TOYOTA SIENNA 2007 Service Manual PDF

SIENNA 2007

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57466/w960_57466-0.png

TOYOTA SIENNA 2007 Service Manual PDF

Page 107 of 3000

TRANSFER – TRANSFER ASSEMBLYTF–9

TF

INSTALLATION

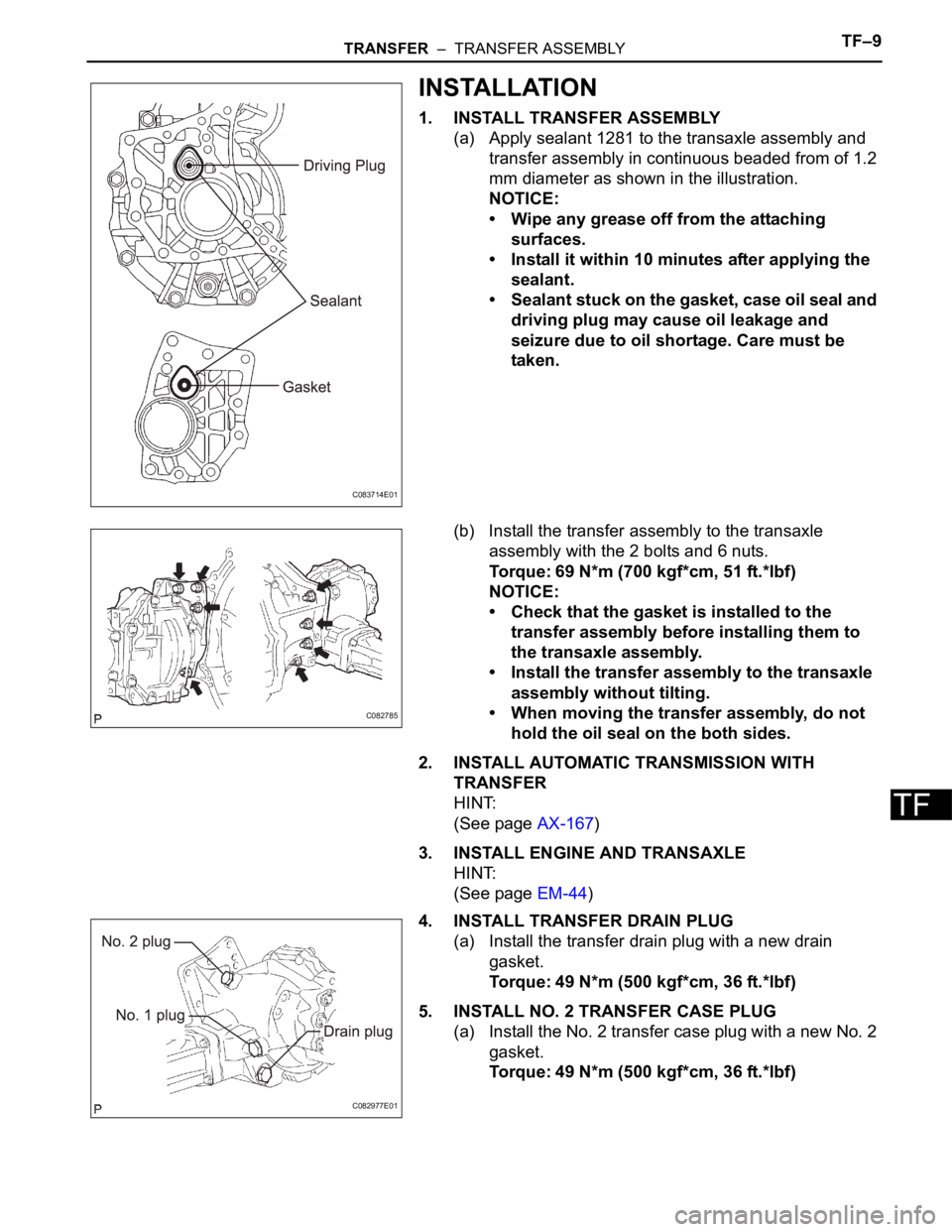

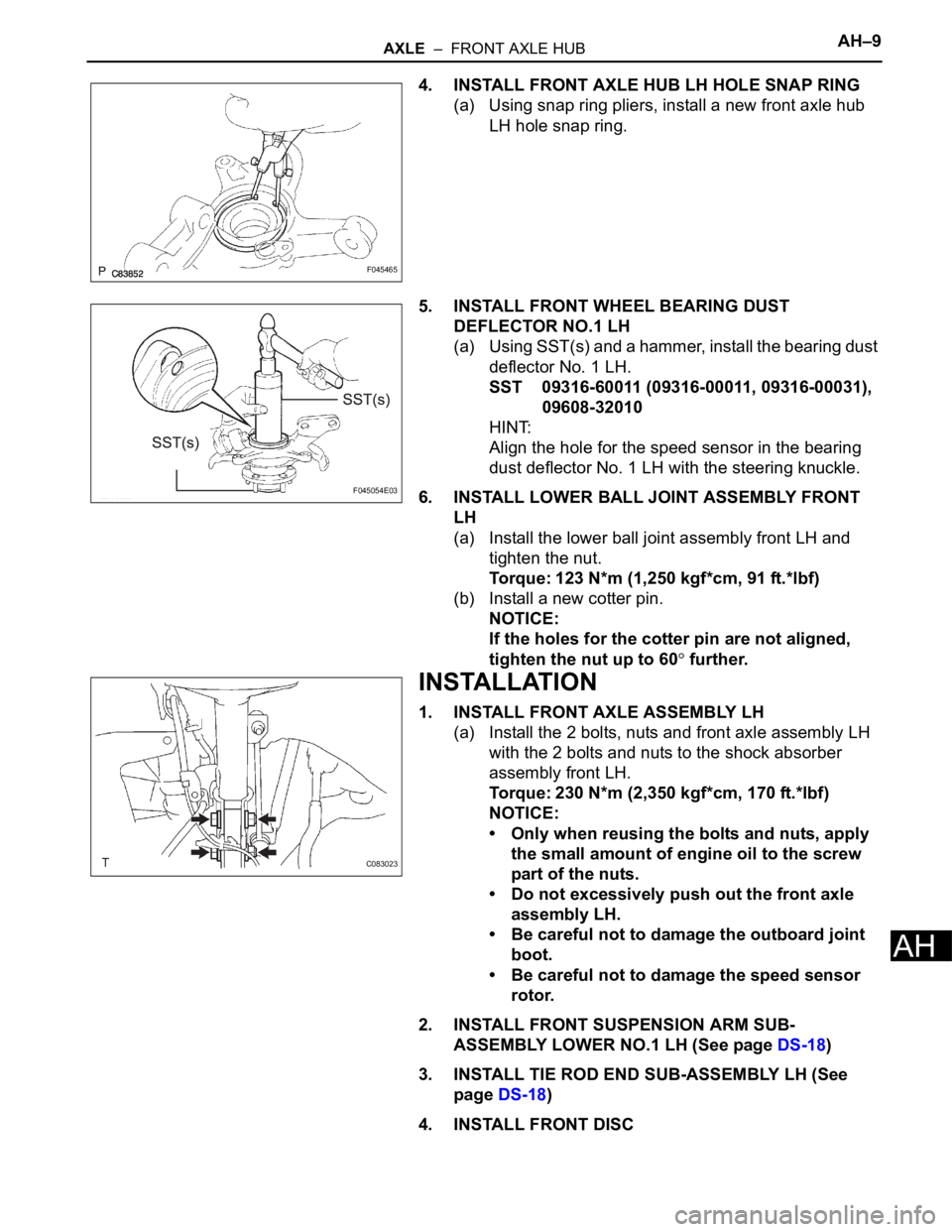

1. INSTALL TRANSFER ASSEMBLY

(a) Apply sealant 1281 to the transaxle assembly and

transfer assembly in continuous beaded from of 1.2

mm diameter as shown in the illustration.

NOTICE:

• Wipe any grease off from the attaching

surfaces.

• Install it within 10 minutes after applying the

sealant.

• Sealant stuck on the gasket, case oil seal and

driving plug may cause oil leakage and

seizure due to oil shortage. Care must be

taken.

