TOYOTA SUPRA 1995 Service Repair Manual

SUPRA 1995

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57468/w960_57468-0.png

TOYOTA SUPRA 1995 Service Repair Manual

Trending: light, ignition, alarm, service indicator, stop start, check transmission fluid, trailer

Page 301 of 2543

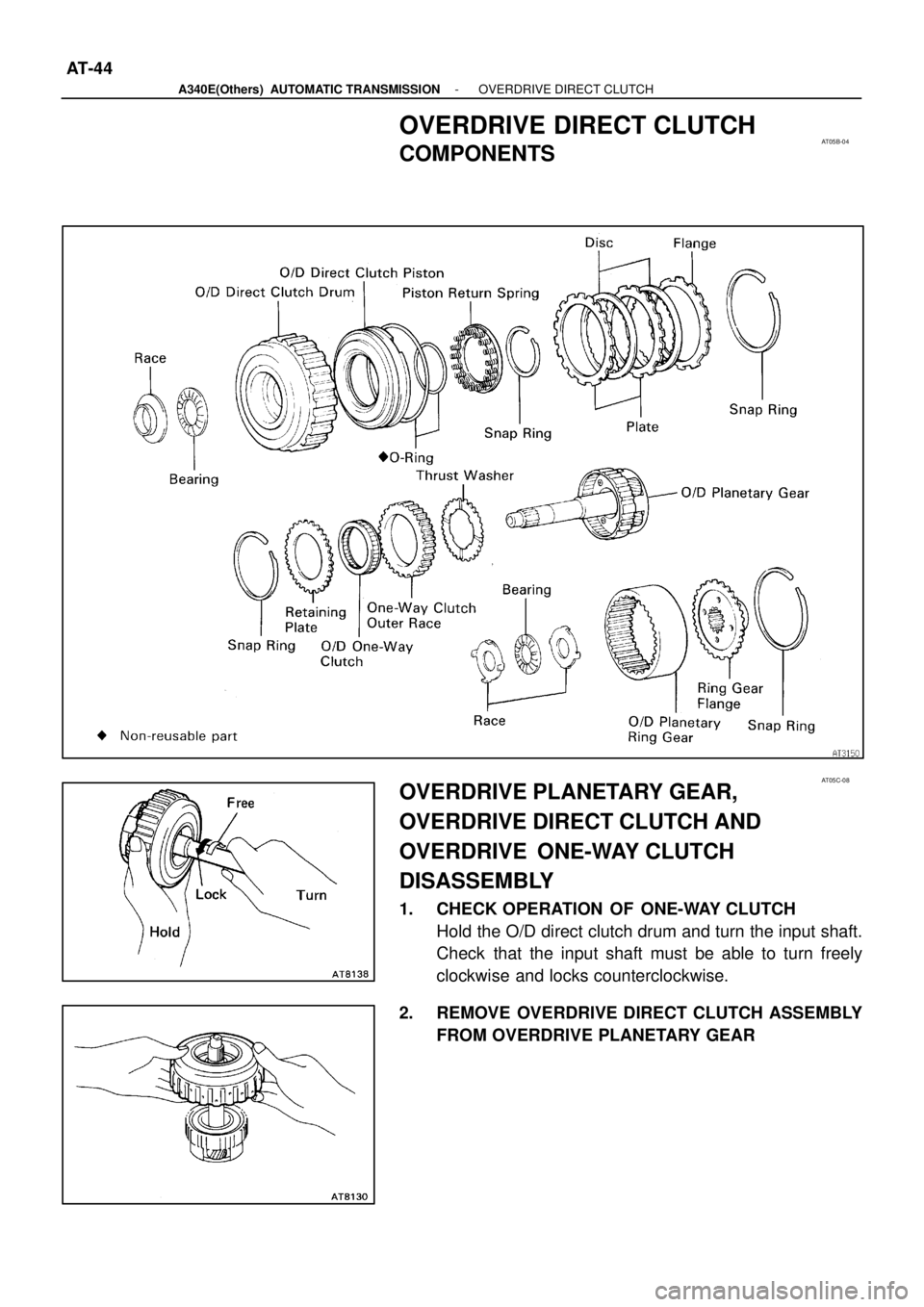

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-44

OVERDRIVE DIRECT CLUTCH

COMPONENTS

OVERDRIVE PLANETARY GEAR,

OVERDRIVE DIRECT CLUTCH AND

OVERDRIVE ONE-WAY CLUTCH

DISASSEMBLY

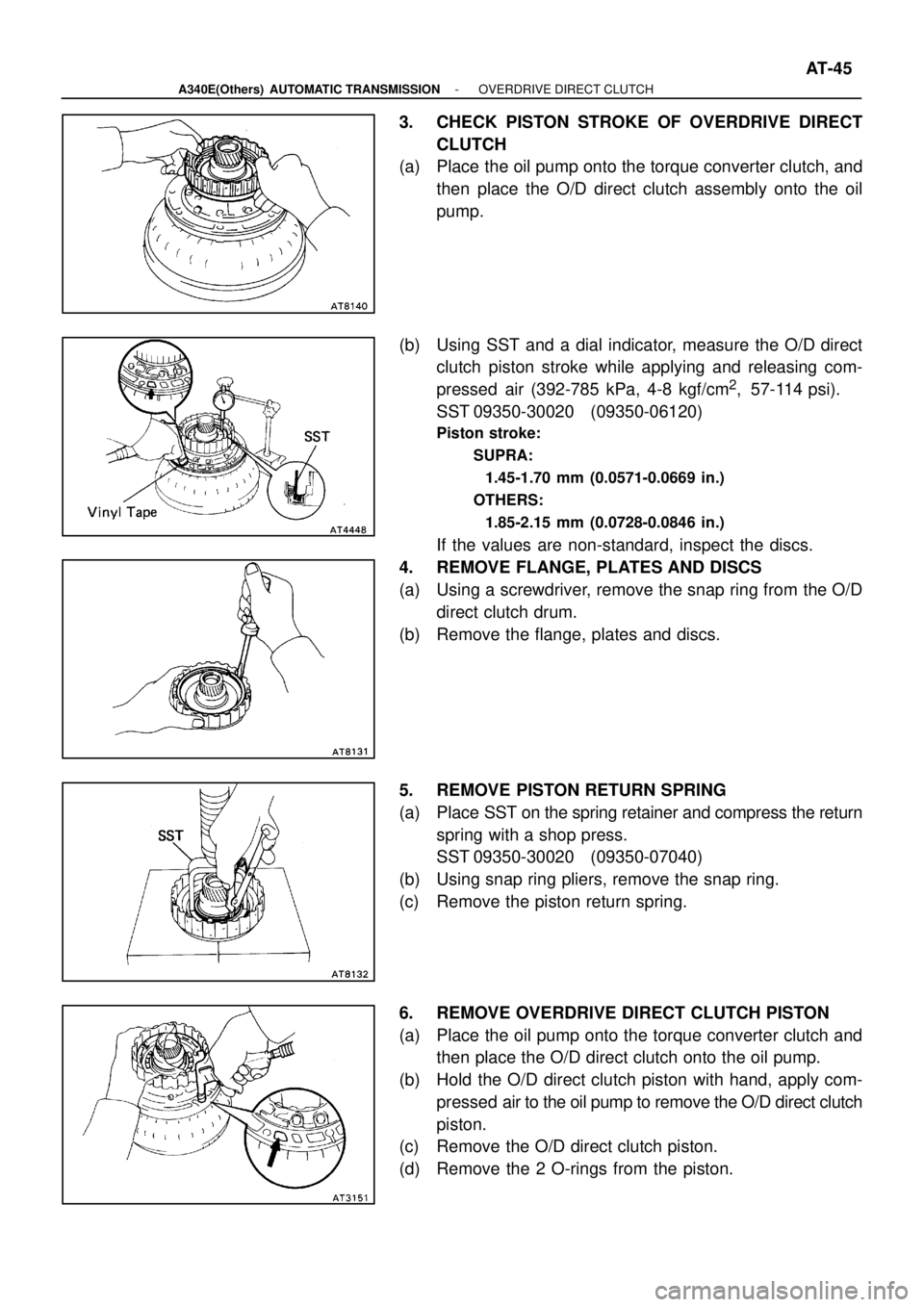

1. CHECK OPERATION OF ONE-WAY CLUTCH

Hold the O/D direct clutch drum and turn the input shaft.

Check that the input shaft must be able to turn freely

clockwise and locks counterclockwise.

