radiator TOYOTA SIENNA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1291 of 3000

CO–462GR-FE COOLING – RADIATOR

CO

24. INSTALL BATTERY (See page EM-59)

25. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

26. ADD ENGINE COOLANT (See page CO-7)

27. INSPECT FOR COOLANT LEAK (See page CO-1)

28. ADD AUTOMATIC TRANSAXLE FLUID

29. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

30. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-84)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1351 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)

Page 1352 of 3000

2GR-FE CHARGING – GENERATORCH–17

CH

24. REMOVE RADIATOR SUPPORT CUSHION (See page

CO-32)

25. REMOVE NO. 1 RADIATOR SUPPORT (See page CO-

32)

26. REMOVE RADIATOR ASSEMBLY WITH FAN

SHROUD AND FAN MOTOR (See page CO-33)

27. REMOVE V-RIBBED BELT (See page EM-6)

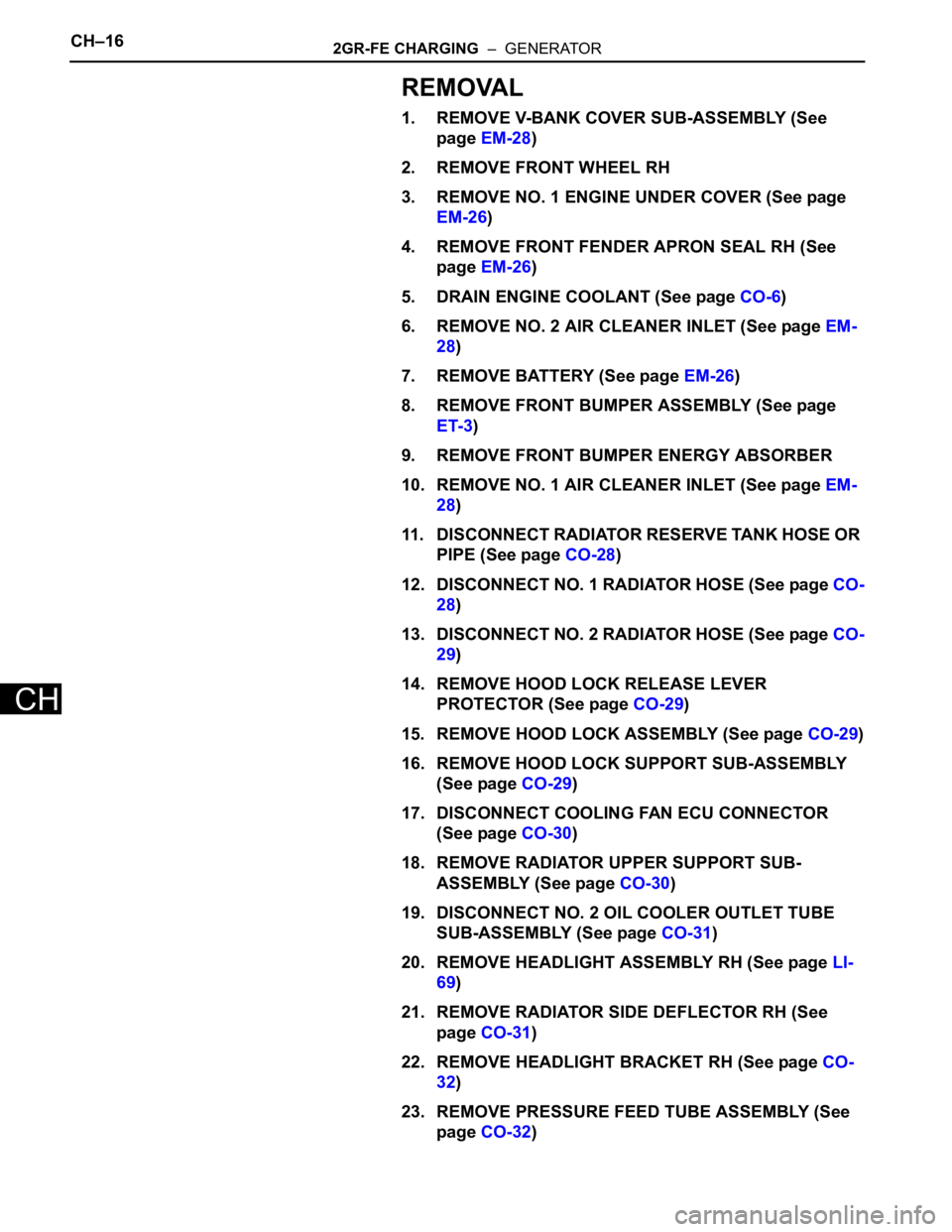

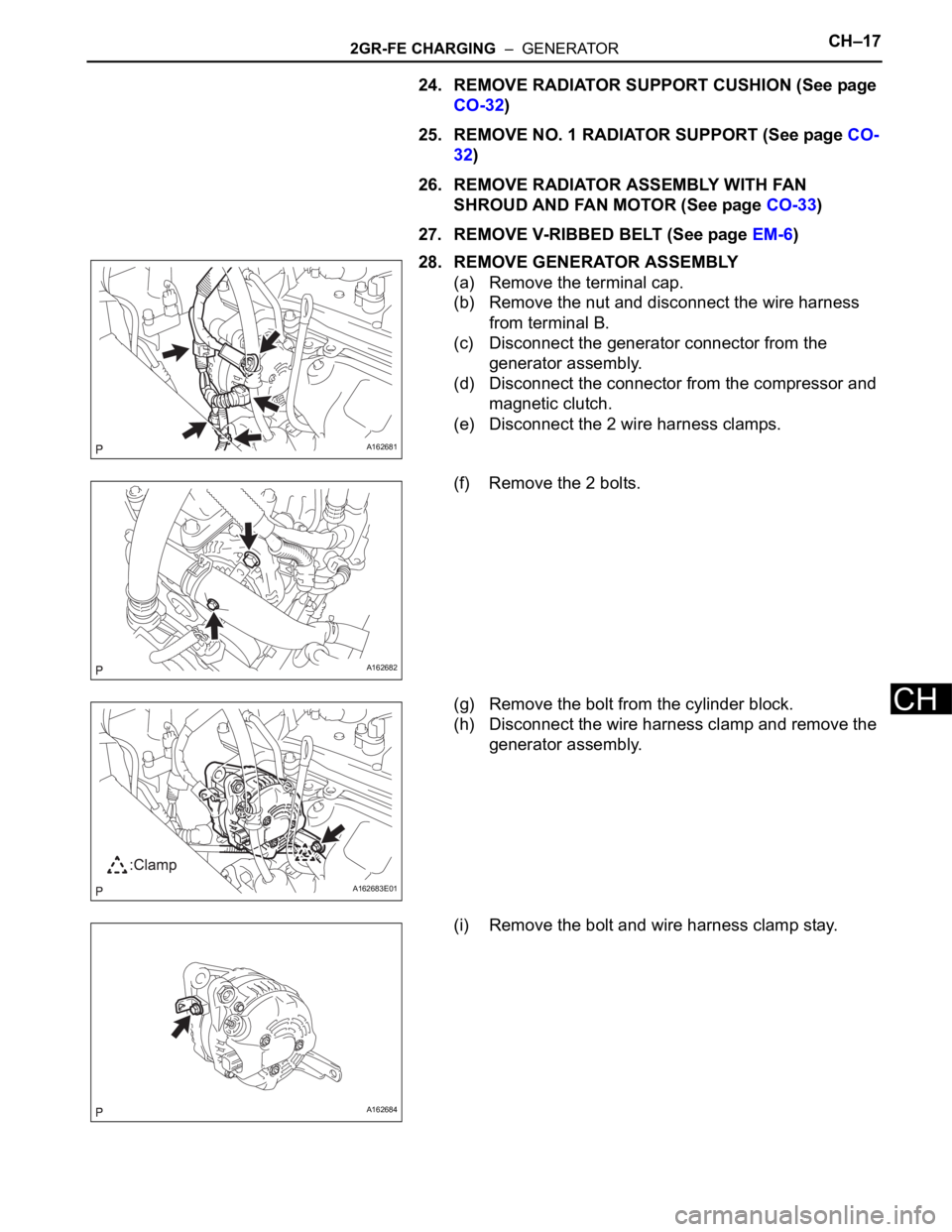

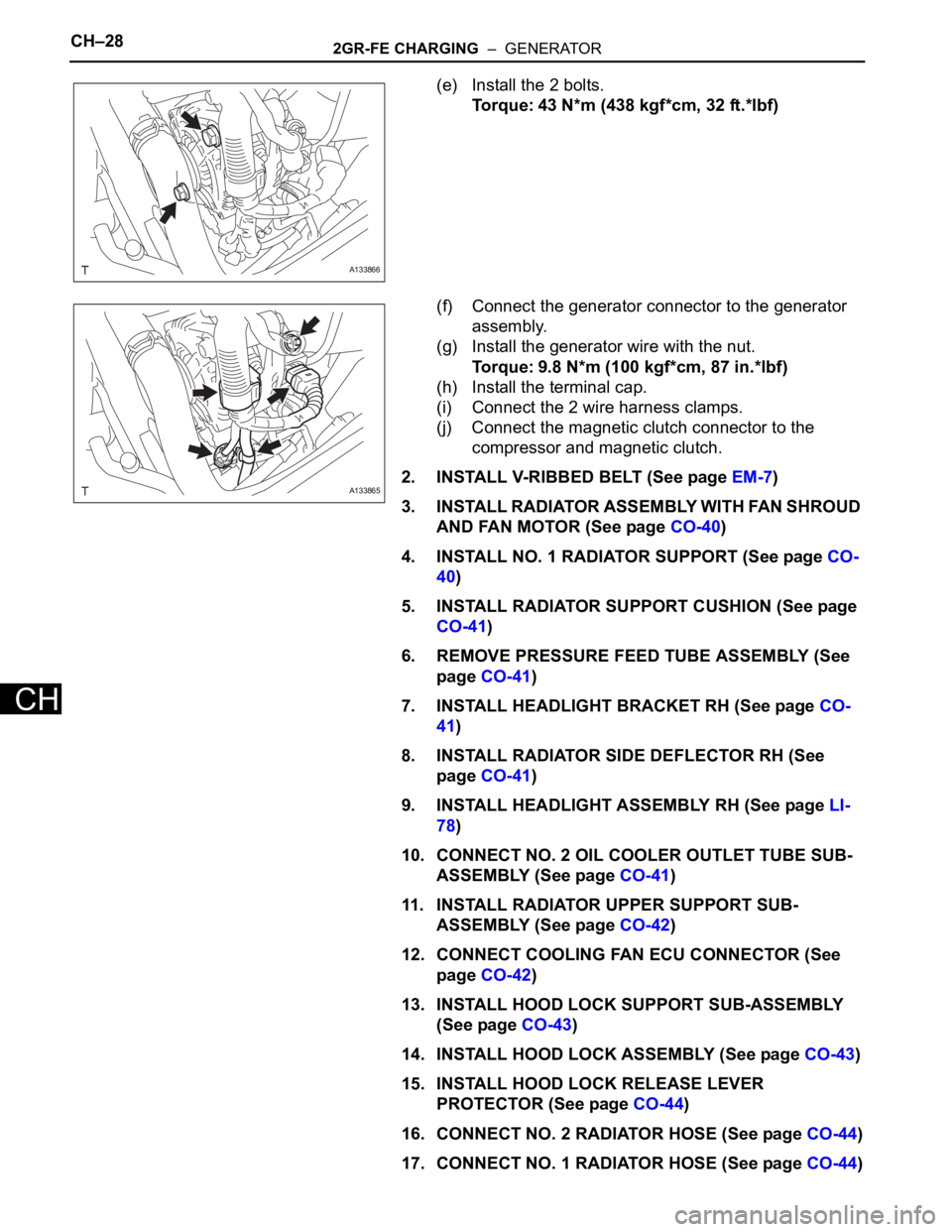

28. REMOVE GENERATOR ASSEMBLY

(a) Remove the terminal cap.

(b) Remove the nut and disconnect the wire harness

from terminal B.

(c) Disconnect the generator connector from the

generator assembly.