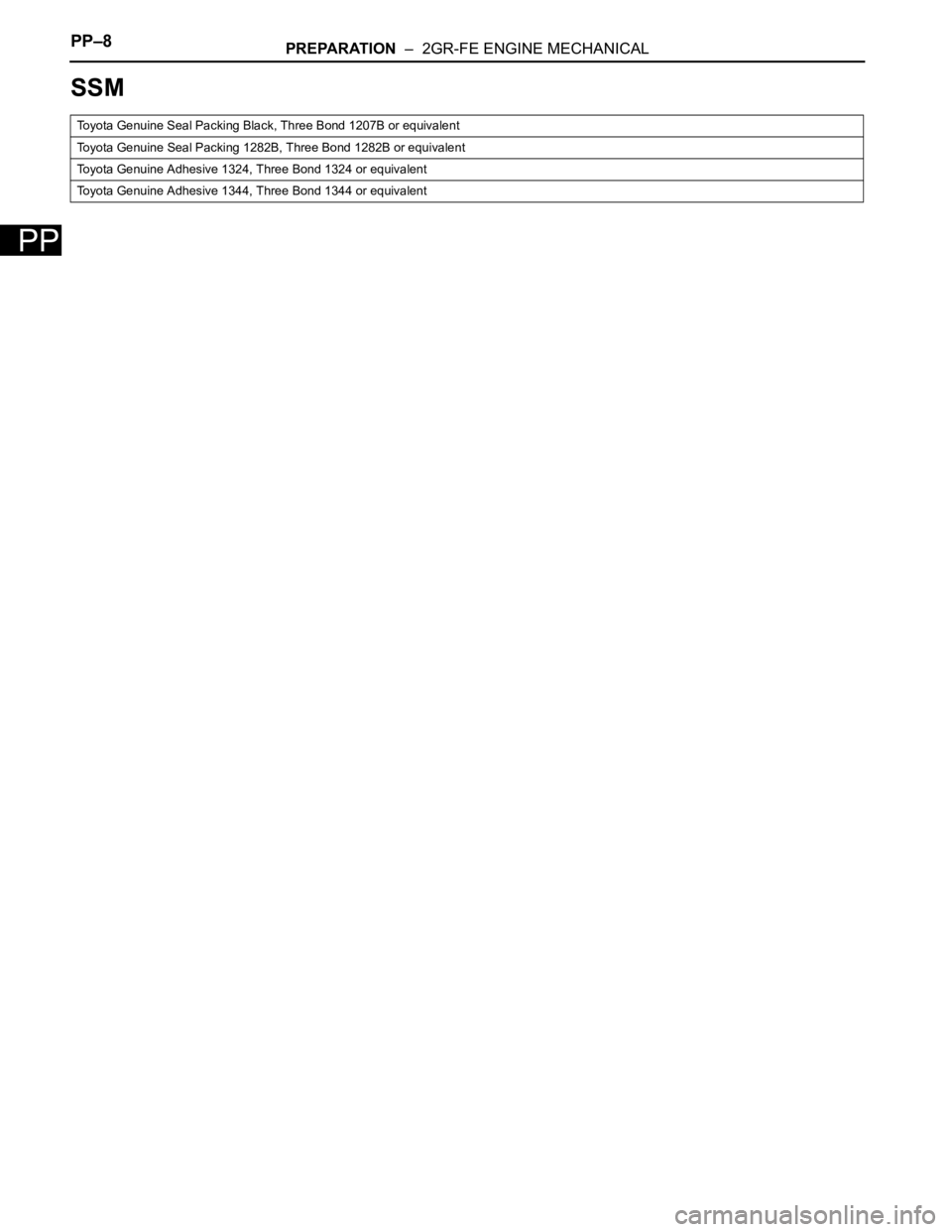

(b) Install the transfer assembly to the transaxle

assembly with the 2 bolts and 6 nuts.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

NOTICE:

• Check that the gasket is installed to the

transfer assembly before installing them to

the transaxle assembly.

• Install the transfer assembly to the transaxle

assembly without tilting.

• When moving the transfer assembly, do not

hold the oil seal on the both sides.

2. INSTALL AUTOMATIC TRANSMISSION WITH

TRANSFER

HINT:

(See page AX-167)

3. INSTALL ENGINE AND TRANSAXLE

HINT:

(See page EM-44)

