differential TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 16 of 3000

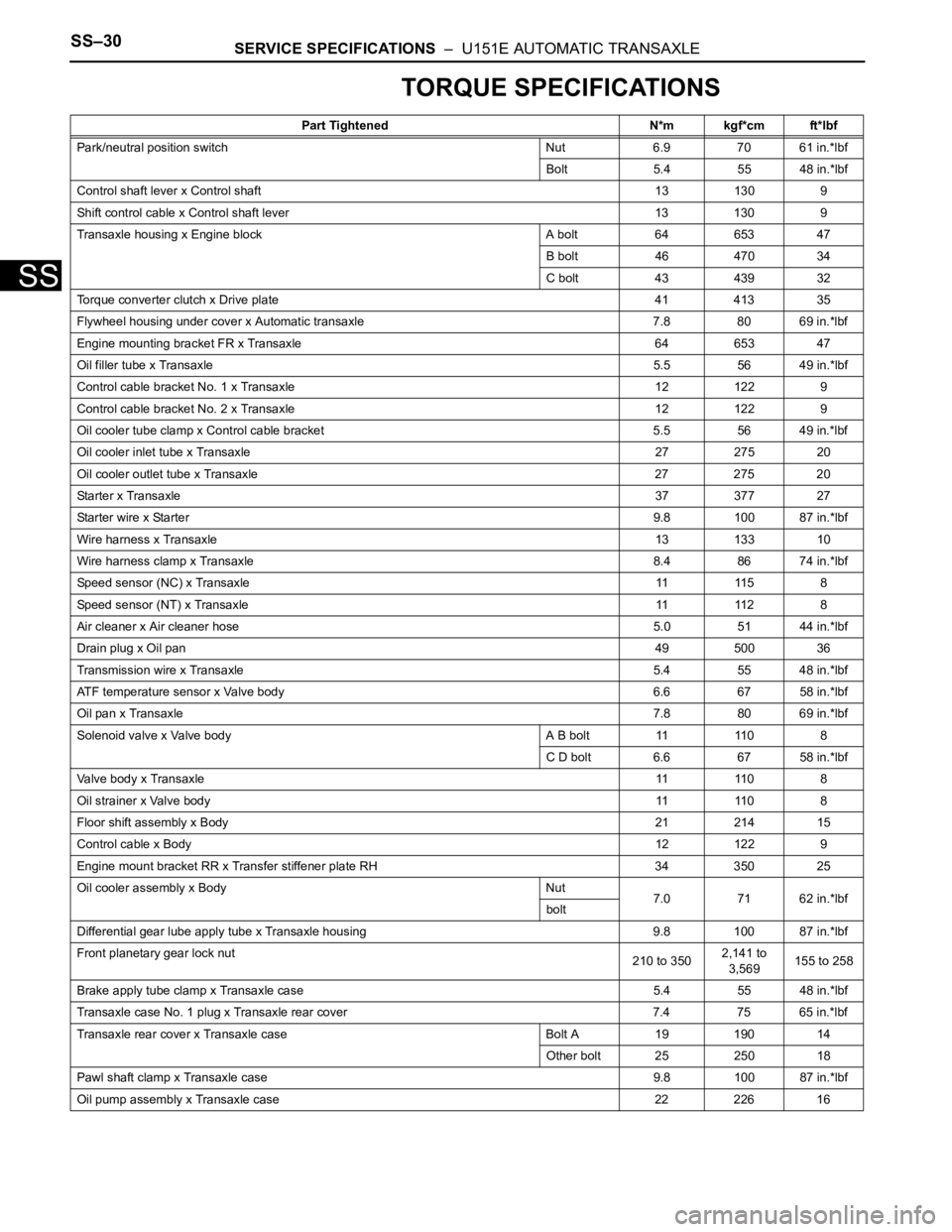

SS–30SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 130 9

Shift control cable x Control shaft lever 13 130 9

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

C bolt 43 439 32

Torque converter clutch x Drive plate 41 413 35

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.5 56 49 in.*lbf

Oil cooler inlet tube x Transaxle27 275 20

Oil cooler outlet tube x Transaxle 27 275 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 87 in.*lbf

Wire harness x Transaxle13 133 10

Wire harness clamp x Transaxle8.4 86 74 in.*lbf

Speed sensor (NC) x Transaxle11 11 5 8

Speed sensor (NT) x Transaxle11 11 2 8

Air cleaner x Air cleaner hose5.0 51 44 in.*lbf

Drain plug x Oil pan49 500 36

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body A B bolt 11 110 8

C D bolt 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 0 8

Oil strainer x Valve body11 11 0 8

Floor shift assembly x Body21 214 15

Control cable x Body12 122 9

Engine mount bracket RR x Transfer stiffener plate RH 34 350 25

Oil cooler assembly x Body Nut

7.0 71 62 in.*lbf

bolt

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut

210 to 3502,141 to

3,569155 to 258

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 190 14

Other bolt 25 250 18

Pawl shaft clamp x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Page 17 of 3000

