TOYOTA SUPRA 1986 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1986, Model line: SUPRA, Model: TOYOTA SUPRA 1986Pages: 878, PDF Size: 20 MB

Page 441 of 878

(d) Install the bearing caps.

(See step 2 in cylinder head installation (2JZ±GE))

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

NOTICE: Do not turn the camshaft.

(e) Remove the bearing caps.

(f) Measure the Plastigage at its widest point.

Standard oil clearance:

0.035±0.072 mm (0.0014±0.0028 in.)

Maximum oil clearance:

0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace the cam-

shaft. If necessary, replace the bearing caps and cylinder

head as a set.

(g) Completely remove the Plastigage.

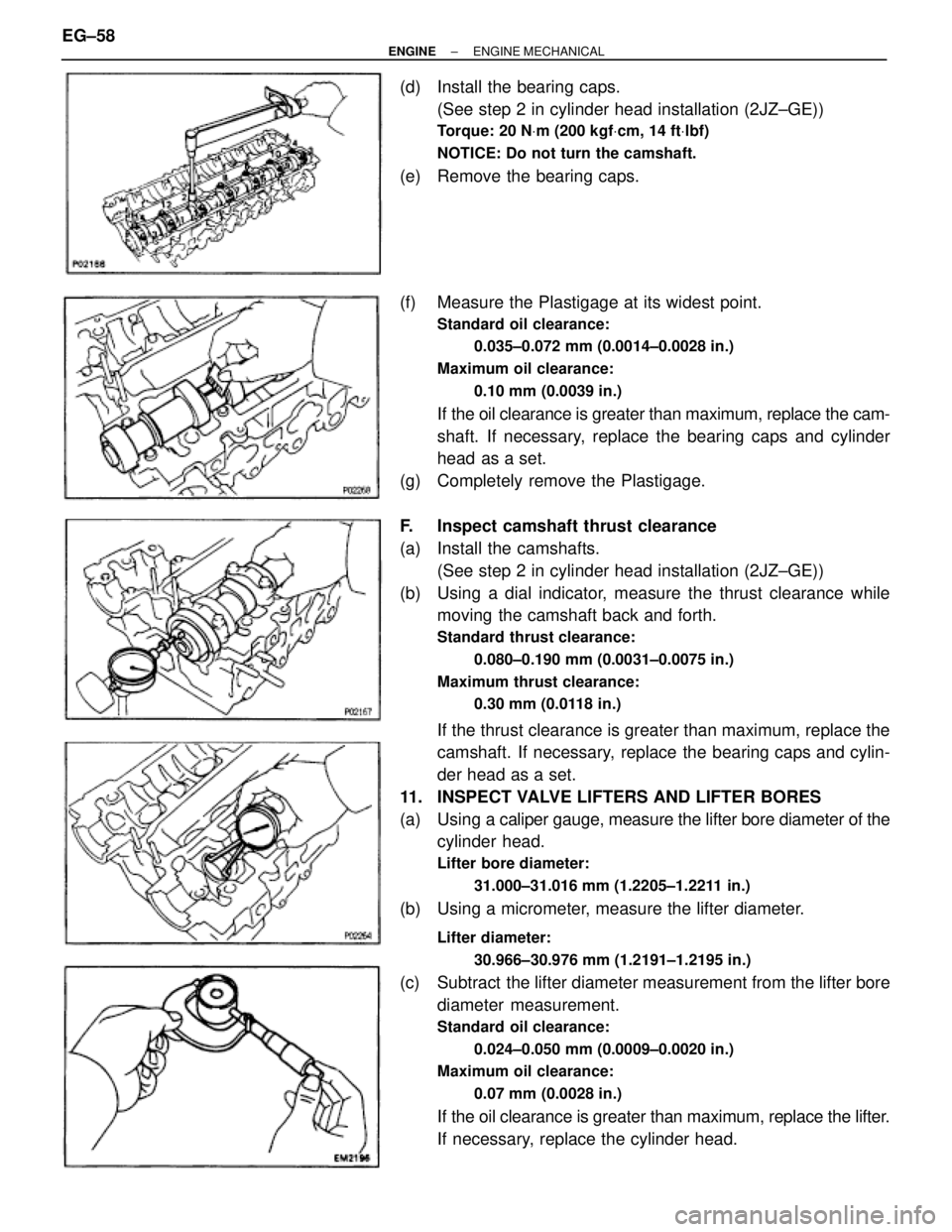

F. Inspect camshaft thrust clearance

(a) Install the camshafts.

(See step 2 in cylinder head installation (2JZ±GE))

(b) Using a dial indicator, measure the thrust clearance while

moving the camshaft back and forth.

Standard thrust clearance:

0.080±0.190 mm (0.0031±0.0075 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than maximum, replace the

camshaft. If necessary, replace the bearing caps and cylin-

der head as a set.

11. INSPECT VALVE LIFTERS AND LIFTER BORES

(a) Using a caliper gauge, measure the lifter bore diameter of the

cylinder head.

Lifter bore diameter:

31.000±31.016 mm (1.2205±1.2211 in.)

(b) Using a micrometer, measure the lifter diameter.

Lifter diameter:

30.966±30.976 mm (1.2191±1.2195 in.)

(c) Subtract the lifter diameter measurement from the lifter bore

diameter measurement.

Standard oil clearance:

0.024±0.050 mm (0.0009±0.0020 in.)

Maximum oil clearance:

0.07 mm (0.0028 in.)

If the oil clearance is greater than maximum, replace the lifter.