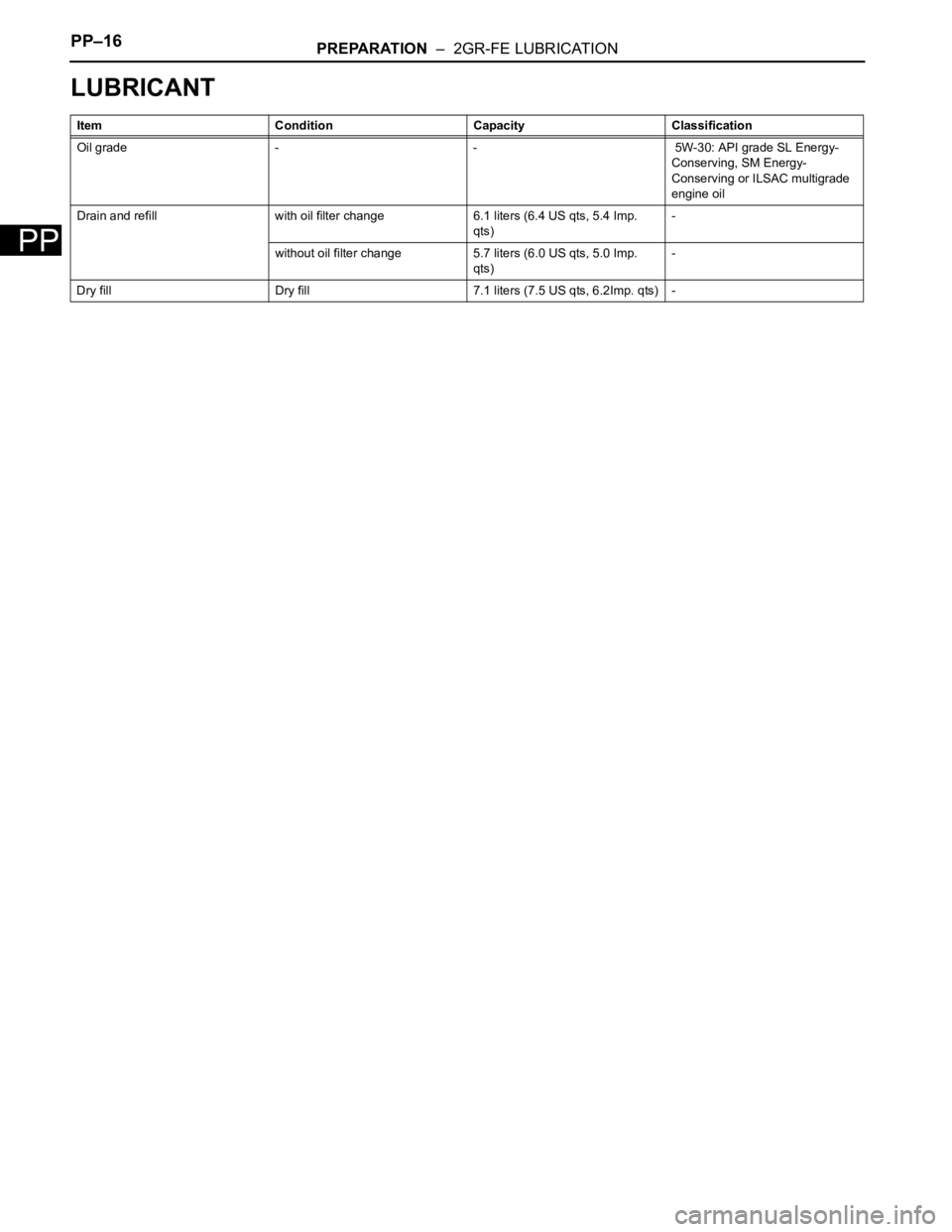

4. INSTALL TRANSFER DRAIN PLUG

(a) Install the transfer drain plug with a new drain

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

5. INSTALL NO. 2 TRANSFER CASE PLUG

(a) Install the No. 2 transfer case plug with a new No. 2

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

C083714E01

C082785

C082977E01

Page 109 of 3000

PP–8PREPARATION – 2GR-FE ENGINE MECHANICAL

PP

SSM

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Page 130 of 3000

PP–16PREPARATION – 2GR-FE LUBRICATION

PP

LUBRICANT