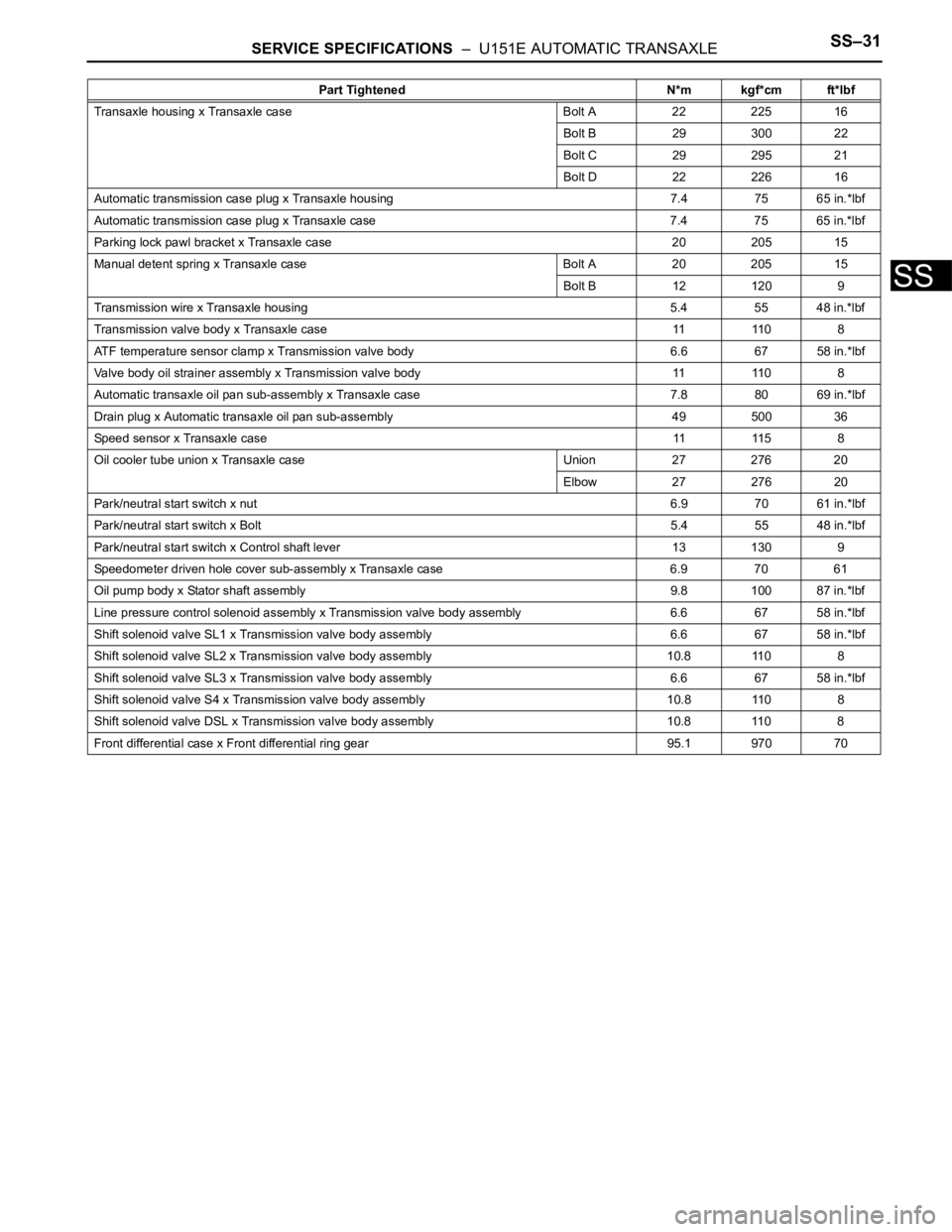

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLESS–31

SS

Transaxle housing x Transaxle case Bolt A 22 225 16

Bolt B 29 300 22

Bolt C 29 295 21

Bolt D 22 226 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Transmission wire x Transaxle housing 5.4 55 48 in.*lbf

Transmission valve body x Transaxle case 11 110 8

ATF temperature sensor clamp x Transmission valve body 6.6 67 58 in.*lbf

Valve body oil strainer assembly x Transmission valve body 11 1108

Automatic transaxle oil pan sub-assembly x Transaxle case 7.8 80 69 in.*lbf

Drain plug x Automatic transaxle oil pan sub-assembly 49 500 36

Speed sensor x Transaxle case11 11 5 8

Oil cooler tube union x Transaxle case Union 27 276 20

Elbow 27 276 20

Park/neutral start switch x nut6.9 70 61 in.*lbf

Park/neutral start switch x Bolt5.4 55 48 in.*lbf

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 6.9 7061

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Line pressure control solenoid assembly x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL1 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL2 x Transmission valve body assembly 10.811 0 8

Shift solenoid valve SL3 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve S4 x Transmission valve body assembly 10.8 110 8

Shift solenoid valve DSL x Transmission valve body assembly 10.811 0 8

Front differential case x Front differential ring gear 95.1 970 70Part Tightened N*m kgf*cm ft*lbf