If necessary, replace the cylinder head. EG±58

± ENGINEENGINE MECHANICAL

Page 442 of 878

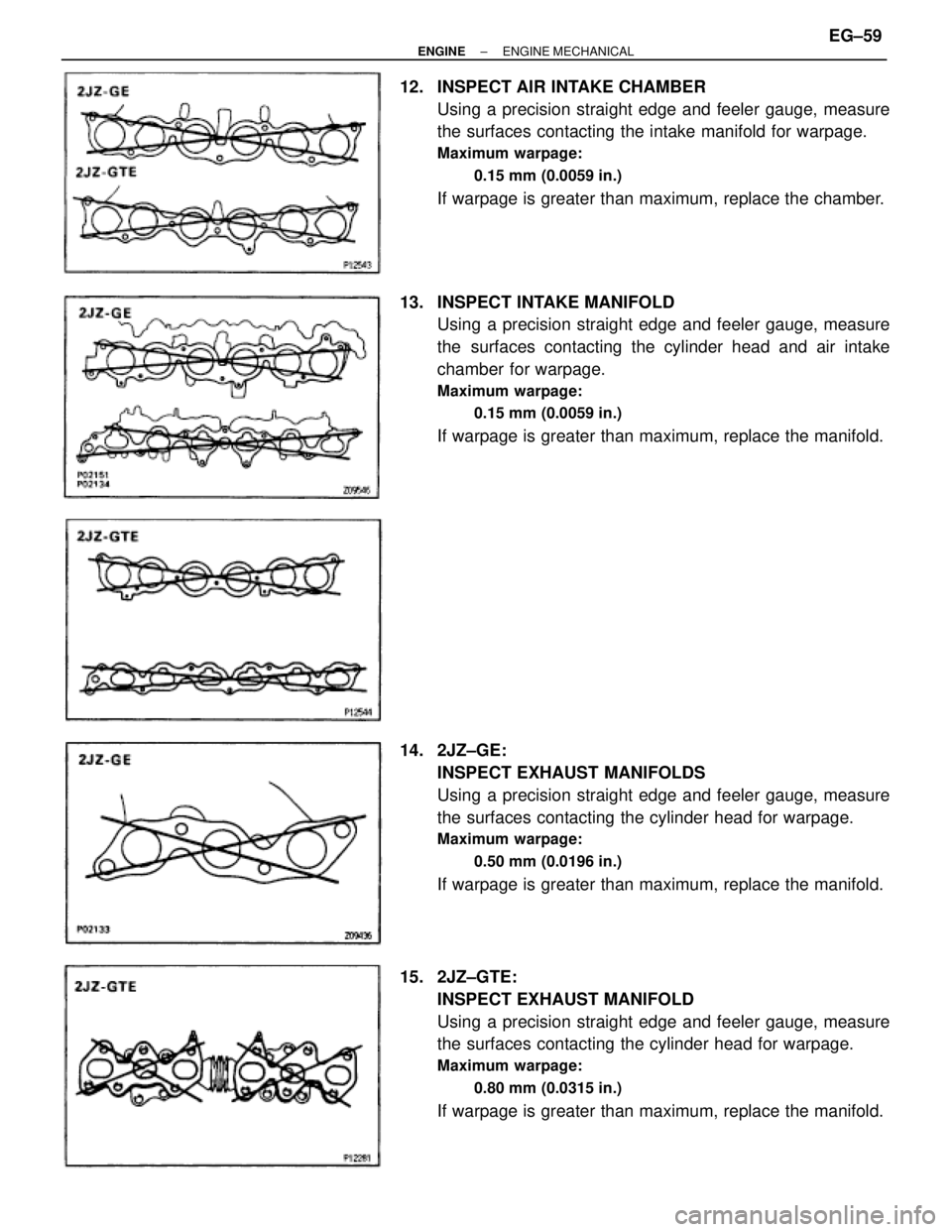

12. INSPECT AIR INTAKE CHAMBER

Using a precision straight edge and feeler gauge, measure

the surfaces contacting the intake manifold for warpage.

Maximum warpage:

0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the chamber.

13. INSPECT INTAKE MANIFOLD

Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder head and air intake

chamber for warpage.

Maximum warpage:

0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the manifold.

14. 2JZ±GE:

INSPECT EXHAUST MANIFOLDS

Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder head for warpage.

Maximum warpage:

0.50 mm (0.0196 in.)

If warpage is greater than maximum, replace the manifold.

15. 2JZ±GTE:

INSPECT EXHAUST MANIFOLD

Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder head for warpage.

Maximum warpage:

0.80 mm (0.0315 in.)

If warpage is greater than maximum, replace the manifold.

