TOYOTA SUPRA 1995 Service Repair Manual

SUPRA 1995

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57468/w960_57468-0.png

TOYOTA SUPRA 1995 Service Repair Manual

Trending: ground clearance, differential, Sfi, recommended oil, CD player, jacking, check oil

Page 151 of 2543

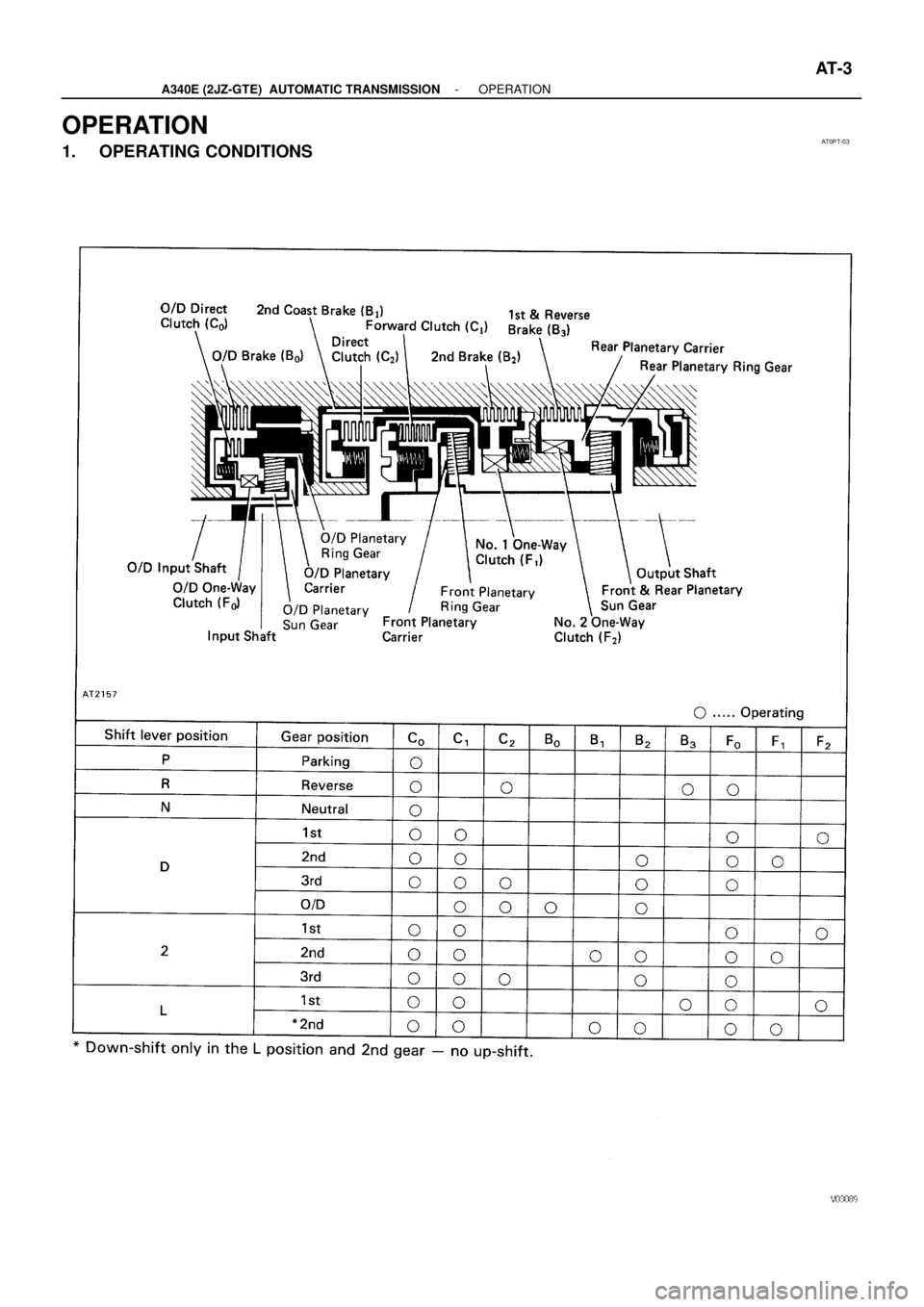

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-3

OPERATION