(d) Disconnect the connector from the compressor and

magnetic clutch.

(e) Disconnect the 2 wire harness clamps.

(f) Remove the 2 bolts.

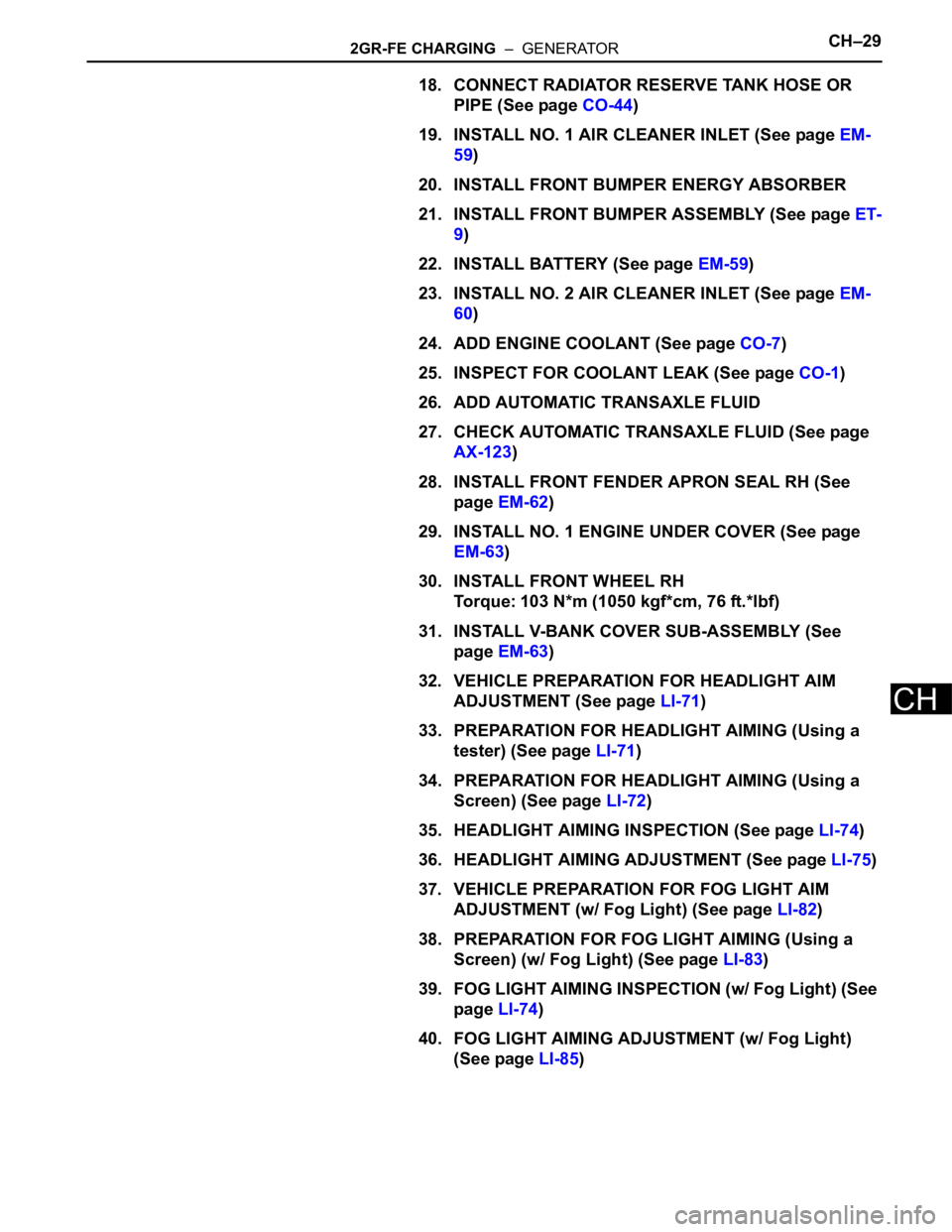

(g) Remove the bolt from the cylinder block.

(h) Disconnect the wire harness clamp and remove the

generator assembly.