± ENGINEENGINE MECHANICALEG±59

Page 443 of 878

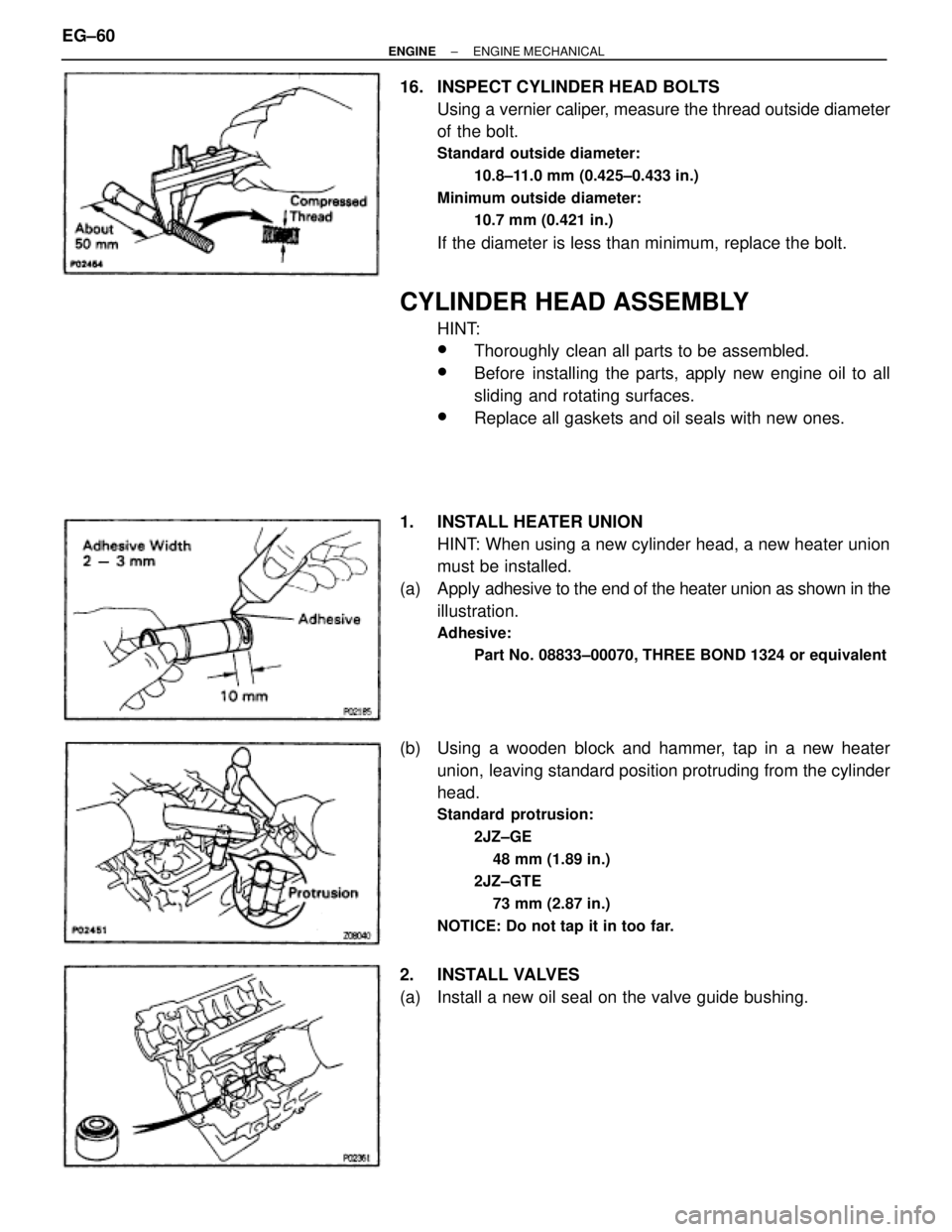

16. INSPECT CYLINDER HEAD BOLTS

Using a vernier caliper, measure the thread outside diameter

of the bolt.

Standard outside diameter:

10.8±11.0 mm (0.425±0.433 in.)

Minimum outside diameter:

10.7 mm (0.421 in.)

If the diameter is less than minimum, replace the bolt.

CYLINDER HEAD ASSEMBLY

HINT:

wThoroughly clean all parts to be assembled.

wBefore installing the parts, apply new engine oil to all

sliding and rotating surfaces.

wReplace all gaskets and oil seals with new ones.

1. INSTALL HEATER UNION

HINT: When using a new cylinder head, a new heater union

must be installed.

(a) Apply adhesive to the end of the heater union as shown in the

illustration.

Adhesive:

Part No. 08833±00070, THREE BOND 1324 or equivalent

(b) Using a wooden block and hammer, tap in a new heater

union, leaving standard position protruding from the cylinder

head.

Standard protrusion:

2JZ±GE

48 mm (1.89 in.)

2JZ±GTE

73 mm (2.87 in.)

NOTICE: Do not tap it in too far.

2. INSTALL VALVES

(a) Install a new oil seal on the valve guide bushing. EG±60

± ENGINEENGINE MECHANICAL

Page 444 of 878

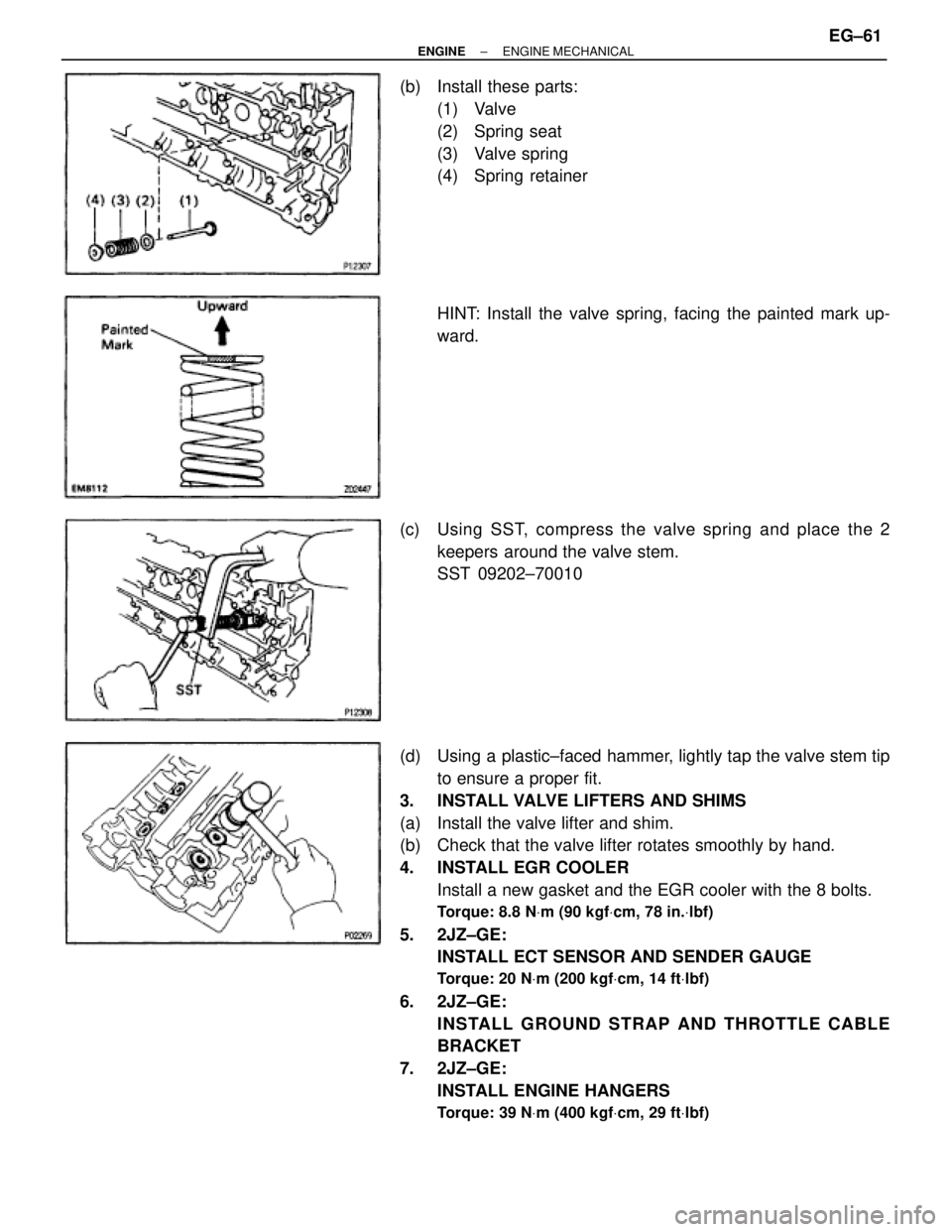

(b) Install these parts:

(1) Valve

(2) Spring seat

(3) Valve spring

(4) Spring retainer

HINT: Install the valve spring, facing the painted mark up-

ward.

