TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 701 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–415

ES

$3D $CE Multiply by 0.01 [kPa]Test value for vent valve stuck OFF

(vent) (P2420)

Refer to pressure C*Minimum test limit for

vent valve stuck TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–415

ES

$3D $CE Multiply by 0.01 [kPa]Test value for vent valve stuck OFF

(vent) (P2420)

Refer to pressure C*Minimum test limit for

vent valve stuck](/img/14/57466/w960_57466-700.png)

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–415

ES

$3D $CE Multiply by 0.01 [kPa]Test value for vent valve stuck OFF

(vent) (P2420)

Refer to pressure C*Minimum test limit for

vent valve stuck ONMaximum test limit for

vent valve stuck ON

$3D $CF Multiply by 0.01 [kPa]Test value for vent valve stuck ON

(P2419)

Refer to pressure A*Minimum test limit for

vent valve stuck OFFMaximum test limit for

vent valve stuck OFF

$3D $D0 Multiply by 0.01 [kPa]Test value for 0.02 inch orifice low flow

(P043E)

Refer to pressure B*Minimum test limit for

0.02 inch orifice low

flowMaximum test limit for

0.02 inch orifice low

flow

$3D $D1 Multiply by 0.01 [kPa]Test value for 0.02 inch orifice high flow

(P043F)

Refer to pressure A*Minimum test limit for

0.02 inch orifice high

flowMaximum test limit for

0.02 inch orifice high

flow

$3D $D4 Multiply by 0.01 [kPa]Test value for purge VSV stuck closed

(P0441)

Refer to pressure F*Minimum test limit for

purge VSV stuck

closedMaximum test limit for

purge VSV stuck

closed

$3D $D5 Multiply by 0.01 [kPa]Test value for purge VSV stuck open

(P0441)

Refer to pressure E*Minimum test limit for

purge VSV stuck

openMaximum test limit for

purge VSV stuck

open

$3D $D7 Multiply by 0.01 [kPa]Test value for purge flow (P0441)

Refer to pressure G*Minimum test limit for

purge flowMaximum test limit for

purge flow MID TID Scaling Description of Test Value Minimum Test Limit Maximum Test Limit

Page 702 of 3000

ES–4162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

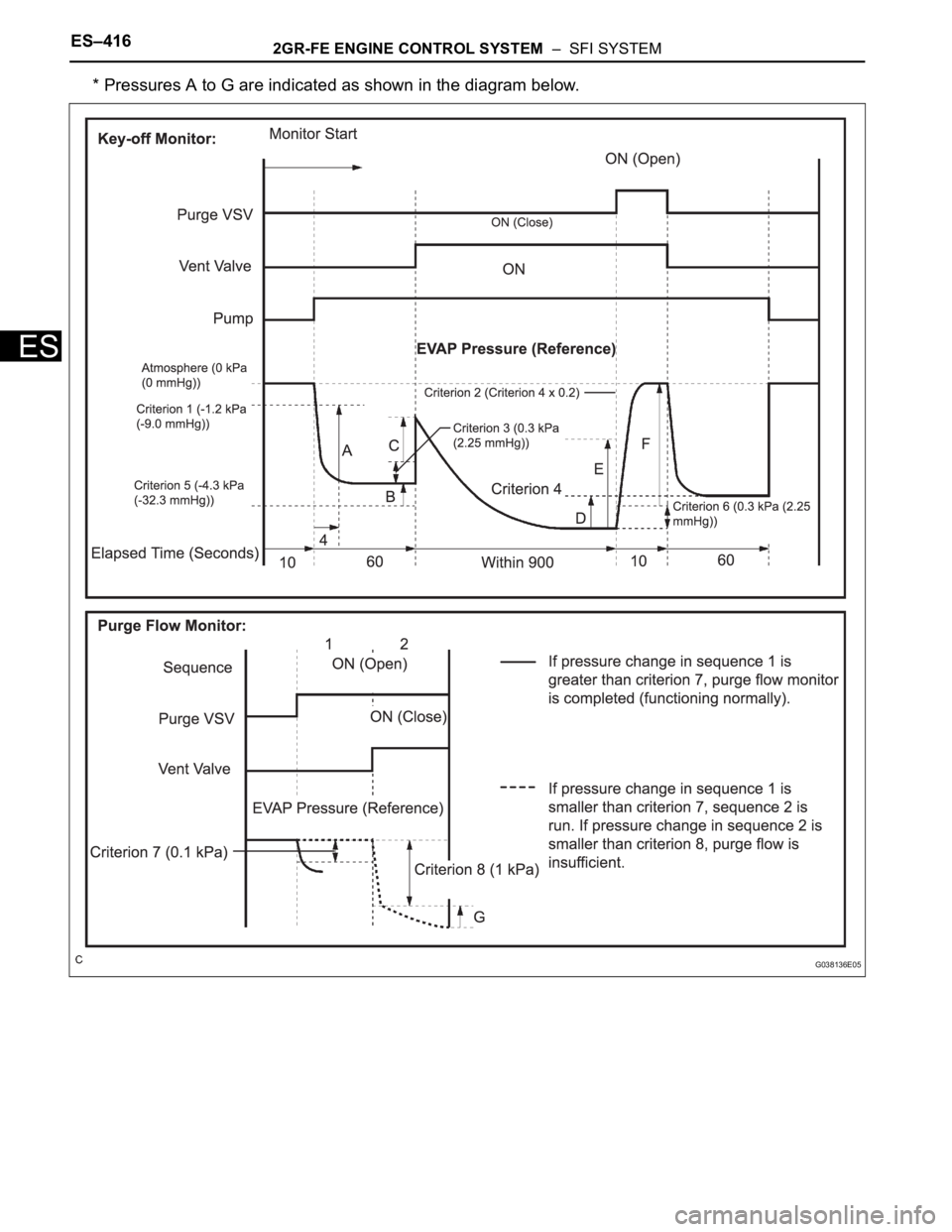

* Pressures A to G are indicated as shown in the diagram below.

