throttle body TOYOTA SIENNA 2007 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 744 of 3000

ES–4582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

B

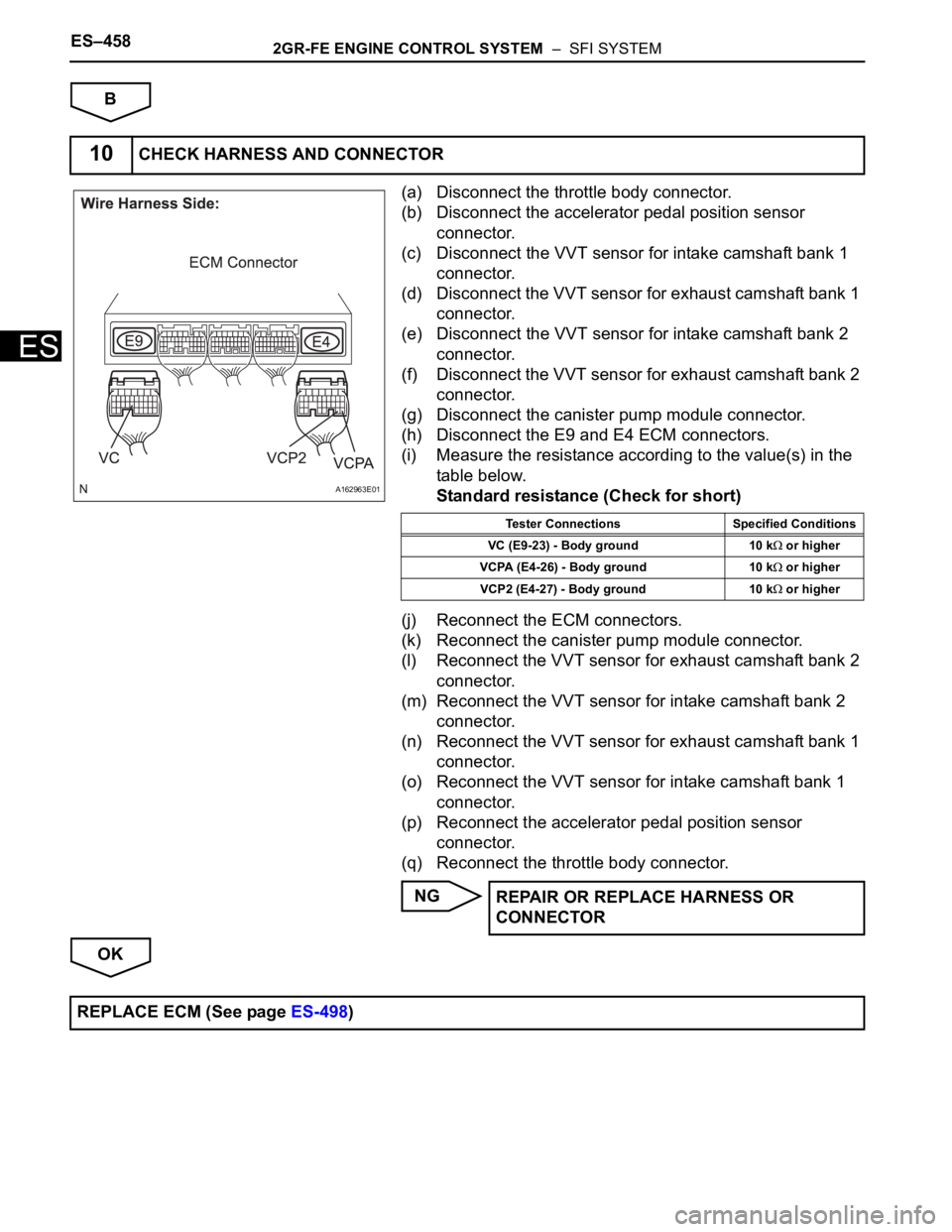

(a) Disconnect the throttle body connector.

(b) Disconnect the accelerator pedal position sensor

connector.

(c) Disconnect the VVT sensor for intake camshaft bank 1

connector.

(d) Disconnect the VVT sensor for exhaust camshaft bank 1

connector.

(e) Disconnect the VVT sensor for intake camshaft bank 2

connector.

(f) Disconnect the VVT sensor for exhaust camshaft bank 2

connector.

(g) Disconnect the canister pump module connector.

(h) Disconnect the E9 and E4 ECM connectors.

(i) Measure the resistance according to the value(s) in the

table below.

Standard resistance (Check for short)

(j) Reconnect the ECM connectors.

(k) Reconnect the canister pump module connector.

(l) Reconnect the VVT sensor for exhaust camshaft bank 2

connector.

(m) Reconnect the VVT sensor for intake camshaft bank 2

connector.

(n) Reconnect the VVT sensor for exhaust camshaft bank 1

connector.

(o) Reconnect the VVT sensor for intake camshaft bank 1

connector.

