TOYOTA SUPRA 1995 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1995, Model line: SUPRA, Model: TOYOTA SUPRA 1995Pages: 2543, PDF Size: 53.25 MB

Page 1461 of 2543

PROPELLER SHAFT REMOVAL

1. REMOVE OXYGEN SENSOR

(a) Remove the 2 bolts.

(b) Remove the oxygen sensor and heat insulator

2. REMOVE EXHAUST PIPE

(a) Remove the 2 bolts on the transmission side.

(b) Remove the 2 bolts and nuts, and pipe support bracket.

(c) Remove the 2 exhaust pipe support rings.

(d) Remove the 2 exhaust pipe support O±rings.

(e) Remove the exhaust pipe.

(f) Remove the gasket.

3. REMOVE HEAT INSULATOR

Remove the 4 nuts and heat insulator.

4. REMOVE CENTER FLOOR CROSSMEMBER BRACE

Normal Roof:

Remove the 4 bolts and crossmember brace.

Sport Roof:

Remove the 6 bolts and crossmember brace.

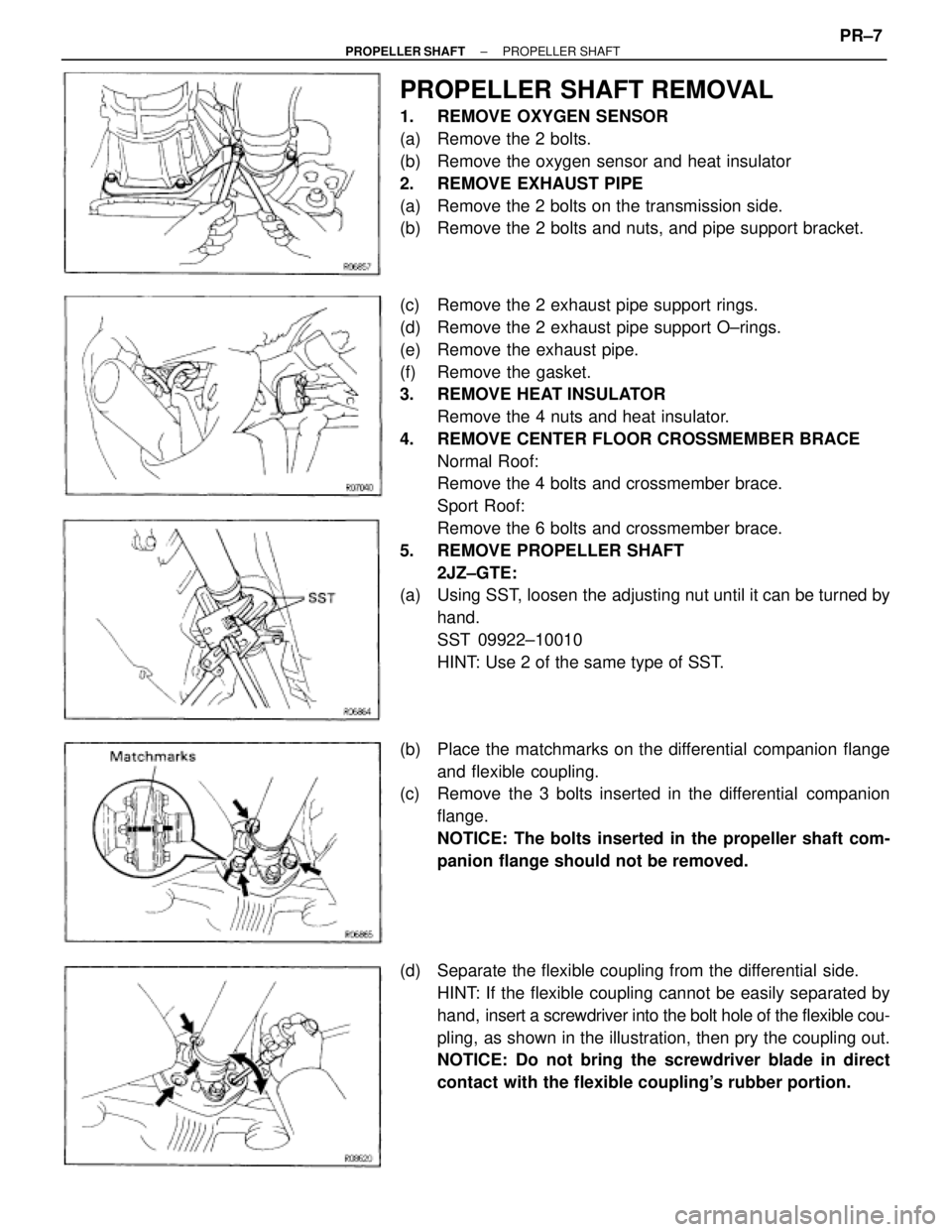

5. REMOVE PROPELLER SHAFT

2JZ±GTE:

(a) Using SST, loosen the adjusting nut until it can be turned by

hand.

SST 09922±10010

HINT: Use 2 of the same type of SST.

