causes, and

then inspect and repair.

CO HC Problems Causes

Normal High Rough idle1. Faulty ignitions:

– Incorrect timing

– Fouled, shorted or improperly gapped plugs

2. Incorrect valve clearance

3. Leaks in intake and exhaust valves

4. Leaks in cylinders

Low HighRough idle

(fluctuating HC reading)1. Vacuum leaks:

– PCV hoses

– Intake manifold

– Throttle body

– Brake booster line

2. Lean mixture causing misfire

High HighRough idle

(black smoke from exhaust)1. Restricted air filter

2. Plugged PCV valve

3. Faulty SFI system:

– Faulty fuel pressure regulator

– Defective ECT sensor

– Defective MAF meter

–Faulty ECM

– Faulty injectors

– Faulty throttle position sensor

Page 997 of 3000

EM–382GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) Remove the engine hangers.

80. REMOVE VENTILATION HOSE

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to remove the ventilation hose.

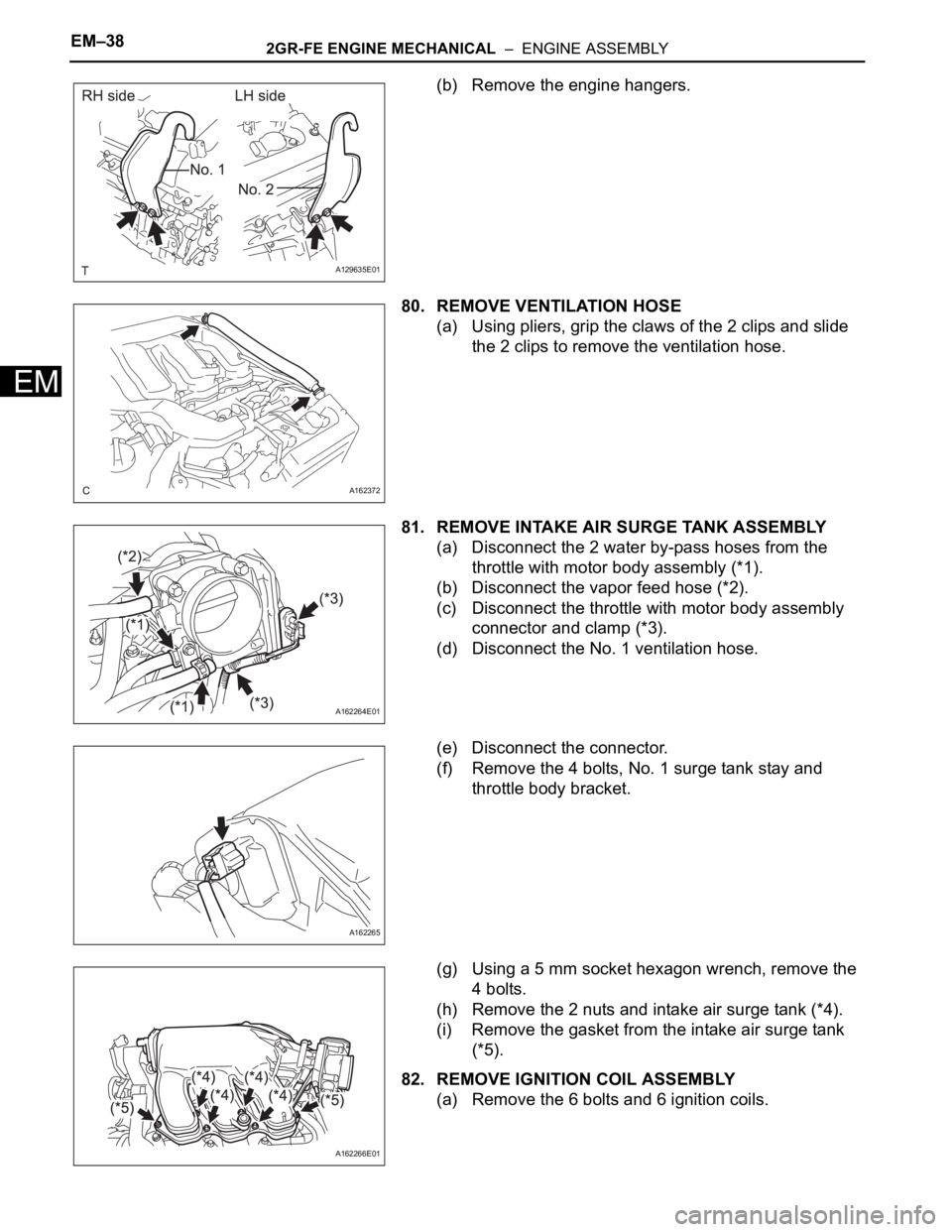

81. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle with motor body assembly (*1).

(b) Disconnect the vapor feed hose (*2).

(c) Disconnect the throttle with motor body assembly

connector and clamp (*3).

(d) Disconnect the No. 1 ventilation hose.

(e) Disconnect the connector.

(f) Remove the 4 bolts, No. 1 surge tank stay and

throttle body bracket.

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts.

(h) Remove the 2 nuts and intake air surge tank (*4).

(i) Remove the gasket from the intake air surge tank

(*5).

82. REMOVE IGNITION COIL ASSEMBLY

(a) Remove the 6 bolts and 6 ignition coils.

A129635E01

A162372

A162264E01

A162265

A162266E01

Page 1008 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–49

EM

(b) Install the exhaust manifold sub-assembly RH with

the 6 nuts in the order shown in the illustration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

21. INSTALL INTAKE MANIFOLD

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Set a new gasket on each cylinder head.

NOTICE:

• Align the port holes of the gasket and

cylinder head.