(p) Reconnect the accelerator pedal position sensor

connector.

(q) Reconnect the throttle body connector.

NG

OK

10CHECK HARNESS AND CONNECTOR

A162963E01

Tester Connections Specified Conditions

VC (E9-23) - Body ground 10 k

or higher

VCPA (E4-26) - Body ground 10 k

or higher

VCP2 (E4-27) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM (See page ES-498)

Page 789 of 3000

2GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODYES–493

ES

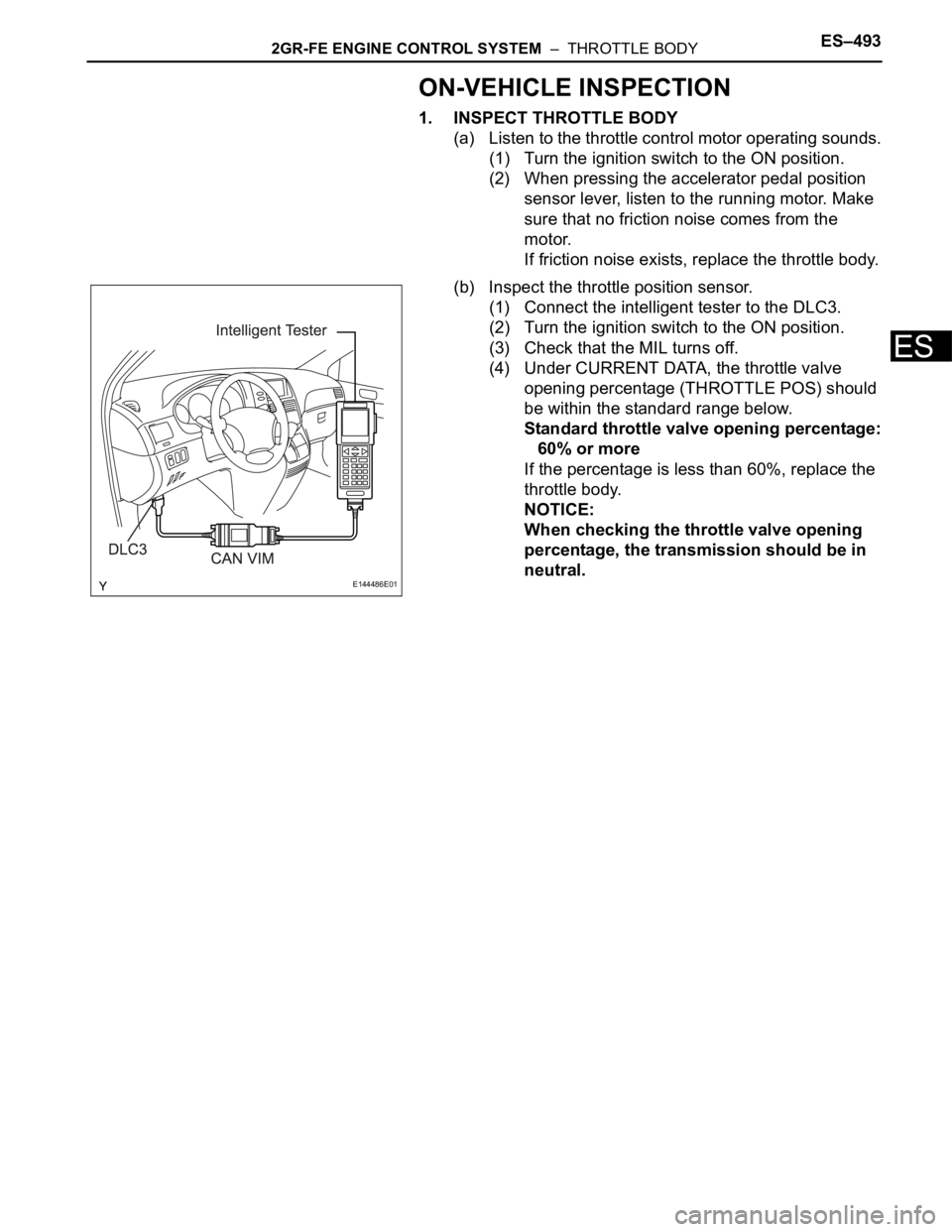

ON-VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Listen to the throttle control motor operating sounds.

(1) Turn the ignition switch to the ON position.

(2) When pressing the accelerator pedal position

sensor lever, listen to the running motor. Make

sure that no friction noise comes from the

motor.

If friction noise exists, replace the throttle body.

(b) Inspect the throttle position sensor.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Check that the MIL turns off.

(4) Under CURRENT DATA, the throttle valve

opening percentage (THROTTLE POS) should

be within the standard range below.

Standard throttle valve opening percentage:

60% or more

If the percentage is less than 60%, replace the

throttle body.