1. OPERATING CONDITIONSAT0PT-03

Page 152 of 2543

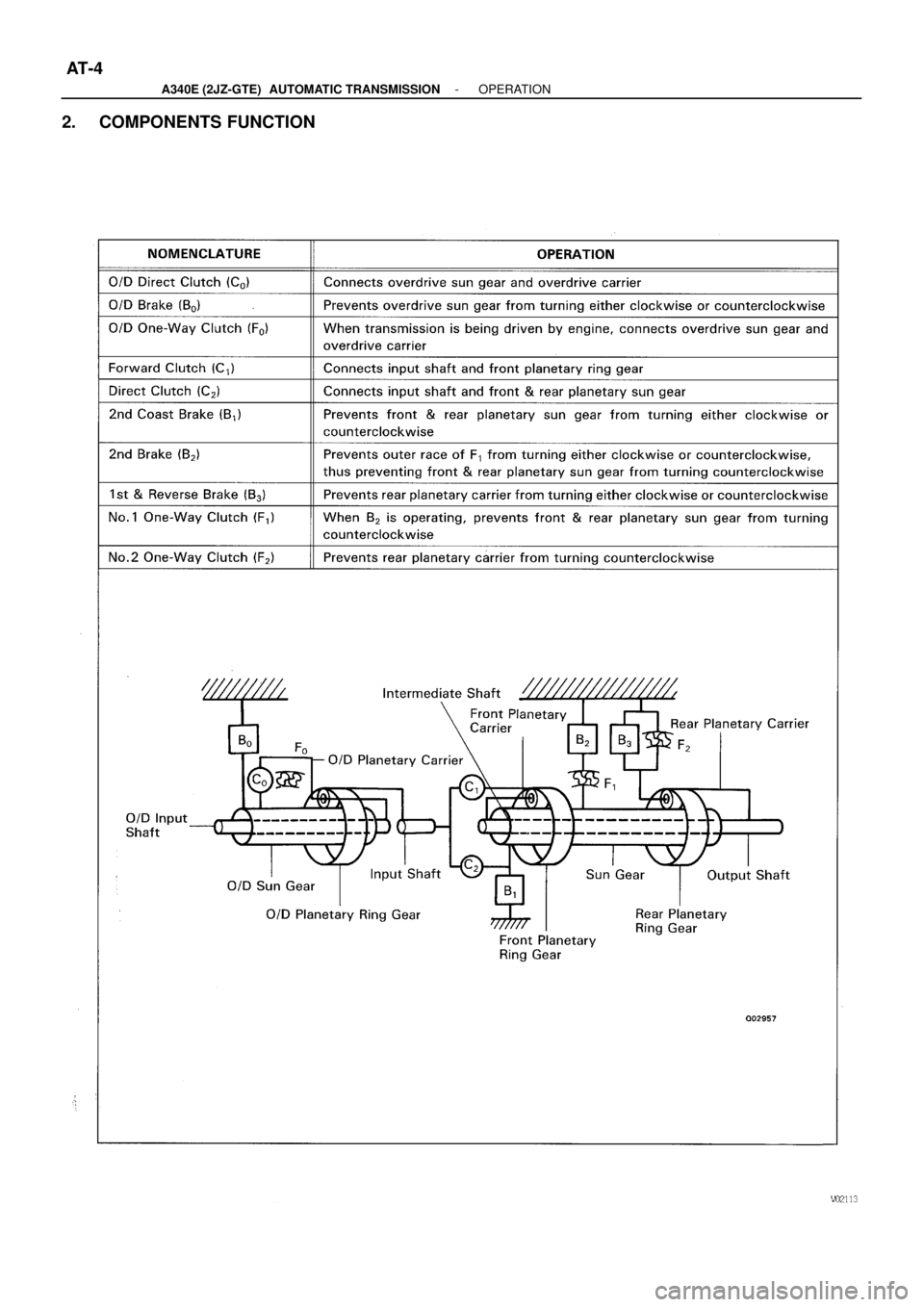

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-4

2. COMPONENTS FUNCTION

Page 153 of 2543

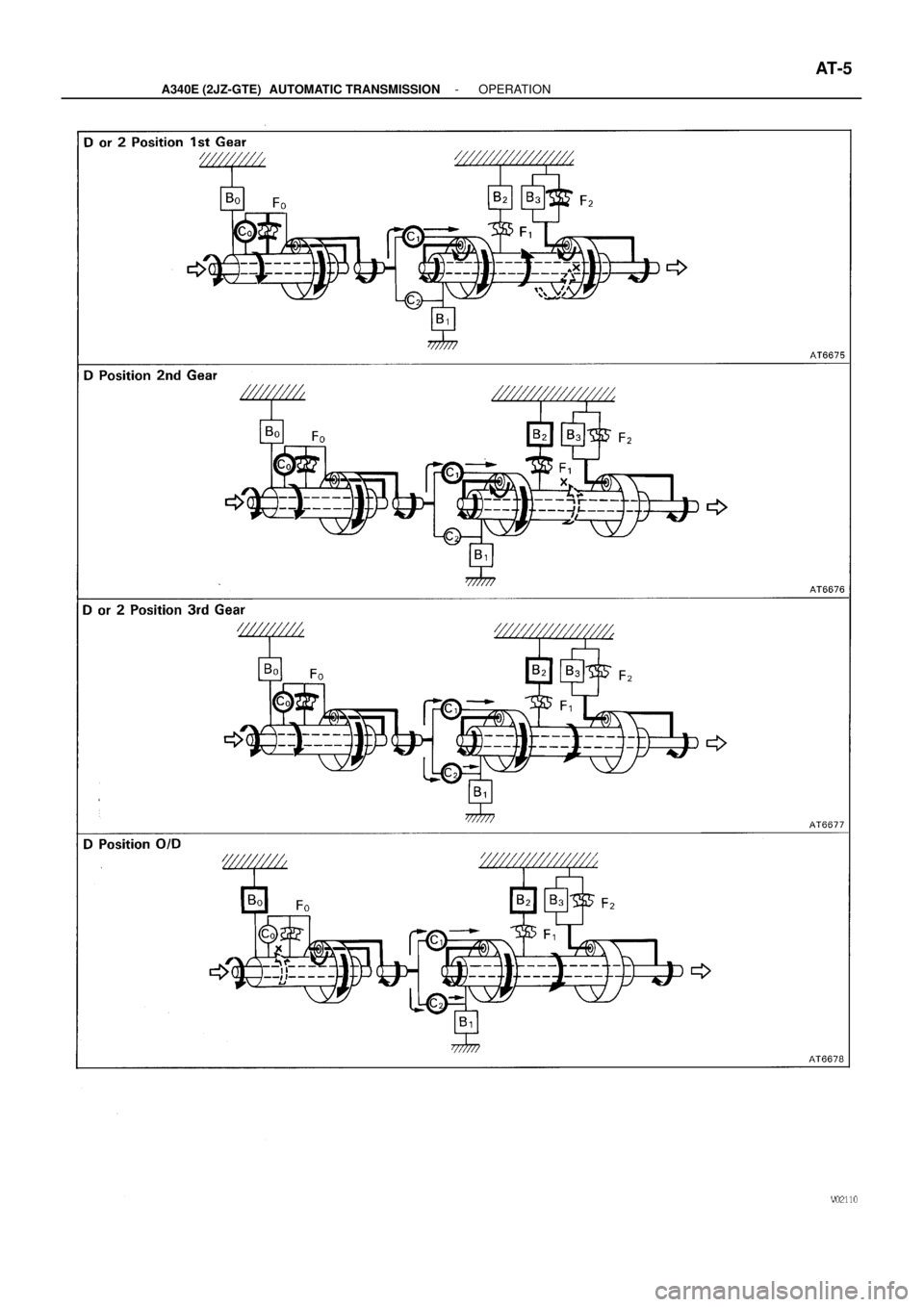

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-5

Page 154 of 2543

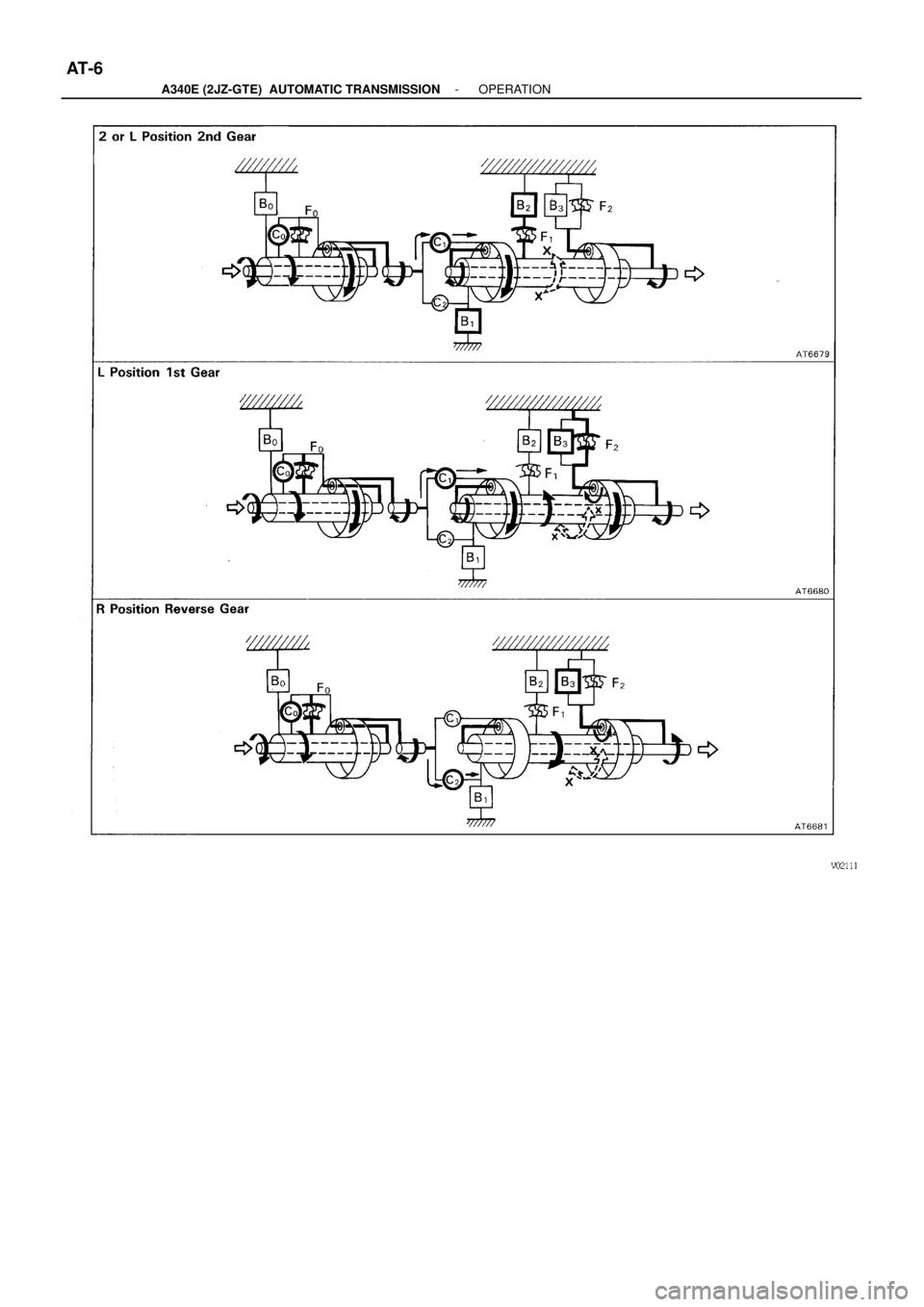

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-6