2. REMOVE OVERDRIVE DIRECT CLUTCH ASSEMBLY

FROM OVERDRIVE PLANETARY GEAR

AT05B-04

AT05C-08

Page 302 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-45

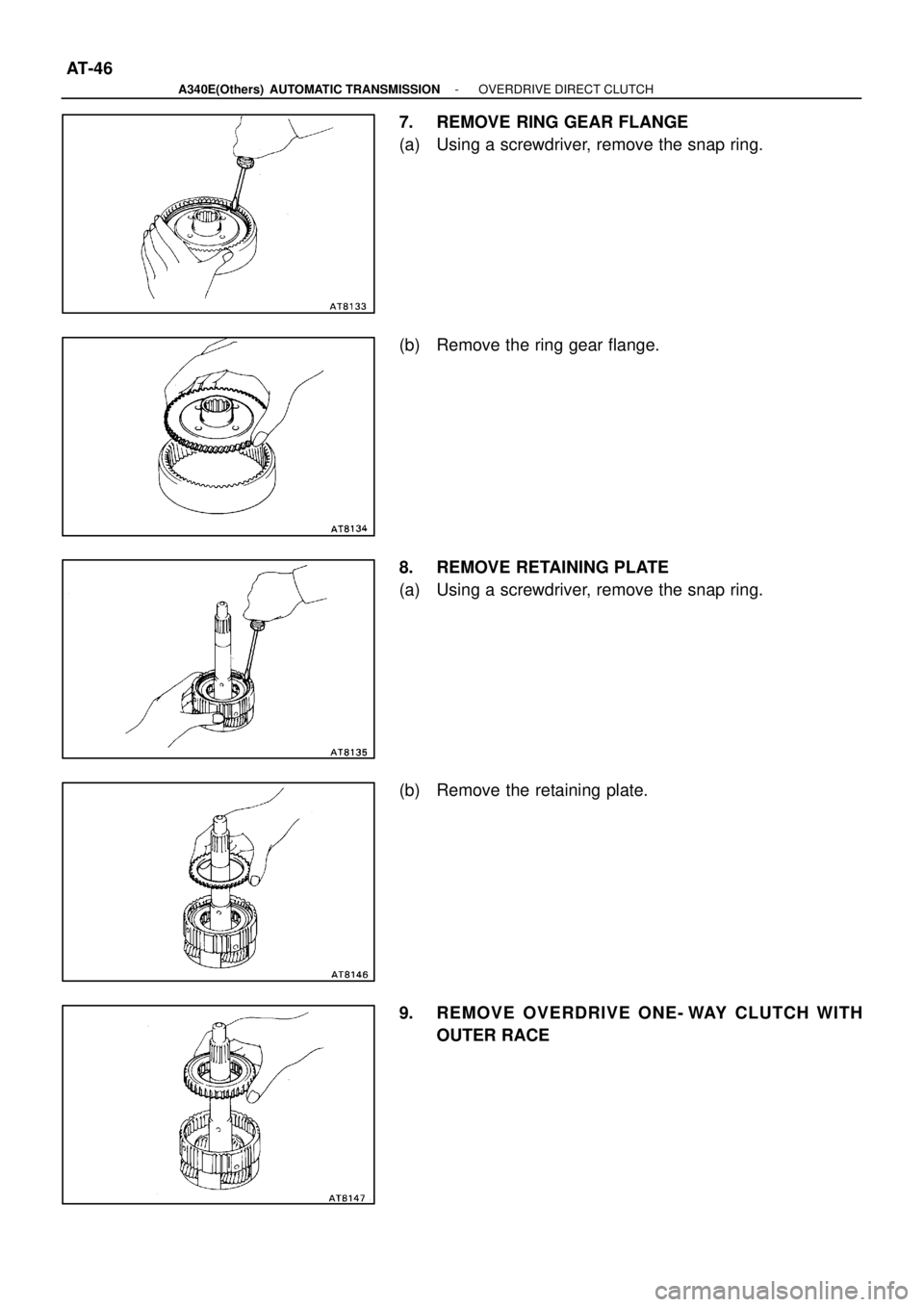

3. CHECK PISTON STROKE OF OVERDRIVE DIRECT

CLUTCH

(a) Place the oil pump onto the torque converter clutch, and

then place the O/D direct clutch assembly onto the oil

pump.

(b) Using SST and a dial indicator, measure the O/D direct

clutch piston stroke while applying and releasing com-

pressed air (392-785 kPa, 4-8 kgf/cm

2, 57-114 psi).

SST 09350-30020 (09350-06120)

Piston stroke:

SUPRA:

1.45-1.70 mm (0.0571-0.0669 in.)

OTHERS:

1.85-2.15 mm (0.0728-0.0846 in.)

If the values are non-standard, inspect the discs.

4. REMOVE FLANGE, PLATES AND DISCS

(a) Using a screwdriver, remove the snap ring from the O/D

direct clutch drum.