(c) Using SST, compress the valve spring and place the 2

keepers around the valve stem.

SST 09202±70010

(d) Using a plastic±faced hammer, lightly tap the valve stem tip

to ensure a proper fit.

3. INSTALL VALVE LIFTERS AND SHIMS

(a) Install the valve lifter and shim.

(b) Check that the valve lifter rotates smoothly by hand.

4. INSTALL EGR COOLER

Install a new gasket and the EGR cooler with the 8 bolts.

Torque: 8.8 NVm (90 kgfVcm, 78 in.Vlbf)

5. 2JZ±GE:

INSTALL ECT SENSOR AND SENDER GAUGE

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

6. 2JZ±GE:

INSTALL GROUND STRAP AND THROTTLE CABLE

BRACKET

7. 2JZ±GE:

INSTALL ENGINE HANGERS

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

± ENGINEENGINE MECHANICALEG±61

Page 445 of 878

8. 2JZ±GTE:

INSTALL CAMSHAFT POSITION SENSORS

Install the gasket and sensor with the 2 bolts.

Torque: 8.8 NVm (90 kgfVcm, 78 in.Vlbf)

9. 2JZ±GTE:

INSTALL ENGINE HANGERS AND GROUND STRAP

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

CYLINDER HEAD INSTALLATION

(2JZ±GE)

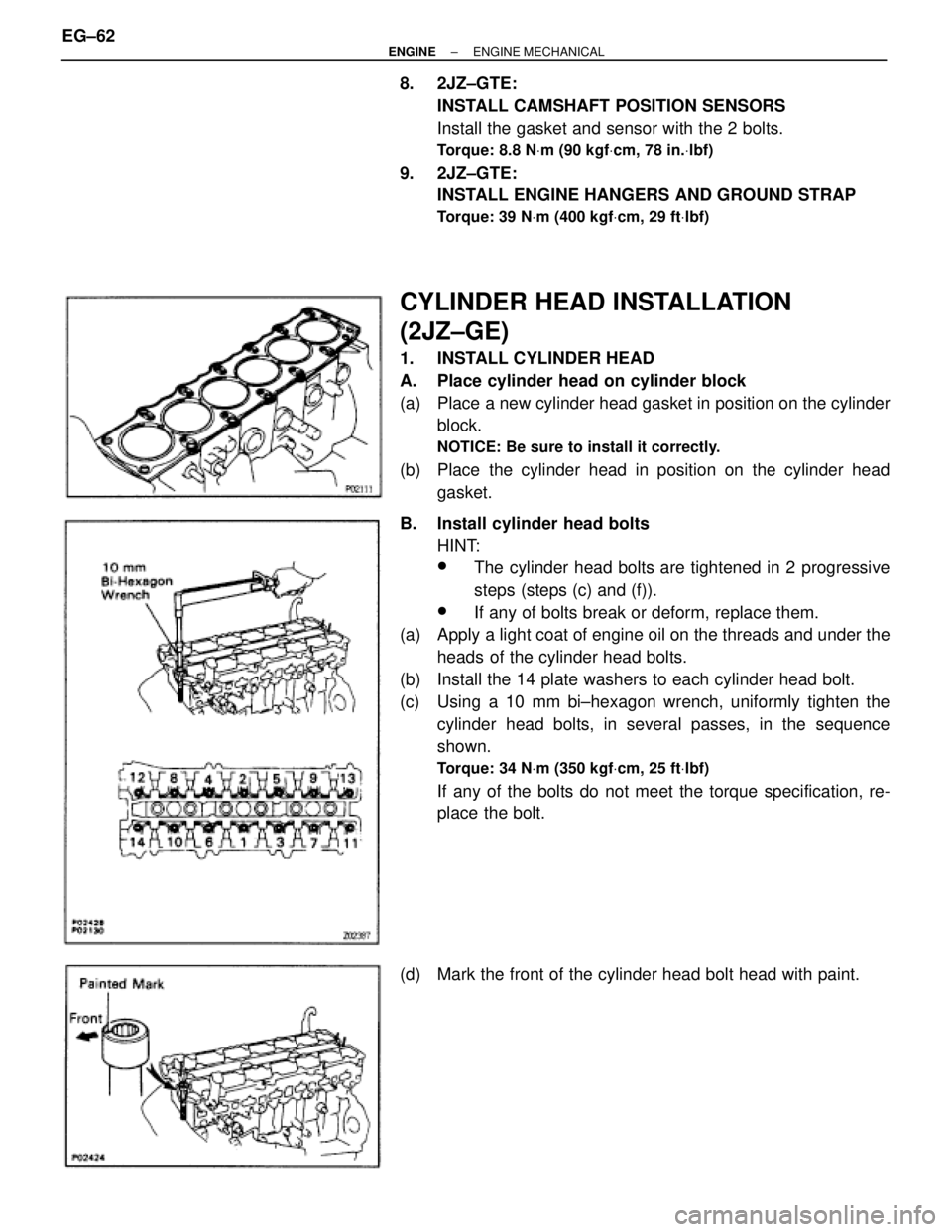

1. INSTALL CYLINDER HEAD

A. Place cylinder head on cylinder block

(a) Place a new cylinder head gasket in position on the cylinder

block.

NOTICE: Be sure to install it correctly.

(b) Place the cylinder head in position on the cylinder head

gasket.

B. Install cylinder head bolts

HINT:

wThe cylinder head bolts are tightened in 2 progressive

steps (steps (c) and (f)).

wIf any of bolts break or deform, replace them.

(a) Apply a light coat of engine oil on the threads and under the

heads of the cylinder head bolts.

(b) Install the 14 plate washers to each cylinder head bolt.

