TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 691 of 3000

ES–3982GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

WIRING DIAGRAM

Refer to DTC P2195 (See page ES-359).

INSPECTION PROCEDURE

HINT:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the ACTIVE

TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated

Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using an intelligent

tester.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

(d) Select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/

F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or LEFT

button to change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS B2S1 and

O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the injection

volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

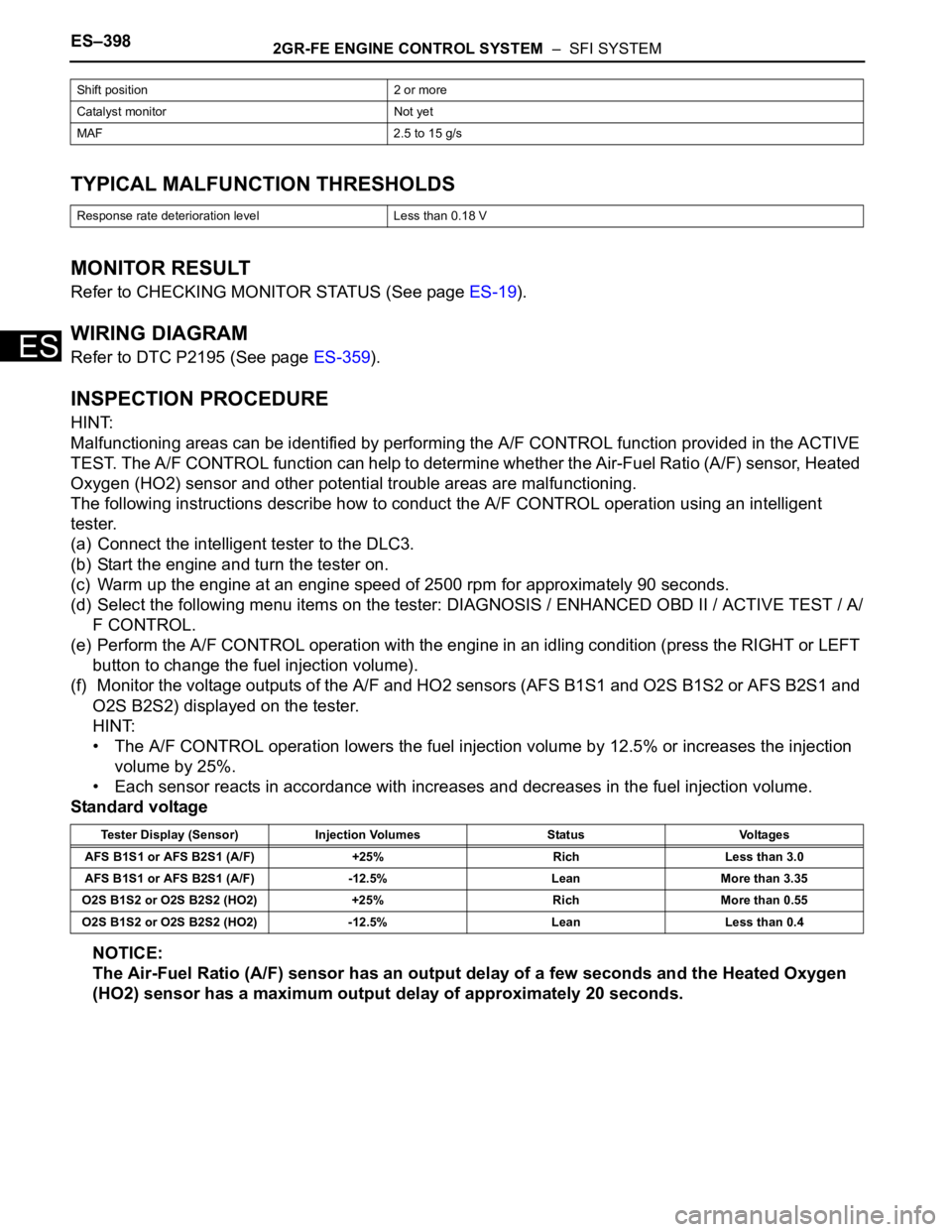

Standard voltage

NOTICE:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen

(HO2) sensor has a maximum output delay of approximately 20 seconds.