NOTICE:

When checking the throttle valve opening

percentage, the transmission should be in

neutral.

E144486E01

Page 790 of 3000

ES–4942GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODY

ES

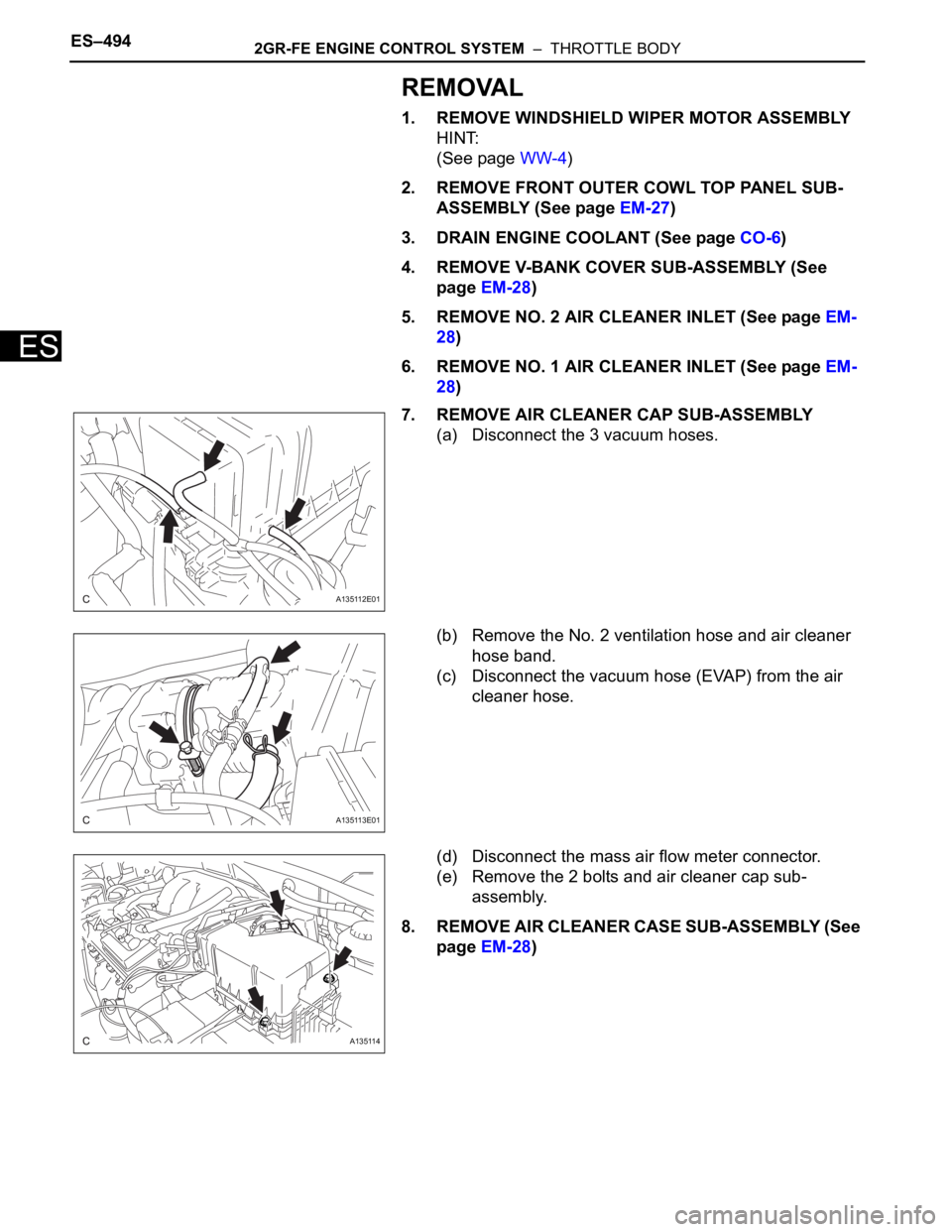

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

(b) Remove the No. 2 ventilation hose and air cleaner

hose band.

(c) Disconnect the vacuum hose (EVAP) from the air

cleaner hose.

(d) Disconnect the mass air flow meter connector.

(e) Remove the 2 bolts and air cleaner cap sub-

assembly.