Page 58 of 3000

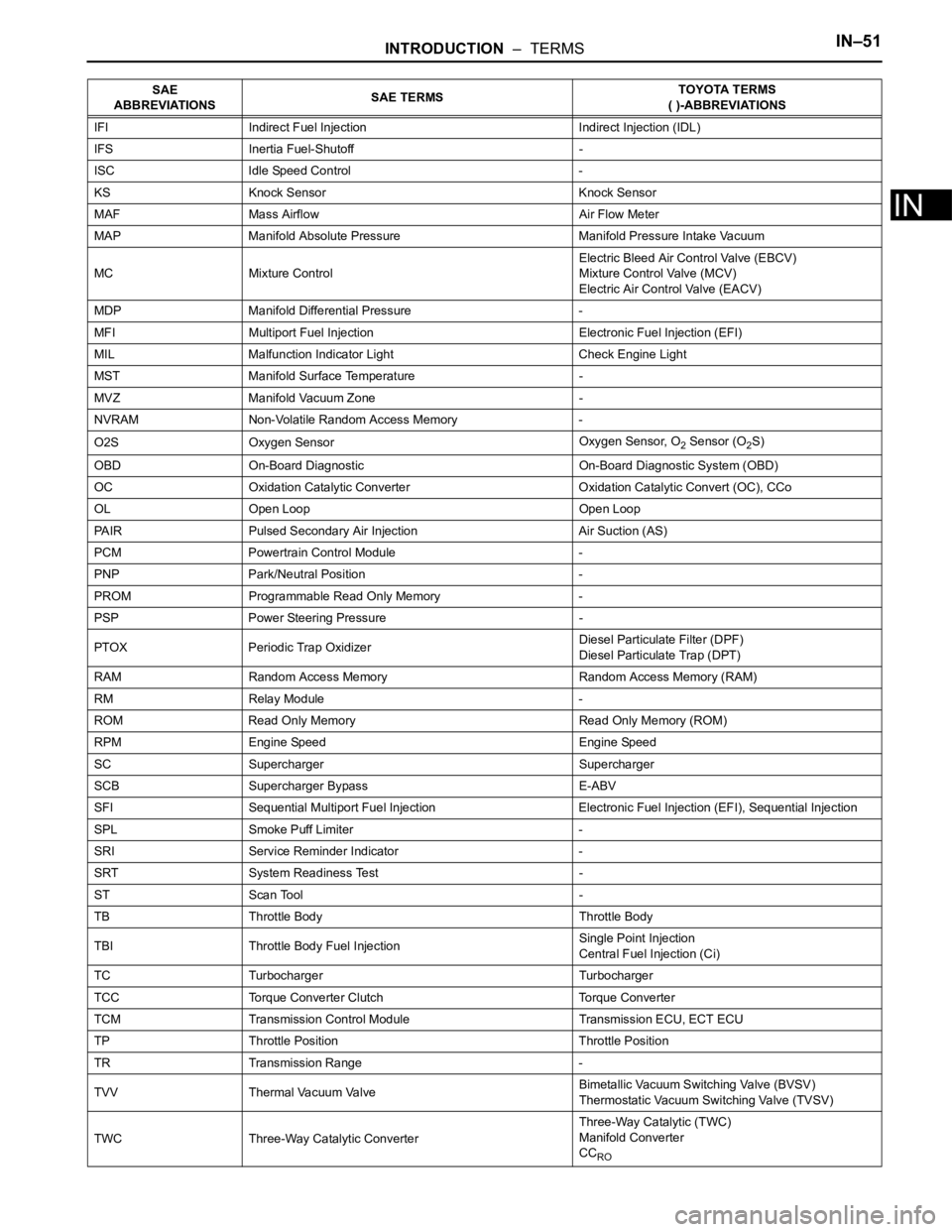

INTRODUCTION – TERMSIN–51

IN

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Light Check Engine Light

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen SensorOxygen Sensor, O

2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalytic Convert (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV)

TWC Three-Way Catalytic ConverterThree-Way Catalytic (TWC)

Manifold Converter

CC

RO

SAE

ABBREVIATIONSSAE TERMSTOYOTA TERMS

( )-ABBREVIATIONS

Page 161 of 3000

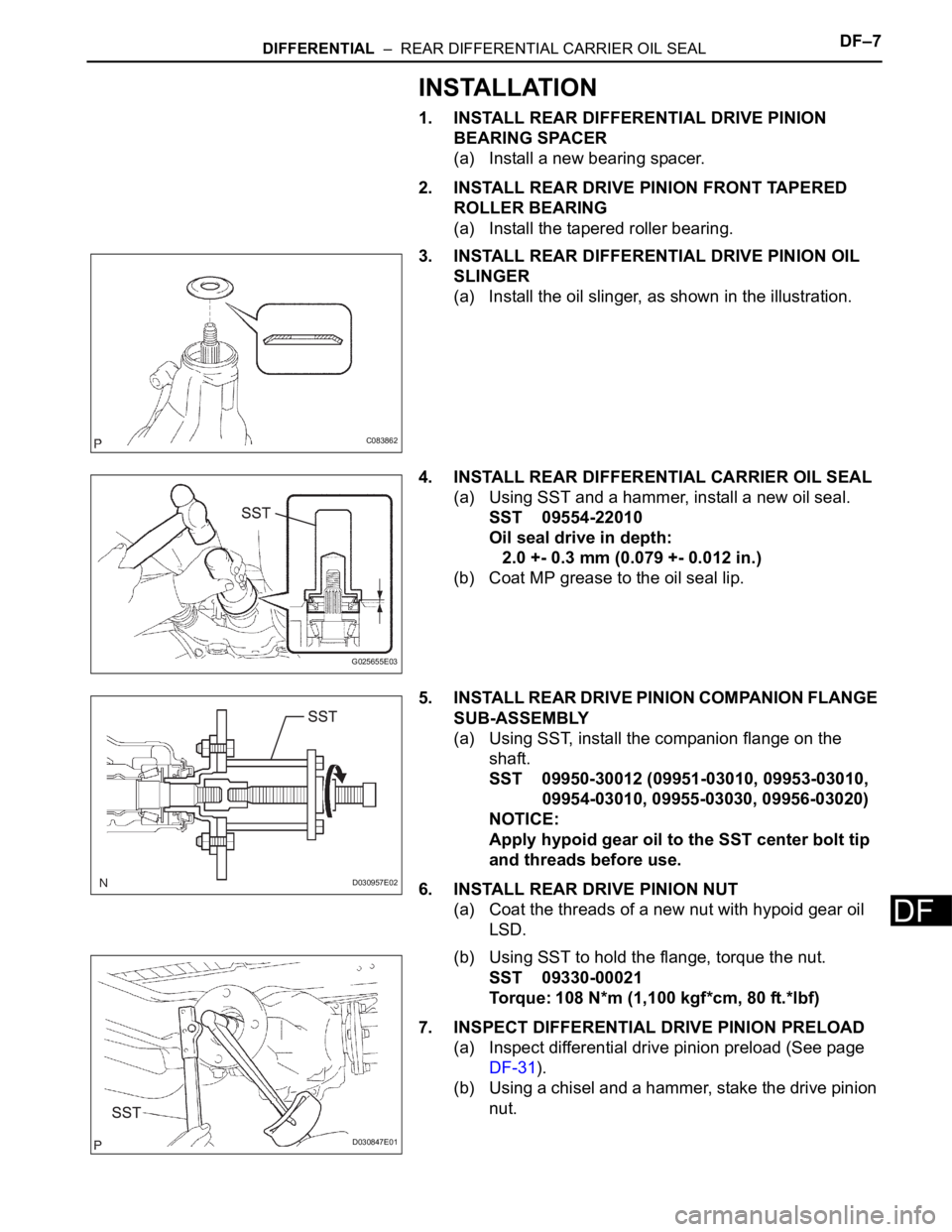

DIFFERENTIAL – REAR DIFFERENTIAL CARRIER OIL SEALDF–7

DF

INSTALLATION

1. INSTALL REAR DIFFERENTIAL DRIVE PINION

BEARING SPACER

(a) Install a new bearing spacer.

2. INSTALL REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Install the tapered roller bearing.

3. INSTALL REAR DIFFERENTIAL DRIVE PINION OIL

SLINGER

(a) Install the oil slinger, as shown in the illustration.

4. INSTALL REAR DIFFERENTIAL CARRIER OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09554-22010

Oil seal drive in depth:

2.0 +- 0.3 mm (0.079 +- 0.012 in.)

(b) Coat MP grease to the oil seal lip.

5. INSTALL REAR DRIVE PINION COMPANION FLANGE

SUB-ASSEMBLY

(a) Using SST, install the companion flange on the

shaft.

SST 09950-30012 (09951-03010, 09953-03010,

09954-03010, 09955-03030, 09956-03020)

NOTICE:

Apply hypoid gear oil to the SST center bolt tip

and threads before use.

6. INSTALL REAR DRIVE PINION NUT

(a) Coat the threads of a new nut with hypoid gear oil

LSD.