Shift position 2 or more

Catalyst monitor Not yet

MAF 2.5 to 15 g/s

Response rate deterioration level Less than 0.18 V

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

Page 692 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–399

ES

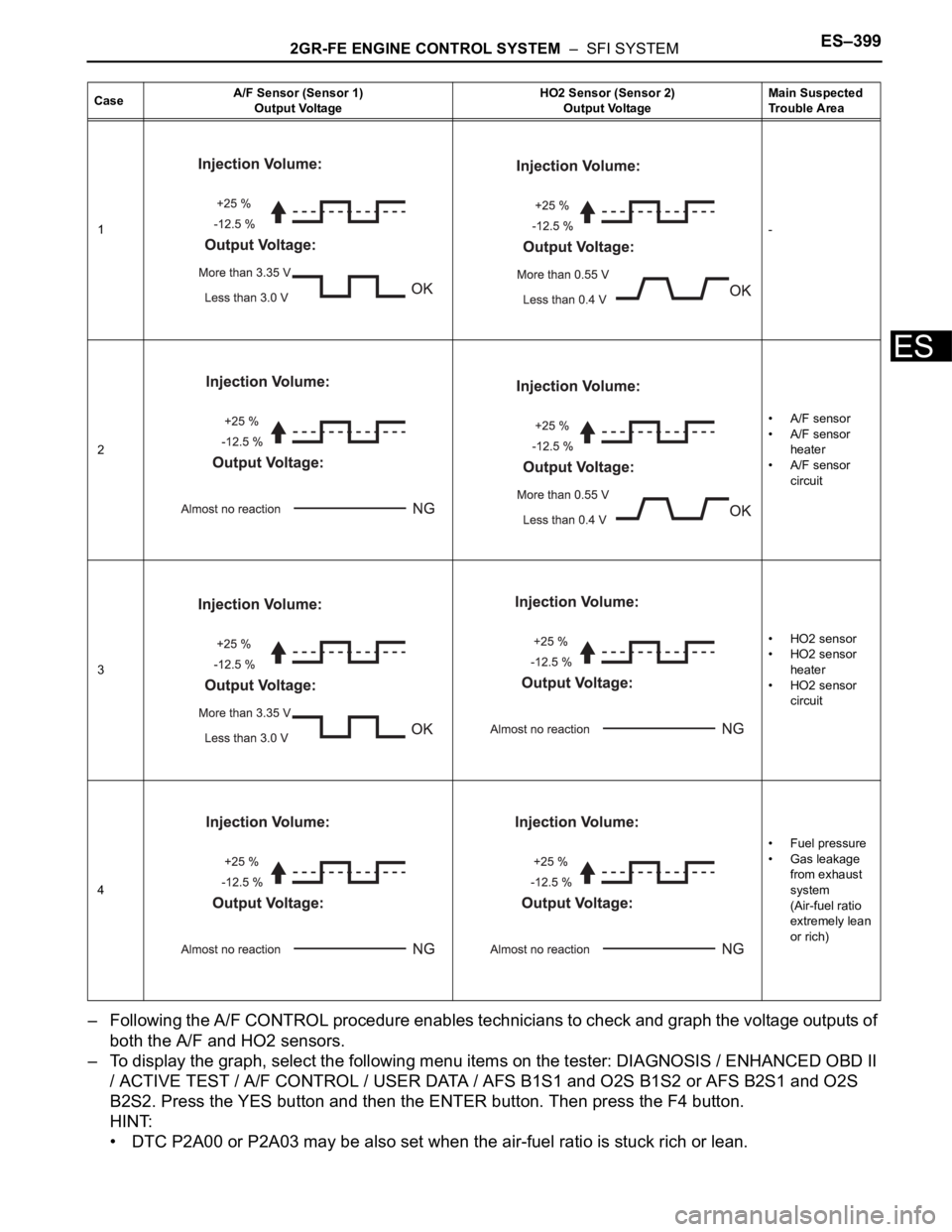

– Following the A/F CONTROL procedure enables technicians to check and graph the voltage outputs of

both the A/F and HO2 sensors.

– To display the graph, select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II

/ ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S

B2S2. Press the YES button and then the ENTER button. Then press the F4 button.

HINT:

• DTC P2A00 or P2A03 may be also set when the air-fuel ratio is stuck rich or lean.

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

2•A/F sensor

•A/F sensor

heater

•A/F sensor

circuit

3•HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4• Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

Page 693 of 3000

ES–4002GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• A low A/F sensor voltage could be caused by a rich air-fuel mixture. Check for conditions that would

cause the engine to run rich.

• A high A/F sensor voltage could be caused by a lean air-fuel mixture. Check for conditions that

would cause the engine to run lean.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at

the time of a malfunction.