Item Condition Capacity Classification

Oil grade - - 5W-30: API grade SL Energy-

Conserving, SM Energy-

Conserving or ILSAC multigrade

engine oil

Drain and refill with oil filter change 6.1 liters (6.4 US qts, 5.4 Imp.

qts)-

without oil filter change 5.7 liters (6.0 US qts, 5.0 Imp.

qts)-

Dry fill Dry fill 7.1 liters (7.5 US qts, 6.2Imp. qts) -

Page 132 of 3000

PREPARATION – U151E AUTOMATIC TRANSAXLEPP–25

PP

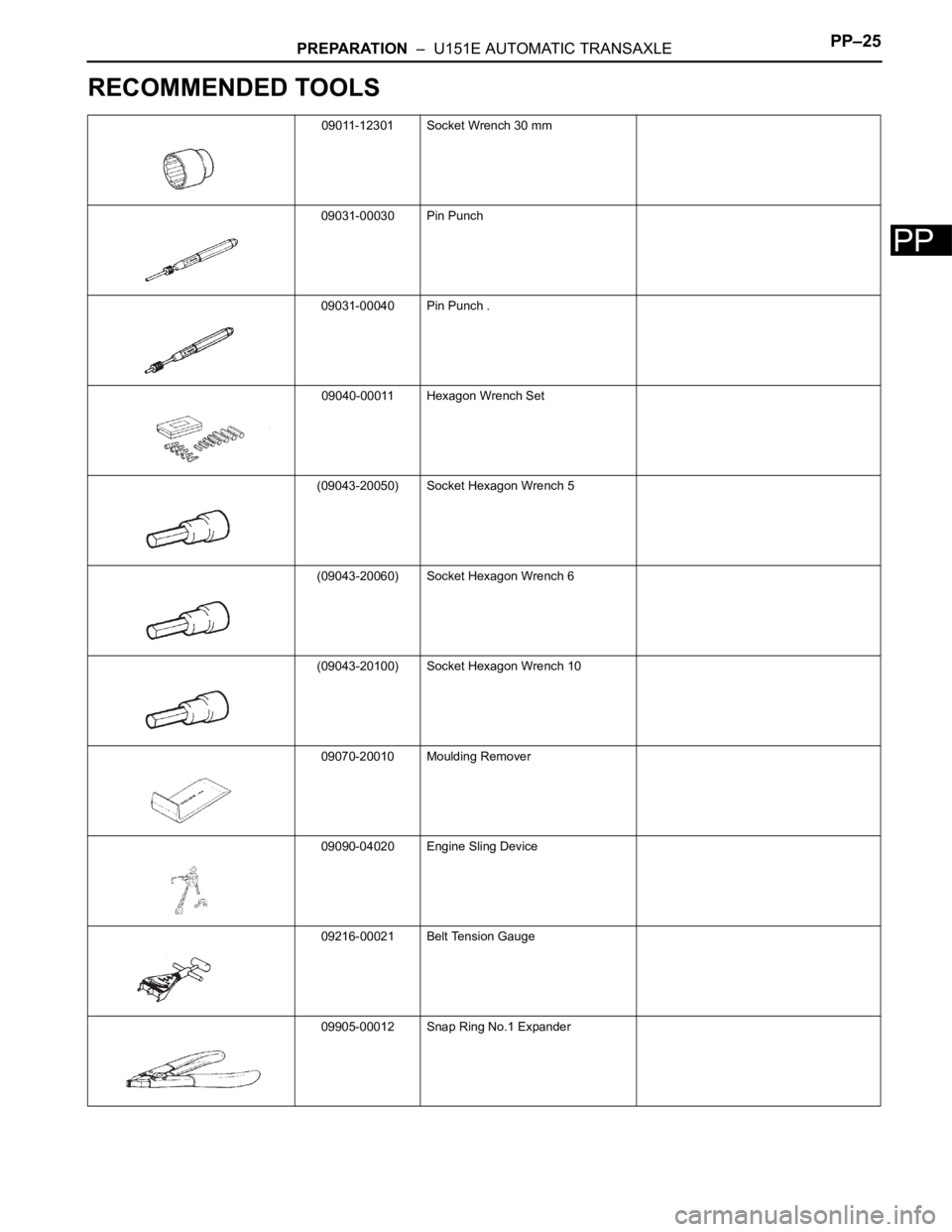

RECOMMENDED TOOLS

09011-12301 Socket Wrench 30 mm

09031-00030 Pin Punch

09031-00040 Pin Punch .