(b) Using SST to hold the flange, torque the nut.

SST 09330-00021

Torque: 108 N*m (1,100 kgf*cm, 80 ft.*lbf)

7. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD

(a) Inspect differential drive pinion preload (See page

DF-31).

(b) Using a chisel and a hammer, stake the drive pinion

nut.

C083862

G025655E03

D030957E02

D030847E01

Page 162 of 3000

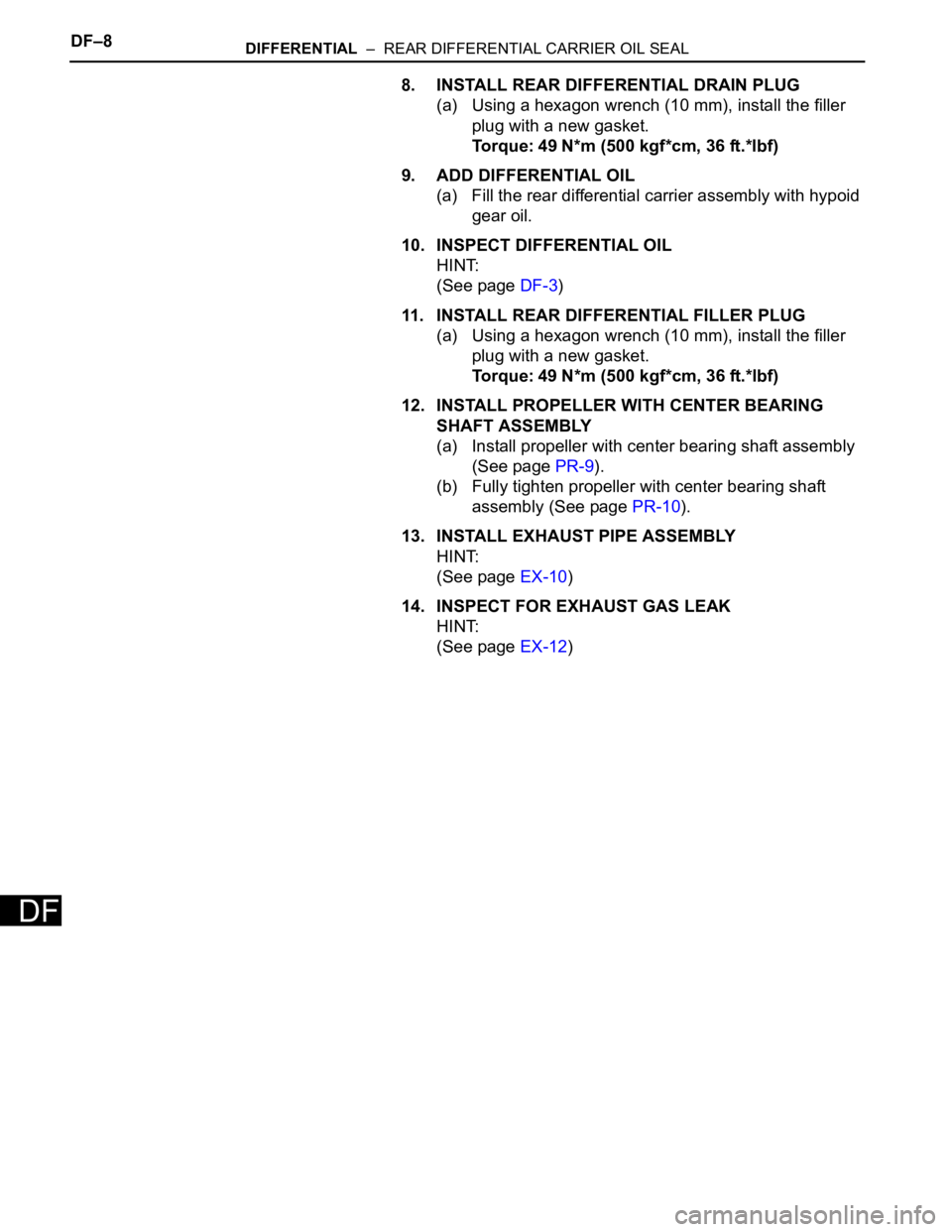

DF–8DIFFERENTIAL – REAR DIFFERENTIAL CARRIER OIL SEAL

DF

8. INSTALL REAR DIFFERENTIAL DRAIN PLUG

(a) Using a hexagon wrench (10 mm), install the filler

plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

9. ADD DIFFERENTIAL OIL

(a) Fill the rear differential carrier assembly with hypoid

gear oil.

10. INSPECT DIFFERENTIAL OIL

HINT:

(See page DF-3)

11. INSTALL REAR DIFFERENTIAL FILLER PLUG

(a) Using a hexagon wrench (10 mm), install the filler

plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

12. INSTALL PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY

(a) Install propeller with center bearing shaft assembly

(See page PR-9).

(b) Fully tighten propeller with center bearing shaft

assembly (See page PR-10).

13. INSTALL EXHAUST PIPE ASSEMBLY

HINT:

(See page EX-10)

14. INSPECT FOR EXHAUST GAS LEAK

HINT:

(See page EX-12)