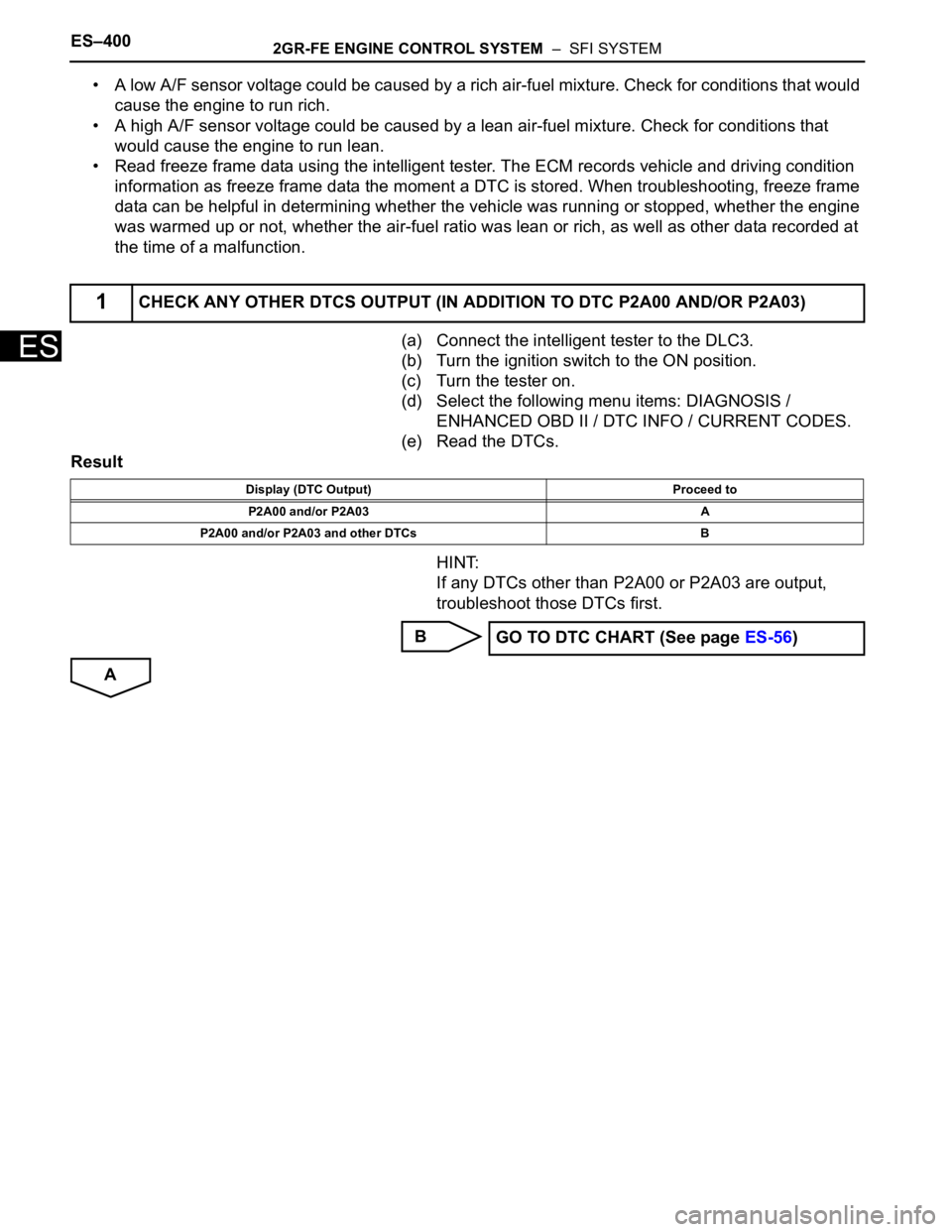

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

HINT:

If any DTCs other than P2A00 or P2A03 are output,

troubleshoot those DTCs first.

B

A

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2A00 AND/OR P2A03)

Display (DTC Output) Proceed to

P2A00 and/or P2A03 A

P2A00 and/or P2A03 and other DTCs B

GO TO DTC CHART (See page ES-56)