Page 155 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-7

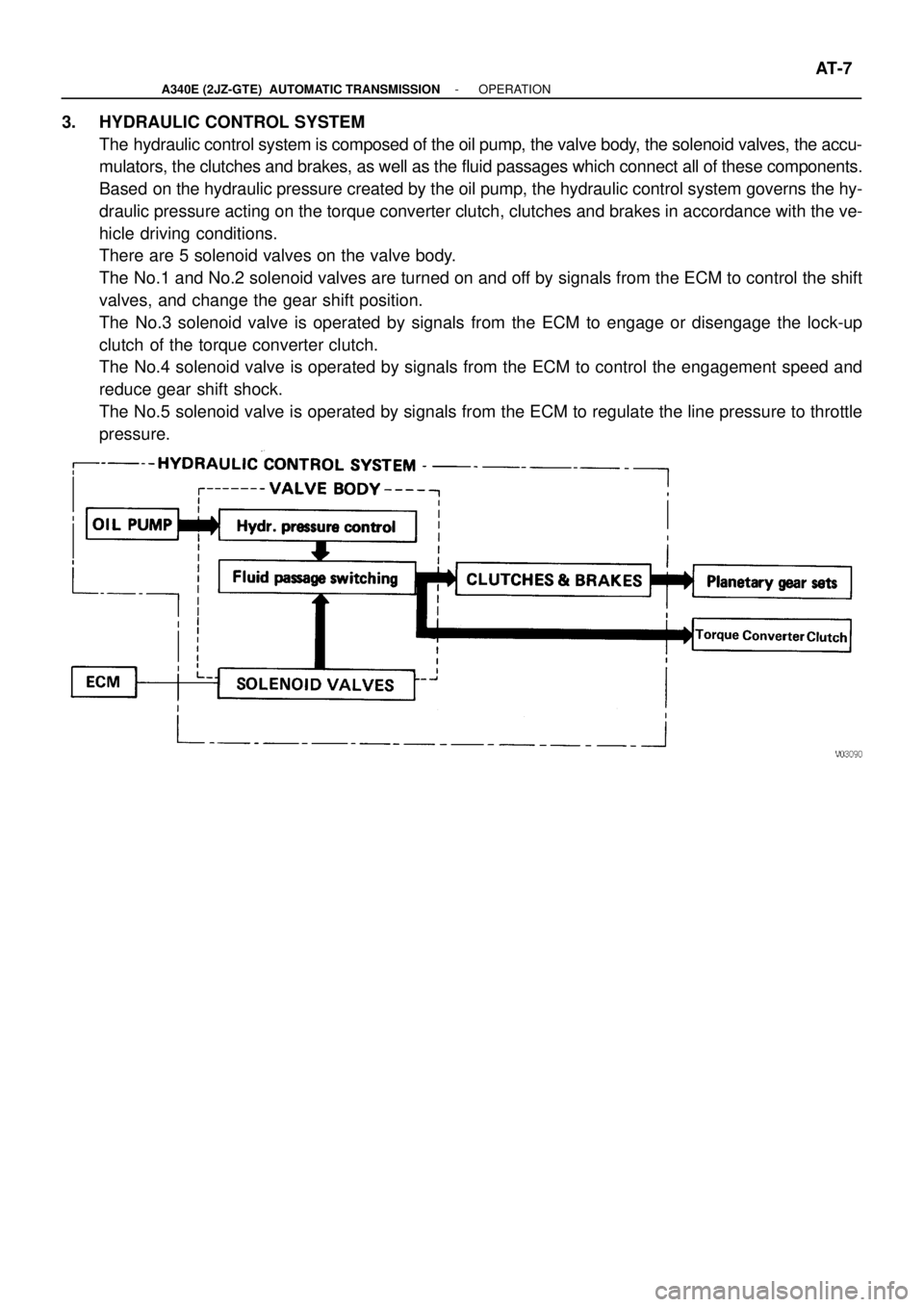

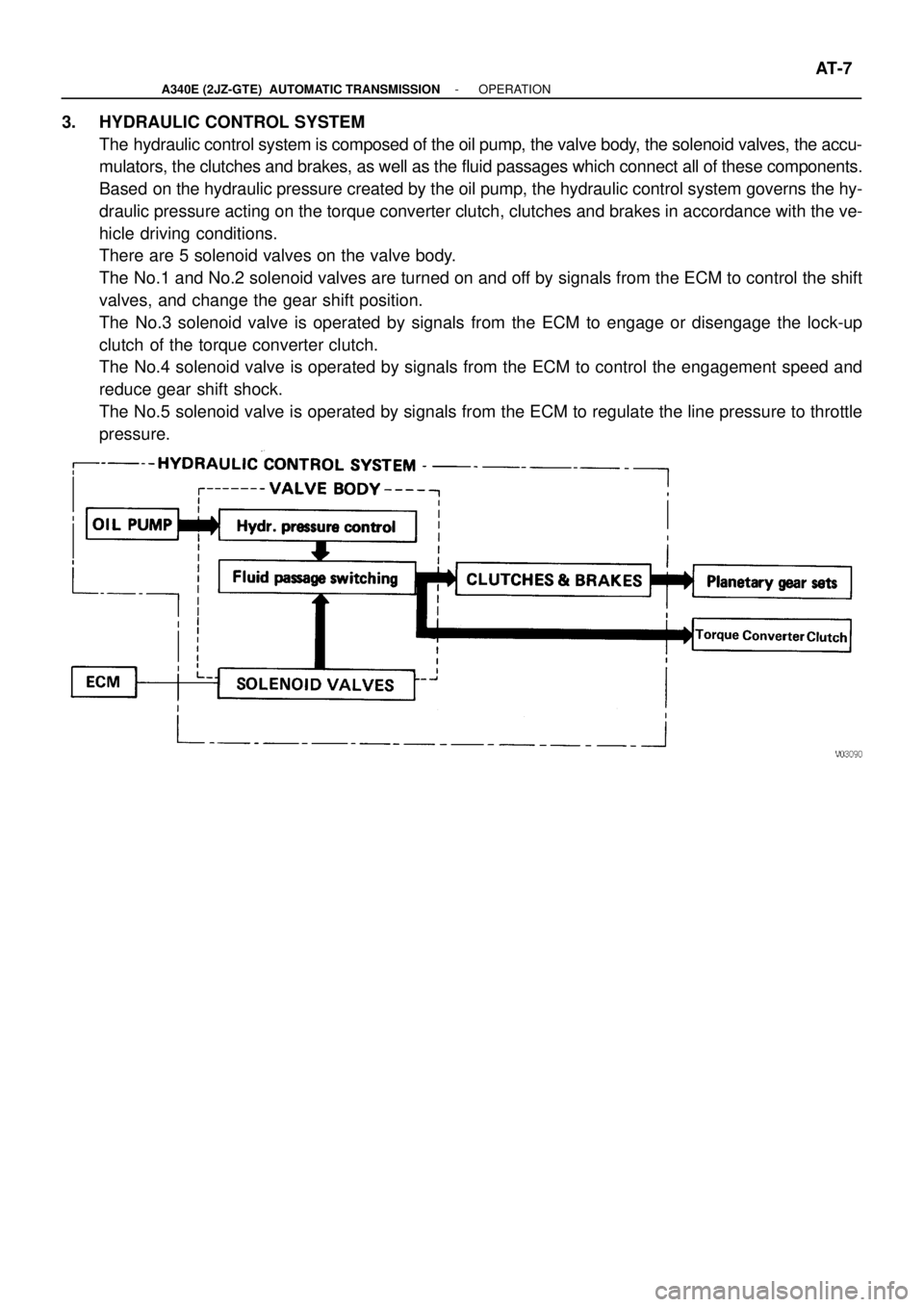

3. HYDRAULIC CONTROL SYSTEM

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, the accu-

mulators, the clutches and brakes, as well as the fluid passages which connect all of these components.

Based on the hydraulic pressure created by the oil pump, the hydraulic control system governs the hy-

draulic pressure acting on the torque converter clutch, clutches and brakes in accordance with the ve-

hicle driving conditions.

There are 5 solenoid valves on the valve body.

The No.1 and No.2 solenoid valves are turned on and off by signals from the ECM to control the shift

valves, and change the gear shift position.

The No.3 solenoid valve is operated by signals from the ECM to engage or disengage the lock-up

clutch of the torque converter clutch.

The No.4 solenoid valve is operated by signals from the ECM to control the engagement speed and

reduce gear shift shock.

The No.5 solenoid valve is operated by signals from the ECM to regulate the line pressure to throttle

pressure.