Page 214 of 3000

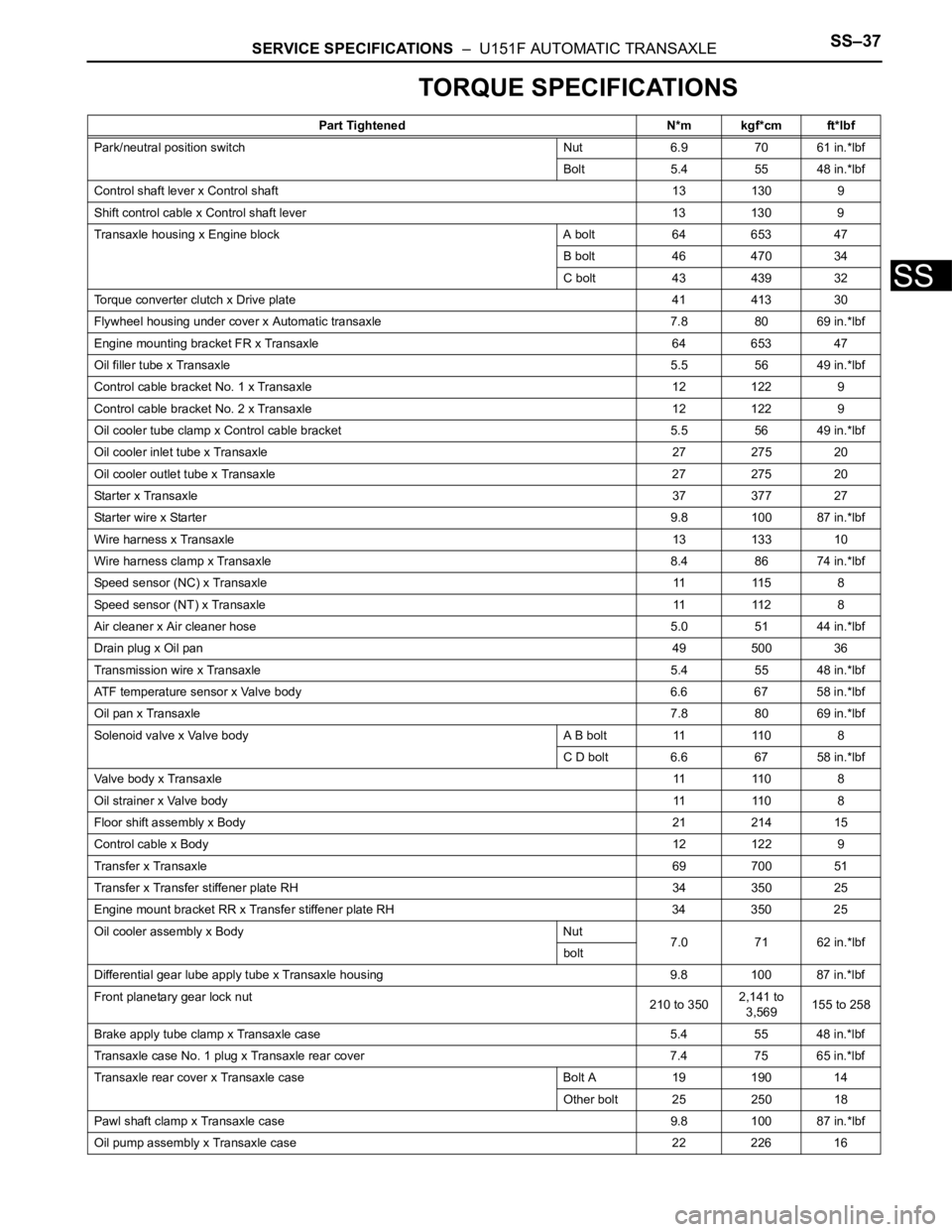

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–37

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 130 9

Shift control cable x Control shaft lever 13 130 9

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

C bolt 43 439 32

Torque converter clutch x Drive plate 41 413 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.5 56 49 in.*lbf

Oil cooler inlet tube x Transaxle27 275 20

Oil cooler outlet tube x Transaxle 27 275 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 87 in.*lbf

Wire harness x Transaxle13 133 10

Wire harness clamp x Transaxle8.4 86 74 in.*lbf

Speed sensor (NC) x Transaxle11 11 5 8

Speed sensor (NT) x Transaxle11 11 2 8

Air cleaner x Air cleaner hose5.0 51 44 in.*lbf

Drain plug x Oil pan49 500 36

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body A B bolt 11 110 8

C D bolt 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 0 8

Oil strainer x Valve body11 11 0 8

Floor shift assembly x Body21 214 15

Control cable x Body12 122 9

Transfer x Transaxle69 700 51

Transfer x Transfer stiffener plate RH 34 350 25

Engine mount bracket RR x Transfer stiffener plate RH 34 350 25

Oil cooler assembly x Body Nut

7.0 71 62 in.*lbf

bolt

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut

210 to 3502,141 to

3,569155 to 258

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 190 14

Other bolt 25 250 18

Pawl shaft clamp x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Page 215 of 3000