Page 694 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–401

ES

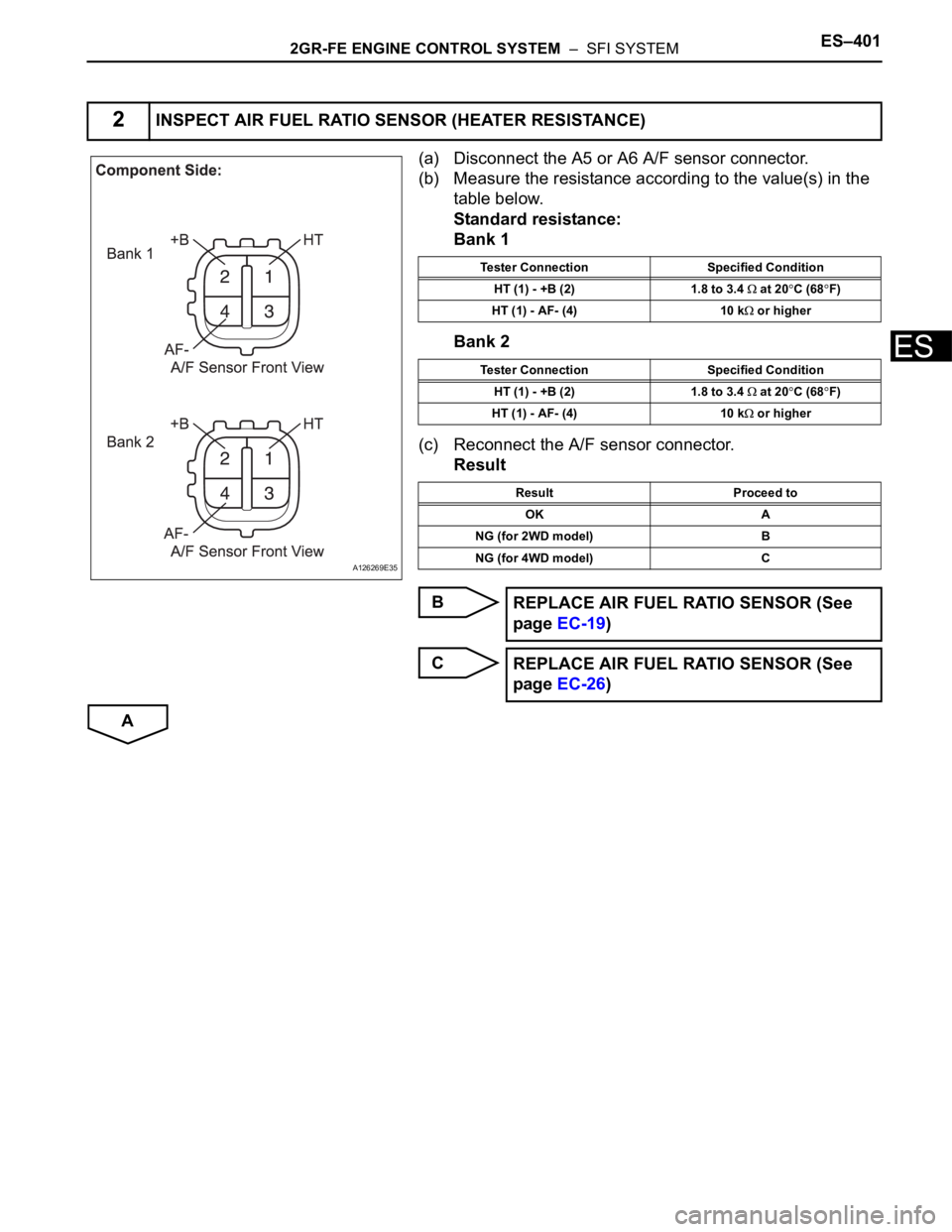

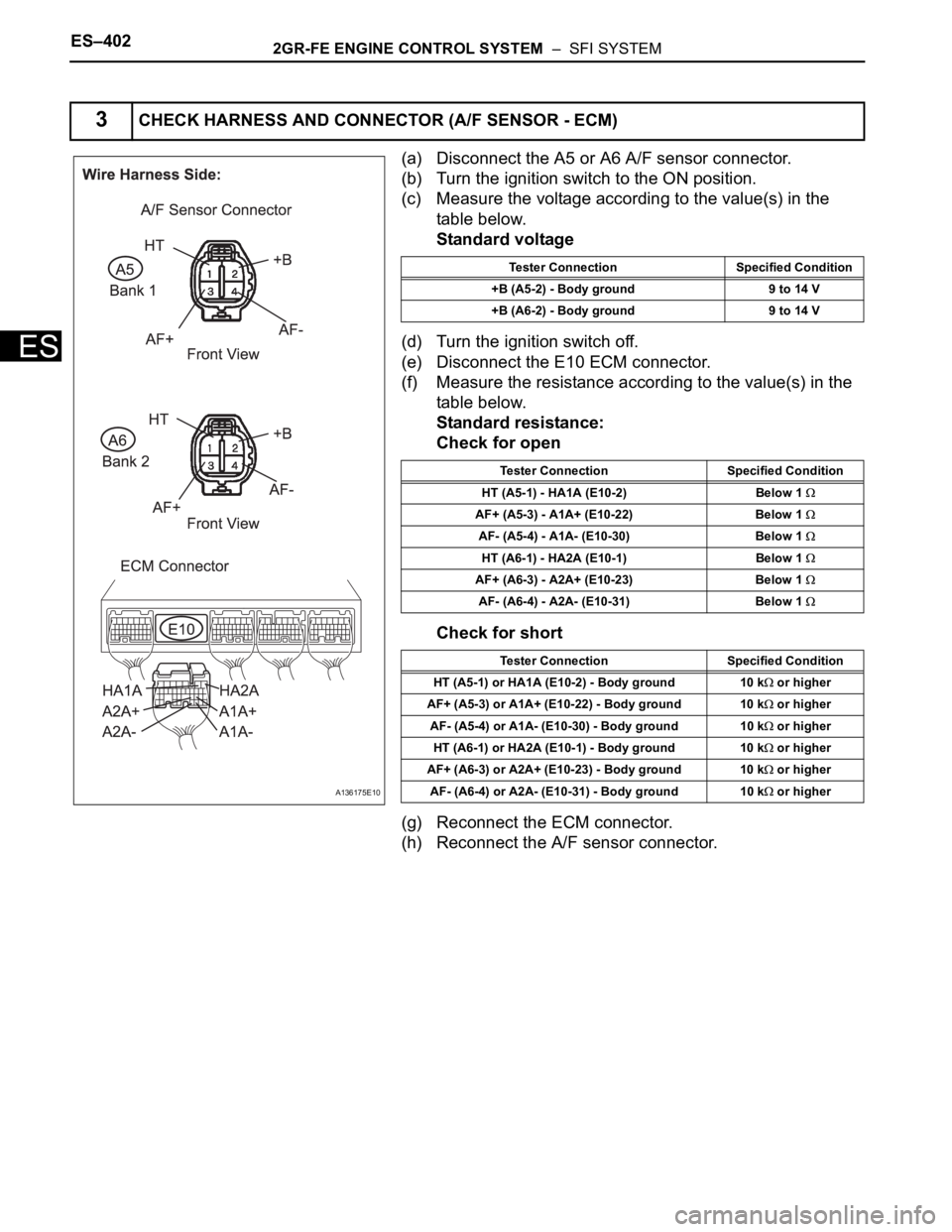

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the A/F sensor connector.

Result

B

C

A

2INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

A126269E35

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE AIR FUEL RATIO SENSOR (See

page EC-19)

REPLACE AIR FUEL RATIO SENSOR (See

page EC-26)

Page 695 of 3000

ES–4022GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Turn the ignition switch off.

(e) Disconnect the E10 ECM connector.

(f) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(g) Reconnect the ECM connector.

(h) Reconnect the A/F sensor connector.