(b) Remove the flange, plates and discs.

5. REMOVE PISTON RETURN SPRING

(a) Place SST on the spring retainer and compress the return

spring with a shop press.

SST 09350-30020 (09350-07040)

(b) Using snap ring pliers, remove the snap ring.

(c) Remove the piston return spring.

6. REMOVE OVERDRIVE DIRECT CLUTCH PISTON

(a) Place the oil pump onto the torque converter clutch and

then place the O/D direct clutch onto the oil pump.

(b) Hold the O/D direct clutch piston with hand, apply com-

pressed air to the oil pump to remove the O/D direct clutch

piston.

(c) Remove the O/D direct clutch piston.

(d) Remove the 2 O-rings from the piston.

Page 303 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-46

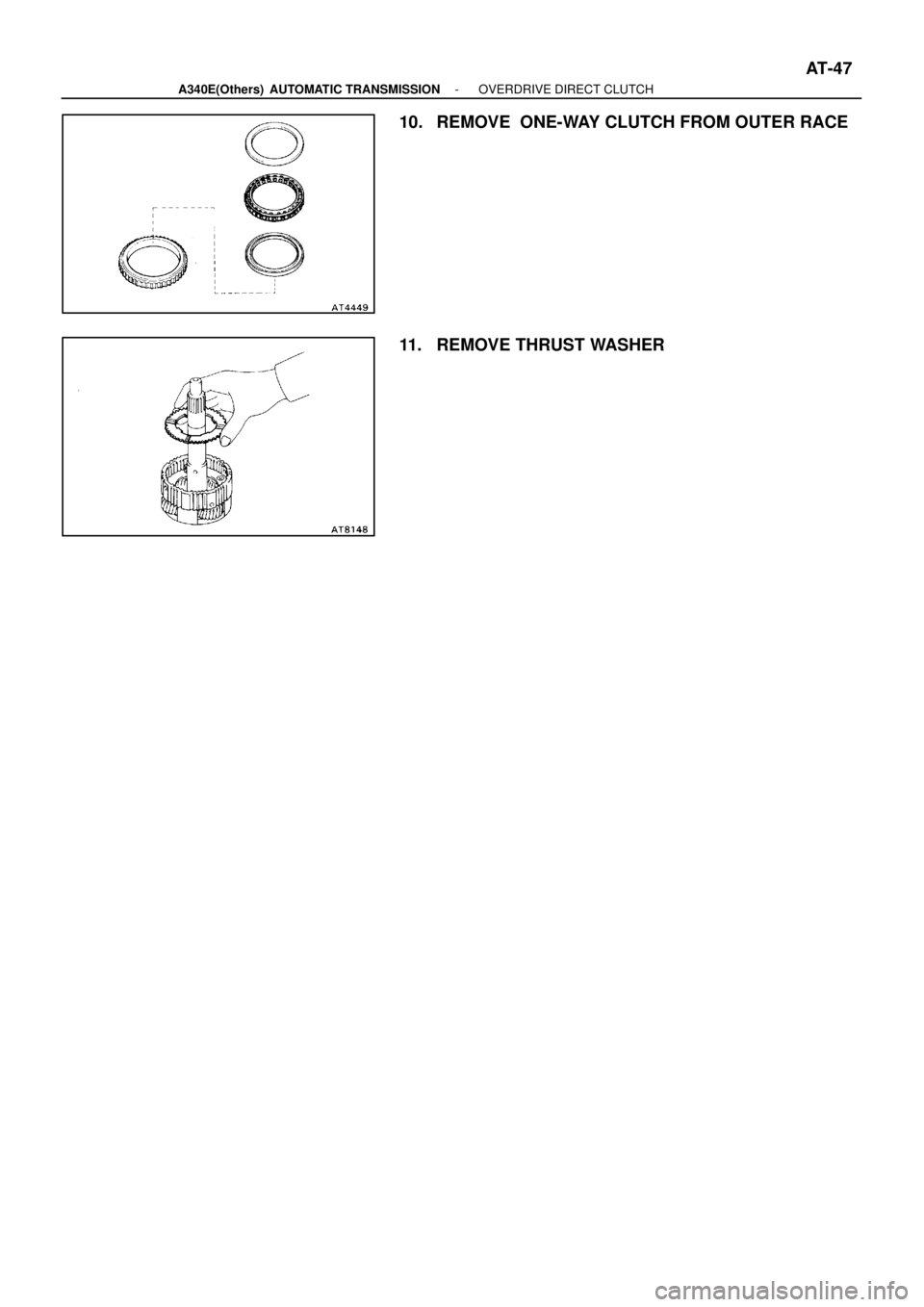

7. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the ring gear flange.