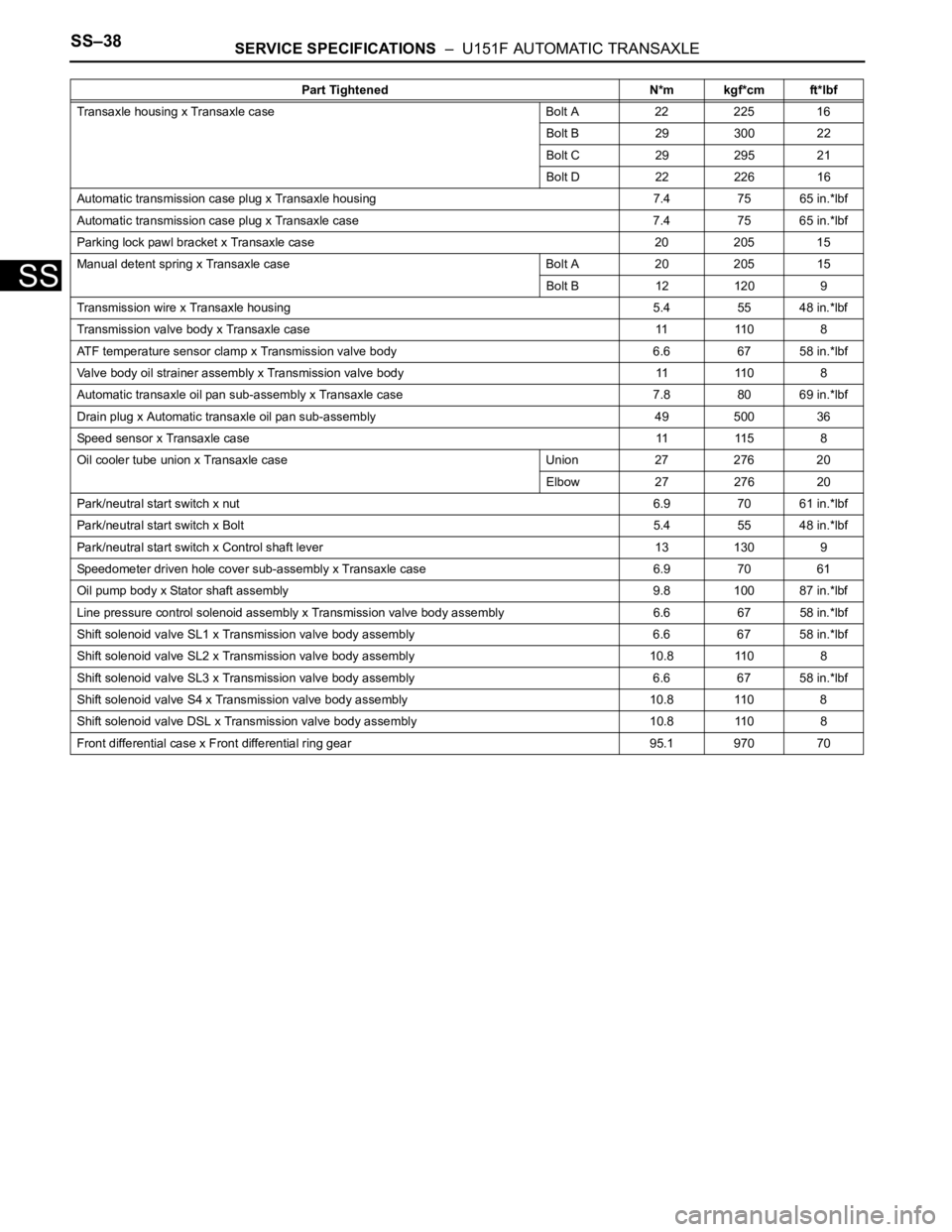

SS–38SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLE

SS

Transaxle housing x Transaxle case Bolt A 22 225 16

Bolt B 29 300 22

Bolt C 29 295 21

Bolt D 22 226 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Transmission wire x Transaxle housing 5.4 55 48 in.*lbf

Transmission valve body x Transaxle case 11 110 8

ATF temperature sensor clamp x Transmission valve body 6.6 67 58 in.*lbf

Valve body oil strainer assembly x Transmission valve body 11 1108

Automatic transaxle oil pan sub-assembly x Transaxle case 7.8 80 69 in.*lbf

Drain plug x Automatic transaxle oil pan sub-assembly 49 500 36

Speed sensor x Transaxle case11 11 5 8

Oil cooler tube union x Transaxle case Union 27 276 20

Elbow 27 276 20

Park/neutral start switch x nut6.9 70 61 in.*lbf

Park/neutral start switch x Bolt5.4 55 48 in.*lbf

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 6.9 7061

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Line pressure control solenoid assembly x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL1 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL2 x Transmission valve body assembly 10.811 0 8

Shift solenoid valve SL3 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve S4 x Transmission valve body assembly 10.8 110 8

Shift solenoid valve DSL x Transmission valve body assembly 10.811 0 8

Front differential case x Front differential ring gear 95.1 970 70Part Tightened N*m kgf*cm ft*lbf