• Make sure that the gasket is installed in the

correct direction.

(b) Set the intake manifold on the cylinder heads.

(c) Install and tighten the 6 bolts and 4 nuts uniformly in

several steps.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

22. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the No. 2 mounting stay RH with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

23. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coil assemblies with the 6 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

24. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts and 2 nuts.

Torque: Bolt

18 N*m (184 kgf*cm, 13 ft.*lbf)

Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

(c) Install the throttle body bracket, No. 1 surge tank

stay and 4 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A140781E01

Tightening Parts

Intake Manifold and Cylinder Head Sub-assembly RH

Intake Manifold and Cylinder Head Sub-assembly LH

A134933

A162388

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Cylinder Head Cover

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Cylinder Head Cover

Throttle Body Bracket and Surge Tank

A139209

Page 1009 of 3000

EM–502GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(d) Connect the connector.

(e) Connect the No. 1 ventilation hose.

(f) Install the clamp and connect the throttle with motor

body assembly connector.

(g) Connect the vapor feed hose.

(h) Connect the 2 water by-pass hoses to the throttle

with motor body assembly.

25. INSTALL VENTILATION HOSE

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to the intake air surge tank assembly and

ventilation valve.

26. INSTALL ENGINE HANGERS

(a) Install the 4 bolts, and 2 engine hangers.

27. REMOVE ENGINE STAND

28. INSTALL DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY (See page EM-13)

29. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-166.

30. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

(See page AX-167).

31. INSTALL TRANSFER STIFFENER PLATE RH (See

page AX-168)