3CHECK HARNESS AND CONNECTOR (A/F SENSOR - ECM)

A136175E10

Tester Connection Specified Condition

+B (A5-2) - Body ground 9 to 14 V

+B (A6-2) - Body ground 9 to 14 V

Tester Connection Specified Condition

HT (A5-1) - HA1A (E10-2) Below 1

AF+ (A5-3) - A1A+ (E10-22) Below 1

AF- (A5-4) - A1A- (E10-30) Below 1

HT (A6-1) - HA2A (E10-1) Below 1

AF+ (A6-3) - A2A+ (E10-23) Below 1

AF- (A6-4) - A2A- (E10-31) Below 1

Tester Connection Specified Condition

HT (A5-1) or HA1A (E10-2) - Body ground 10 k

or higher

AF+ (A5-3) or A1A+ (E10-22) - Body ground 10 k

or higher

AF- (A5-4) or A1A- (E10-30) - Body ground 10 k

or higher

HT (A6-1) or HA2A (E10-1) - Body ground 10 k

or higher

AF+ (A6-3) or A2A+ (E10-23) - Body ground 10 k

or higher

AF- (A6-4) or A2A- (E10-31) - Body ground 10 k

or higher

Page 696 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–403

ES

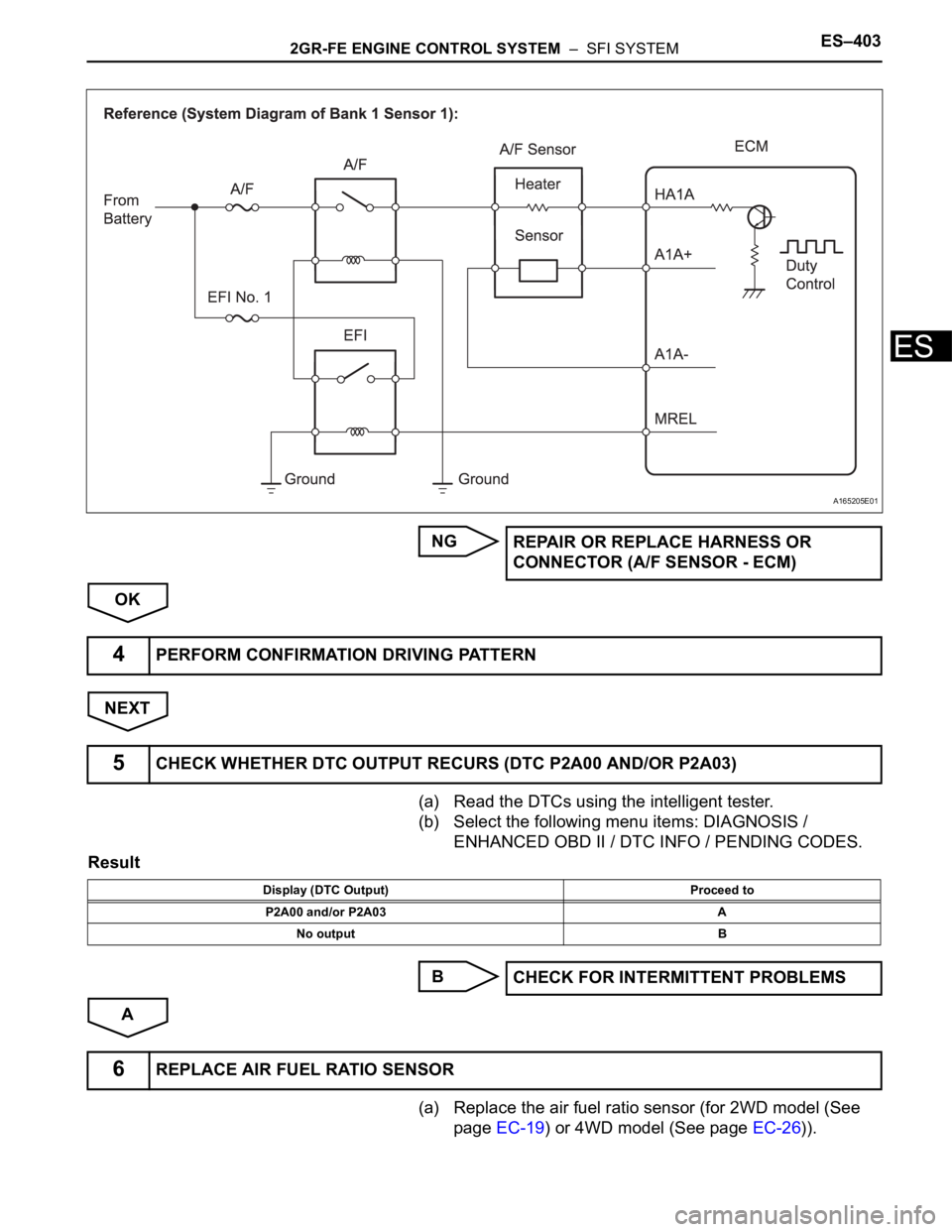

NG

OK

NEXT

(a) Read the DTCs using the intelligent tester.

(b) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / PENDING CODES.

Result

B

A

(a) Replace the air fuel ratio sensor (for 2WD model (See

page EC-19) or 4WD model (See page EC-26)).

A165205E01

REPAIR OR REPLACE HARNESS OR

CONNECTOR (A/F SENSOR - ECM)

4PERFORM CONFIRMATION DRIVING PATTERN

5CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00 AND/OR P2A03)

Display (DTC Output) Proceed to

P2A00 and/or P2A03 A

No output B

CHECK FOR INTERMITTENT PROBLEMS

6REPLACE AIR FUEL RATIO SENSOR

Page 697 of 3000

ES–4042GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NEXT

NEXT

(a) Read the DTCs using the intelligent tester.

(b) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / PENDING CODES.