09040-00011 Hexagon Wrench Set

(09043-20050) Socket Hexagon Wrench 5

(09043-20060) Socket Hexagon Wrench 6

(09043-20100) Socket Hexagon Wrench 10

09070-20010 Moulding Remover

09090-04020 Engine Sling Device

09216-00021 Belt Tension Gauge

09905-00012 Snap Ring No.1 Expander

Page 137 of 3000

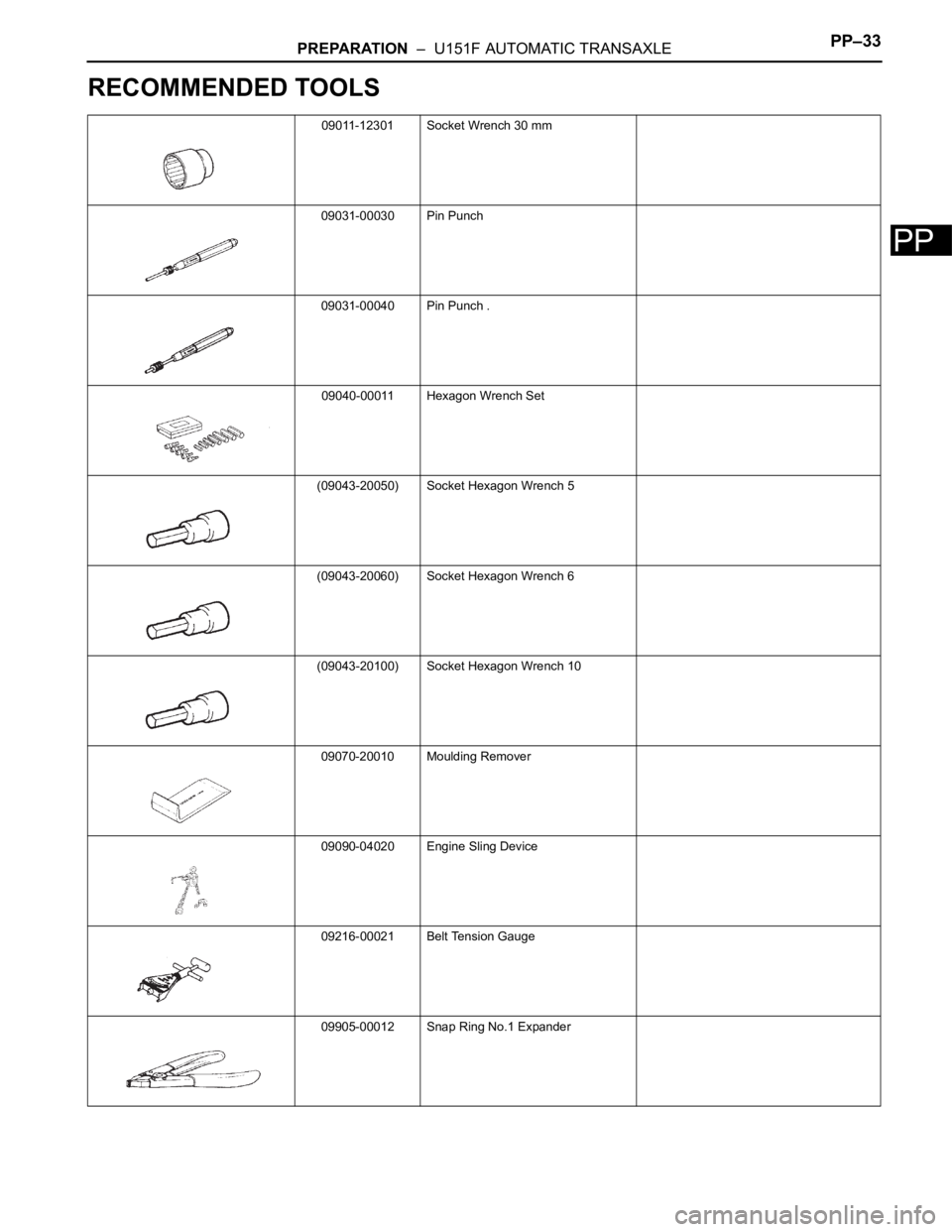

PREPARATION – U151F AUTOMATIC TRANSAXLEPP–33

PP

RECOMMENDED TOOLS

09011-12301 Socket Wrench 30 mm

09031-00030 Pin Punch

09031-00040 Pin Punch .