A129467

A129464E04

A162372

A129635E01

Page 1021 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 1120 of 3000

FU–142GR-FE FUEL – FUEL INJECTOR

FU

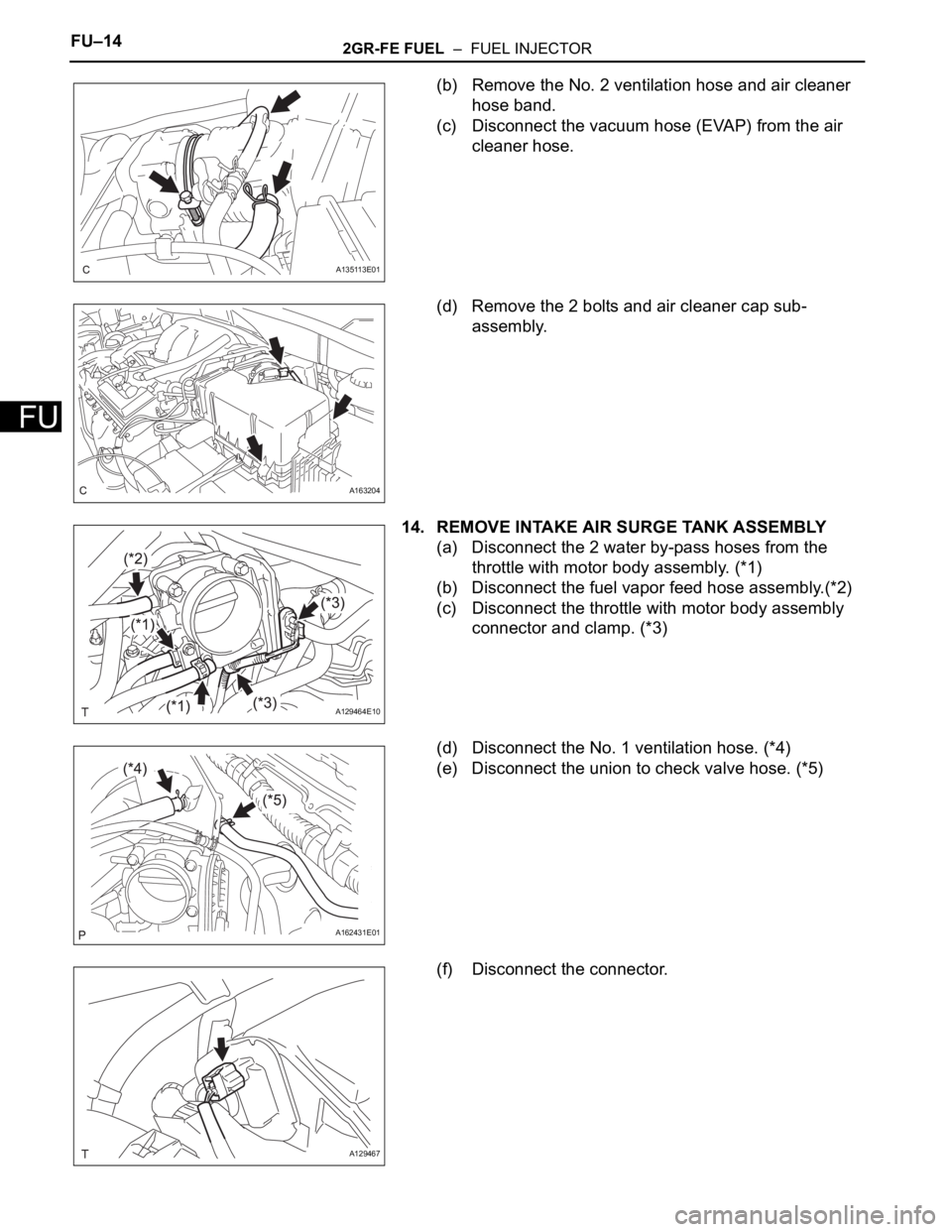

(b) Remove the No. 2 ventilation hose and air cleaner

hose band.

(c) Disconnect the vacuum hose (EVAP) from the air

cleaner hose.

(d) Remove the 2 bolts and air cleaner cap sub-

assembly.

14. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle with motor body assembly. (*1)

(b) Disconnect the fuel vapor feed hose assembly.(*2)

(c) Disconnect the throttle with motor body assembly

connector and clamp. (*3)

(d) Disconnect the No. 1 ventilation hose. (*4)

(e) Disconnect the union to check valve hose. (*5)

(f) Disconnect the connector.