8. REMOVE RETAINING PLATE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the retaining plate.

9. REMOVE OVERDRIVE ONE- WAY CLUTCH WITH

OUTER RACE

Page 304 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-47

10. REMOVE ONE-WAY CLUTCH FROM OUTER RACE

11. REMOVE THRUST WASHER

Page 305 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-48

OVERDRIVE PLANETARY GEAR AND

OVERDRIVE DIRECT CLUTCH INSPECTION

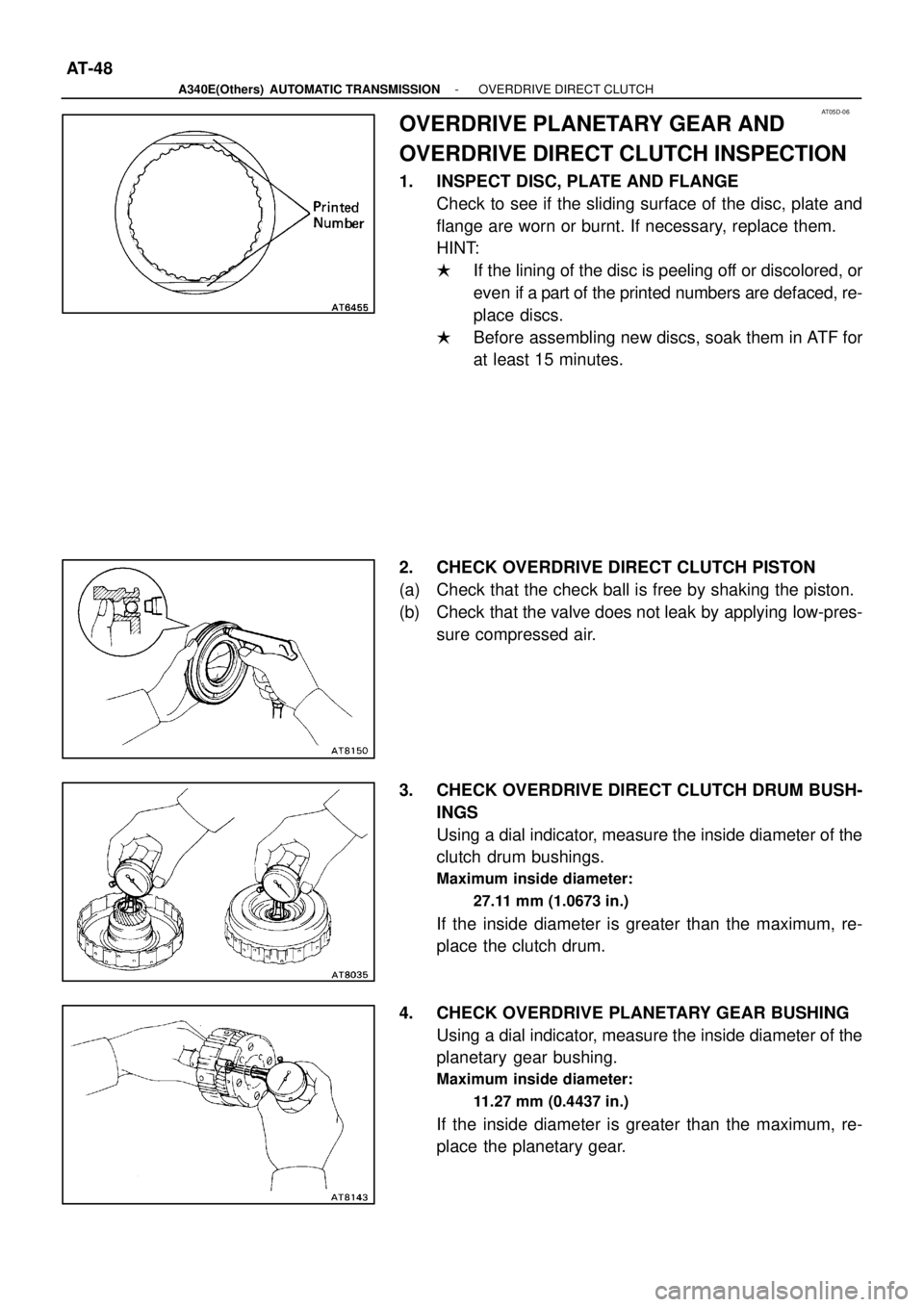

1. INSPECT DISC, PLATE AND FLANGE

Check to see if the sliding surface of the disc, plate and

flange are worn or burnt. If necessary, replace them.

HINT:

�If the lining of the disc is peeling off or discolored, or

even if a part of the printed numbers are defaced, re-

place discs.

�Before assembling new discs, soak them in ATF for

at least 15 minutes.