G038136E05

Page 703 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–417

ES

DESCRIPTION

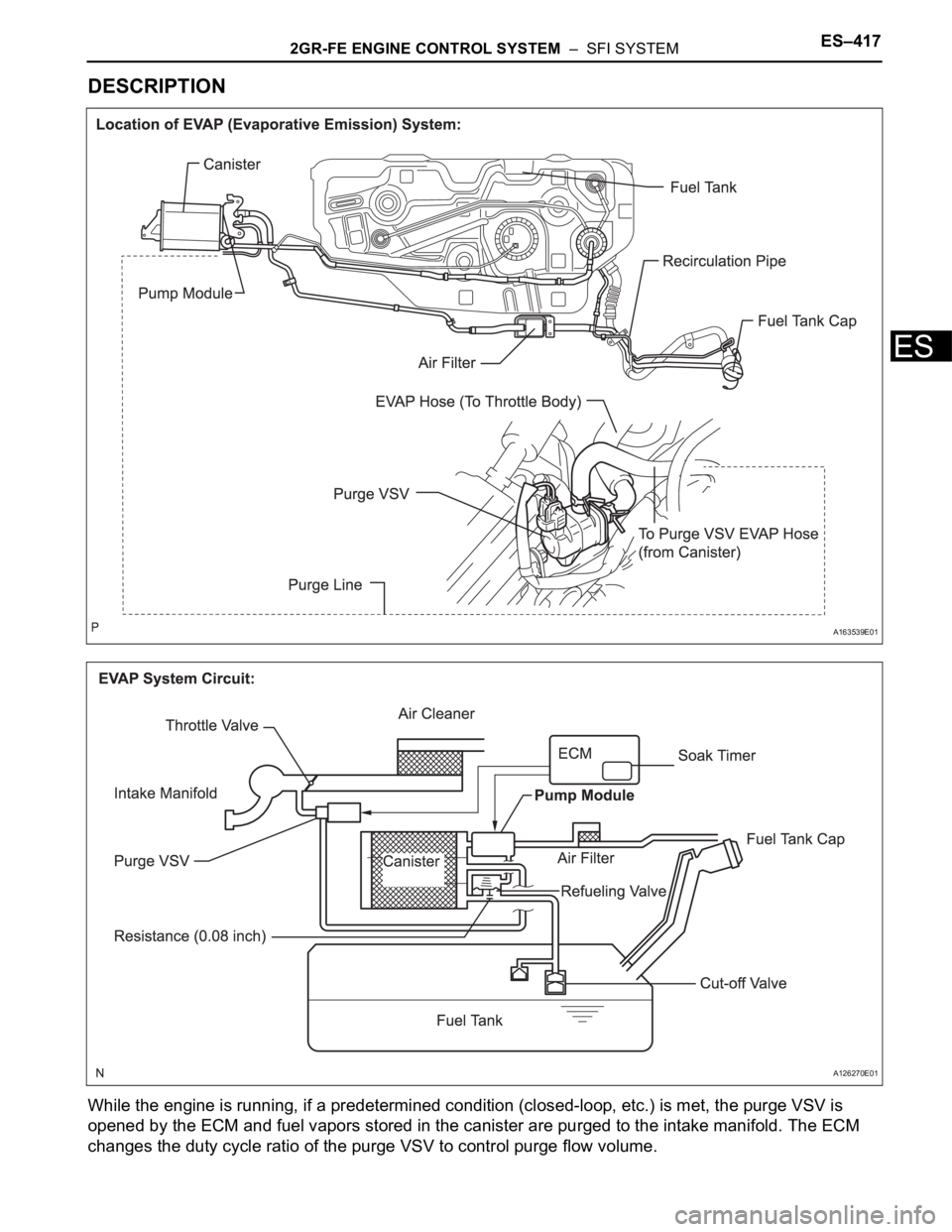

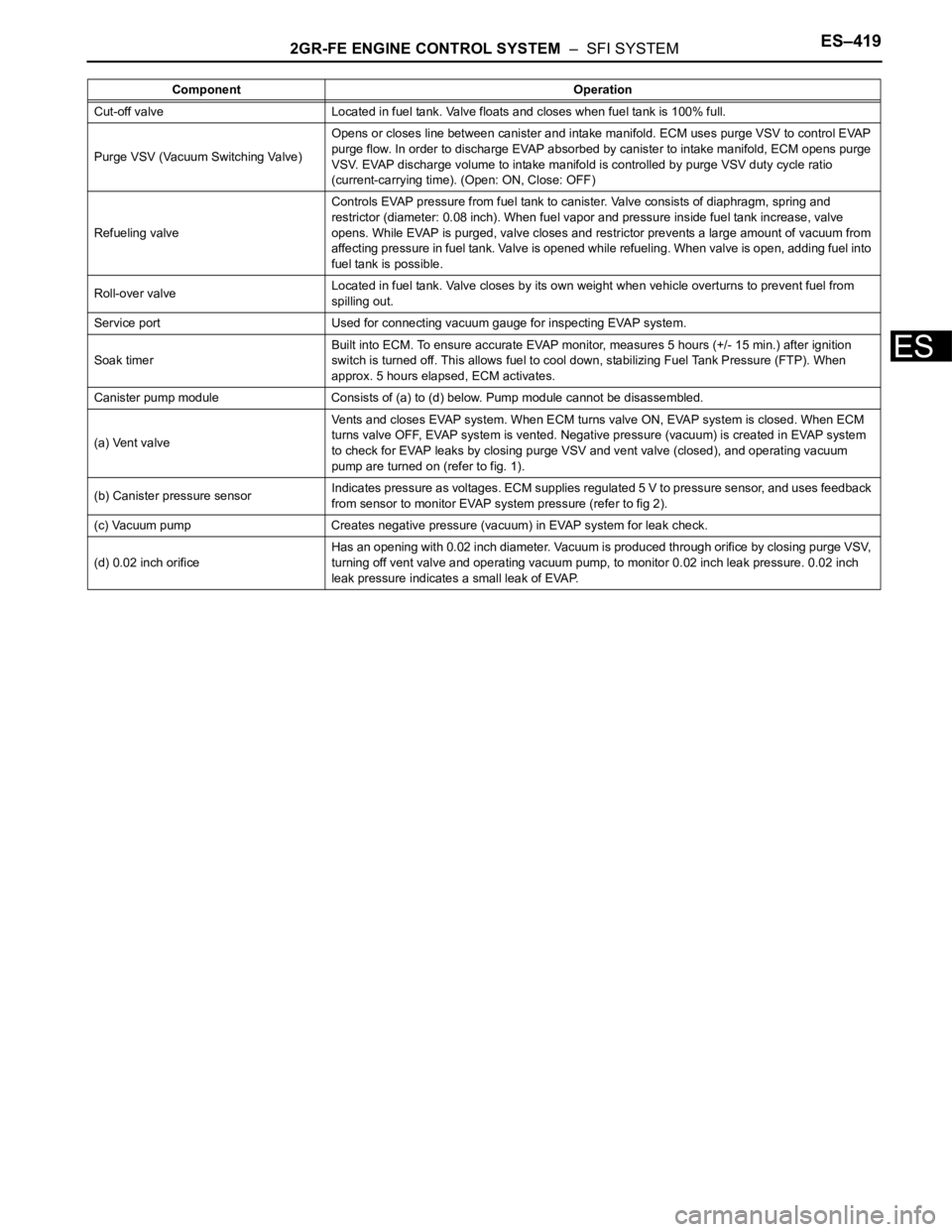

While the engine is running, if a predetermined condition (closed-loop, etc.) is met, the purge VSV is

opened by the ECM and fuel vapors stored in the canister are purged to the intake manifold. The ECM

changes the duty cycle ratio of the purge VSV to control purge flow volume.

A163539E01

A126270E01

Page 704 of 3000

ES–4182GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

The purge flow volume is also determined by the intake manifold pressure. Atmospheric pressure is

allowed into the canister through the vent valve to ensure that the purge flow is maintained when negative

pressure (vacuum) is applied to the canister.

The following two monitors run to confirm appropriate EVAP system operation.

1. Key-off monitor

This monitor checks for EVAP (Evaporative Emission) system leaks and pump module malfunctions.

The monitor starts 5 hours* after the ignition switch is turned off. More than 5 hours are required to

allow the fuel to cool down to stabilize the Fuel Tank Pressure (FTP), thus making the EVAP system

monitor more accurate.

The electric vacuum pump creates negative pressure (vacuum) in the EVAP system, and the