A135113E01

A163204

A129464E10

A162431E01

A129467

Page 1131 of 3000

2GR-FE FUEL – FUEL INJECTORFU–19

FU

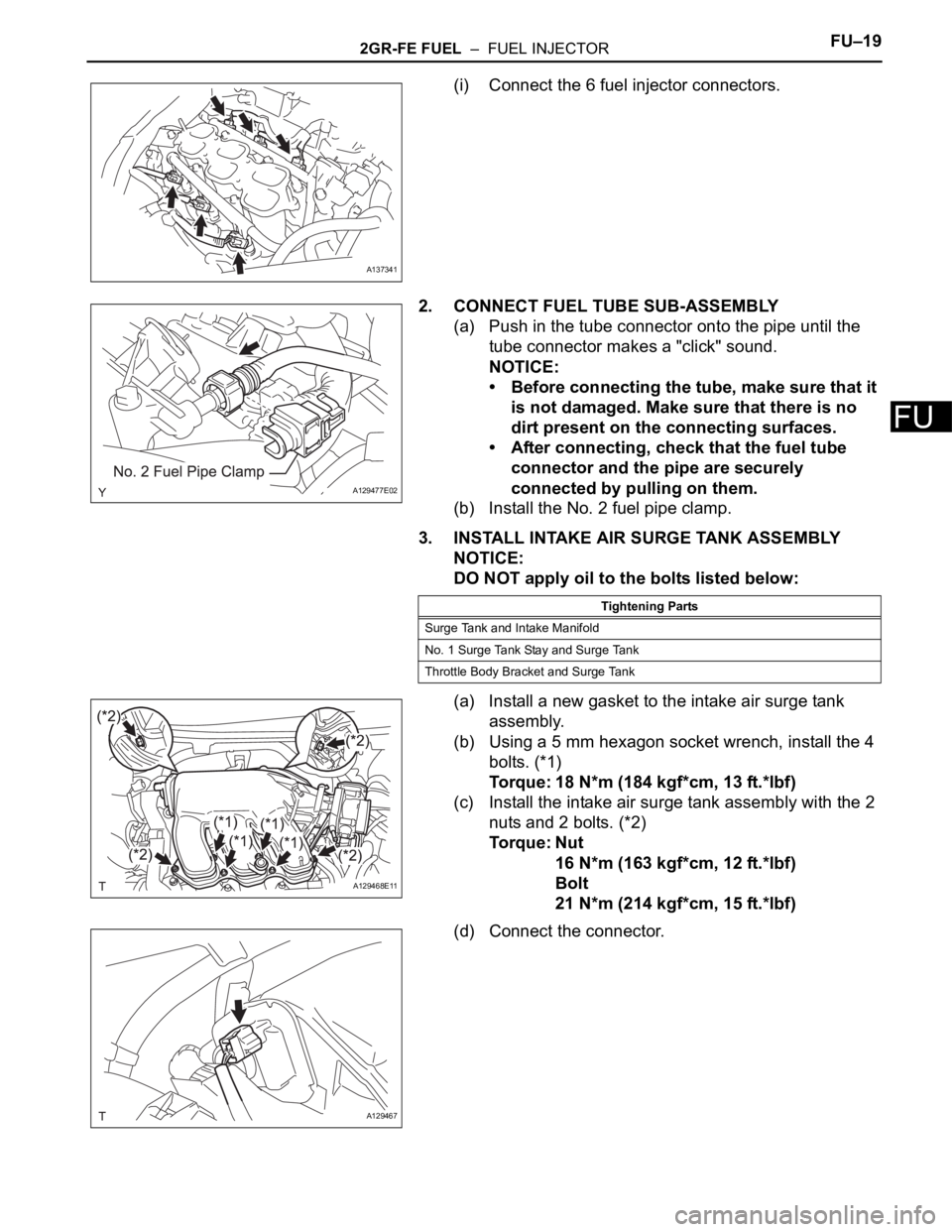

(i) Connect the 6 fuel injector connectors.

2. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the tube connector onto the pipe until the

tube connector makes a "click" sound.

NOTICE:

• Before connecting the tube, make sure that it

is not damaged. Make sure that there is no

dirt present on the connecting surfaces.

• After connecting, check that the fuel tube

connector and the pipe are securely

connected by pulling on them.

(b) Install the No. 2 fuel pipe clamp.

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank

assembly.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts. (*1)

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank assembly with the 2

nuts and 2 bolts. (*2)

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector.

A137341

A129477E02

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Surge Tank

A129468E11

A129467