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

A135112E01

A135113E01

A135114

Page 791 of 3000

2GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODYES–495

ES

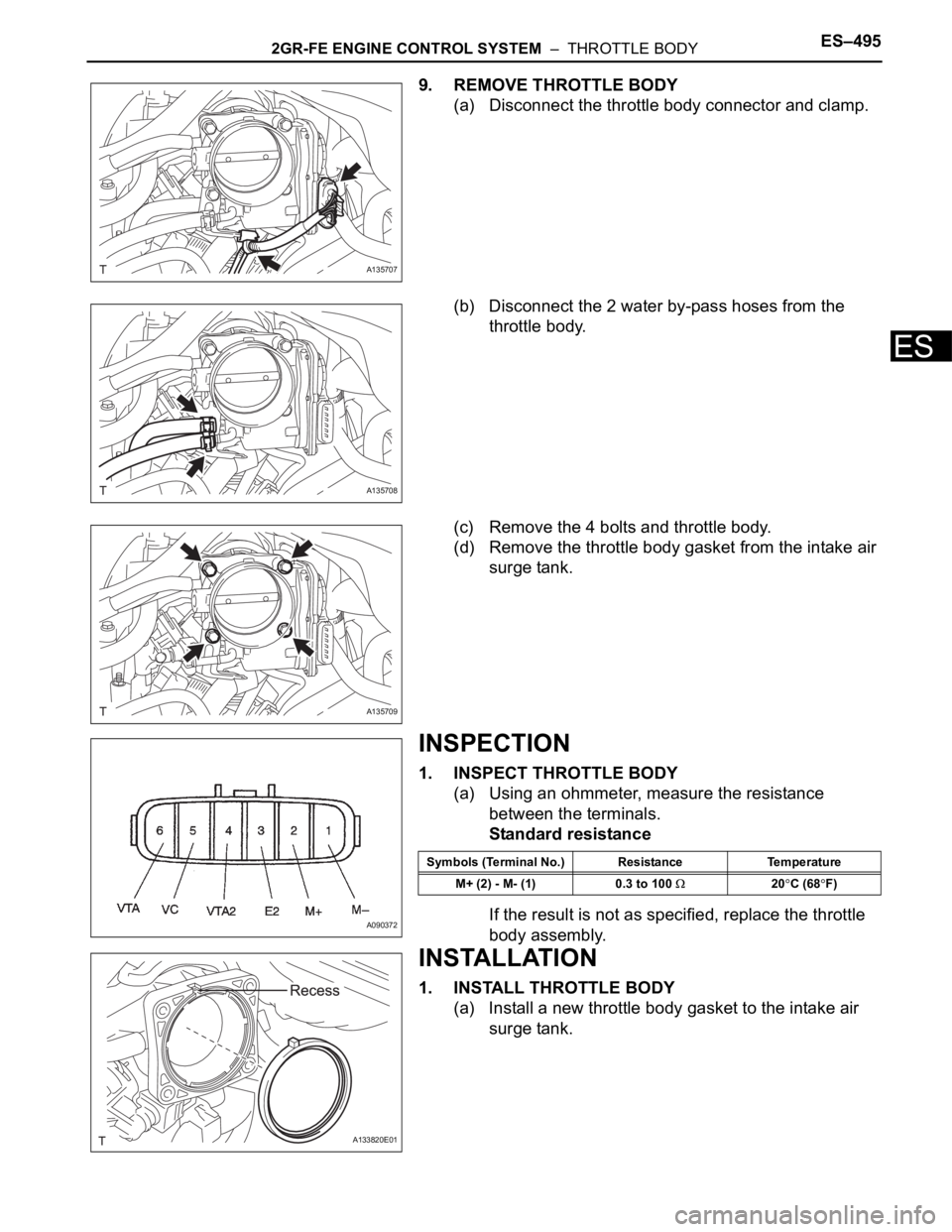

9. REMOVE THROTTLE BODY

(a) Disconnect the throttle body connector and clamp.

(b) Disconnect the 2 water by-pass hoses from the

throttle body.

(c) Remove the 4 bolts and throttle body.

(d) Remove the throttle body gasket from the intake air

surge tank.

INSPECTION

1. INSPECT THROTTLE BODY

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

If the result is not as specified, replace the throttle

body assembly.

INSTALLATION

1. INSTALL THROTTLE BODY

(a) Install a new throttle body gasket to the intake air

surge tank.

A135707

A135708

A135709

A090372

Symbols (Terminal No.) Resistance Temperature

M+ (2) - M- (1) 0.3 to 100

20C (68F)