09040-00011 Hexagon Wrench Set

(09043-20050) Socket Hexagon Wrench 5

(09043-20060) Socket Hexagon Wrench 6

(09043-20100) Socket Hexagon Wrench 10

09070-20010 Moulding Remover

09090-04020 Engine Sling Device

09216-00021 Belt Tension Gauge

09905-00012 Snap Ring No.1 Expander

Page 143 of 3000

PP–38PREPARATION – TRANSFER

PP

EQUIPMENT

To r q u e w r e n c h

Dial gauge with magnetic base

V-block

Universal engine lifter

Page 159 of 3000

PP–86PREPARATION – ENGINE HOOD / DOOR

PP

EQUIPMENT

Clip remover

Plastic-faced hammer

Tape To avoid surface damage

Tire

To r q u e w r e n c h

Page 160 of 3000

PREPARATION – ENGINE HOOD / DOORPP–87

PP

SSM

08833-00070 Adhesive 1324,

THREE BOND 1324 or equivalent

Page 166 of 3000

AXLE – FRONT AXLE HUBAH–9

AH

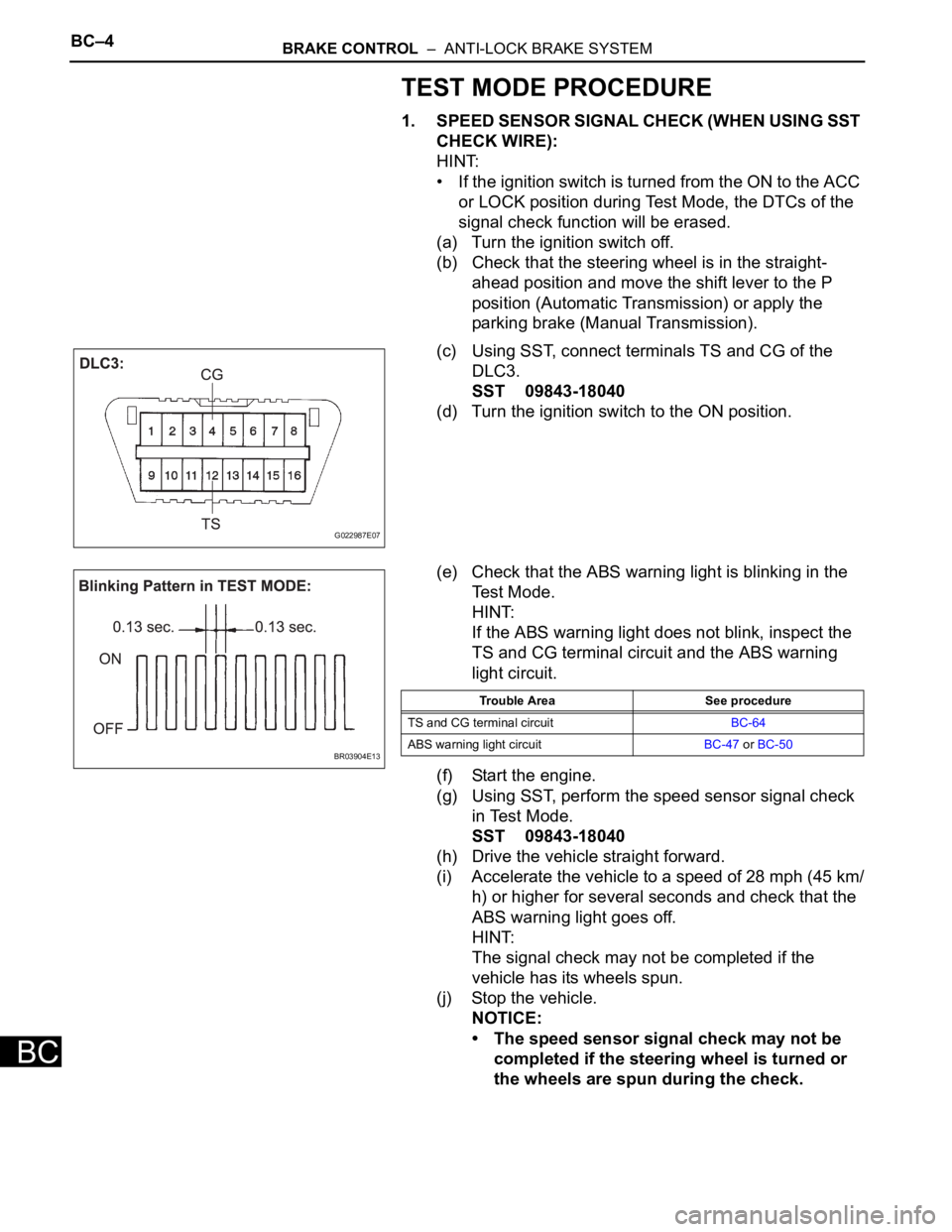

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub

LH hole snap ring.

5. INSTALL FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust

deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031),

09608-32010

HINT:

Align the hole for the speed sensor in the bearing

dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut up to 60

further.