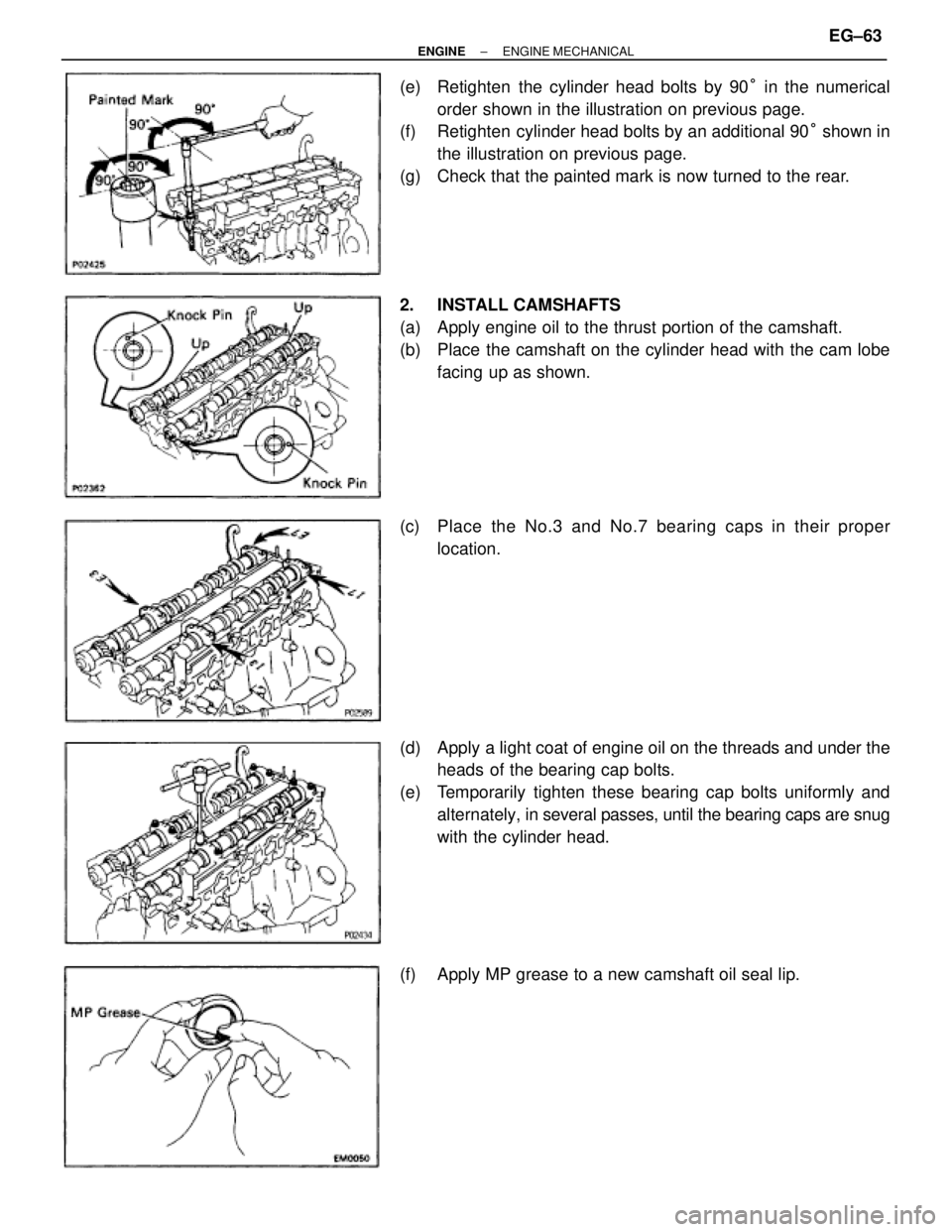

(c) Using a 10 mm bi±hexagon wrench, uniformly tighten the

cylinder head bolts, in several passes, in the sequence

shown.

Torque: 34 NVm (350 kgfVcm, 25 ftVlbf)

If any of the bolts do not meet the torque specification, re-

place the bolt.