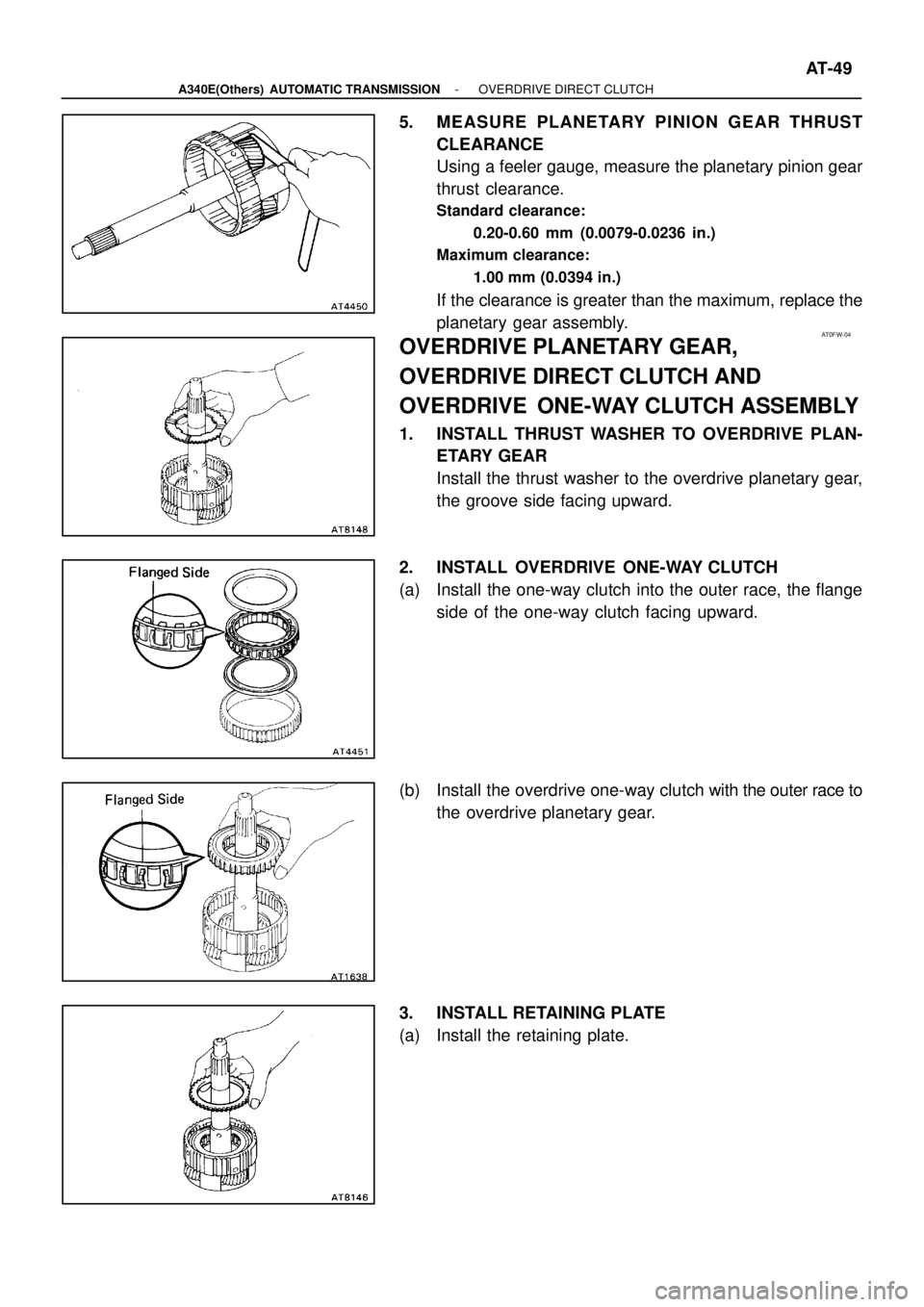

2. CHECK OVERDRIVE DIRECT CLUTCH PISTON

(a) Check that the check ball is free by shaking the piston.

(b) Check that the valve does not leak by applying low-pres-

sure compressed air.