pressure is measured. Finally, the ECM monitors for leaks from the EVAP system and malfunctions in

both the pump module and purge VSV, based on the EVAP pressure.

HINT:

*: If the engine coolant temperature is not below 35

C (95F) 5 hours after the ignition switch is

turned off, the monitor check starts 2 hours later. If it is still not below 35

C (95F) 7 hours after the

ignition switch is turned off, the monitor check starts 2.5 hours later.

2. Purge flow monitor

The purge flow monitor consists of the two monitors. The 1st monitor is always conducted every time

and the 2nd monitor is activated if necessary.

• The 1st monitor

While the engine is running and the purge VSV (Vacuum Switching Valve) is ON (open), the ECM

monitors the purge flow by measuring the EVAP pressure change. If negative pressure is not

created, the ECM begins the 2nd monitor.

• The 2nd monitor

The vent valve is turned OFF (open) and the EVAP pressure is then measured. If the variation in

the pressure is less than 0.5 kPa (3.75 mmHg), the ECM interprets this as the purge VSV being

stuck closed, and illuminates the MIL and sets DTC P0441 (2 trip detection logic).

Atmospheric pressure check:

In order to ensure reliable malfunction detection, the variation between the atmospheric pressures,

before and after conduction of the purge flow monitor, is measured by the ECM.