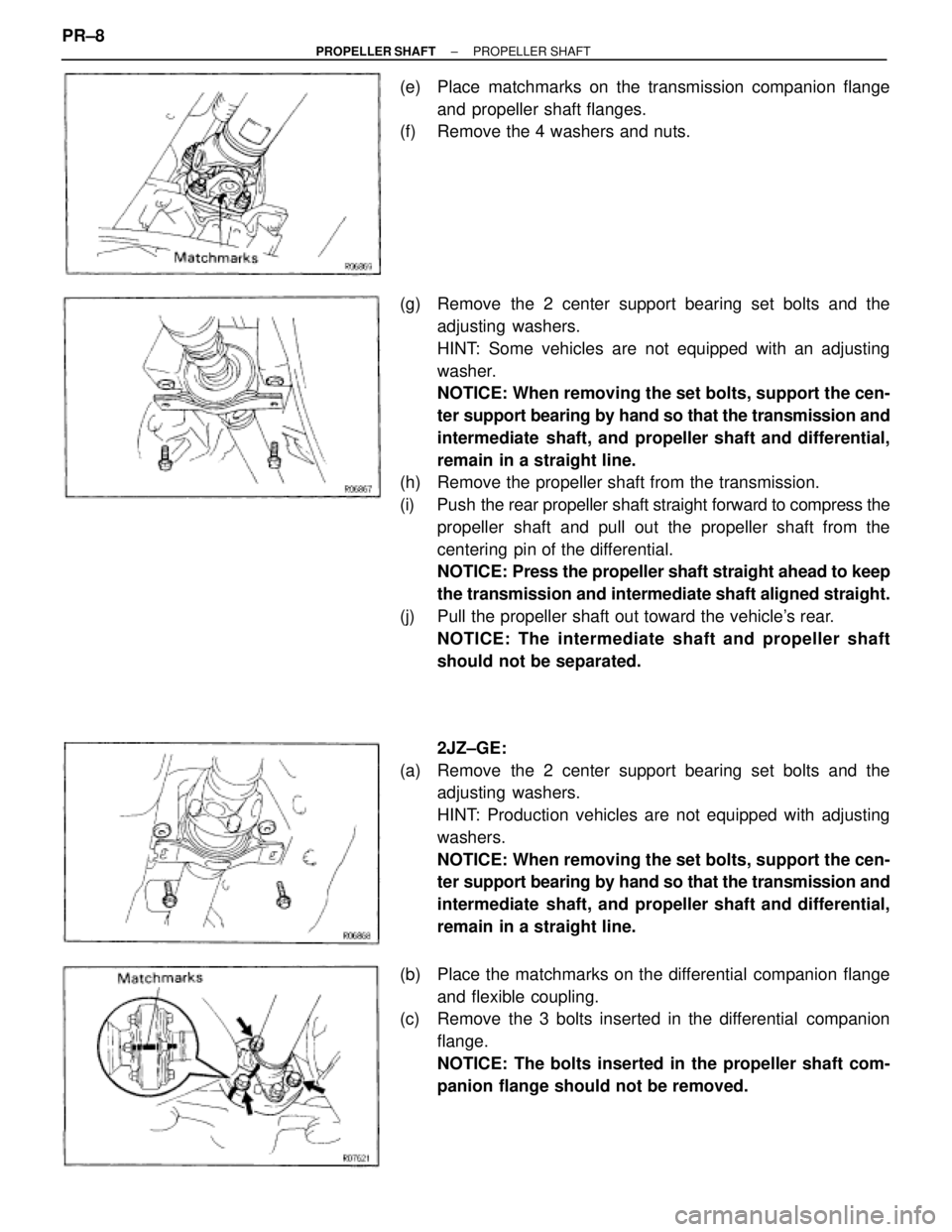

(b) Place the matchmarks on the differential companion flange

and flexible coupling.

(c) Remove the 3 bolts inserted in the differential companion

flange.

NOTICE: The bolts inserted in the propeller shaft com-

panion flange should not be removed.

(d) Separate the flexible coupling from the differential side.

HINT: If the flexible coupling cannot be easily separated by

hand, insert a screwdriver into the bolt hole of the flexible cou-

pling, as shown in the illustration, then pry the coupling out.

NOTICE: Do not bring the screwdriver blade in direct

contact with the flexible coupling's rubber portion.

± PROPELLER SHAFTPROPELLER SHAFTPR±7

Page 1462 of 2543

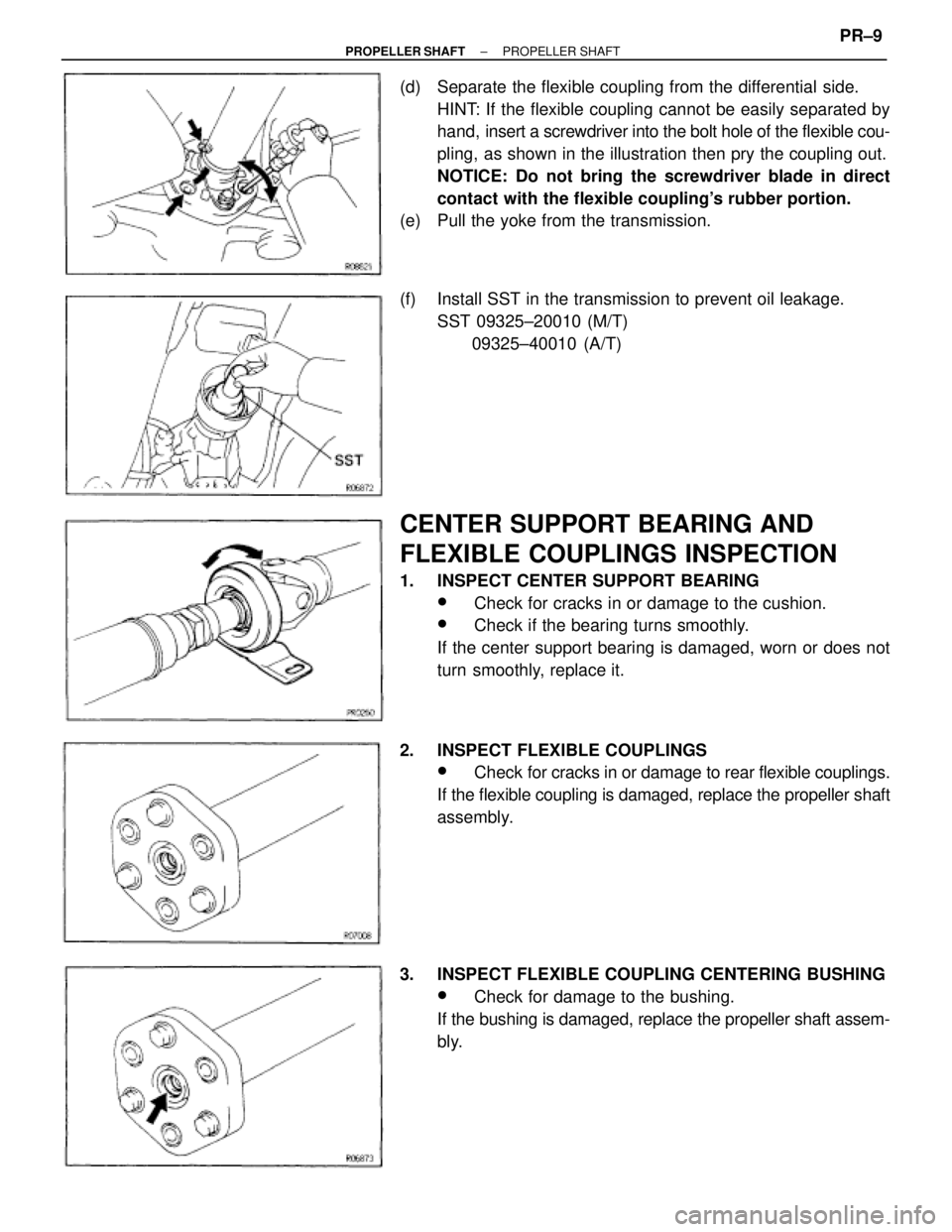

(e) Place matchmarks on the transmission companion flange

and propeller shaft flanges.