INSTALLATION

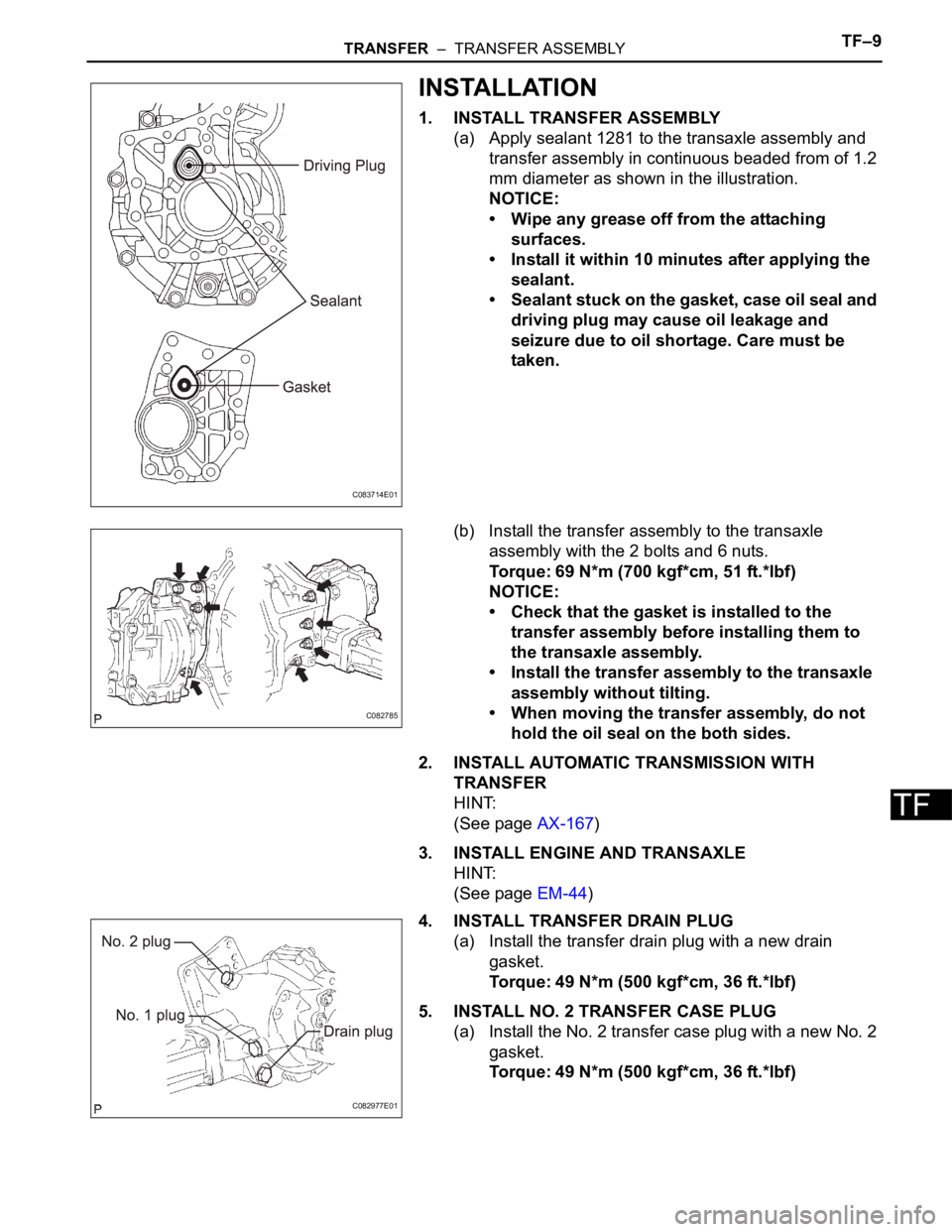

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

• Only when reusing the bolts and nuts, apply

the small amount of engine oil to the screw

part of the nuts.

• Do not excessively push out the front axle

assembly LH.

• Be careful not to damage the outboard joint

boot.

• Be careful not to damage the speed sensor

rotor.

2. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-18)

3. INSTALL TIE ROD END SUB-ASSEMBLY LH (See

page DS-18)