Result

B

A

7PERFORM CONFIRMATION DRIVING PATTERN

8CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00 AND/OR P2A03)

Display (DTC Output) Proceed to

No output A

P2A00 and/or P2A03 B

REPLACE ECM

END

Page 698 of 3000

ES–4122GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

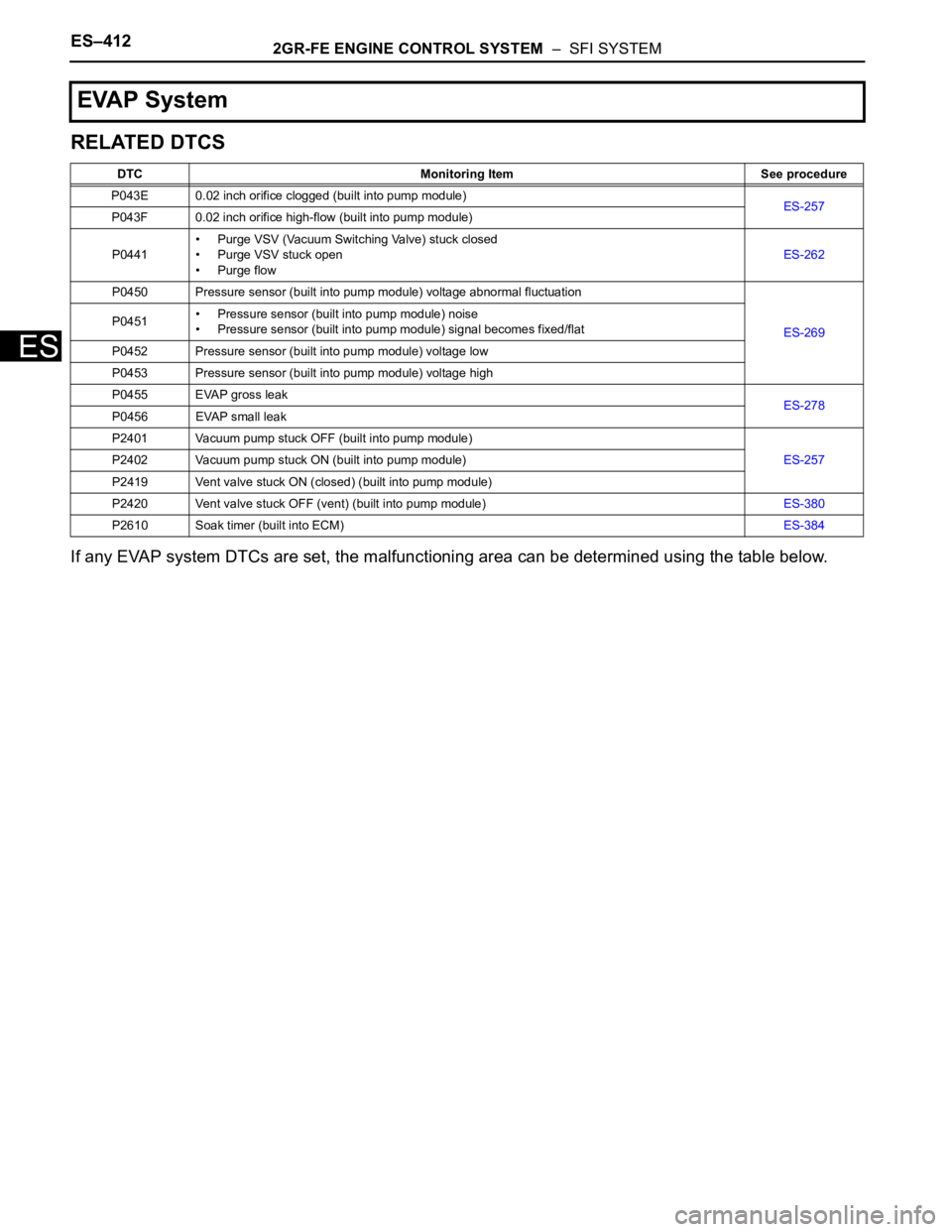

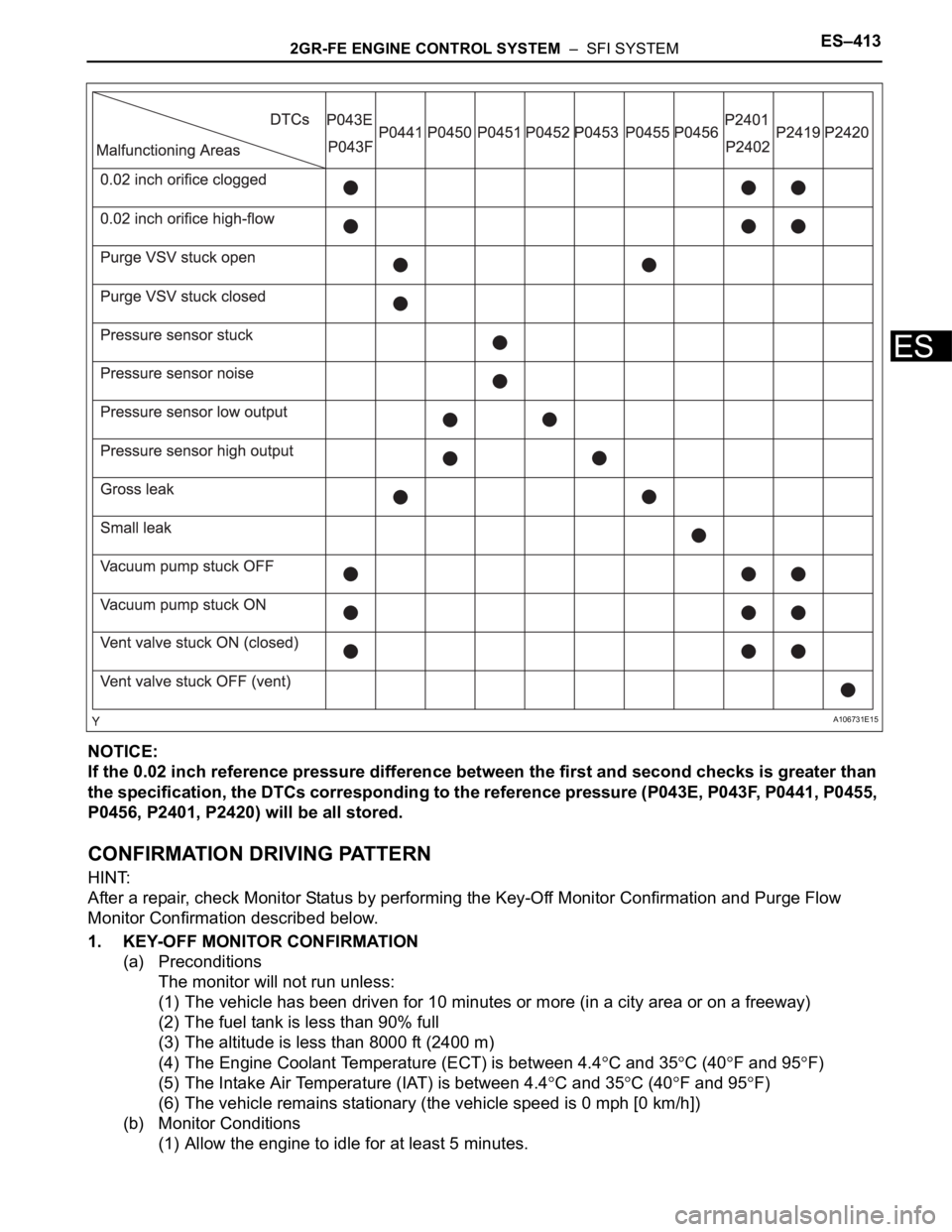

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined using the table below.

EVAP System

DTC Monitoring Item See procedure

P043E 0.02 inch orifice clogged (built into pump module)

ES-257

P043F 0.02 inch orifice high-flow (built into pump module)

P0441• Purge VSV (Vacuum Switching Valve) stuck closed

• Purge VSV stuck open

• Purge flowES-262

P0450 Pressure sensor (built into pump module) voltage abnormal fluctuation

ES-269 P0451• Pressure sensor (built into pump module) noise

• Pressure sensor (built into pump module) signal becomes fixed/flat

P0452 Pressure sensor (built into pump module) voltage low

P0453 Pressure sensor (built into pump module) voltage high

P0455 EVAP gross leak

ES-278

P0456 EVAP small leak

P2401 Vacuum pump stuck OFF (built into pump module)

ES-257 P2402 Vacuum pump stuck ON (built into pump module)

P2419 Vent valve stuck ON (closed) (built into pump module)

P2420 Vent valve stuck OFF (vent) (built into pump module)ES-380

P2610 Soak timer (built into ECM)ES-384

Page 699 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–413

ES

NOTICE:

If the 0.02 inch reference pressure difference between the first and second checks is greater than

the specification, the DTCs corresponding to the reference pressure (P043E, P043F, P0441, P0455,

P0456, P2401, P2420) will be all stored.

CONFIRMATION DRIVING PATTERN

HINT:

After a repair, check Monitor Status by performing the Key-Off Monitor Confirmation and Purge Flow

Monitor Confirmation described below.

1. KEY-OFF MONITOR CONFIRMATION

(a) Preconditions