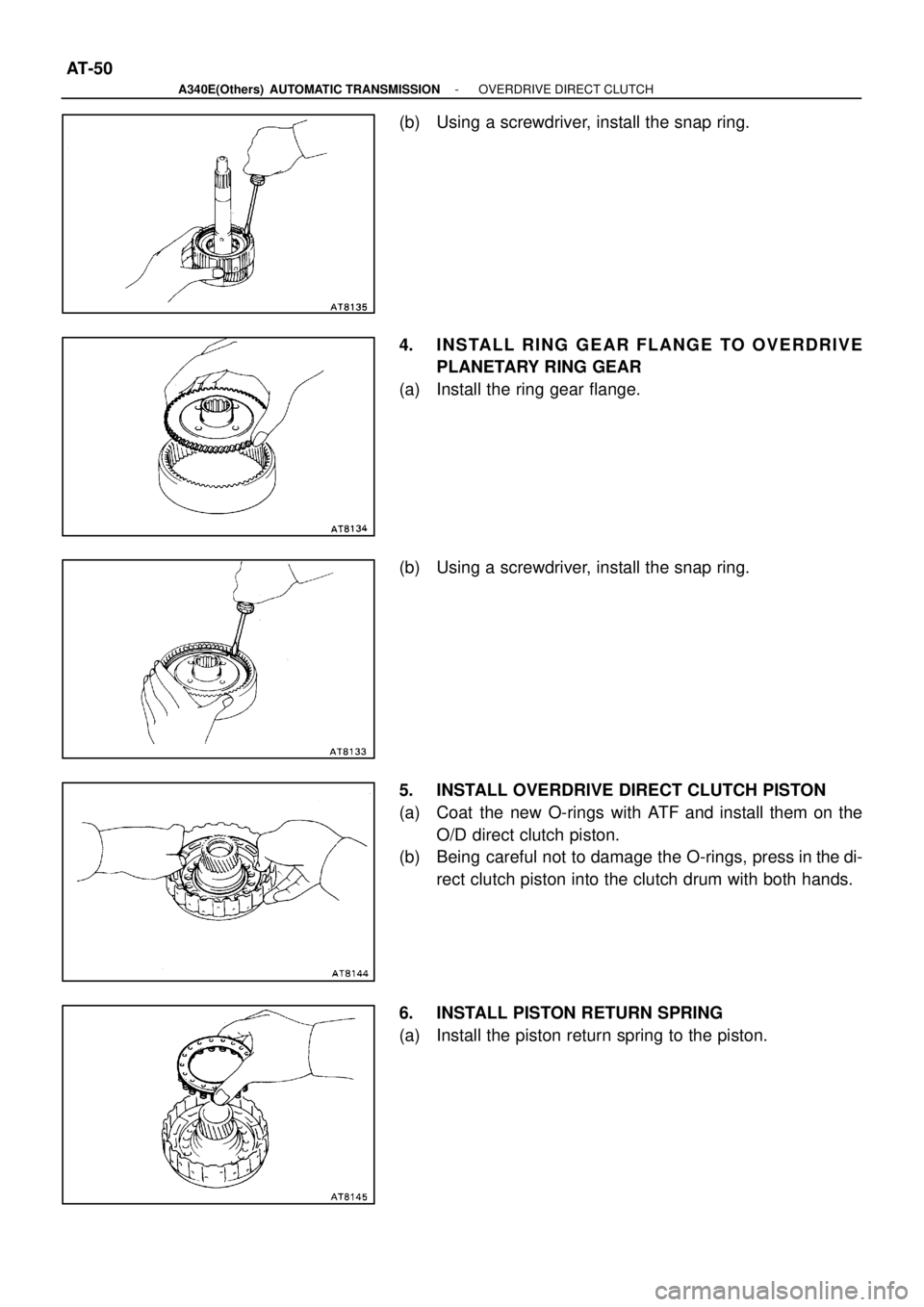

3. CHECK OVERDRIVE DIRECT CLUTCH DRUM BUSH-

INGS

Using a dial indicator, measure the inside diameter of the

clutch drum bushings.

Maximum inside diameter:

27.11 mm (1.0673 in.)

If the inside diameter is greater than the maximum, re-

place the clutch drum.

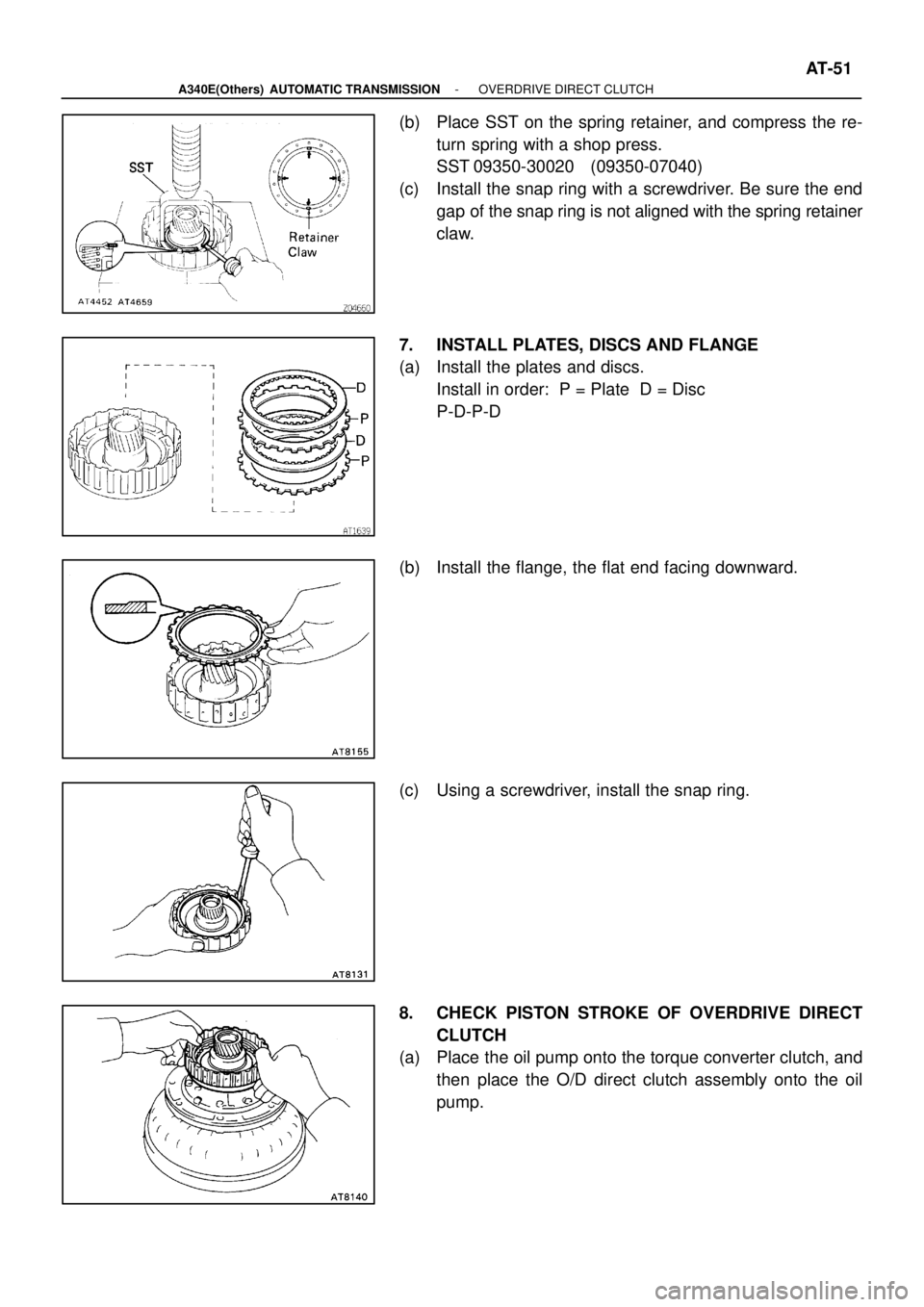

4. CHECK OVERDRIVE PLANETARY GEAR BUSHING

Using a dial indicator, measure the inside diameter of the

planetary gear bushing.