(f) Remove the 4 washers and nuts.

(g) Remove the 2 center support bearing set bolts and the

adjusting washers.

HINT: Some vehicles are not equipped with an adjusting

washer.

NOTICE: When removing the set bolts, support the cen-

ter support bearing by hand so that the transmission and

intermediate shaft, and propeller shaft and differential,

remain in a straight line.

(h) Remove the propeller shaft from the transmission.

(i) Push the rear propeller shaft straight forward to compress the

propeller shaft and pull out the propeller shaft from the

centering pin of the differential.

NOTICE: Press the propeller shaft straight ahead to keep

the transmission and intermediate shaft aligned straight.

(j) Pull the propeller shaft out toward the vehicle's rear.

NOTICE: The intermediate shaft and propeller shaft

should not be separated.

2JZ±GE:

(a) Remove the 2 center support bearing set bolts and the

adjusting washers.

HINT: Production vehicles are not equipped with adjusting

washers.

NOTICE: When removing the set bolts, support the cen-

ter support bearing by hand so that the transmission and

intermediate shaft, and propeller shaft and differential,

remain in a straight line.

(b) Place the matchmarks on the differential companion flange

and flexible coupling.

(c) Remove the 3 bolts inserted in the differential companion

flange.

NOTICE: The bolts inserted in the propeller shaft com-

panion flange should not be removed. PR±8

± PROPELLER SHAFTPROPELLER SHAFT

Page 1463 of 2543

(d) Separate the flexible coupling from the differential side.

HINT: If the flexible coupling cannot be easily separated by

hand, insert a screwdriver into the bolt hole of the flexible cou-

pling, as shown in the illustration then pry the coupling out.

NOTICE: Do not bring the screwdriver blade in direct

contact with the flexible coupling's rubber portion.

(e) Pull the yoke from the transmission.

(f) Install SST in the transmission to prevent oil leakage.

SST 09325±20010 (M/T)

09325±40010 (A/T)

CENTER SUPPORT BEARING AND

FLEXIBLE COUPLINGS INSPECTION

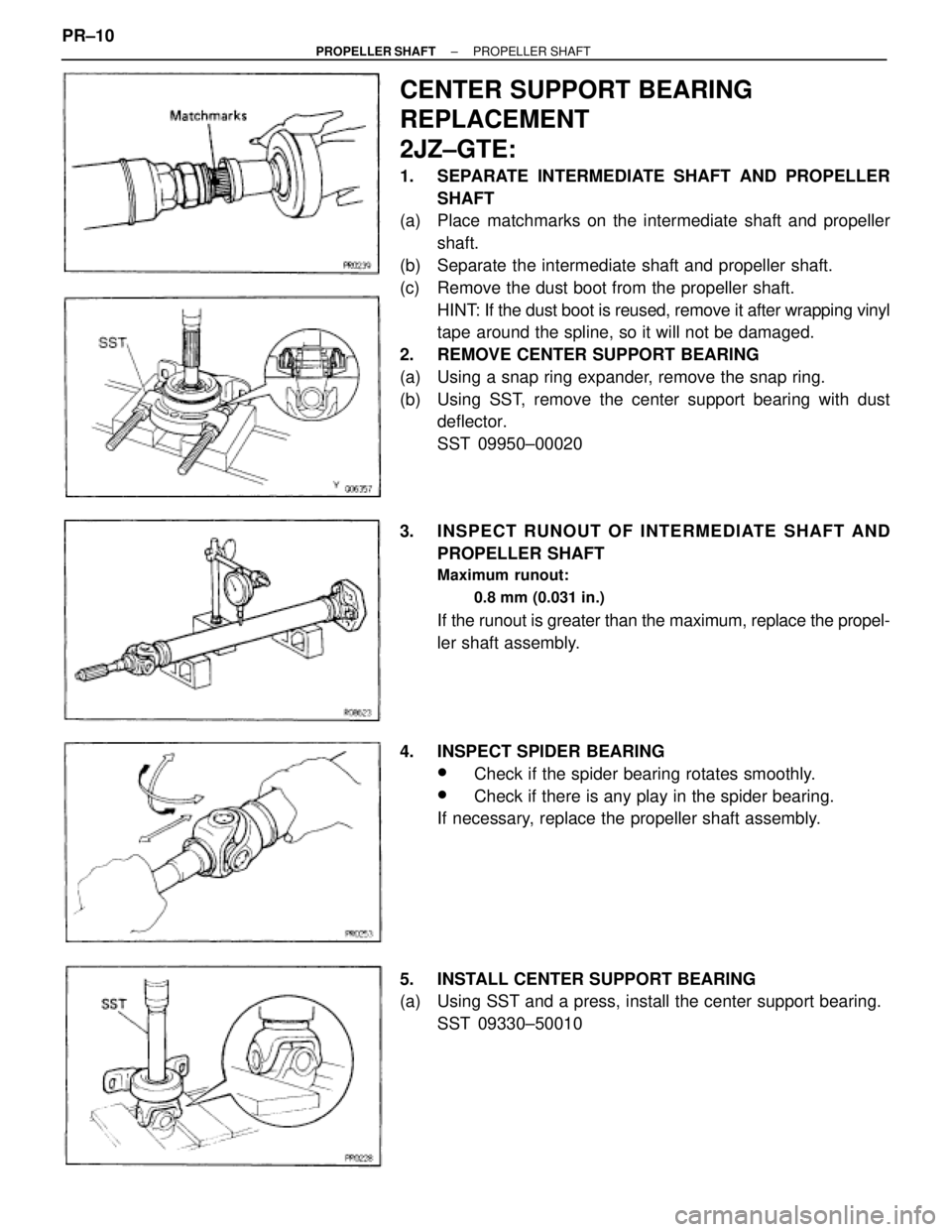

1. INSPECT CENTER SUPPORT BEARING

wCheck for cracks in or damage to the cushion.

wCheck if the bearing turns smoothly.

If the center support bearing is damaged, worn or does not

turn smoothly, replace it.

2. INSPECT FLEXIBLE COUPLINGS

wCheck for cracks in or damage to rear flexible couplings.

If the flexible coupling is damaged, replace the propeller shaft

assembly.

3. INSPECT FLEXIBLE COUPLING CENTERING BUSHING

wCheck for damage to the bushing.

If the bushing is damaged, replace the propeller shaft assem-

bly.