Page 217 of 3000

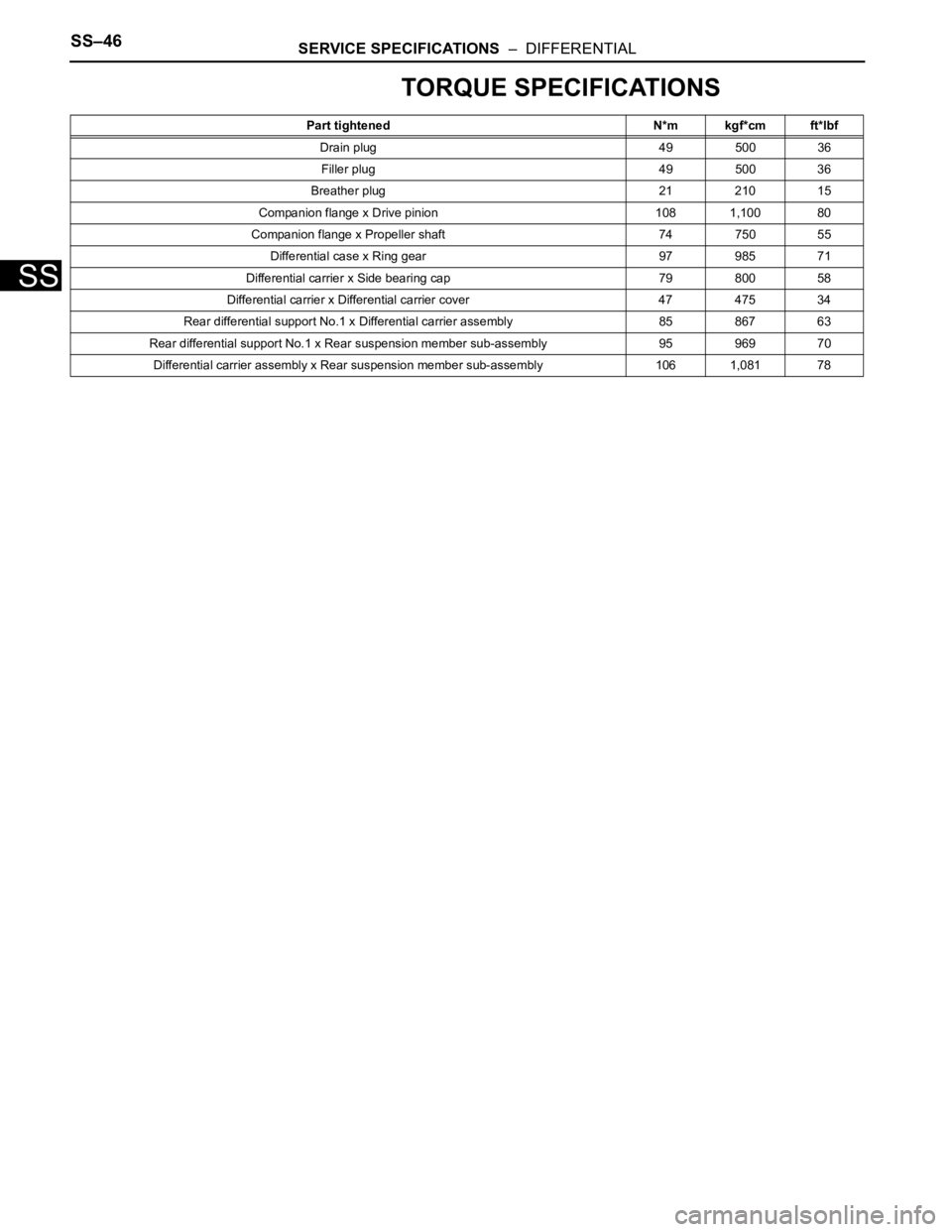

SS–46SERVICE SPECIFICATIONS – DIFFERENTIAL

SS

TORQUE SPECIFICATIONS

Part tightened N*m kgf*cm ft*lbf

Drain plug 49 500 36

Filler plug 49 500 36

Breather plug 21 210 15

Companion flange x Drive pinion 108 1,100 80

Companion flange x Propeller shaft 74 750 55

Differential case x Ring gear 97 985 71

Differential carrier x Side bearing cap 79 800 58

Differential carrier x Differential carrier cover 47 475 34

Rear differential support No.1 x Differential carrier assembly 8586763

Rear differential support No.1 x Rear suspension member sub-assembly 95 969 70

Differential carrier assembly x Rear suspension member sub-assembly 106 1,081 78

Page 218 of 3000

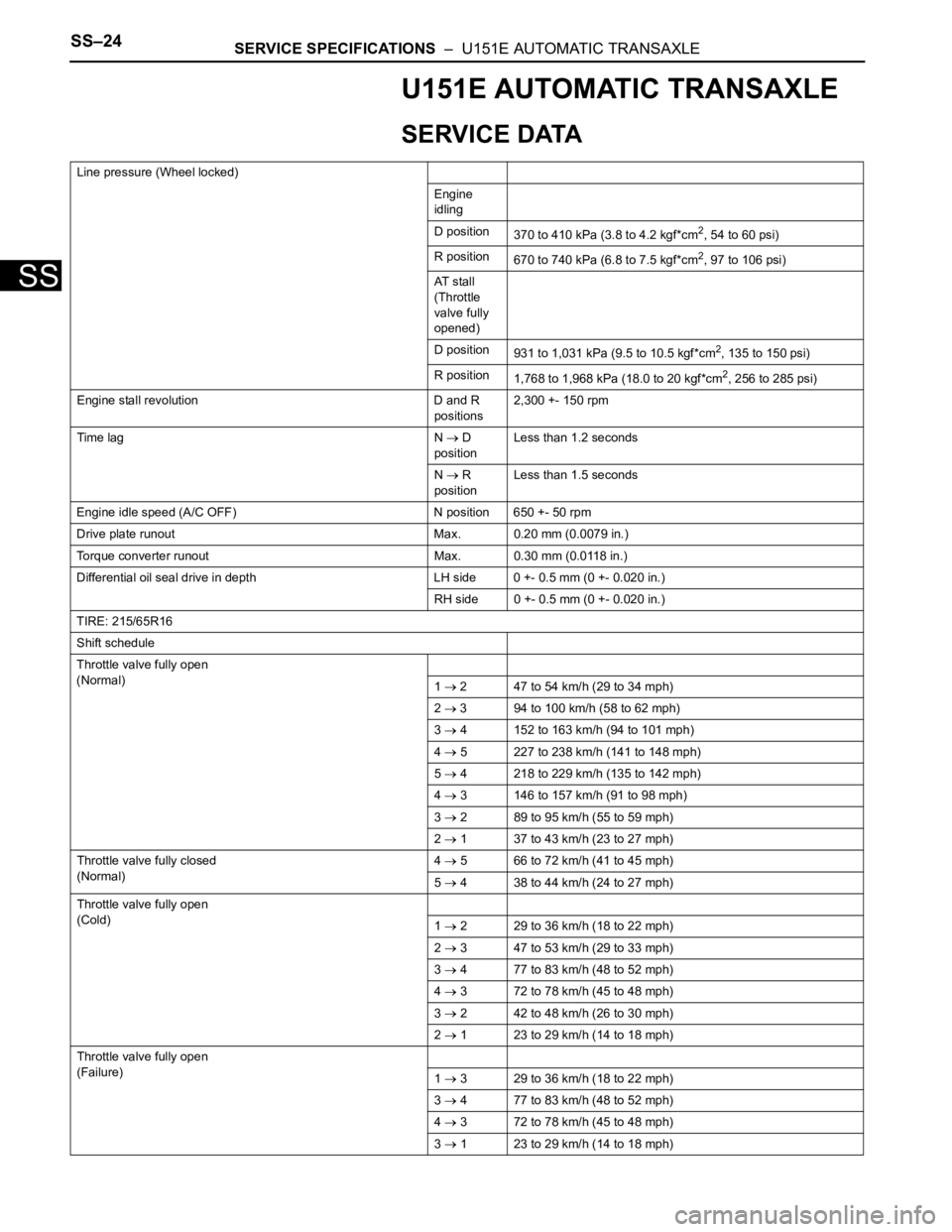

SS–24SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

U151E AUTOMATIC TRANSAXLE

SERVICE DATA

Line pressure (Wheel locked)

Engine

idling

D position

370 to 410 kPa (3.8 to 4.2 kgf*cm

2, 54 to 60 psi)

R position

670 to 740 kPa (6.8 to 7.5 kgf*cm

2, 97 to 106 psi)

AT s t a l l

(Throttle

valve fully

opened)

D position

931 to 1,031 kPa (9.5 to 10.5 kgf*cm

2, 135 to 150 psi)

R position

1,768 to 1,968 kPa (18.0 to 20 kgf*cm

2, 256 to 285 psi)

Engine stall revolution D and R

positions2,300 +- 150 rpm

Time lag N

D

positionLess than 1.2 seconds

N

R

positionLess than 1.5 seconds

Engine idle speed (A/C OFF) N position 650 +- 50 rpm

Drive plate runout Max. 0.20 mm (0.0079 in.)

Torque converter runout Max. 0.30 mm (0.0118 in.)

Differential oil seal drive in depth LH side 0 +- 0.5 mm (0 +- 0.020 in.)

RH side 0 +- 0.5 mm (0 +- 0.020 in.)