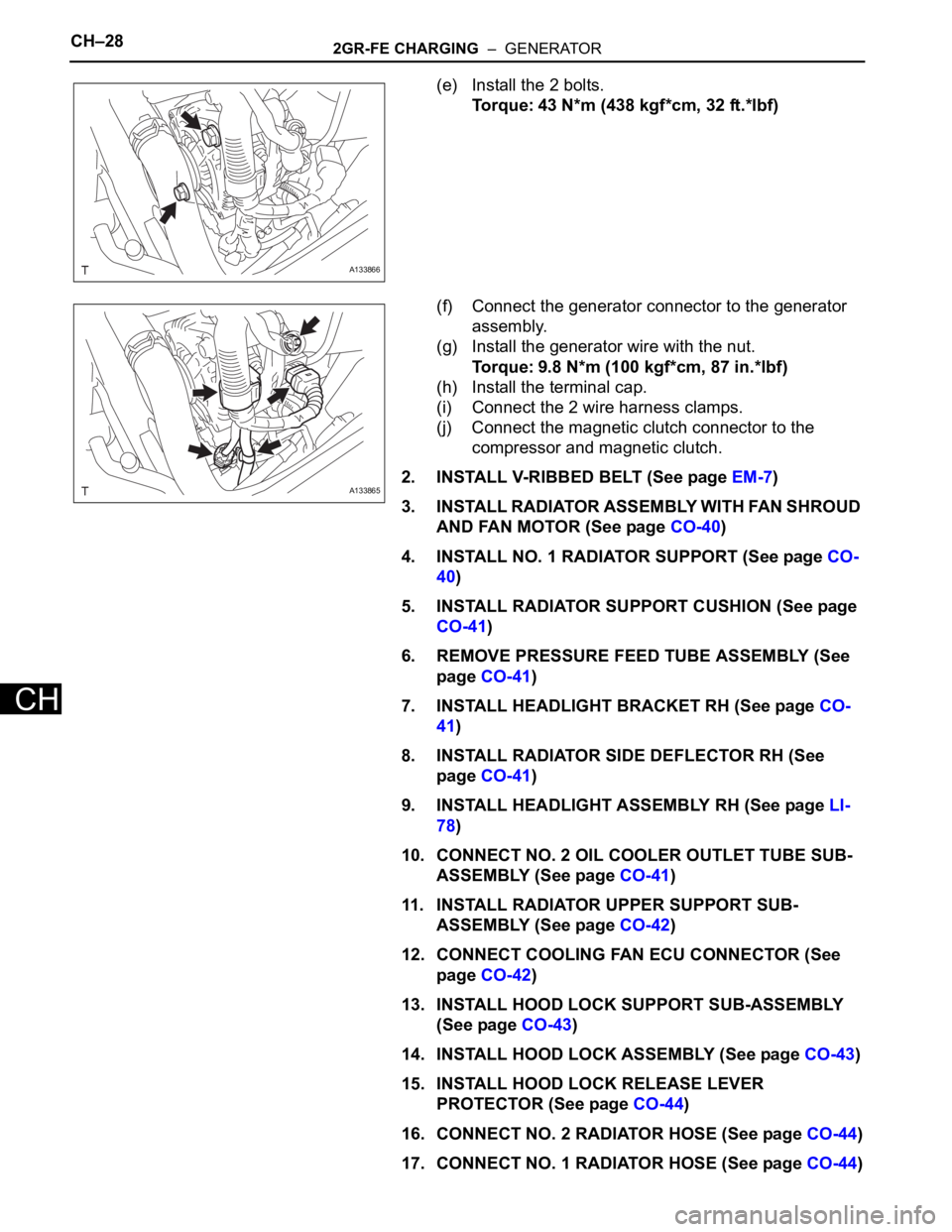

(i) Remove the bolt and wire harness clamp stay.