Page 156 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-8

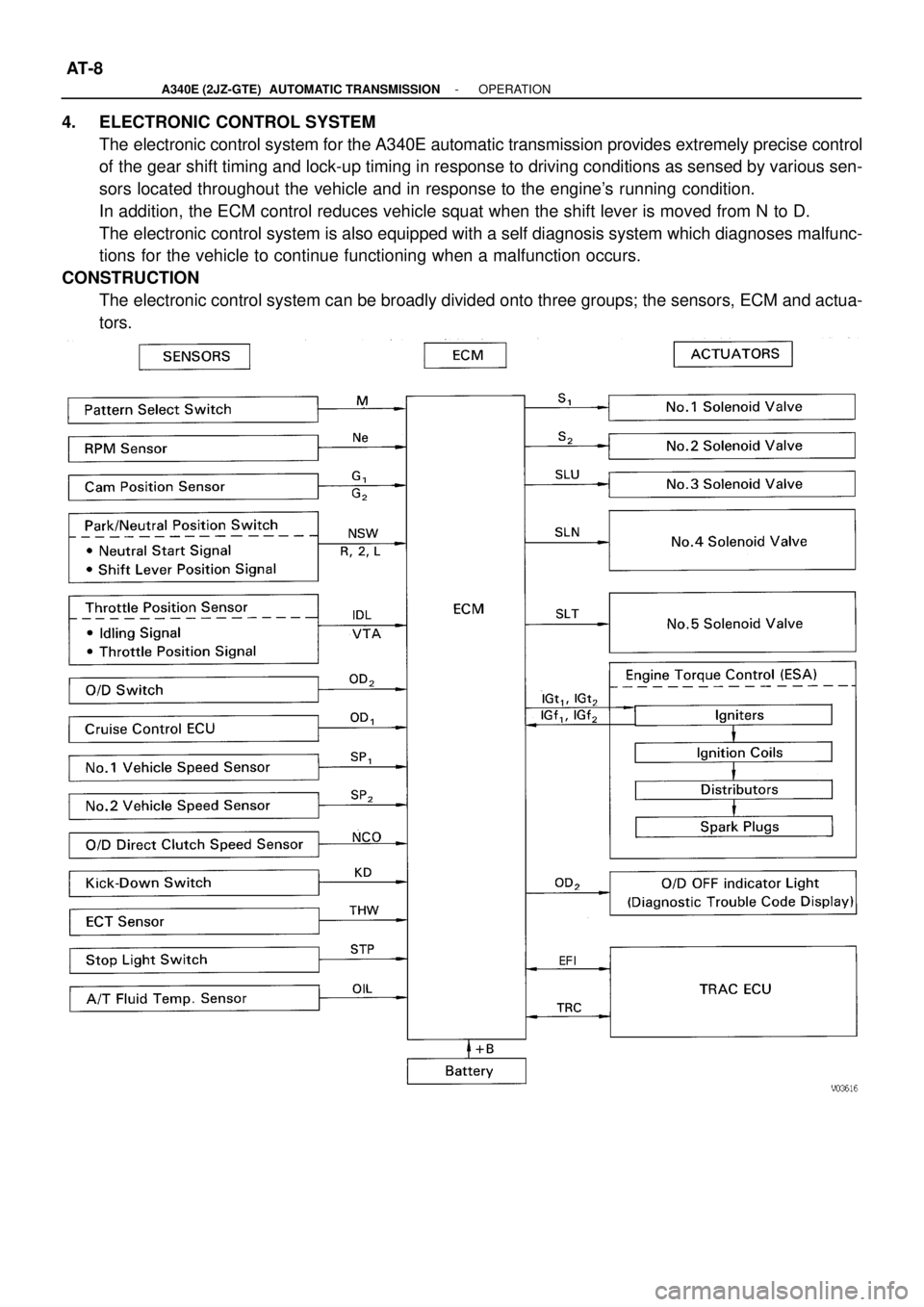

4. ELECTRONIC CONTROL SYSTEM

The electronic control system for the A340E automatic transmission provides extremely precise control

of the gear shift timing and lock-up timing in response to driving conditions as sensed by various sen-

sors located throughout the vehicle and in response to the engine's running condition.

In addition, the ECM control reduces vehicle squat when the shift lever is moved from N to D.

The electronic control system is also equipped with a self diagnosis system which diagnoses malfunc-

tions for the vehicle to continue functioning when a malfunction occurs.

CONSTRUCTION

The electronic control system can be broadly divided onto three groups; the sensors, ECM and actua-

tors.