4. INSTALL FRONT DISC

F045465

F045054E03

C083023

Page 180 of 3000

BC–4BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

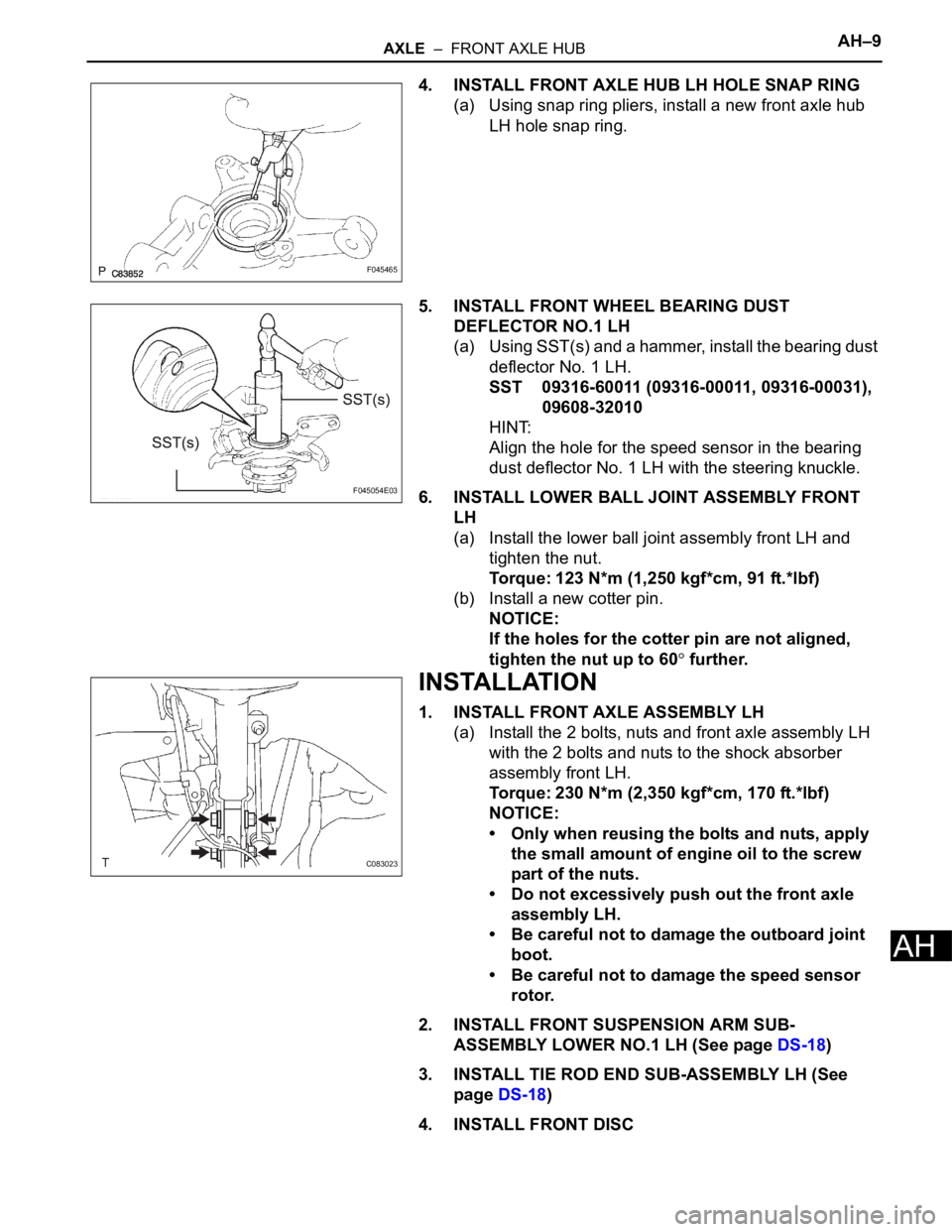

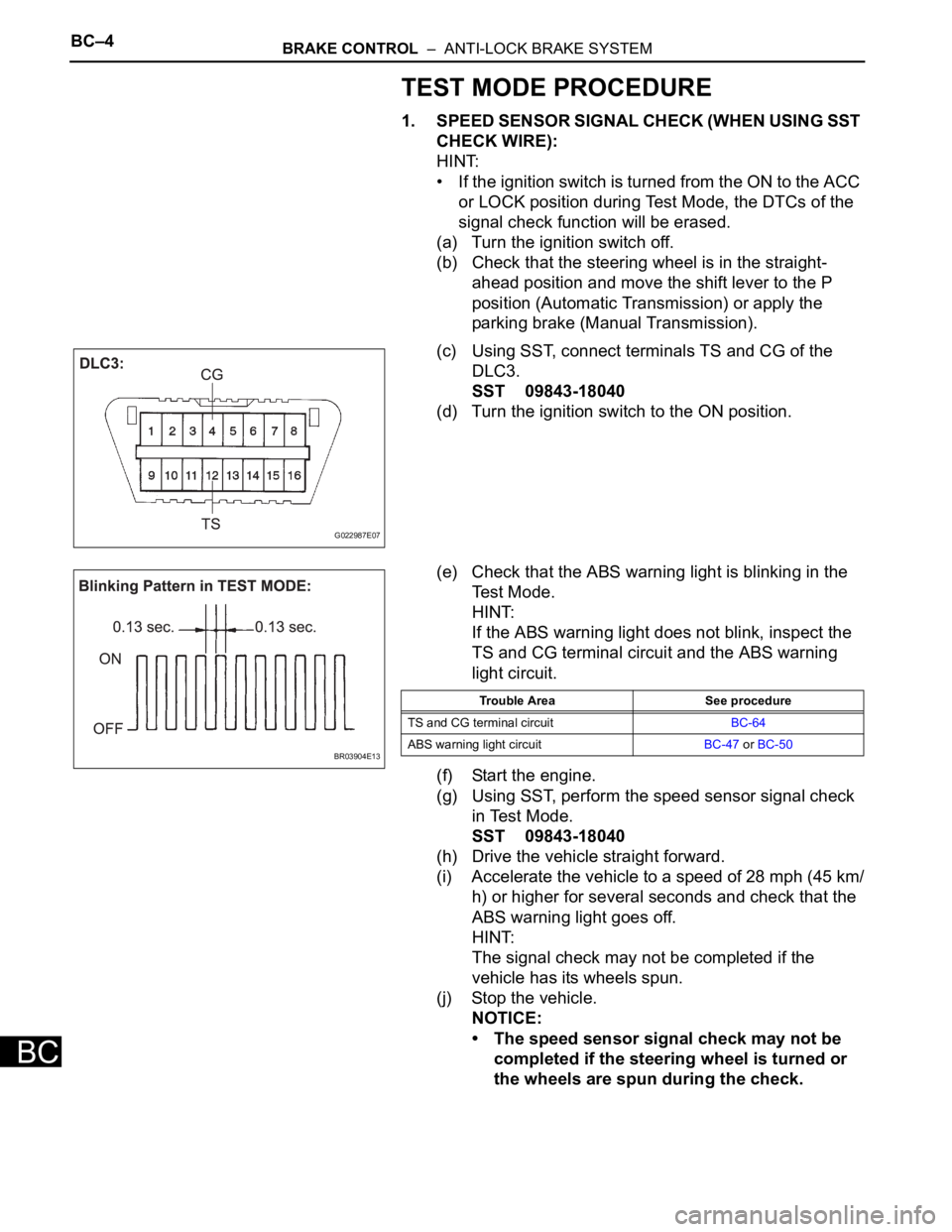

TEST MODE PROCEDURE

1. SPEED SENSOR SIGNAL CHECK (WHEN USING SST

CHECK WIRE):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, the DTCs of the

signal check function will be erased.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position and move the shift lever to the P

position (Automatic Transmission) or apply the

parking brake (Manual Transmission).

(c) Using SST, connect terminals TS and CG of the

DLC3.

SST 09843-18040

(d) Turn the ignition switch to the ON position.

(e) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(f) Start the engine.

(g) Using SST, perform the speed sensor signal check

in Test Mode.

SST 09843-18040

(h) Drive the vehicle straight forward.

(i) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(j) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

G022987E07

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50