Maximum inside diameter:

11.27 mm (0.4437 in.)

If the inside diameter is greater than the maximum, re-

place the planetary gear.

AT05D-06

Page 306 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-49

5. MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance:

0.20-0.60 mm (0.0079-0.0236 in.)

Maximum clearance:

1.00 mm (0.0394 in.)

If the clearance is greater than the maximum, replace the

planetary gear assembly.

OVERDRIVE PLANETARY GEAR,

OVERDRIVE DIRECT CLUTCH AND

OVERDRIVE ONE-WAY CLUTCH ASSEMBLY

1. INSTALL THRUST WASHER TO OVERDRIVE PLAN-

ETARY GEAR

Install the thrust washer to the overdrive planetary gear,

the groove side facing upward.

2. INSTALL OVERDRIVE ONE-WAY CLUTCH

(a) Install the one-way clutch into the outer race, the flange

side of the one-way clutch facing upward.

(b) Install the overdrive one-way clutch with the outer race to

the overdrive planetary gear.

3. INSTALL RETAINING PLATE

(a) Install the retaining plate.

AT0FW-04

Page 307 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-50

(b) Using a screwdriver, install the snap ring.

4. INSTALL RING GEAR FLANGE TO OVERDRIVE

PLANETARY RING GEAR

(a) Install the ring gear flange.

(b) Using a screwdriver, install the snap ring.

5. INSTALL OVERDRIVE DIRECT CLUTCH PISTON

(a) Coat the new O-rings with ATF and install them on the

O/D direct clutch piston.

(b) Being careful not to damage the O-rings, press in the di-

rect clutch piston into the clutch drum with both hands.

6. INSTALL PISTON RETURN SPRING

(a) Install the piston return spring to the piston.

Page 308 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-51

(b) Place SST on the spring retainer, and compress the re-

turn spring with a shop press.

SST 09350-30020 (09350-07040)

(c) Install the snap ring with a screwdriver. Be sure the end

gap of the snap ring is not aligned with the spring retainer

claw.

7. INSTALL PLATES, DISCS AND FLANGE

(a) Install the plates and discs.

Install in order: P = Plate D = Disc

P-D-P-D

(b) Install the flange, the flat end facing downward.

(c) Using a screwdriver, install the snap ring.

8. CHECK PISTON STROKE OF OVERDRIVE DIRECT

CLUTCH

(a) Place the oil pump onto the torque converter clutch, and

then place the O/D direct clutch assembly onto the oil

pump.