± PROPELLER SHAFTPROPELLER SHAFTPR±9

Page 1464 of 2543

CENTER SUPPORT BEARING

REPLACEMENT

2JZ±GTE:

1. SEPARATE INTERMEDIATE SHAFT AND PROPELLER

SHAFT

(a) Place matchmarks on the intermediate shaft and propeller

shaft.

(b) Separate the intermediate shaft and propeller shaft.

(c) Remove the dust boot from the propeller shaft.

HINT: If the dust boot is reused, remove it after wrapping vinyl

tape around the spline, so it will not be damaged.

2. REMOVE CENTER SUPPORT BEARING

(a) Using a snap ring expander, remove the snap ring.

(b) Using SST, remove the center support bearing with dust

deflector.

SST 09950±00020

3. INSPECT RUNOUT OF INTERMEDIATE SHAFT AND

PROPELLER SHAFT

Maximum runout:

0.8 mm (0.031 in.)

If the runout is greater than the maximum, replace the propel-

ler shaft assembly.

4. INSPECT SPIDER BEARING

wCheck if the spider bearing rotates smoothly.

wCheck if there is any play in the spider bearing.

If necessary, replace the propeller shaft assembly.

5. INSTALL CENTER SUPPORT BEARING

(a) Using SST and a press, install the center support bearing.

SST 09330±50010 PR±10

± PROPELLER SHAFTPROPELLER SHAFT

Page 1465 of 2543

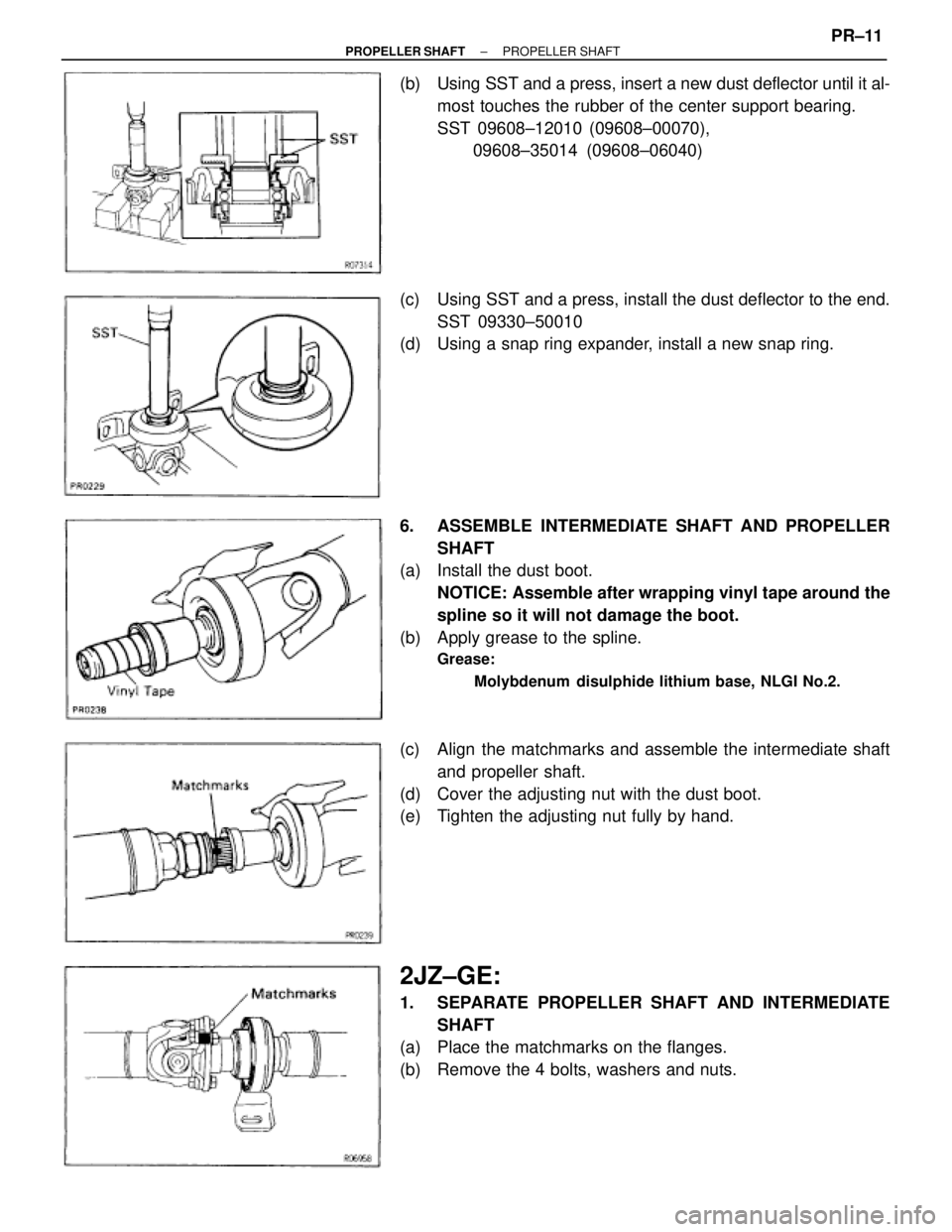

(b) Using SST and a press, insert a new dust deflector until it al-

most touches the rubber of the center support bearing.

SST 09608±12010 (09608±00070),

09608±35014 (09608±06040)

(c) Using SST and a press, install the dust deflector to the end.

SST 09330±50010

(d) Using a snap ring expander, install a new snap ring.