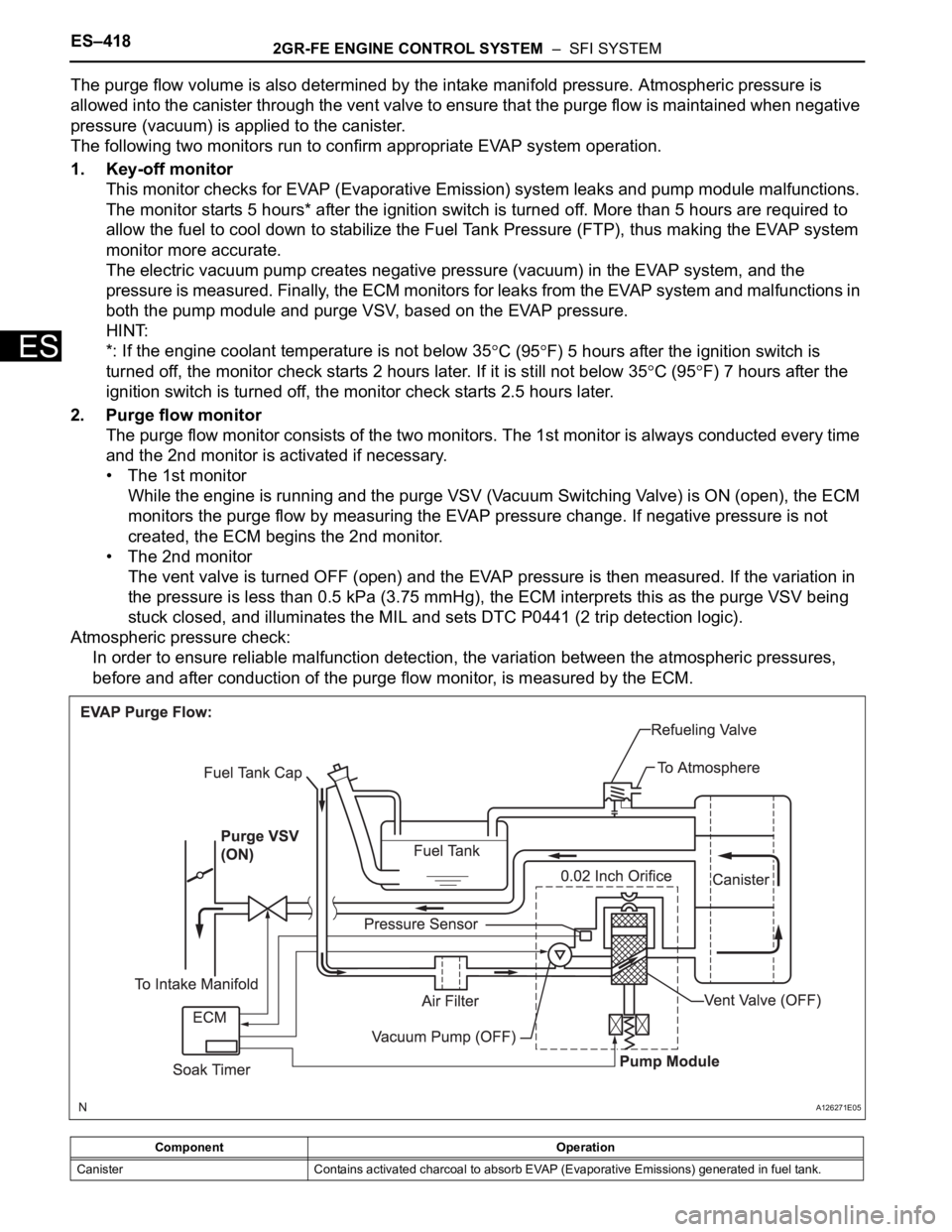

Component Operation

Canister Contains activated charcoal to absorb EVAP (Evaporative Emissions) generated in fuel tank.

A126271E05

Page 705 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–419

ES

Cut-off valve Located in fuel tank. Valve floats and closes when fuel tank is 100% full.

Purge VSV (Vacuum Switching Valve)Opens or closes line between canister and intake manifold. ECM uses purge VSV to control EVAP

purge flow. In order to discharge EVAP absorbed by canister to intake manifold, ECM opens purge

VSV. EVAP discharge volume to intake manifold is controlled by purge VSV duty cycle ratio

(current-carrying time). (Open: ON, Close: OFF)

Refueling valveControls EVAP pressure from fuel tank to canister. Valve consists of diaphragm, spring and

restrictor (diameter: 0.08 inch). When fuel vapor and pressure inside fuel tank increase, valve

opens. While EVAP is purged, valve closes and restrictor prevents a large amount of vacuum from

affecting pressure in fuel tank. Valve is opened while refueling. When valve is open, adding fuel into

fuel tank is possible.

Roll-over valveLocated in fuel tank. Valve closes by its own weight when vehicle overturns to prevent fuel from

spilling out.

Service port Used for connecting vacuum gauge for inspecting EVAP system.

Soak timerBuilt into ECM. To ensure accurate EVAP monitor, measures 5 hours (+/- 15 min.) after ignition

switch is turned off. This allows fuel to cool down, stabilizing Fuel Tank Pressure (FTP). When

approx. 5 hours elapsed, ECM activates.

Canister pump module Consists of (a) to (d) below. Pump module cannot be disassembled.