(d) Mark the front of the cylinder head bolt head with paint. EG±62

± ENGINEENGINE MECHANICAL

Page 446 of 878

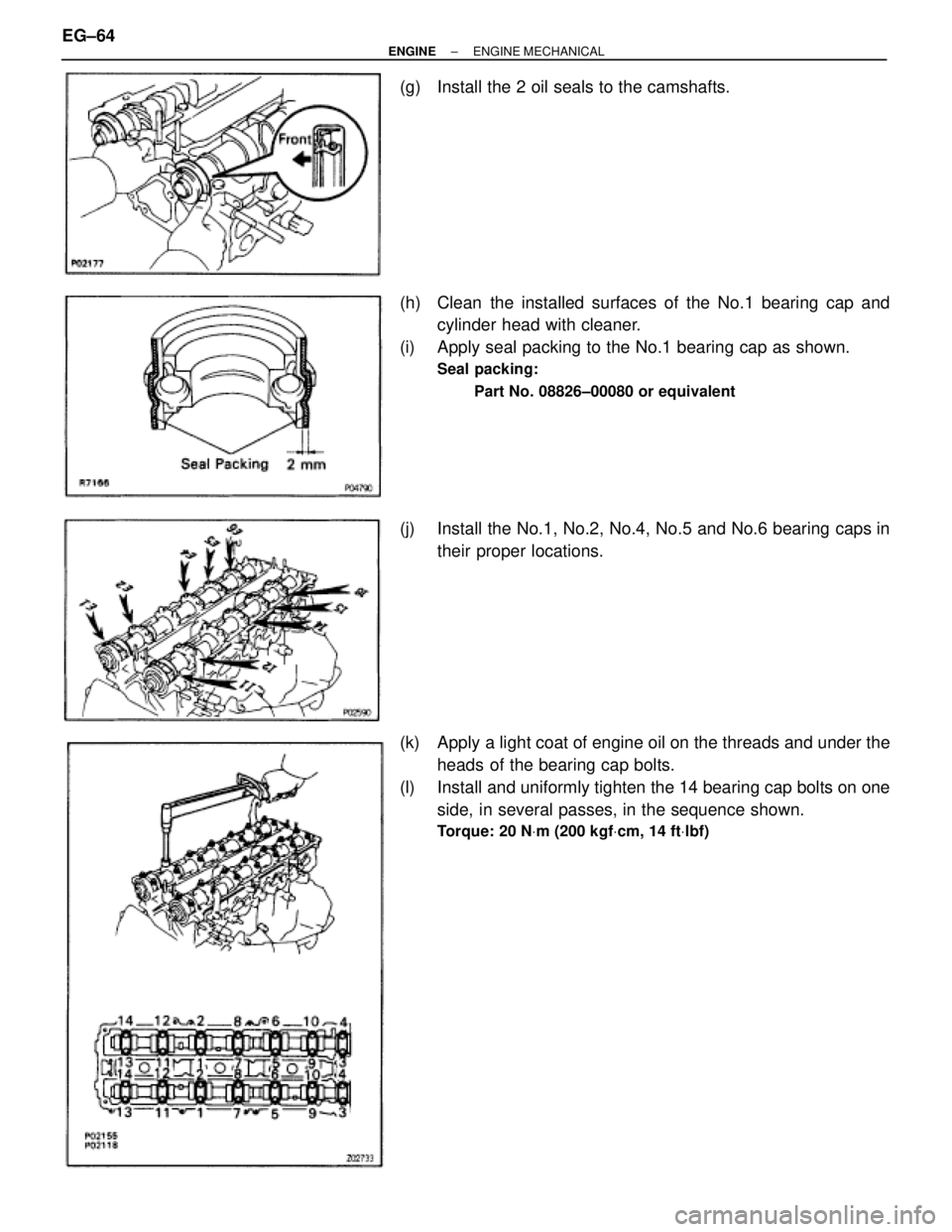

(e) Retighten the cylinder head bolts by 90° in the numerical

order shown in the illustration on previous page.

(f) Retighten cylinder head bolts by an additional 90° shown in

the illustration on previous page.

(g) Check that the painted mark is now turned to the rear.

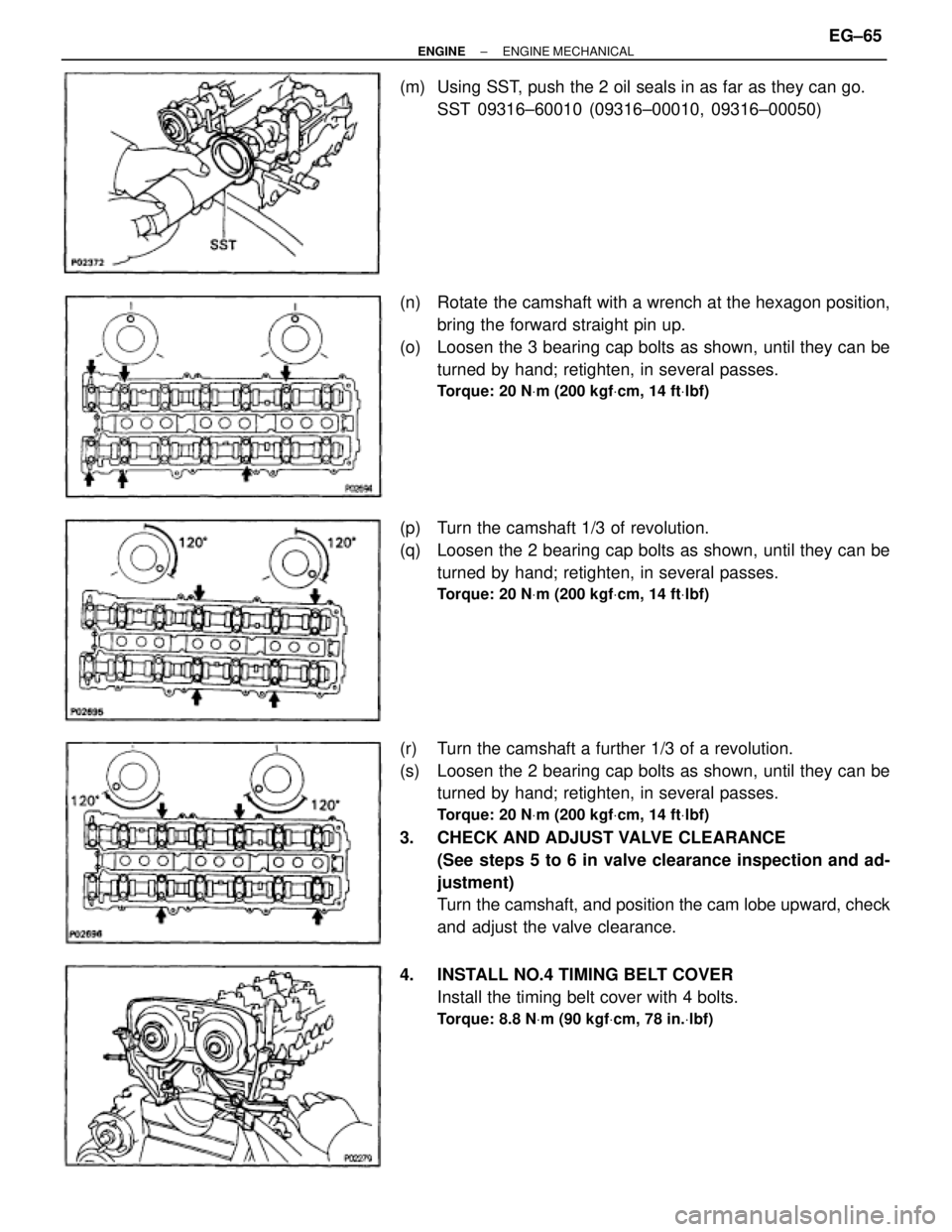

2. INSTALL CAMSHAFTS

(a) Apply engine oil to the thrust portion of the camshaft.

(b) Place the camshaft on the cylinder head with the cam lobe

facing up as shown.

(c) Place the No.3 and No.7 bearing caps in their proper

location.

(d) Apply a light coat of engine oil on the threads and under the

heads of the bearing cap bolts.

(e) Temporarily tighten these bearing cap bolts uniformly and

alternately, in several passes, until the bearing caps are snug

with the cylinder head.

(f) Apply MP grease to a new camshaft oil seal lip.

± ENGINEENGINE MECHANICALEG±63

Page 447 of 878

(g) Install the 2 oil seals to the camshafts.

(h) Clean the installed surfaces of the No.1 bearing cap and

cylinder head with cleaner.

(i) Apply seal packing to the No.1 bearing cap as shown.

Seal packing:

Part No. 08826±00080 or equivalent

(j) Install the No.1, No.2, No.4, No.5 and No.6 bearing caps in

their proper locations.

(k) Apply a light coat of engine oil on the threads and under the

heads of the bearing cap bolts.

(l) Install and uniformly tighten the 14 bearing cap bolts on one

side, in several passes, in the sequence shown.