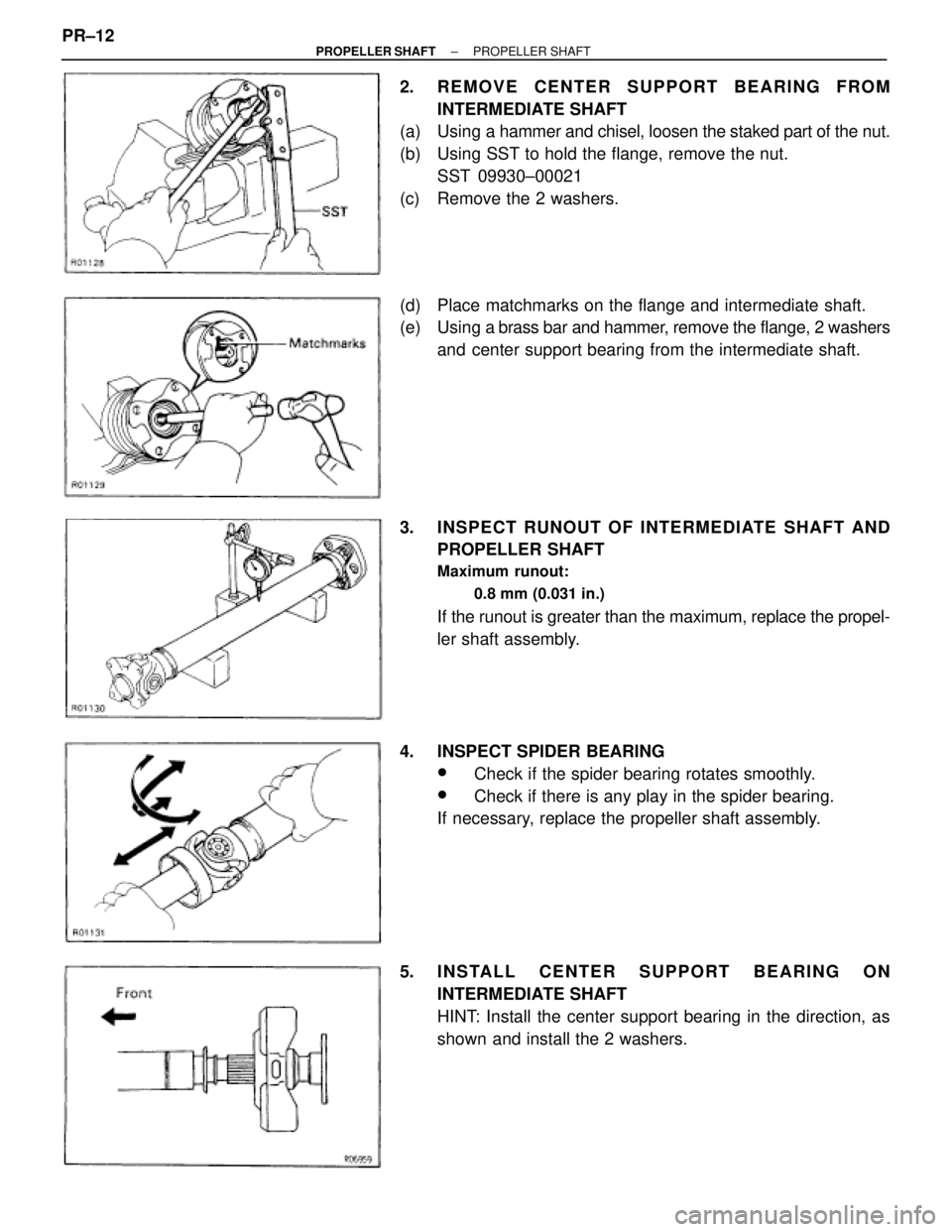

6. ASSEMBLE INTERMEDIATE SHAFT AND PROPELLER

SHAFT

(a) Install the dust boot.

NOTICE: Assemble after wrapping vinyl tape around the

spline so it will not damage the boot.

(b) Apply grease to the spline.

Grease:

Molybdenum disulphide lithium base, NLGI No.2.

(c) Align the matchmarks and assemble the intermediate shaft

and propeller shaft.

(d) Cover the adjusting nut with the dust boot.

(e) Tighten the adjusting nut fully by hand.

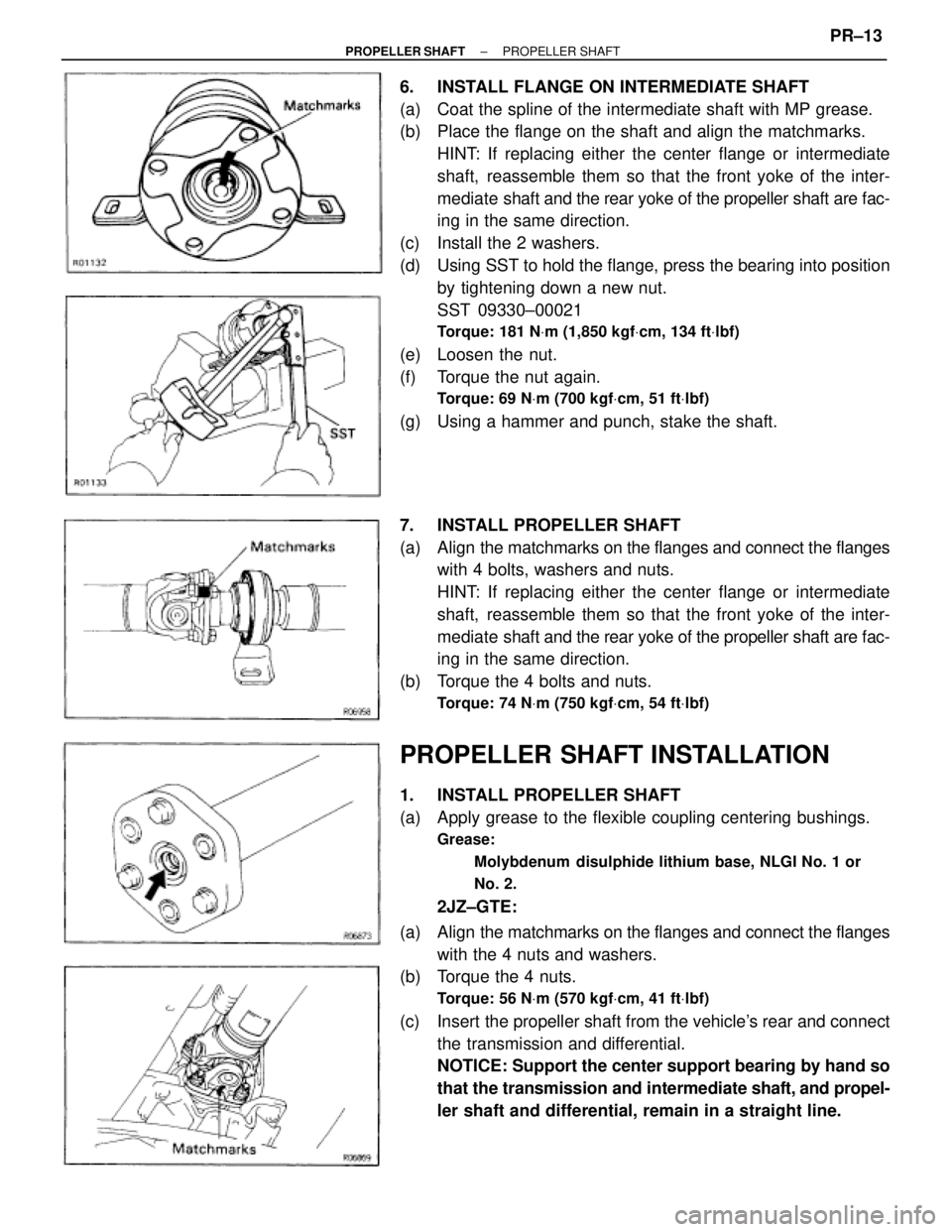

2JZ±GE:

1. SEPARATE PROPELLER SHAFT AND INTERMEDIATE

SHAFT

(a) Place the matchmarks on the flanges.