TIRE: 215/65R16

Shift schedule

Throttle valve fully open

(Normal)

1

2 47 to 54 km/h (29 to 34 mph)

2

3 94 to 100 km/h (58 to 62 mph)

3

4 152 to 163 km/h (94 to 101 mph)

4

5 227 to 238 km/h (141 to 148 mph)

5

4 218 to 229 km/h (135 to 142 mph)

4

3 146 to 157 km/h (91 to 98 mph)

3

2 89 to 95 km/h (55 to 59 mph)

2

1 37 to 43 km/h (23 to 27 mph)

Throttle valve fully closed

(Normal)4

5 66 to 72 km/h (41 to 45 mph)

5

4 38 to 44 km/h (24 to 27 mph)

Throttle valve fully open

(Cold)

1

2 29 to 36 km/h (18 to 22 mph)

2

3 47 to 53 km/h (29 to 33 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

2 42 to 48 km/h (26 to 30 mph)

2

1 23 to 29 km/h (14 to 18 mph)

Throttle valve fully open

(Failure)

1

3 29 to 36 km/h (18 to 22 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

1 23 to 29 km/h (14 to 18 mph)

Page 222 of 3000

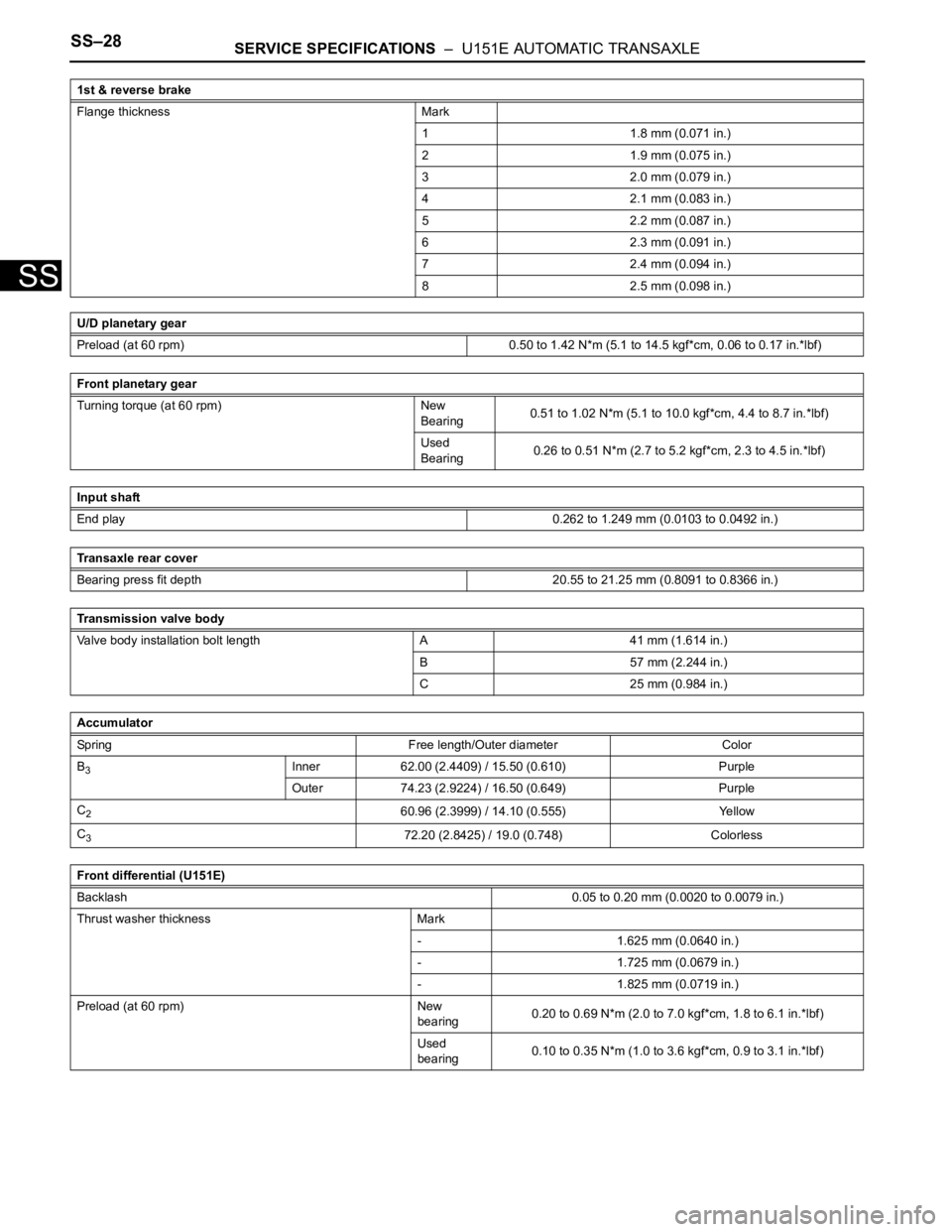

SS–28SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

Flange thickness Mark

1 1.8 mm (0.071 in.)

2 1.9 mm (0.075 in.)

3 2.0 mm (0.079 in.)

4 2.1 mm (0.083 in.)

5 2.2 mm (0.087 in.)

6 2.3 mm (0.091 in.)

7 2.4 mm (0.094 in.)

8 2.5 mm (0.098 in.)

U/D planetary gear

Preload (at 60 rpm) 0.50 to 1.42 N*m (5.1 to 14.5 kgf*cm, 0.06 to 0.17 in.*lbf)

Front planetary gear

Turning torque (at 60 rpm) New

Bearing0.51 to 1.02 N*m (5.1 to 10.0 kgf*cm, 4.4 to 8.7 in.*lbf)

Used

Bearing0.26 to 0.51 N*m (2.7 to 5.2 kgf*cm, 2.3 to 4.5 in.*lbf)

Input shaft

End play0.262 to 1.249 mm (0.0103 to 0.0492 in.)

Transaxle rear cover

Bearing press fit depth 20.55 to 21.25 mm (0.8091 to 0.8366 in.)

Transmission valve body

Valve body installation bolt length A 41 mm (1.614 in.)

B 57 mm (2.244 in.)

C 25 mm (0.984 in.)

Accumulator

Spring Free length/Outer diameter Color

B

3Inner 62.00 (2.4409) / 15.50 (0.610) Purple

Outer 74.23 (2.9224) / 16.50 (0.649) Purple

C

260.96 (2.3999) / 14.10 (0.555) Yellow

C

372.20 (2.8425) / 19.0 (0.748) Colorless

Front differential (U151E)

Backlash0.05 to 0.20 mm (0.0020 to 0.0079 in.)

Thrust washer thickness Mark

- 1.625 mm (0.0640 in.)

- 1.725 mm (0.0679 in.)

- 1.825 mm (0.0719 in.)

Preload (at 60 rpm) New

bearing0.20 to 0.69 N*m (2.0 to 7.0 kgf*cm, 1.8 to 6.1 in.*lbf)

Used

bearing0.10 to 0.35 N*m (1.0 to 3.6 kgf*cm, 0.9 to 3.1 in.*lbf) 1st & reverse brake