A133820E01

Page 792 of 3000

ES–4962GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODY

ES

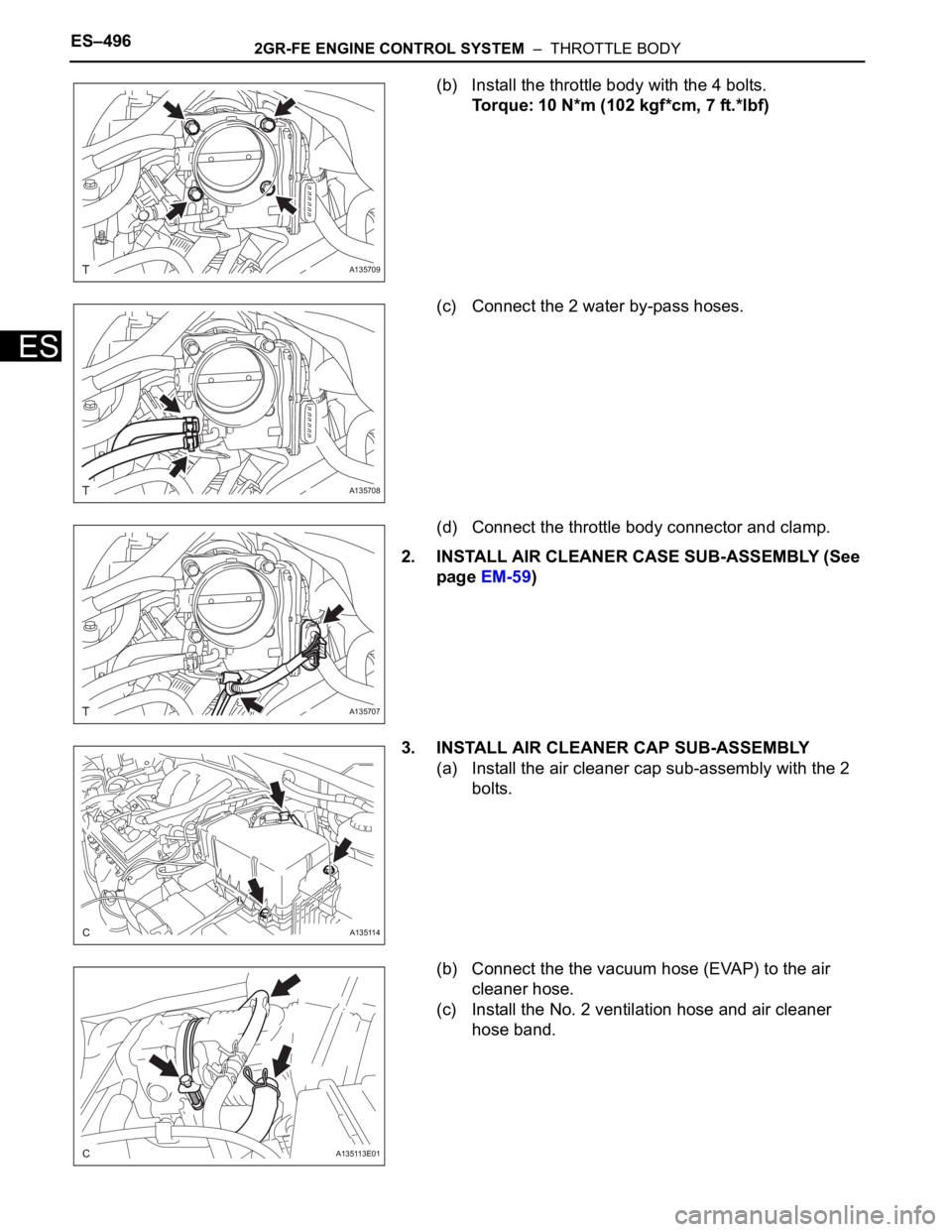

(b) Install the throttle body with the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(c) Connect the 2 water by-pass hoses.

(d) Connect the throttle body connector and clamp.

2. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the air cleaner cap sub-assembly with the 2

bolts.

(b) Connect the the vacuum hose (EVAP) to the air

cleaner hose.

(c) Install the No. 2 ventilation hose and air cleaner

hose band.

A135709

A135708

A135707

A135114

A135113E01

Page 793 of 3000

2GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODYES–497

ES

(d) Connect the 3 vacuum hoses.

4. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

5. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

6. ADD ENGINE COOLANT (See page CO-7)

7. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

8. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

9. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

10. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A135112E01

Page 816 of 3000

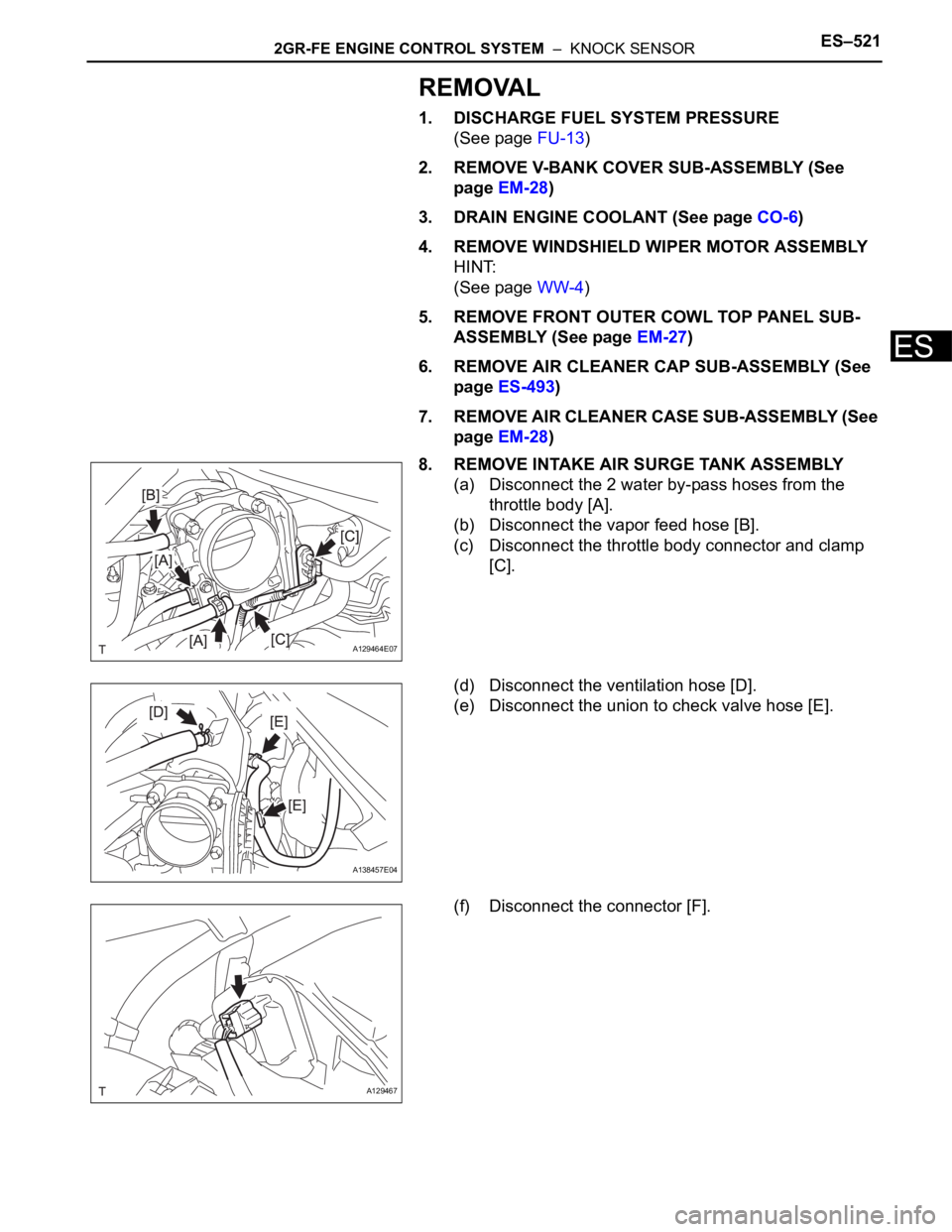

ES–362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

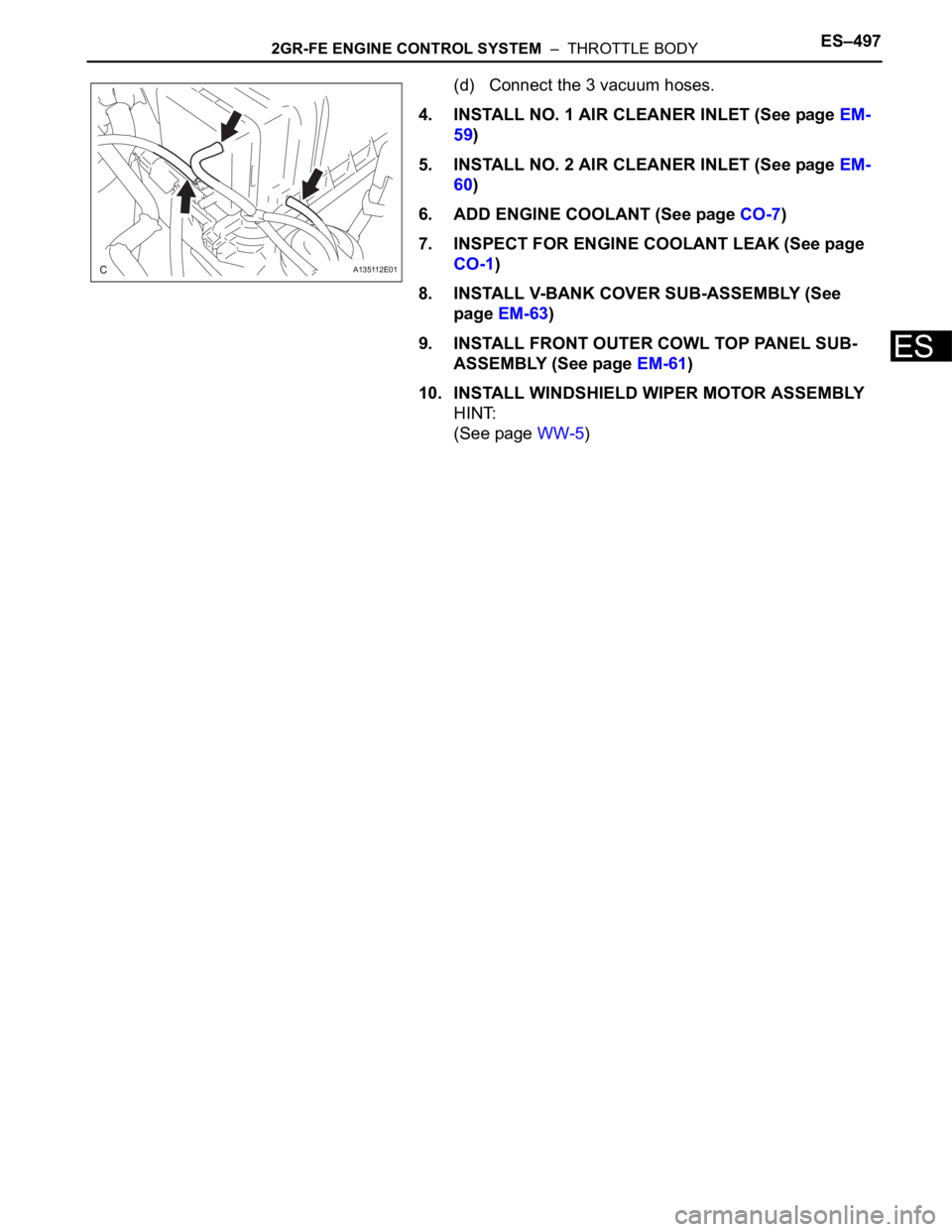

M+ (E9-5) - ME01 (E10-3) B - W-BThrottle drive motor

operation signal (positive

terminal)Idling with warm enginePluse generation

(see waveform 9)

E02 (E9-6) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

E01 (E9-7) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

IGT1 (E9-8) - E1 (E11-1)

IGT2 (E9-9) - E1 (E11-1)

IGT3 (E9-10) - E1 (E11-1)

IGT4 (E9-11) - E1 (E11-1)

IGT5 (E9-12) - E1 (E11-1)

IGT6 (E9-13) - E1 (E11-1)R-L - BR

P - BR

Y- B - B R

L-Y - BR

G-Y - BR

L-R - BRIgnition coil with igniter

(ignition signal)IdlingPulse generation

(see waveform 6)

GE01 (E9-17) - E1 (E11-1) - - BRShielded earth (ground)

circuit of throttle drive

motorAlways Below 1 V

OX1B (E9-18) - E2 (E9-28)

OX2B (E10-33) - E2 (E9-28)W - BR

B - BRHeated oxygen sensor

signalWith engine speed at 2500 rpm

for 2 minutes after warming upPulse generation

(see waveform 2)