(b) Remove the 4 bolts, washers and nuts.

± PROPELLER SHAFTPROPELLER SHAFTPR±11

Page 1466 of 2543

2. REMOVE CENTER SUPPORT BEARING FROM

INTERMEDIATE SHAFT

(a) Using a hammer and chisel, loosen the staked part of the nut.

(b) Using SST to hold the flange, remove the nut.

SST 09930±00021

(c) Remove the 2 washers.

(d) Place matchmarks on the flange and intermediate shaft.

(e) Using a brass bar and hammer, remove the flange, 2 washers

and center support bearing from the intermediate shaft.

3. INSPECT RUNOUT OF INTERMEDIATE SHAFT AND

PROPELLER SHAFT

Maximum runout:

0.8 mm (0.031 in.)

If the runout is greater than the maximum, replace the propel-

ler shaft assembly.

4. INSPECT SPIDER BEARING

wCheck if the spider bearing rotates smoothly.

wCheck if there is any play in the spider bearing.

If necessary, replace the propeller shaft assembly.

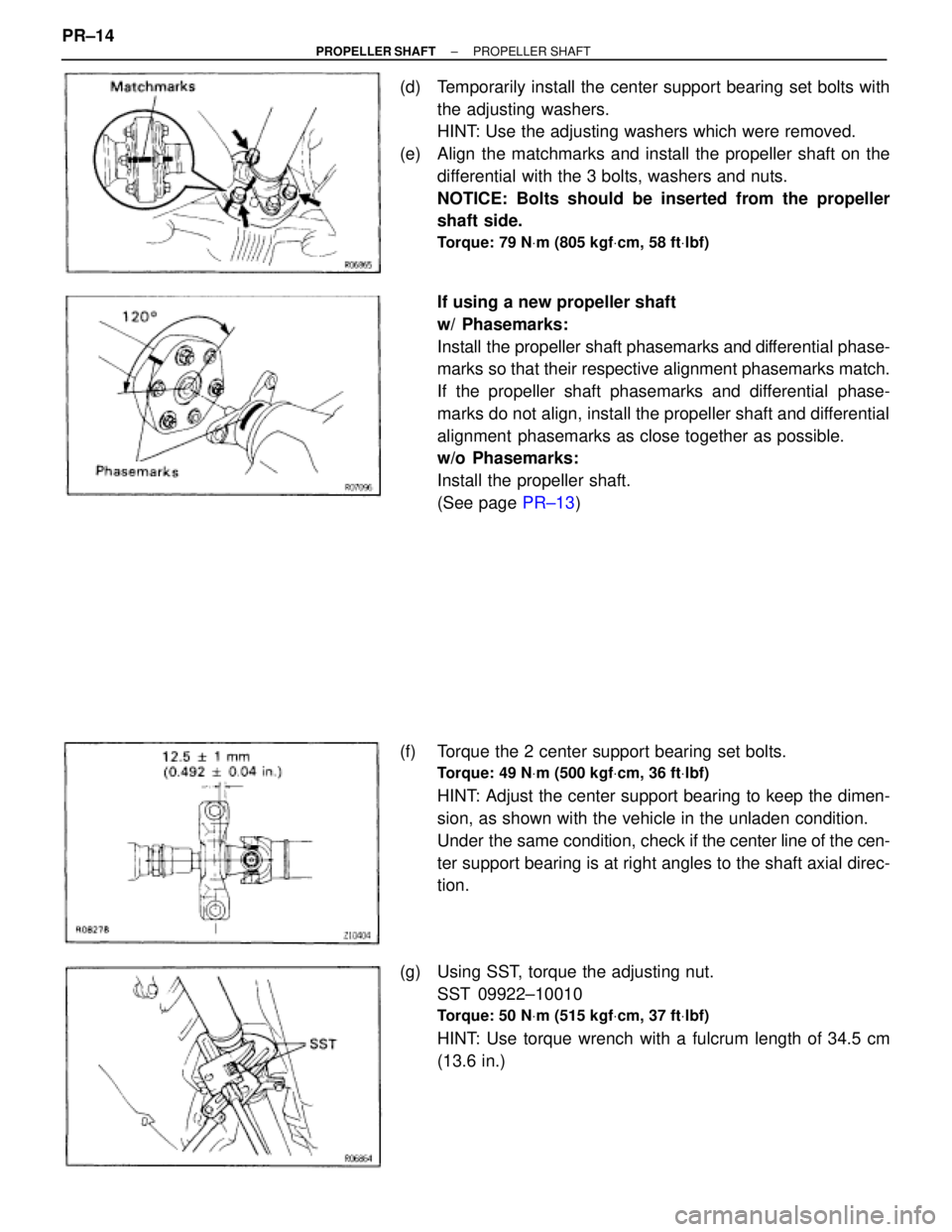

5. INSTALL CENTER SUPPORT BEARING ON

INTERMEDIATE SHAFT

HINT: Install the center support bearing in the direction, as

shown and install the 2 washers. PR±12

± PROPELLER SHAFTPROPELLER SHAFT

Page 1467 of 2543

6. INSTALL FLANGE ON INTERMEDIATE SHAFT

(a) Coat the spline of the intermediate shaft with MP grease.

(b) Place the flange on the shaft and align the matchmarks.

HINT: If replacing either the center flange or intermediate

shaft, reassemble them so that the front yoke of the inter-

mediate shaft and the rear yoke of the propeller shaft are fac-

ing in the same direction.

(c) Install the 2 washers.

(d) Using SST to hold the flange, press the bearing into position

by tightening down a new nut.

SST 09330±00021

Torque: 181 NVm (1,850 kgfVcm, 134 ftVlbf)

(e) Loosen the nut.

(f) Torque the nut again.

Torque: 69 NVm (700 kgfVcm, 51 ftVlbf)

(g) Using a hammer and punch, stake the shaft.

7. INSTALL PROPELLER SHAFT

(a) Align the matchmarks on the flanges and connect the flanges

with 4 bolts, washers and nuts.

HINT: If replacing either the center flange or intermediate

shaft, reassemble them so that the front yoke of the inter-

mediate shaft and the rear yoke of the propeller shaft are fac-

ing in the same direction.