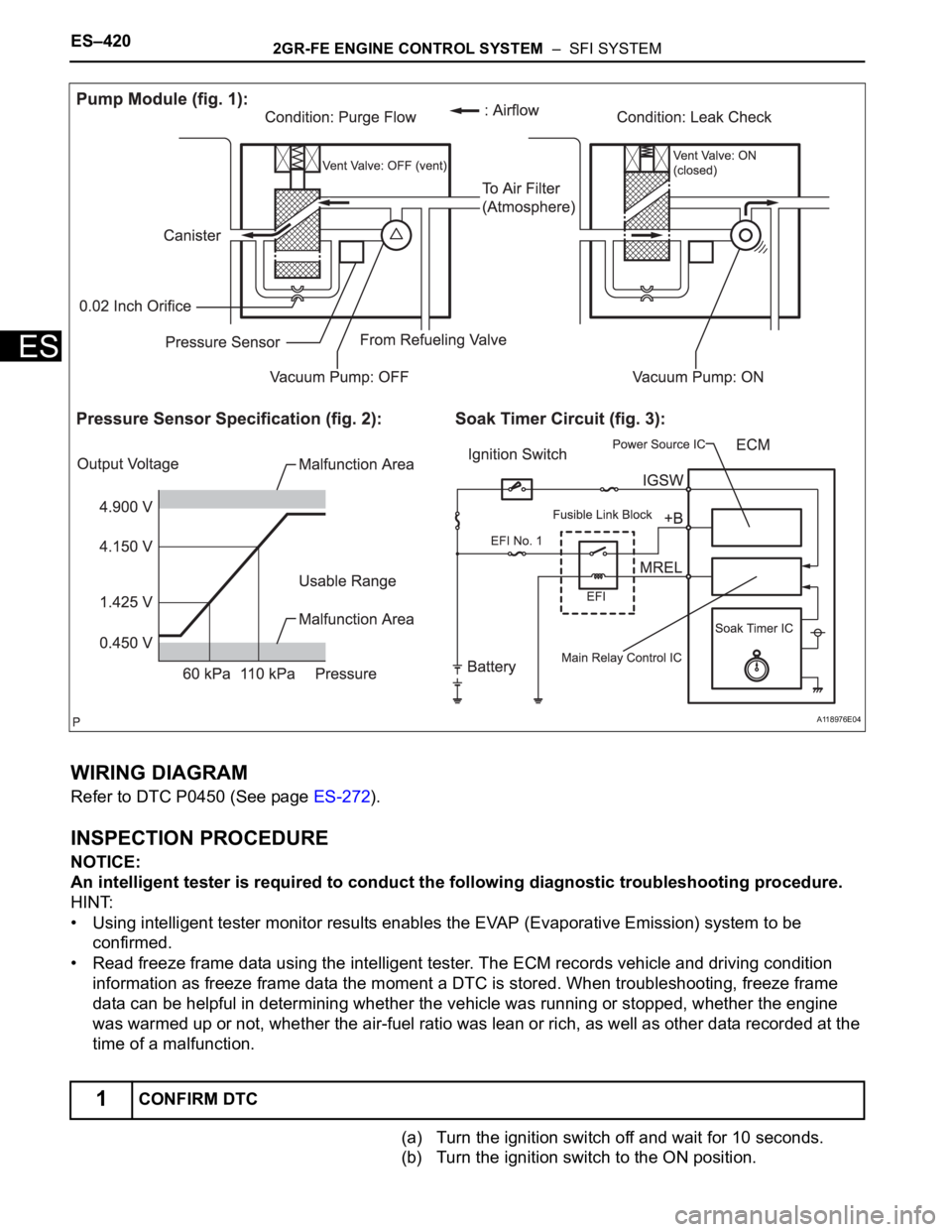

(a) Vent valveVents and closes EVAP system. When ECM turns valve ON, EVAP system is closed. When ECM

turns valve OFF, EVAP system is vented. Negative pressure (vacuum) is created in EVAP system

to check for EVAP leaks by closing purge VSV and vent valve (closed), and operating vacuum

pump are turned on (refer to fig. 1).

(b) Canister pressure sensorIndicates pressure as voltages. ECM supplies regulated 5 V to pressure sensor, and uses feedback

from sensor to monitor EVAP system pressure (refer to fig 2).

(c) Vacuum pump Creates negative pressure (vacuum) in EVAP system for leak check.

(d) 0.02 inch orificeHas an opening with 0.02 inch diameter. Vacuum is produced through orifice by closing purge VSV,

turning off vent valve and operating vacuum pump, to monitor 0.02 inch leak pressure. 0.02 inch

leak pressure indicates a small leak of EVAP. Component Operation

Page 706 of 3000

ES–4202GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

WIRING DIAGRAM

Refer to DTC P0450 (See page ES-272).

INSPECTION PROCEDURE

NOTICE:

An intelligent tester is required to conduct the following diagnostic troubleshooting procedure.

HINT:

• Using intelligent tester monitor results enables the EVAP (Evaporative Emission) system to be

confirmed.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Turn the ignition switch off and wait for 10 seconds.

(b) Turn the ignition switch to the ON position.