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

EG±64± ENGINEENGINE MECHANICAL

Page 448 of 878

(m) Using SST, push the 2 oil seals in as far as they can go.

SST 09316±60010 (09316±00010, 09316±00050)

(n) Rotate the camshaft with a wrench at the hexagon position,

bring the forward straight pin up.

(o) Loosen the 3 bearing cap bolts as shown, until they can be

turned by hand; retighten, in several passes.

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

(p) Turn the camshaft 1/3 of revolution.

(q) Loosen the 2 bearing cap bolts as shown, until they can be

turned by hand; retighten, in several passes.

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

(r) Turn the camshaft a further 1/3 of a revolution.

(s) Loosen the 2 bearing cap bolts as shown, until they can be

turned by hand; retighten, in several passes.

Torque: 20 NVm (200 kgfVcm, 14 ftVlbf)

3. CHECK AND ADJUST VALVE CLEARANCE

(See steps 5 to 6 in valve clearance inspection and ad-

justment)

Turn the camshaft, and position the cam lobe upward, check

and adjust the valve clearance.

4. INSTALL NO.4 TIMING BELT COVER

Install the timing belt cover with 4 bolts.

Torque: 8.8 NVm (90 kgfVcm, 78 in.Vlbf)

± ENGINEENGINE MECHANICALEG±65

Page 449 of 878

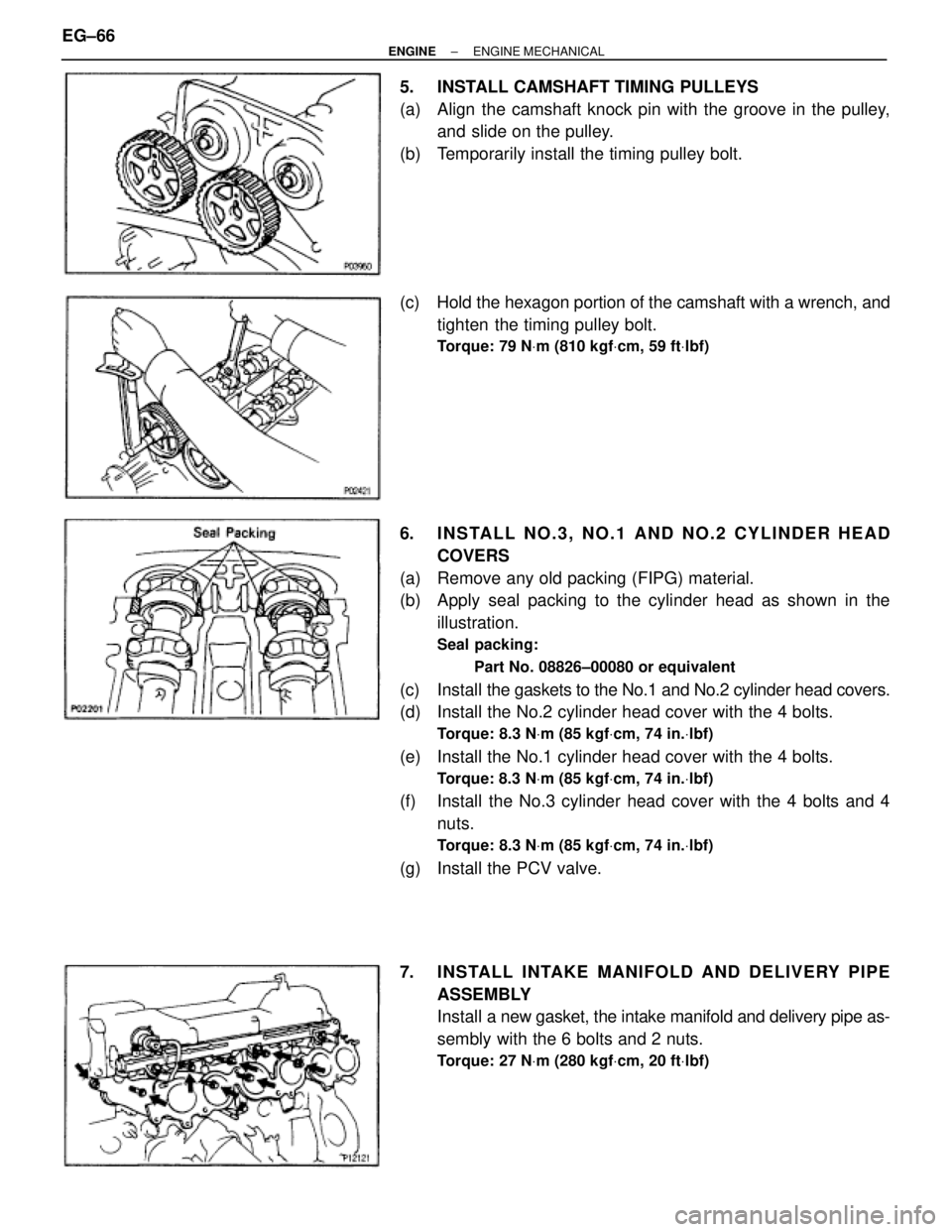

5. INSTALL CAMSHAFT TIMING PULLEYS

(a) Align the camshaft knock pin with the groove in the pulley,

and slide on the pulley.

(b) Temporarily install the timing pulley bolt.

(c) Hold the hexagon portion of the camshaft with a wrench, and

tighten the timing pulley bolt.

Torque: 79 NVm (810 kgfVcm, 59 ftVlbf)

6. INSTALL NO.3, NO.1 AND NO.2 CYLINDER HEAD

COVERS

(a) Remove any old packing (FIPG) material.

(b) Apply seal packing to the cylinder head as shown in the

illustration.

Seal packing:

Part No. 08826±00080 or equivalent

(c) Install the gaskets to the No.1 and No.2 cylinder head covers.

(d) Install the No.2 cylinder head cover with the 4 bolts.

Torque: 8.3 NVm (85 kgfVcm, 74 in.Vlbf)

(e) Install the No.1 cylinder head cover with the 4 bolts.

Torque: 8.3 NVm (85 kgfVcm, 74 in.Vlbf)

(f) Install the No.3 cylinder head cover with the 4 bolts and 4

nuts.

Torque: 8.3 NVm (85 kgfVcm, 74 in.Vlbf)

(g) Install the PCV valve.