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully released2.1 to 3.1 V

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully depressed4.5 to 5.0 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully closed0.5 to 1.2 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully open3.2 to 4.8 V

THW (E9-21) - E2 (E9-28) G-B - BREngine coolant

temperature sensor signalIdling, Engine coolant

temperature 80

C (176F)0.2 to 1.0 V

THA (E9-22) - E2 (E9-28) L-B - BRIntake air temperature

sensor signalIdling, Intake air temperature

20

C (68F)0.5 to 3.4 V

VC (E9-23) - E2 (E9-28) Y - BRPower source of sensors

(specific voltage)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)IdlingPulse generation

(see waveform 6)

AICV (E9-27) - E1 (E11-1) W - BRVSV for Air intake control

system operation signalIgnition switch ON 9 to 14 V

E2 (E9-28) - E1 (E11-1) BR - BREarth (ground) circuit of

sensors for ETCSAlways Below 1 V

E2G (E9-29) - E1 (E11-1) L-W - BREarth (ground) circuit of

sensor for mass air flow

meterAlways Below 1 V

VG (E9-30) - E2G (E9-29) R - L-WMass Air Flow (MAF)

meter signalIdling, Shift lever position P or N,

A/C switch OFF0.5 to 3.0 V

ACIS (E9-33) - E1 (E11-1) R-Y - BRVSV for ACIS (Acoustic

Control Induction System)

operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIdlingPulse generation

(see waveform 7)

HA2A (E10-1) - E05 (E10-6) Y - W-BA/F sensor heater

operation signalIdling Below 3.0 V Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