1CONFIRM DTC

A118976E04

Page 707 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–421

ES

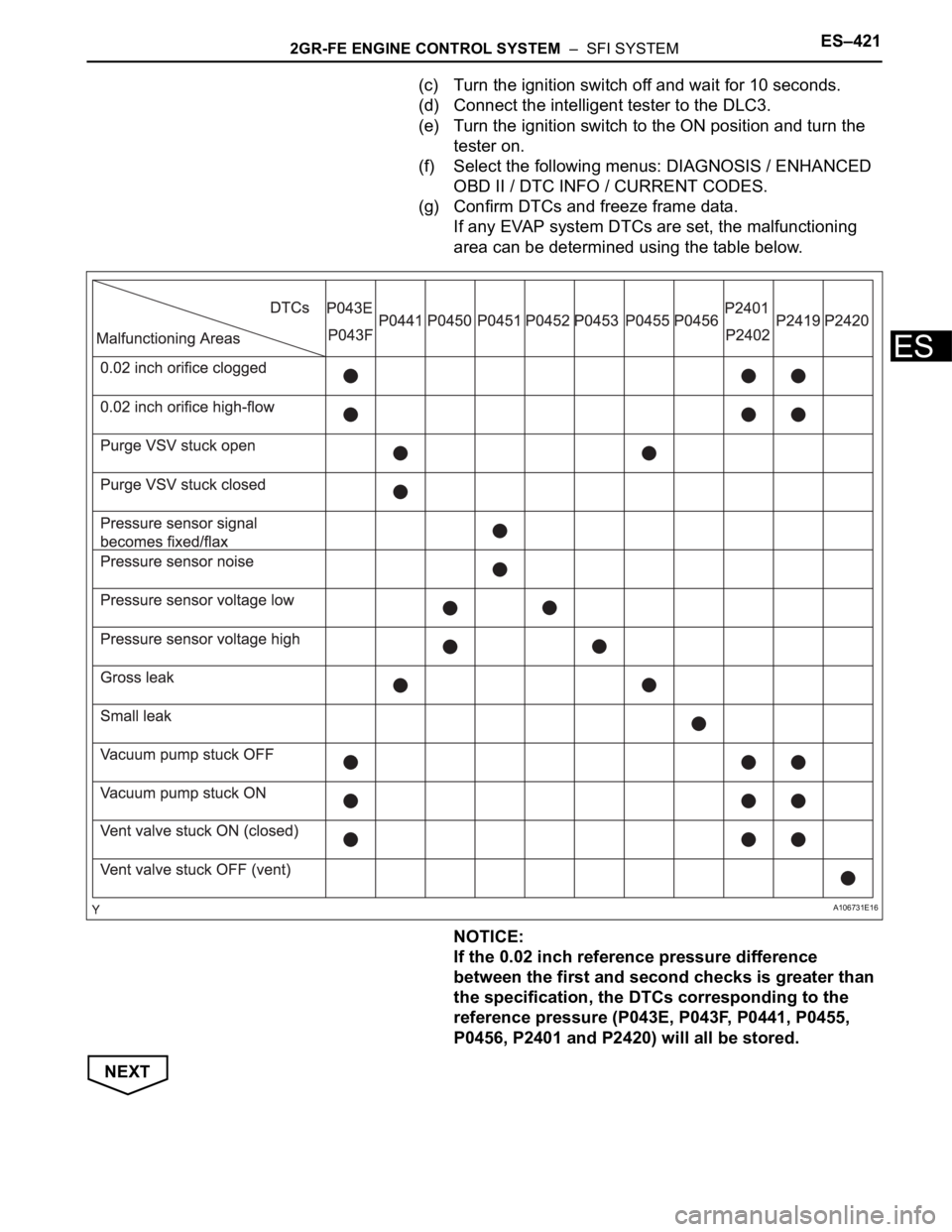

(c) Turn the ignition switch off and wait for 10 seconds.

(d) Connect the intelligent tester to the DLC3.

(e) Turn the ignition switch to the ON position and turn the

tester on.

(f) Select the following menus: DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CURRENT CODES.

(g) Confirm DTCs and freeze frame data.

If any EVAP system DTCs are set, the malfunctioning

area can be determined using the table below.

NOTICE:

If the 0.02 inch reference pressure difference

between the first and second checks is greater than

the specification, the DTCs corresponding to the

reference pressure (P043E, P043F, P0441, P0455,

P0456, P2401 and P2420) will all be stored.