A162681

A162682

A162683E01

A162684

Page 1356 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)

Page 1357 of 3000

2GR-FE CHARGING – GENERATORCH–17

CH

24. REMOVE RADIATOR SUPPORT CUSHION (See page

CO-32)

25. REMOVE NO. 1 RADIATOR SUPPORT (See page CO-

32)

26. REMOVE RADIATOR ASSEMBLY WITH FAN

SHROUD AND FAN MOTOR (See page CO-33)

27. REMOVE V-RIBBED BELT (See page EM-6)

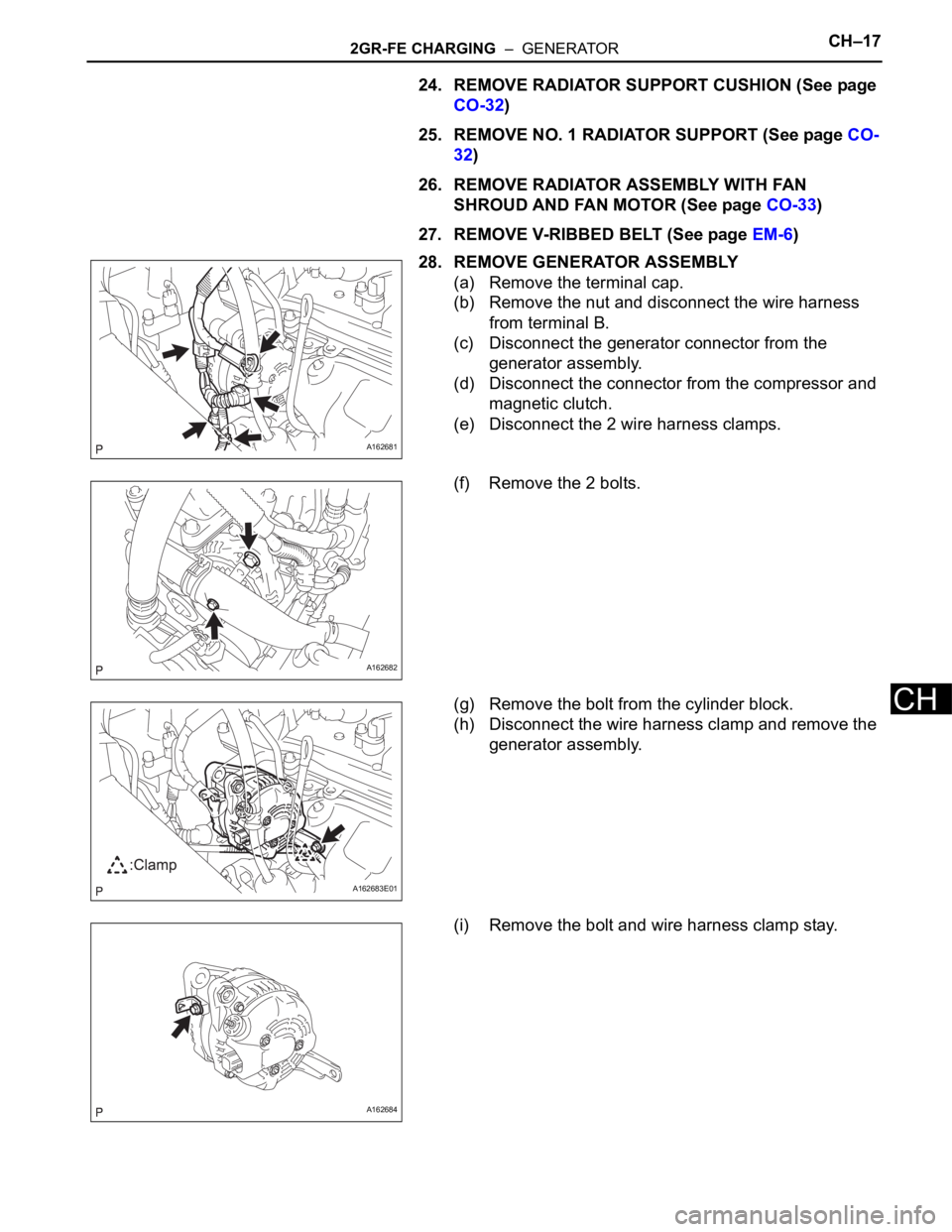

28. REMOVE GENERATOR ASSEMBLY

(a) Remove the terminal cap.

(b) Remove the nut and disconnect the wire harness

from terminal B.

(c) Disconnect the generator connector from the

generator assembly.

(d) Disconnect the connector from the compressor and

magnetic clutch.