(b) Torque the 4 bolts and nuts.

Torque: 74 NVm (750 kgfVcm, 54 ftVlbf)

PROPELLER SHAFT INSTALLATION

1. INSTALL PROPELLER SHAFT

(a) Apply grease to the flexible coupling centering bushings.

Grease:

Molybdenum disulphide lithium base, NLGI No. 1 or

No. 2.

2JZ±GTE:

(a) Align the matchmarks on the flanges and connect the flanges

with the 4 nuts and washers.

(b) Torque the 4 nuts.

Torque: 56 NVm (570 kgfVcm, 41 ftVlbf)

(c) Insert the propeller shaft from the vehicle's rear and connect

the transmission and differential.

NOTICE: Support the center support bearing by hand so

that the transmission and intermediate shaft, and propel-

ler shaft and differential, remain in a straight line.

± PROPELLER SHAFTPROPELLER SHAFTPR±13

Page 1468 of 2543

(d) Temporarily install the center support bearing set bolts with

the adjusting washers.

HINT: Use the adjusting washers which were removed.

(e) Align the matchmarks and install the propeller shaft on the

differential with the 3 bolts, washers and nuts.

NOTICE: Bolts should be inserted from the propeller

shaft side.

Torque: 79 NVm (805 kgfVcm, 58 ftVlbf)

If using a new propeller shaft

w/ Phasemarks:

Install the propeller shaft phasemarks and differential phase-

marks so that their respective alignment phasemarks match.

If the propeller shaft phasemarks and differential phase-

marks do not align, install the propeller shaft and differential

alignment phasemarks as close together as possible.

w/o Phasemarks:

Install the propeller shaft.

(See page PR±13)

(f) Torque the 2 center support bearing set bolts.

Torque: 49 NVm (500 kgfVcm, 36 ftVlbf)

HINT: Adjust the center support bearing to keep the dimen-

sion, as shown with the vehicle in the unladen condition.

Under the same condition, check if the center line of the cen-

ter support bearing is at right angles to the shaft axial direc-

tion.

(g) Using SST, torque the adjusting nut.

SST 09922±10010

Torque: 50 NVm (515 kgfVcm, 37 ftVlbf)

HINT: Use torque wrench with a fulcrum length of 34.5 cm

(13.6 in.) PR±14

± PROPELLER SHAFTPROPELLER SHAFT

Page 1469 of 2543

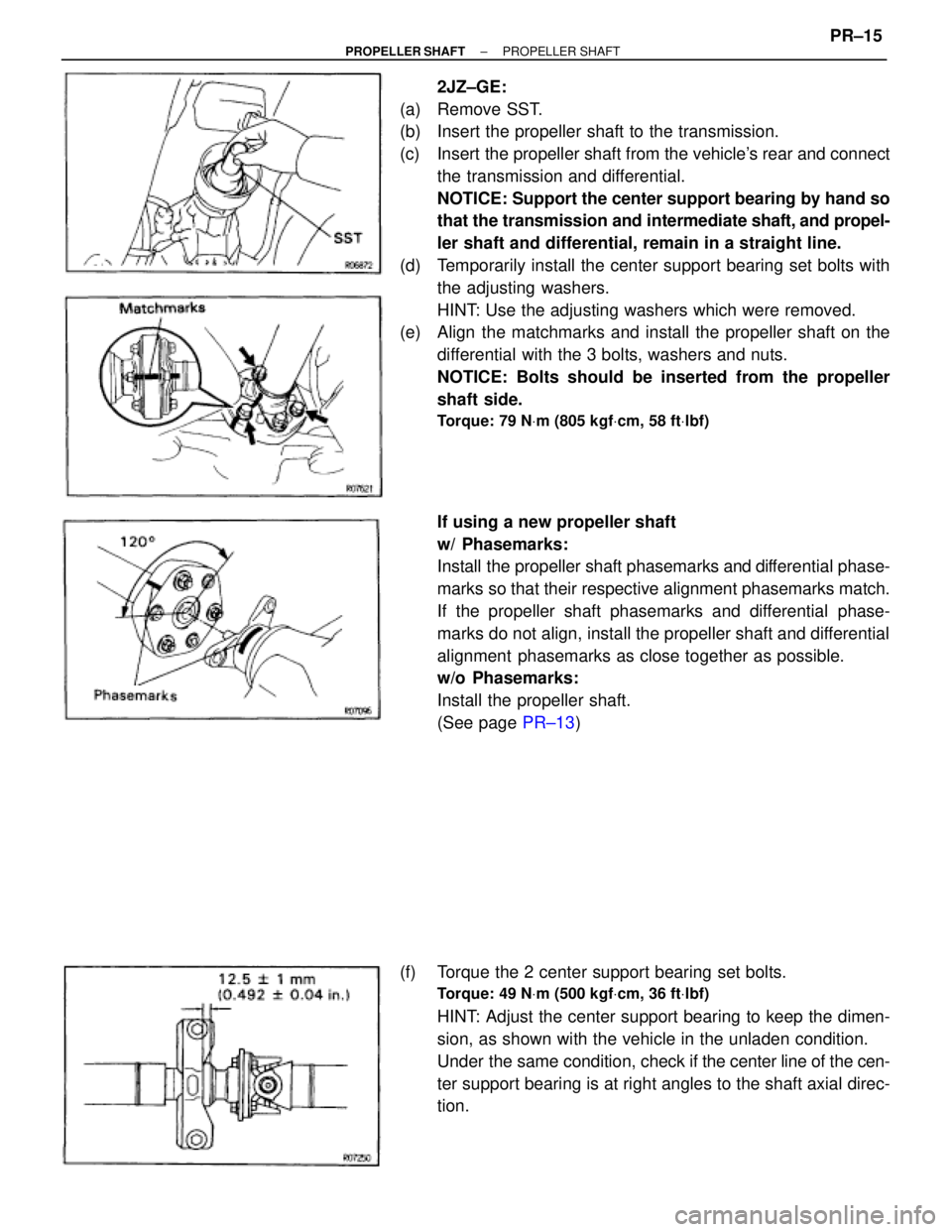

2JZ±GE:

(a) Remove SST.

(b) Insert the propeller shaft to the transmission.

(c) Insert the propeller shaft from the vehicle's rear and connect

the transmission and differential.

NOTICE: Support the center support bearing by hand so

that the transmission and intermediate shaft, and propel-

ler shaft and differential, remain in a straight line.

(d) Temporarily install the center support bearing set bolts with

the adjusting washers.