NEXT

A106731E16

Page 708 of 3000

ES–4222GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

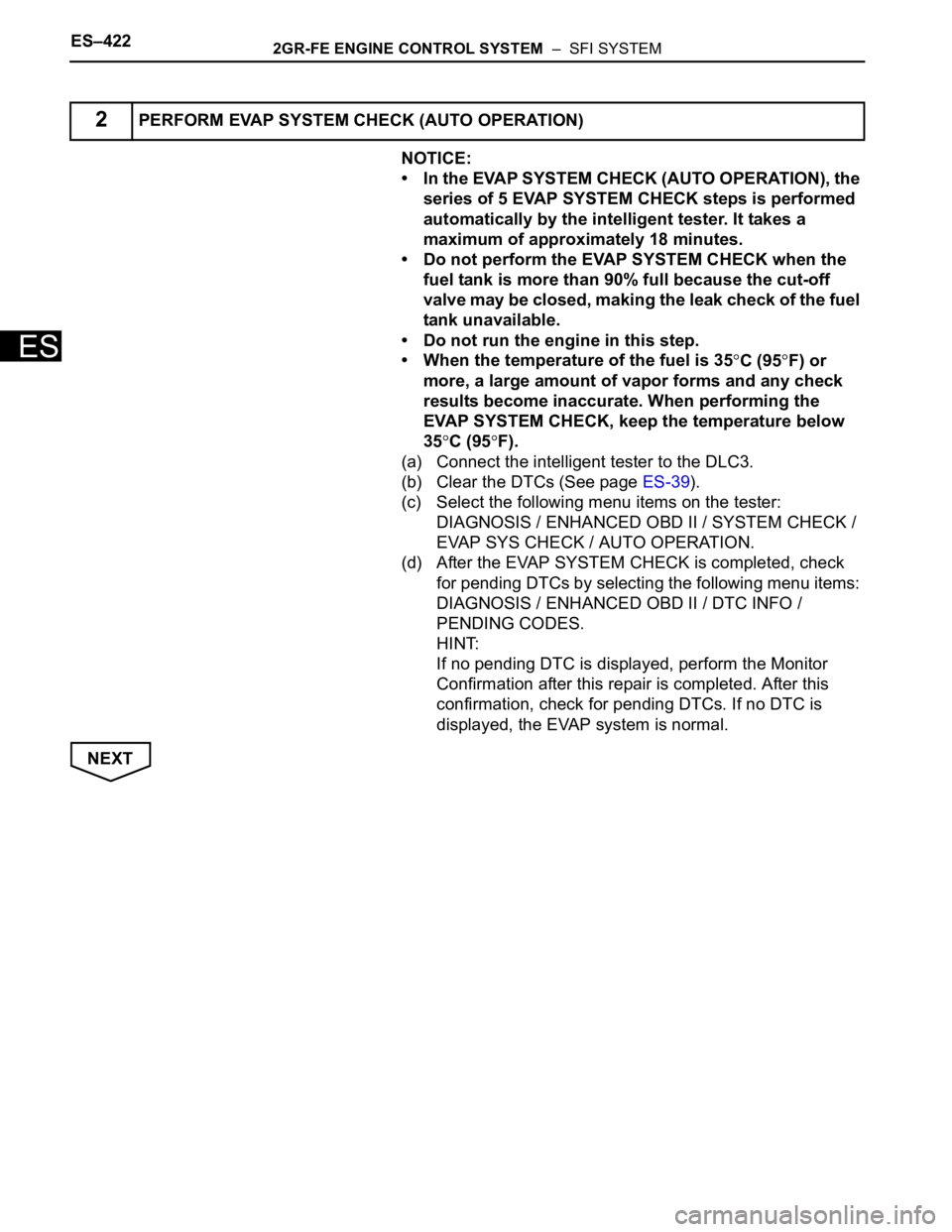

NOTICE:

• In the EVAP SYSTEM CHECK (AUTO OPERATION), the

series of 5 EVAP SYSTEM CHECK steps is performed

automatically by the intelligent tester. It takes a

maximum of approximately 18 minutes.

• Do not perform the EVAP SYSTEM CHECK when the

fuel tank is more than 90% full because the cut-off

valve may be closed, making the leak check of the fuel

tank unavailable.

• Do not run the engine in this step.

• When the temperature of the fuel is 35

C (95F) or

more, a large amount of vapor forms and any check

results become inaccurate. When performing the

EVAP SYSTEM CHECK, keep the temperature below

35

C (95F).

(a) Connect the intelligent tester to the DLC3.

(b) Clear the DTCs (See page ES-39).

(c) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / SYSTEM CHECK /

EVAP SYS CHECK / AUTO OPERATION.

(d) After the EVAP SYSTEM CHECK is completed, check

for pending DTCs by selecting the following menu items:

DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES.

HINT:

If no pending DTC is displayed, perform the Monitor

Confirmation after this repair is completed. After this

confirmation, check for pending DTCs. If no DTC is

displayed, the EVAP system is normal.

NEXT

2PERFORM EVAP SYSTEM CHECK (AUTO OPERATION)

Page 709 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–423

ES

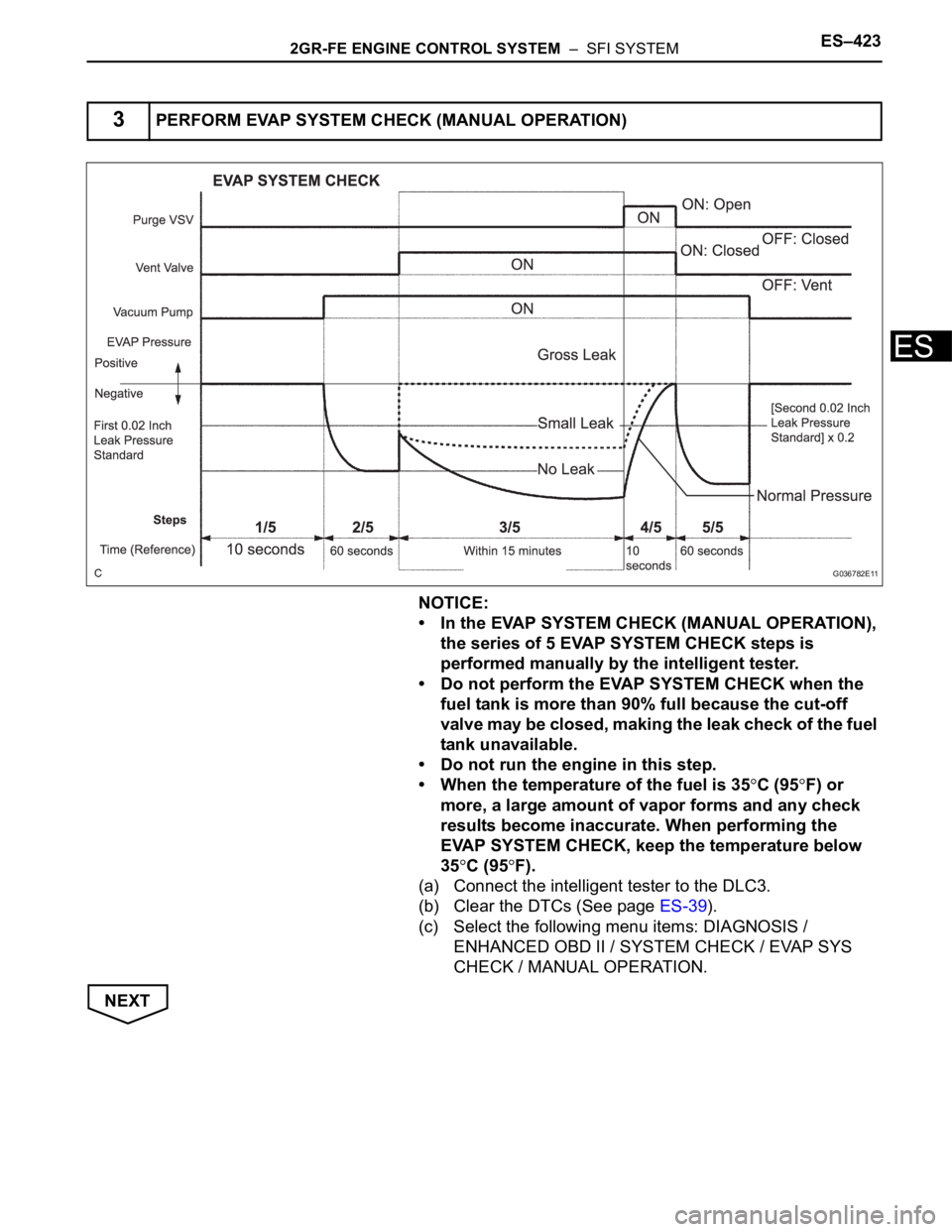

NOTICE:

• In the EVAP SYSTEM CHECK (MANUAL OPERATION),

the series of 5 EVAP SYSTEM CHECK steps is

performed manually by the intelligent tester.