7. INSTALL INTAKE MANIFOLD AND DELIVERY PIPE

ASSEMBLY

Install a new gasket, the intake manifold and delivery pipe as-

sembly with the 6 bolts and 2 nuts.

Torque: 27 NVm (280 kgfVcm, 20 ftVlbf)

EG±66± ENGINEENGINE MECHANICAL

Page 450 of 878

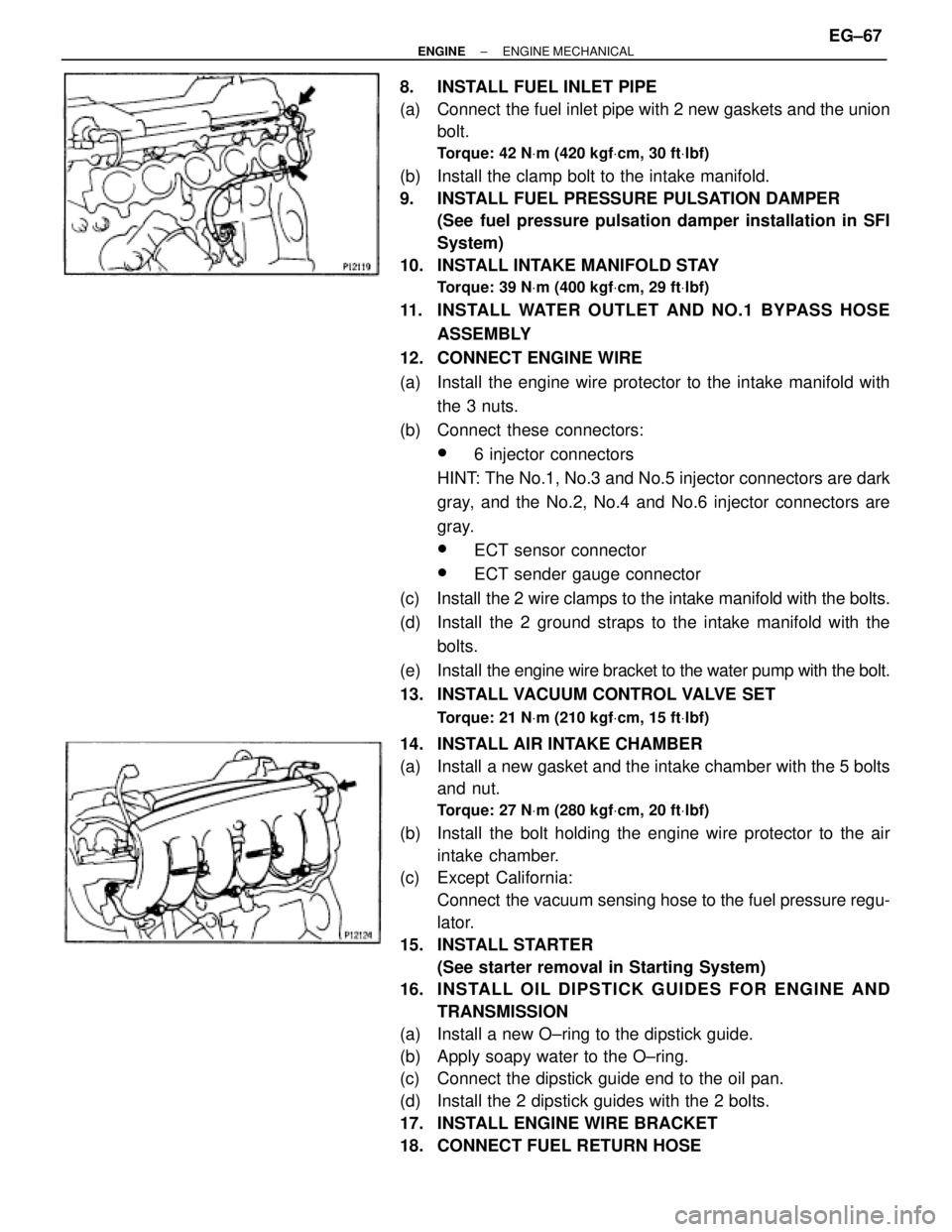

8. INSTALL FUEL INLET PIPE

(a) Connect the fuel inlet pipe with 2 new gaskets and the union

bolt.

Torque: 42 NVm (420 kgfVcm, 30 ftVlbf)

(b) Install the clamp bolt to the intake manifold.

9. INSTALL FUEL PRESSURE PULSATION DAMPER

(See fuel pressure pulsation damper installation in SFI

System)

10. INSTALL INTAKE MANIFOLD STAY

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

11. INSTALL WATER OUTLET AND NO.1 BYPASS HOSE

ASSEMBLY

12. CONNECT ENGINE WIRE

(a) Install the engine wire protector to the intake manifold with

the 3 nuts.

(b) Connect these connectors:

w6 injector connectors

HINT: The No.1, No.3 and No.5 injector connectors are dark

gray, and the No.2, No.4 and No.6 injector connectors are

gray.

wECT sensor connector

wECT sender gauge connector

(c) Install the 2 wire clamps to the intake manifold with the bolts.

(d) Install the 2 ground straps to the intake manifold with the

bolts.

(e) Install the engine wire bracket to the water pump with the bolt.

13. INSTALL VACUUM CONTROL VALVE SET

Torque: 21 NVm (210 kgfVcm, 15 ftVlbf)

14. INSTALL AIR INTAKE CHAMBER

(a) Install a new gasket and the intake chamber with the 5 bolts

and nut.

Torque: 27 NVm (280 kgfVcm, 20 ftVlbf)

(b) Install the bolt holding the engine wire protector to the air

intake chamber.

(c) Except California:

Connect the vacuum sensing hose to the fuel pressure regu-

lator.

15. INSTALL STARTER

(See starter removal in Starting System)

16. INS TALL OIL DIP S TICK GUIDE S FO R ENG INE AND

TRANSMISSION

(a) Install a new O±ring to the dipstick guide.

(b) Apply soapy water to the O±ring.

(c) Connect the dipstick guide end to the oil pan.

(d) Install the 2 dipstick guides with the 2 bolts.

17. INSTALL ENGINE WIRE BRACKET

18. CONNECT FUEL RETURN HOSE

± ENGINEENGINE MECHANICALEG±67