Page 157 of 2543

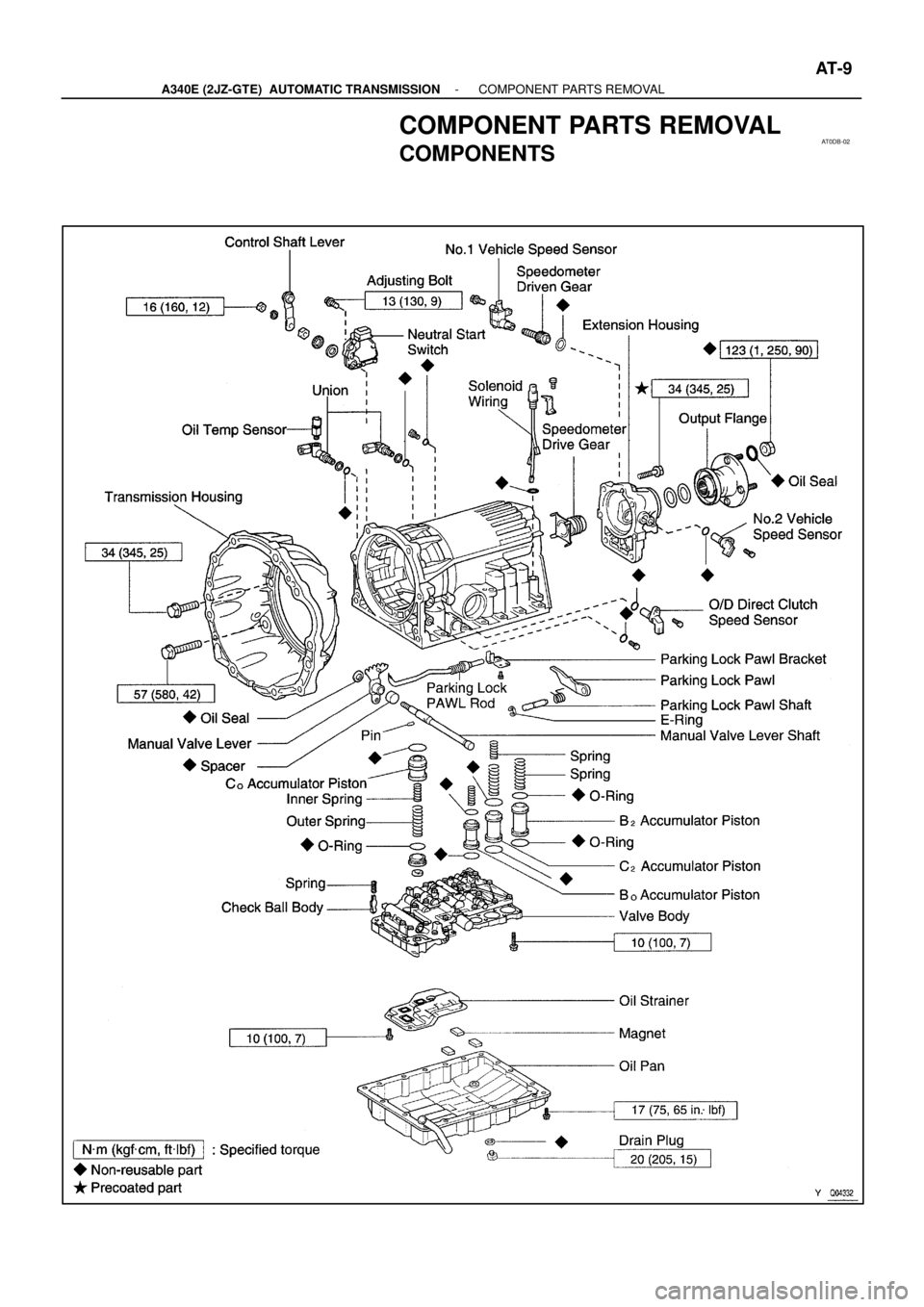

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-9

COMPONENT PARTS REMOVAL

COMPONENTS

AT0DB-02

Page 158 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-10

Page 159 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-1 1

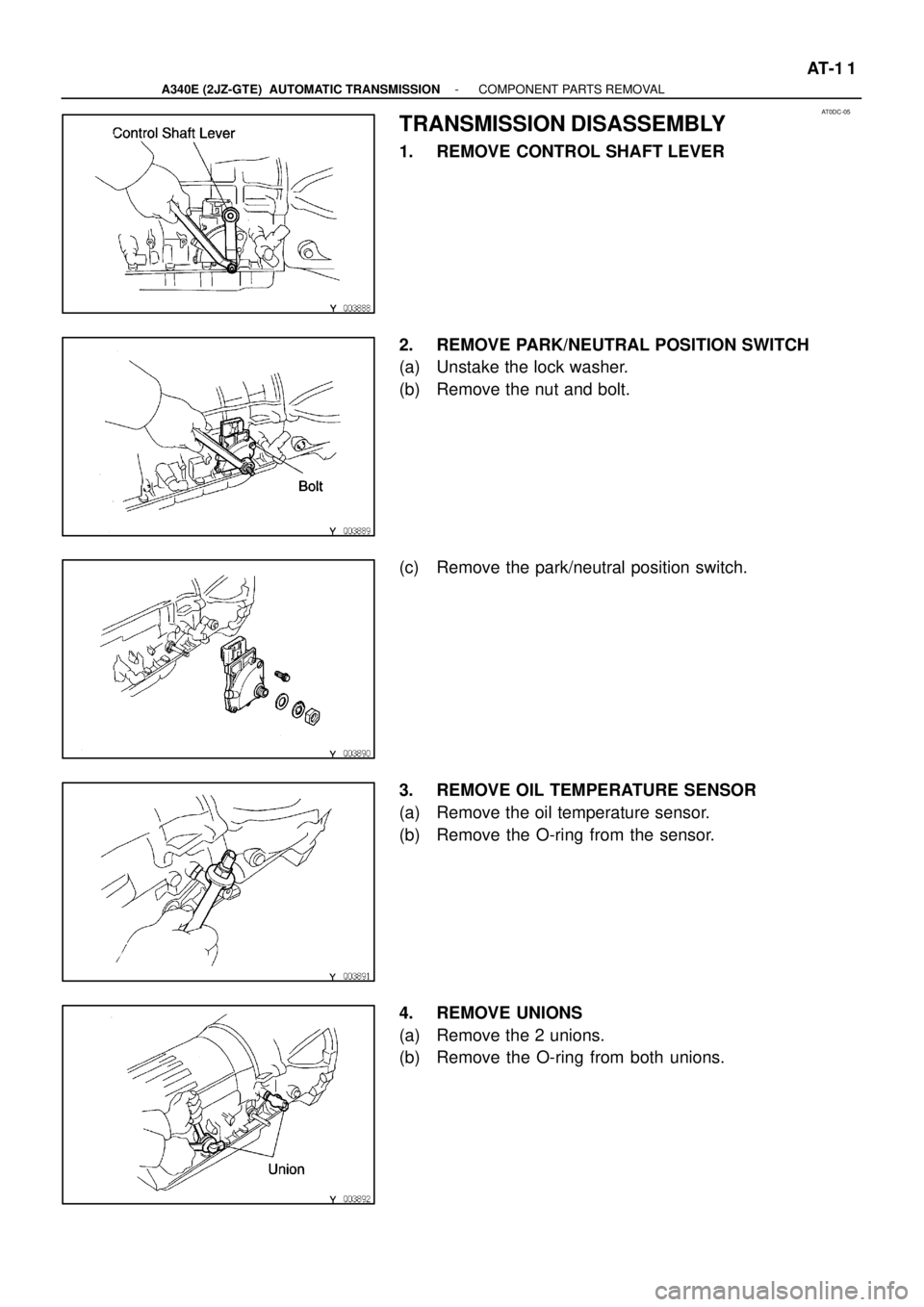

TRANSMISSION DISASSEMBLY

1. REMOVE CONTROL SHAFT LEVER

2. REMOVE PARK/NEUTRAL POSITION SWITCH

(a) Unstake the lock washer.