The monitor will not run unless:

(1) The vehicle has been driven for 10 minutes or more (in a city area or on a freeway)

(2) The fuel tank is less than 90% full

(3) The altitude is less than 8000 ft (2400 m)

(4) The Engine Coolant Temperature (ECT) is between 4.4

C and 35C (40F and 95F)

(5) The Intake Air Temperature (IAT) is between 4.4

C and 35C (40F and 95F)

(6) The vehicle remains stationary (the vehicle speed is 0 mph [0 km/h])

(b) Monitor Conditions

(1) Allow the engine to idle for at least 5 minutes.

A106731E15

Page 700 of 3000

ES–4142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(2) Turn the ignition switch off and wait for 6 hours (8 or 10.5 hours).

HINT:

Do not start the engine until checking MONITOR STATUS. If the engine is started, the steps

described above must be repeated.

(c) Monitor Status

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position and turn the tester on.

(3) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / MONITOR STATUS.

(4) Check the "Monitor Status" displayed on the tester.

HINT:

If INCMP is displayed, the monitor is not completed. Make sure that the preconditions have

been met, and perform "Monitor Conditions" again.

2. PURGE FLOW MONITOR CONFIRMATION (P0441)

HINT:

Perform this monitor confirmation after the Key-Off Monitor Confirmation shows COMPL (complete).

(a) Preconditions

The monitor will not run unless:

• The vehicle has been driven for 10 minutes or more (in a city area or on a freeway)

• The ECT is between 4.4

C and 35C (40F and 95F)

• The IAT is between 4.4

C and 35C (40F and 95F)

(b) Monitor Conditions

(1) Release the pressure from the fuel tank by removing and reinstalling the fuel tank cap.

(2) Warm the engine up until the ECT reaches more than 75

C (167F).

(3) Increase the engine speed to 3000 rpm once.

(4) Allow the engine to idle and turn the A/C ON for 1 minute.

(c) Monitor Status

(1) Turn the ignition switch off.