HINT: Use the adjusting washers which were removed.

(e) Align the matchmarks and install the propeller shaft on the

differential with the 3 bolts, washers and nuts.

NOTICE: Bolts should be inserted from the propeller

shaft side.

Torque: 79 NVm (805 kgfVcm, 58 ftVlbf)

If using a new propeller shaft

w/ Phasemarks:

Install the propeller shaft phasemarks and differential phase-

marks so that their respective alignment phasemarks match.

If the propeller shaft phasemarks and differential phase-

marks do not align, install the propeller shaft and differential

alignment phasemarks as close together as possible.

w/o Phasemarks:

Install the propeller shaft.

(See page PR±13)

(f) Torque the 2 center support bearing set bolts.

Torque: 49 NVm (500 kgfVcm, 36 ftVlbf)

HINT: Adjust the center support bearing to keep the dimen-

sion, as shown with the vehicle in the unladen condition.

Under the same condition, check if the center line of the cen-

ter support bearing is at right angles to the shaft axial direc-

tion.

± PROPELLER SHAFTPROPELLER SHAFTPR±15

Page 1470 of 2543

2. INSPECT PROPELLER SHAFT JOINT ANGLE

(See page PR±17)

NOTICE: The joint angle should be checked when the

propeller shaft is removed and installed.

3. INSTALL CROSSMEMBER BRACE

Normal Roof:

Install the center floor crossmember brace and torque the 4

bolts.

Torque: 13 NVm (130 kgfVcm, 8 ftVlbf)

Sport Roof:

Install the center floor crossmember brace and torque the 6

bolts.

Torque: 13 NVm (130 kgfVcm, 8 ftVlbf)

4. INSTALL HEAT INSULATOR

Install the heat insulator and torque the 4 nuts.

Torque: 5.4 NVm (55 kgfVcm, 48 in.Vlbf)

5. INSTALL EXHAUST PIPE

(a) Install a new gasket.

(b) Insert the exhaust pipe.

(c) Install the exhaust pipe to the 2 exhaust pipe support rings.

(d) Install the exhaust pipe to the 2 exhaust pipe support

O±rings.

(e) Temporary install the pipe support bracket to the

transmission with 2 bolts.

(f) Install the exhaust pipe with the 2 bolts and new 2 nuts.

Torque: 58 NVm (590 kgfVcm, 43 ftVlbf)

(g) Torque the 2 bolts.

Torque: 37 NVm (380 kgfVcm, 27 ftVlbf)

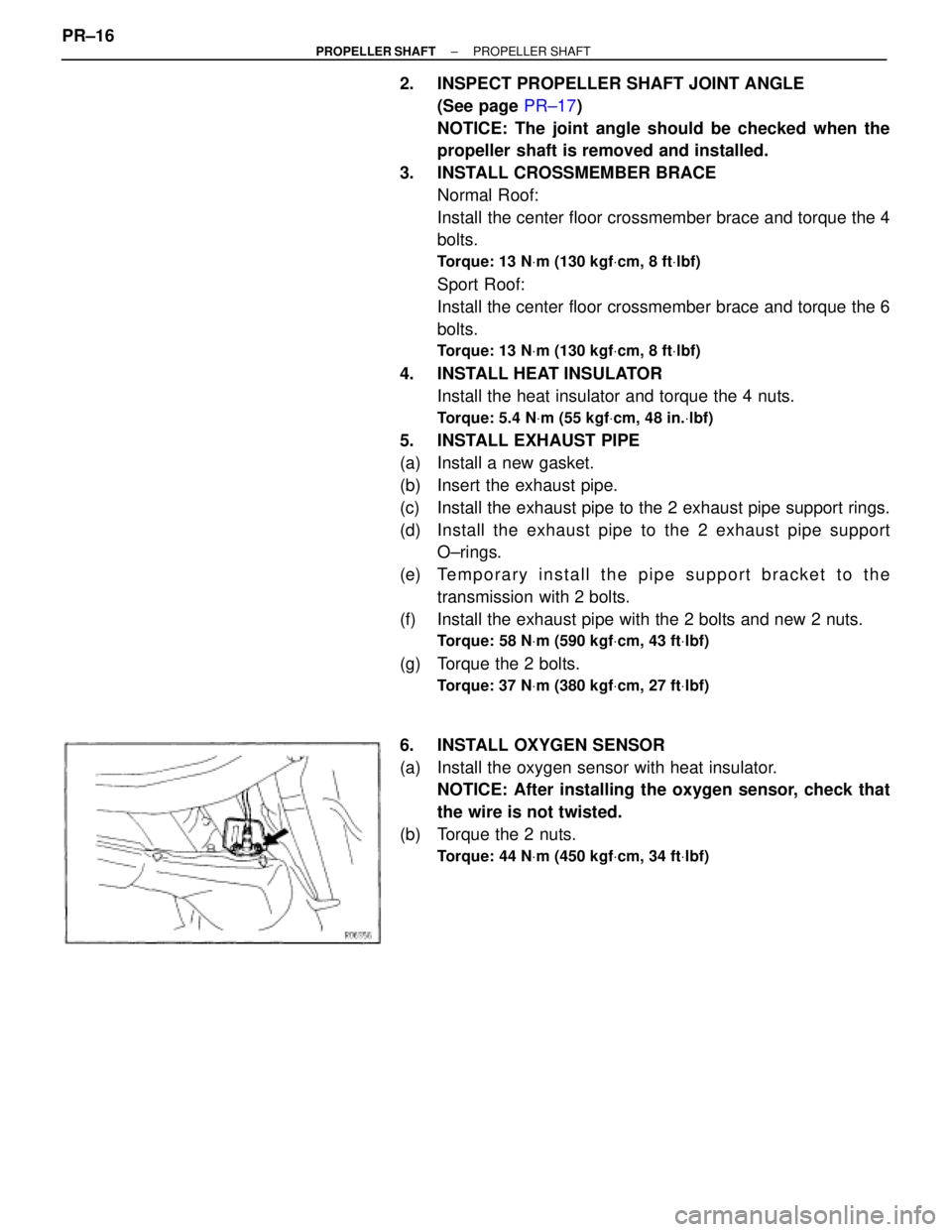

6. INSTALL OXYGEN SENSOR

(a) Install the oxygen sensor with heat insulator.

NOTICE: After installing the oxygen sensor, check that

the wire is not twisted.

(b) Torque the 2 nuts.

Torque: 44 NVm (450 kgfVcm, 34 ftVlbf)

PR±16± PROPELLER SHAFTPROPELLER SHAFT