(b) Remove the nut and bolt.

(c) Remove the park/neutral position switch.

3. REMOVE OIL TEMPERATURE SENSOR

(a) Remove the oil temperature sensor.

(b) Remove the O-ring from the sensor.

4. REMOVE UNIONS

(a) Remove the 2 unions.

(b) Remove the O-ring from both unions.

AT0DC-05

Page 160 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-12

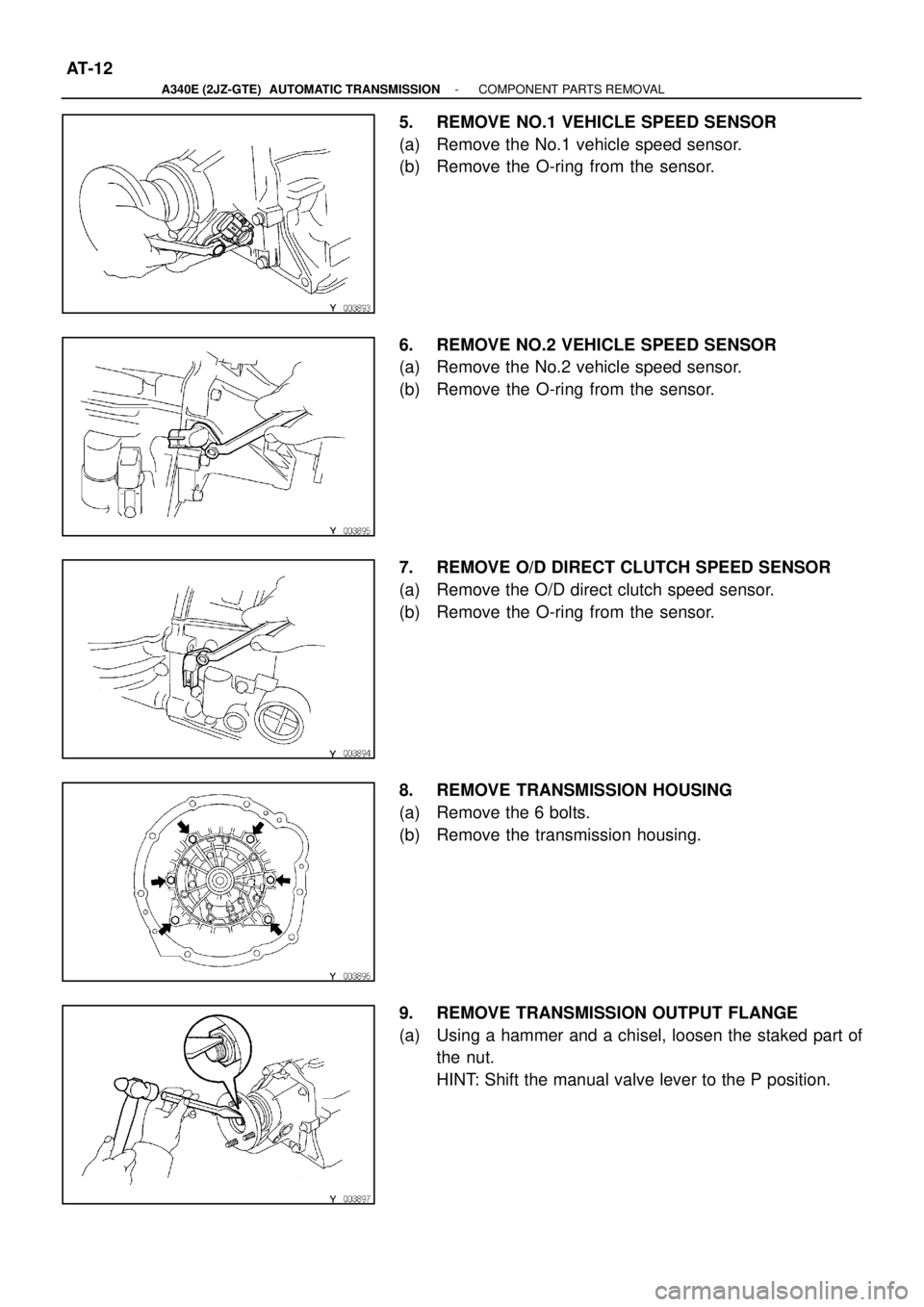

5. REMOVE NO.1 VEHICLE SPEED SENSOR

(a) Remove the No.1 vehicle speed sensor.

(b) Remove the O-ring from the sensor.

6. REMOVE NO.2 VEHICLE SPEED SENSOR

(a) Remove the No.2 vehicle speed sensor.

(b) Remove the O-ring from the sensor.

7. REMOVE O/D DIRECT CLUTCH SPEED SENSOR

(a) Remove the O/D direct clutch speed sensor.

(b) Remove the O-ring from the sensor.

8. REMOVE TRANSMISSION HOUSING

(a) Remove the 6 bolts.

(b) Remove the transmission housing.

9. REMOVE TRANSMISSION OUTPUT FLANGE

(a) Using a hammer and a chisel, loosen the staked part of

the nut.

HINT: Shift the manual valve lever to the P position.

Trending: engine overheat, steering wheel adjustment, windshield wipers, oil and filter replacement, clutch, flat tire, spark plugs