• Do not perform the EVAP SYSTEM CHECK when the

fuel tank is more than 90% full because the cut-off

valve may be closed, making the leak check of the fuel

tank unavailable.

• Do not run the engine in this step.

• When the temperature of the fuel is 35

C (95F) or

more, a large amount of vapor forms and any check

results become inaccurate. When performing the

EVAP SYSTEM CHECK, keep the temperature below

35

C (95F).

(a) Connect the intelligent tester to the DLC3.

(b) Clear the DTCs (See page ES-39).

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / SYSTEM CHECK / EVAP SYS

CHECK / MANUAL OPERATION.

NEXT

3PERFORM EVAP SYSTEM CHECK (MANUAL OPERATION)

G036782E11

Page 710 of 3000

ES–4242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

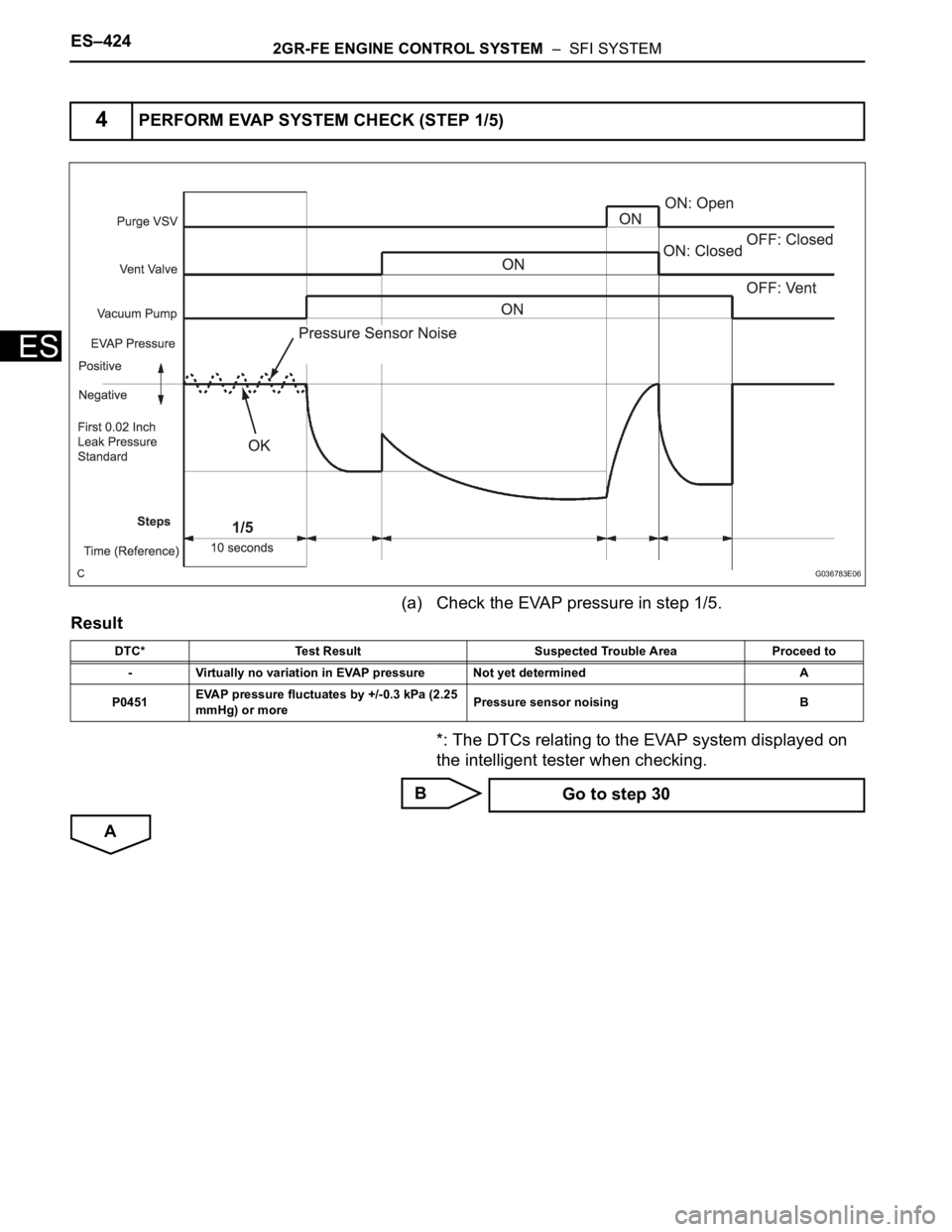

(a) Check the EVAP pressure in step 1/5.

Result

*: The DTCs relating to the EVAP system displayed on

the intelligent tester when checking.

B

A

4PERFORM EVAP SYSTEM CHECK (STEP 1/5)

G036783E06

DTC* Test Result Suspected Trouble Area Proceed to

- Virtually no variation in EVAP pressure Not yet determined A

P0451EVAP pressure fluctuates by +/-0.3 kPa (2.25

mmHg) or morePressure sensor noising B

Go to step 30