(2) Connect the intelligent tester to the DLC3.

(3) Turn the ignition switch to the ON position and turn the tester on.

(4) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / MONITOR STATUS.

(5) Check the "Monitor Status" displayed on the tester.

HINT:

If INCMP is displayed, the monitor is not completed. Make sure that the preconditions have

been met, and perform "Monitor Conditions" again.

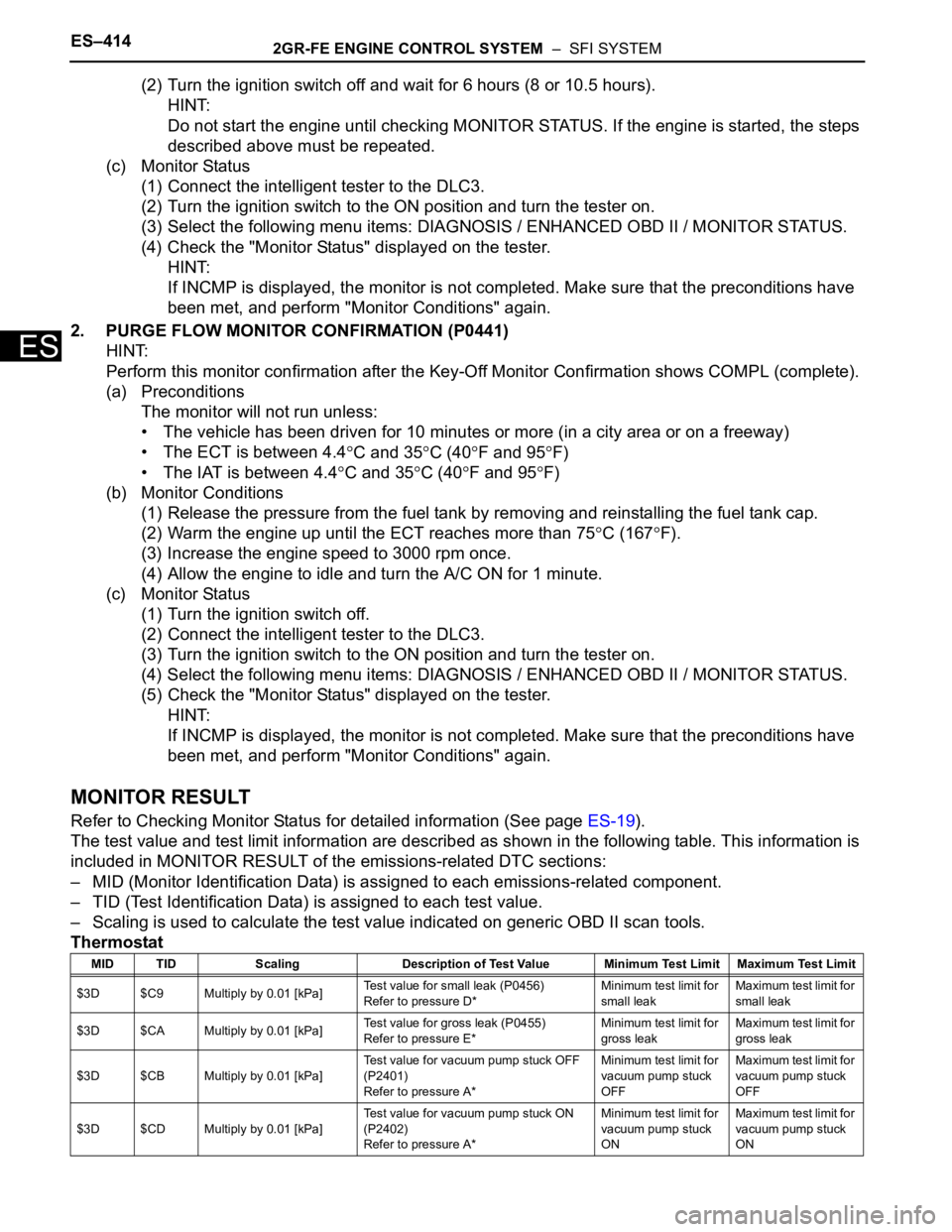

MONITOR RESULT

Refer to Checking Monitor Status for detailed information (See page ES-19).

The test value and test limit information are described as shown in the following table. This information is

included in MONITOR RESULT of the emissions-related DTC sections:

– MID (Monitor Identification Data) is assigned to each emissions-related component.

– TID (Test Identification Data) is assigned to each test value.

– Scaling is used to calculate the test value indicated on generic OBD II scan tools.

Thermostat

MID TID Scaling Description of Test Value Minimum Test Limit Maximum Test Limit

$3D $C9 Multiply by 0.01 [kPa]Test value for small leak (P0456)

Refer to pressure D*Minimum test limit for

small leakMaximum test limit for

small leak

$3D $CA Multiply by 0.01 [kPa]Test value for gross leak (P0455)

Refer to pressure E*Minimum test limit for

gross leakMaximum test limit for

gross leak

$3D $CB Multiply by 0.01 [kPa]Test value for vacuum pump stuck OFF

(P2401)

Refer to pressure A*Minimum test limit for

vacuum pump stuck

OFFMaximum test limit for

vacuum pump stuck

OFF

$3D $CD Multiply by 0.01 [kPa]Test value for vacuum pump stuck ON

(P2402)

Refer to pressure A*Minimum test limit for

vacuum pump stuck

ONMaximum test limit for

vacuum pump stuck

ON