Page 836 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

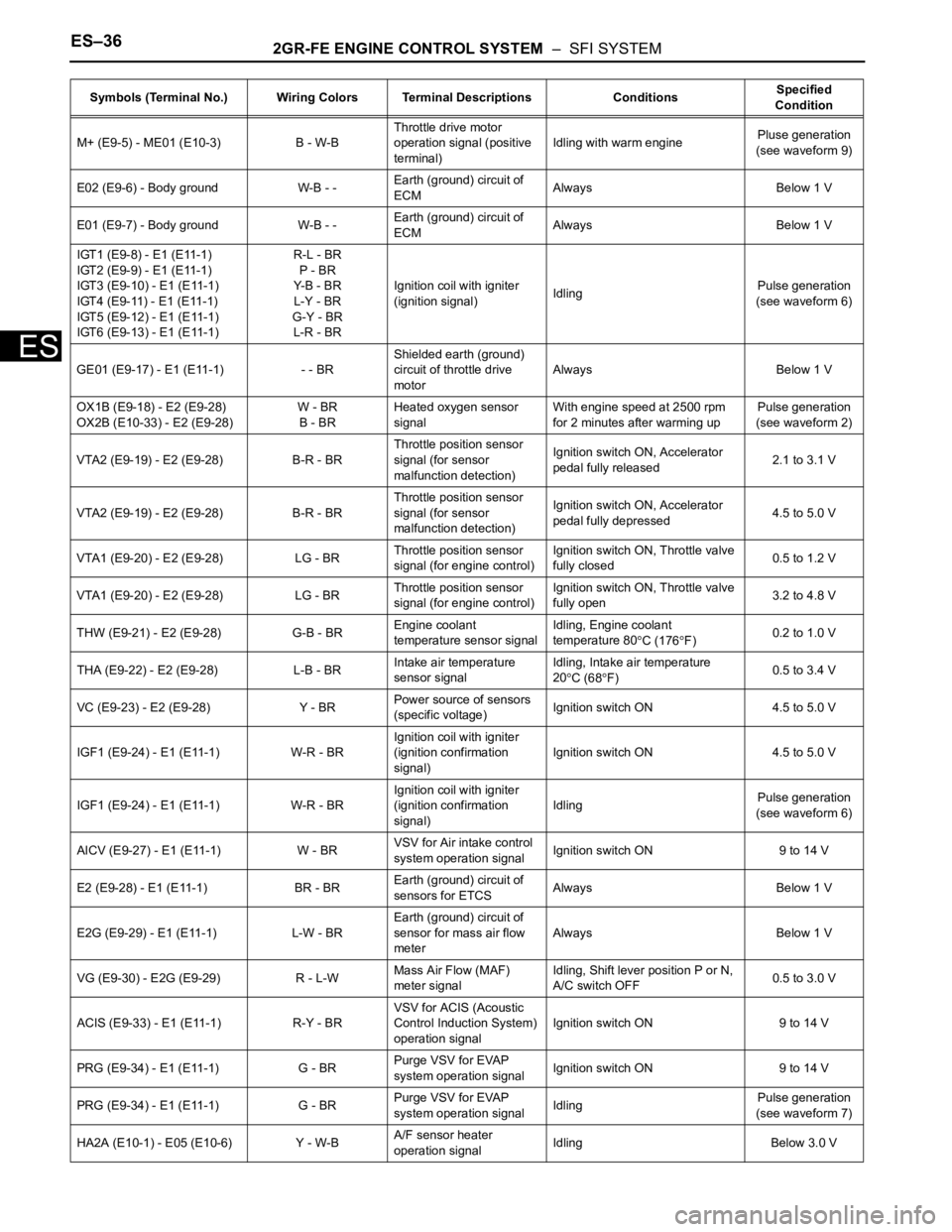

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 837 of 3000

![TOYOTA SIENNA 2007 Service Service Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th TOYOTA SIENNA 2007 Service Service Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th](/img/14/57466/w960_57466-836.png)

ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove the gasket from the intake air surge tank [I].

9. REMOVE FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-30)

10. REMOVE INTAKE MANIFOLD (See page EM-39)

11. REMOVE KNOCK CONTROL SENSOR

(a) Disconnect the 2 knock sensor connectors.

(b) Remove the 2 bolts and then remove the 2 knock

control sensors.

INSPECTION

1. KNOCK CONTROL SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Resistance:

120 to 280 k

at 20C (68F)

If the resistance is not specified, replace the knock

control sensor.

INSTALLATION

1. INSTALL KNOCK CONTROL SENSOR

(a) Install the 2 knock control sensors with the 2 bolts

as shown in the illustration.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the 2 knock control sensor connectors.

2. INSTALL INTAKE MANIFOLD (See page EM-49)

3. INSTALL FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-56)

4. INSTALL INTAKE AIR SURGE TANK

NOTICE:

DO NOT apply oil to the bolts listed below.

A129468E08

A129615

A065174

A132951E01

Tightening PartsTo r q u e

N*m (kgf*cm, ft.*lbf)QTY

Surge Tank and Intake Manifold 18 (184, 13) 4

No. 1 Surge Tank Stay and Surge Tank 21 (214, 15) 1

Throttle Body Bracket and Surge Tank 21 (214, 15) 1

Page 838 of 3000

![TOYOTA SIENNA 2007 Service Service Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m ( TOYOTA SIENNA 2007 Service Service Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (](/img/14/57466/w960_57466-837.png)

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank with the 2 nuts and 2

bolts [C].

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor

body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle

with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-496)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A129468E09

A129467

A138457E05

A129464E08