(e) Disconnect the 2 wire harness clamps.

(f) Remove the 2 bolts.

(g) Remove the bolt from the cylinder block.

(h) Disconnect the wire harness clamp and remove the

generator assembly.

(i) Remove the bolt and wire harness clamp stay.

A162681

A162682

A162683E01

A162684

Page 1368 of 3000

CH–282GR-FE CHARGING – GENERATOR

CH

(e) Install the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Connect the generator connector to the generator

assembly.

(g) Install the generator wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

(h) Install the terminal cap.

(i) Connect the 2 wire harness clamps.

(j) Connect the magnetic clutch connector to the

compressor and magnetic clutch.

2. INSTALL V-RIBBED BELT (See page EM-7)

3. INSTALL RADIATOR ASSEMBLY WITH FAN SHROUD

AND FAN MOTOR (See page CO-40)

4. INSTALL NO. 1 RADIATOR SUPPORT (See page CO-

40)

5. INSTALL RADIATOR SUPPORT CUSHION (See page

CO-41)

6. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-41)

7. INSTALL HEADLIGHT BRACKET RH (See page CO-

41)

8. INSTALL RADIATOR SIDE DEFLECTOR RH (See

page CO-41)

9. INSTALL HEADLIGHT ASSEMBLY RH (See page LI-

78)

10. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUB-

ASSEMBLY (See page CO-41)

11. INSTALL RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-42)

12. CONNECT COOLING FAN ECU CONNECTOR (See

page CO-42)

13. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-43)

14. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

15. INSTALL HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-44)

16. CONNECT NO. 2 RADIATOR HOSE (See page CO-44)

17. CONNECT NO. 1 RADIATOR HOSE (See page CO-44)

A133866

A133865

Page 1369 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1377 of 3000

CH–282GR-FE CHARGING – GENERATOR

CH

(e) Install the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Connect the generator connector to the generator

assembly.

(g) Install the generator wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

(h) Install the terminal cap.

(i) Connect the 2 wire harness clamps.

(j) Connect the magnetic clutch connector to the

compressor and magnetic clutch.

2. INSTALL V-RIBBED BELT (See page EM-7)

3. INSTALL RADIATOR ASSEMBLY WITH FAN SHROUD

AND FAN MOTOR (See page CO-40)

4. INSTALL NO. 1 RADIATOR SUPPORT (See page CO-

40)

5. INSTALL RADIATOR SUPPORT CUSHION (See page

CO-41)

6. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-41)

7. INSTALL HEADLIGHT BRACKET RH (See page CO-

41)

8. INSTALL RADIATOR SIDE DEFLECTOR RH (See

page CO-41)

9. INSTALL HEADLIGHT ASSEMBLY RH (See page LI-

78)

10. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUB-

ASSEMBLY (See page CO-41)

11. INSTALL RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-42)

12. CONNECT COOLING FAN ECU CONNECTOR (See

page CO-42)

13. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-43)

14. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

15. INSTALL HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-44)

16. CONNECT NO. 2 RADIATOR HOSE (See page CO-44)

17. CONNECT NO. 1 RADIATOR HOSE (See page CO-44)

A133866

A133865

Page 1378 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1619 of 3000

U151E AUTOMATIC TRANSAXLE – TORQUE CONVERTER CLUTCH AND DRIVE PLATEAX–171

AX

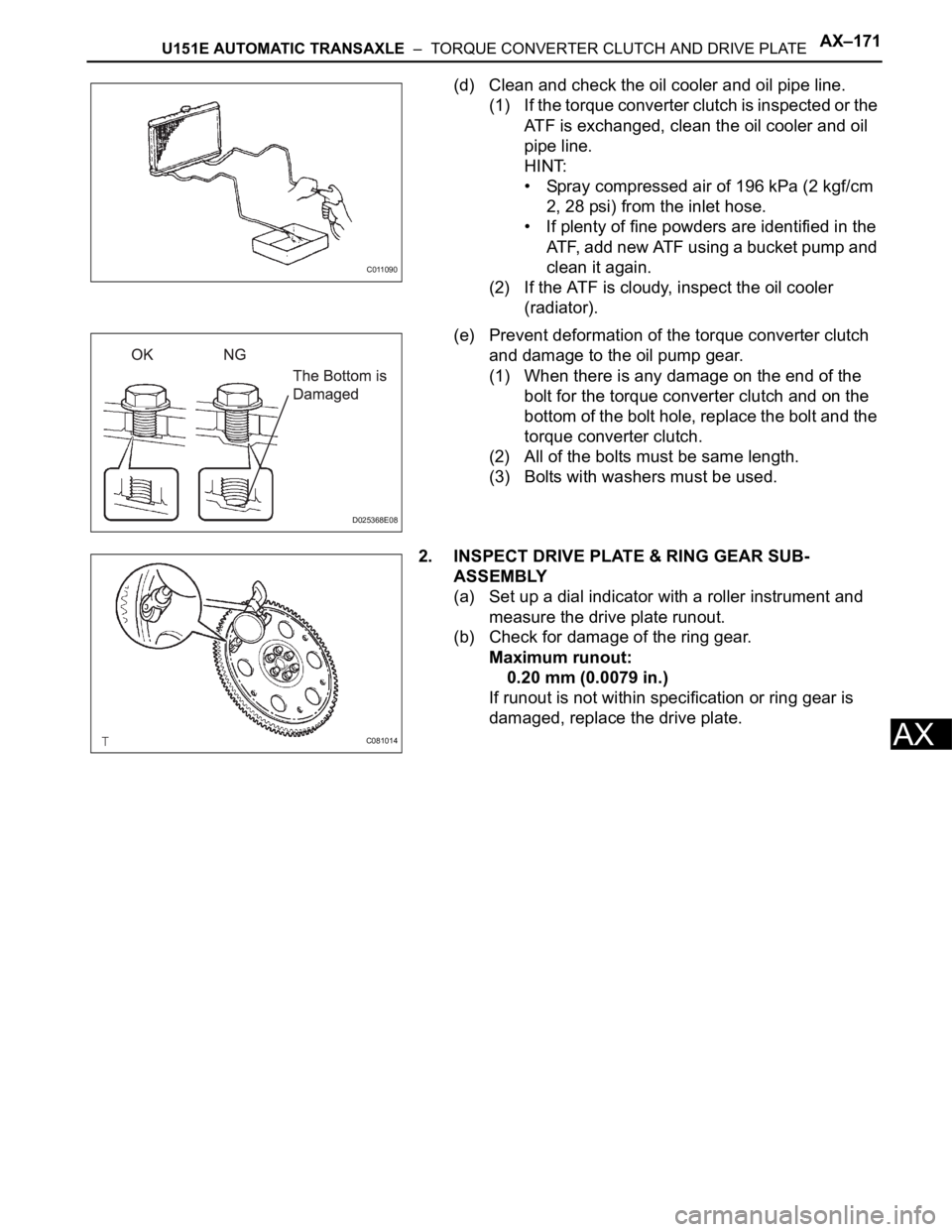

(d) Clean and check the oil cooler and oil pipe line.

(1) If the torque converter clutch is inspected or the

ATF is exchanged, clean the oil cooler and oil

pipe line.

HINT:

• Spray compressed air of 196 kPa (2 kgf/cm

2, 28 psi) from the inlet hose.

• If plenty of fine powders are identified in the

ATF, add new ATF using a bucket pump and

clean it again.

(2) If the ATF is cloudy, inspect the oil cooler

(radiator).

(e) Prevent deformation of the torque converter clutch

and damage to the oil pump gear.

(1) When there is any damage on the end of the

bolt for the torque converter clutch and on the

bottom of the bolt hole, replace the bolt and the

torque converter clutch.

(2) All of the bolts must be same length.

(3) Bolts with washers must be used.

2. INSPECT DRIVE PLATE & RING GEAR SUB-

ASSEMBLY

(a) Set up a dial indicator with a roller instrument and

measure the drive plate runout.

(b) Check for damage of the ring gear.

Maximum runout:

0.20 mm (0.0079 in.)

If runout is not within specification or ring gear is

damaged, replace the drive plate.

C011090

D025368E08

C081014