Page 309 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE DIRECT CLUTCH -

AT-52

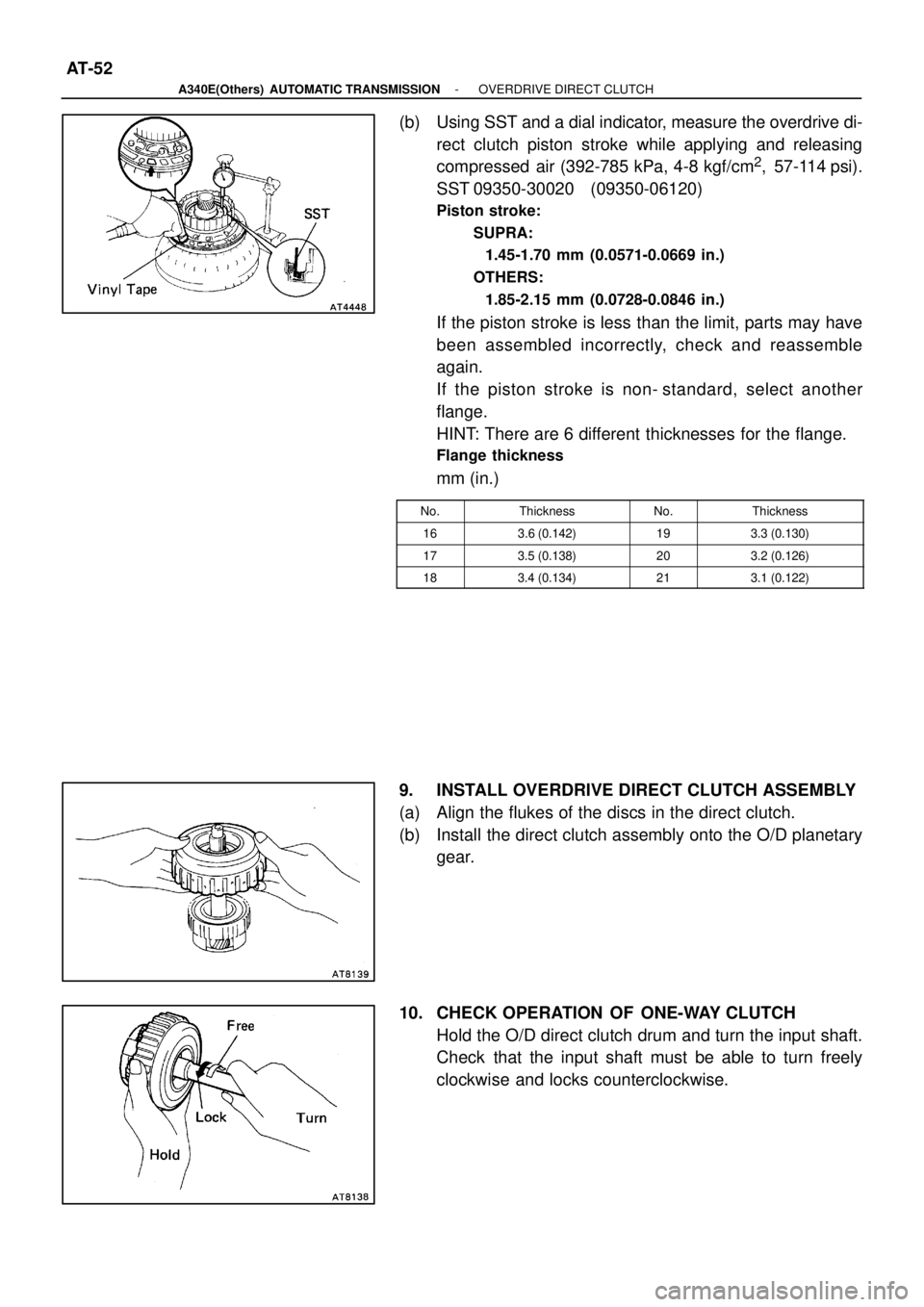

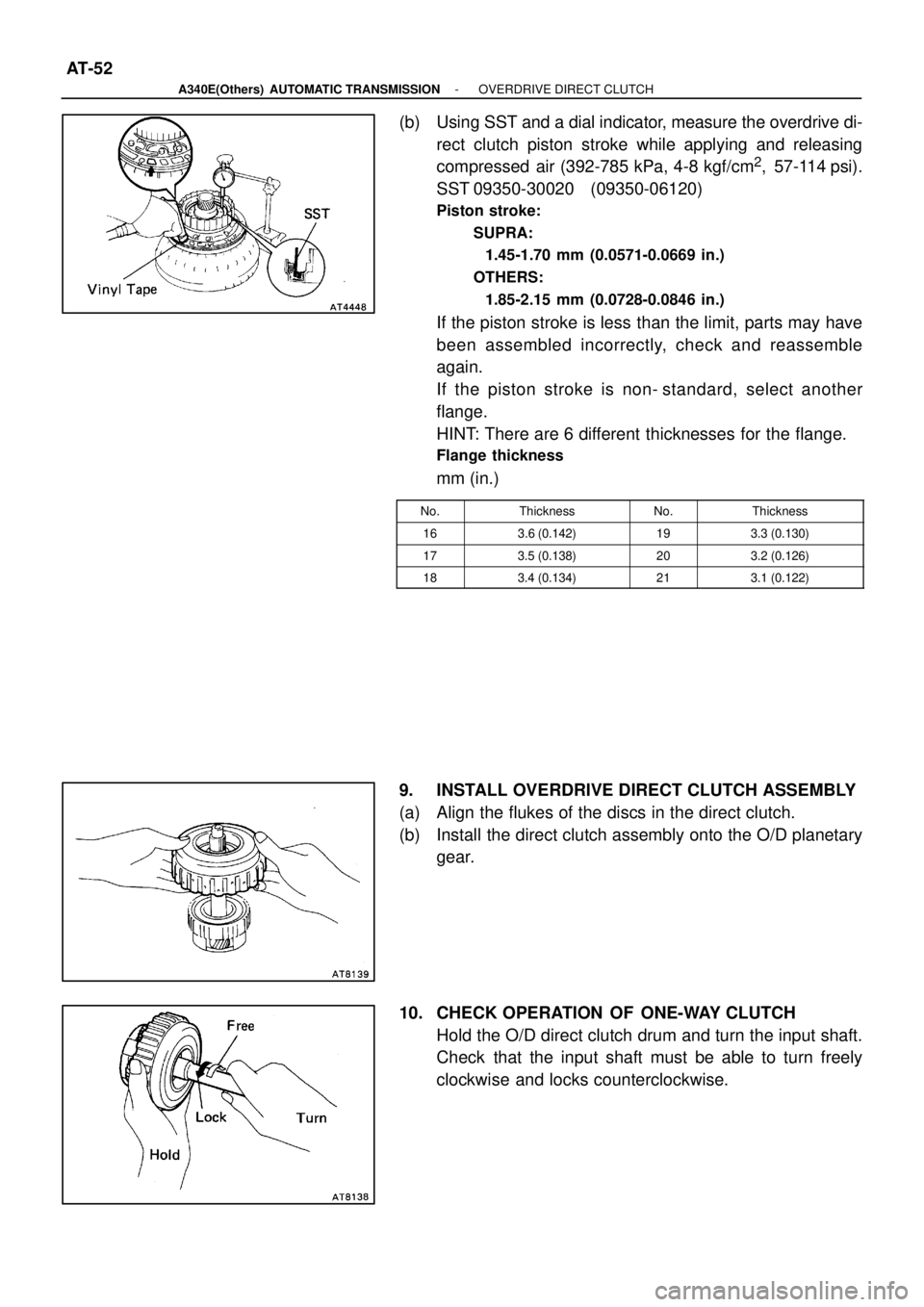

(b) Using SST and a dial indicator, measure the overdrive di-

rect clutch piston stroke while applying and releasing

compressed air (392-785 kPa, 4-8 kgf/cm

2, 57-114 psi).

SST 09350-30020 (09350-06120)

Piston stroke:

SUPRA:

1.45-1.70 mm (0.0571-0.0669 in.)

OTHERS:

1.85-2.15 mm (0.0728-0.0846 in.)

If the piston stroke is less than the limit, parts may have

been assembled incorrectly, check and reassemble

again.

If the piston stroke is non- standard, select another

flange.

HINT: There are 6 different thicknesses for the flange.

Flange thickness

mm (in.)

No.ThicknessNo.Thickness

163.6 (0.142)193.3 (0.130)

173.5 (0.138)203.2 (0.126)

183.4 (0.134)213.1 (0.122)

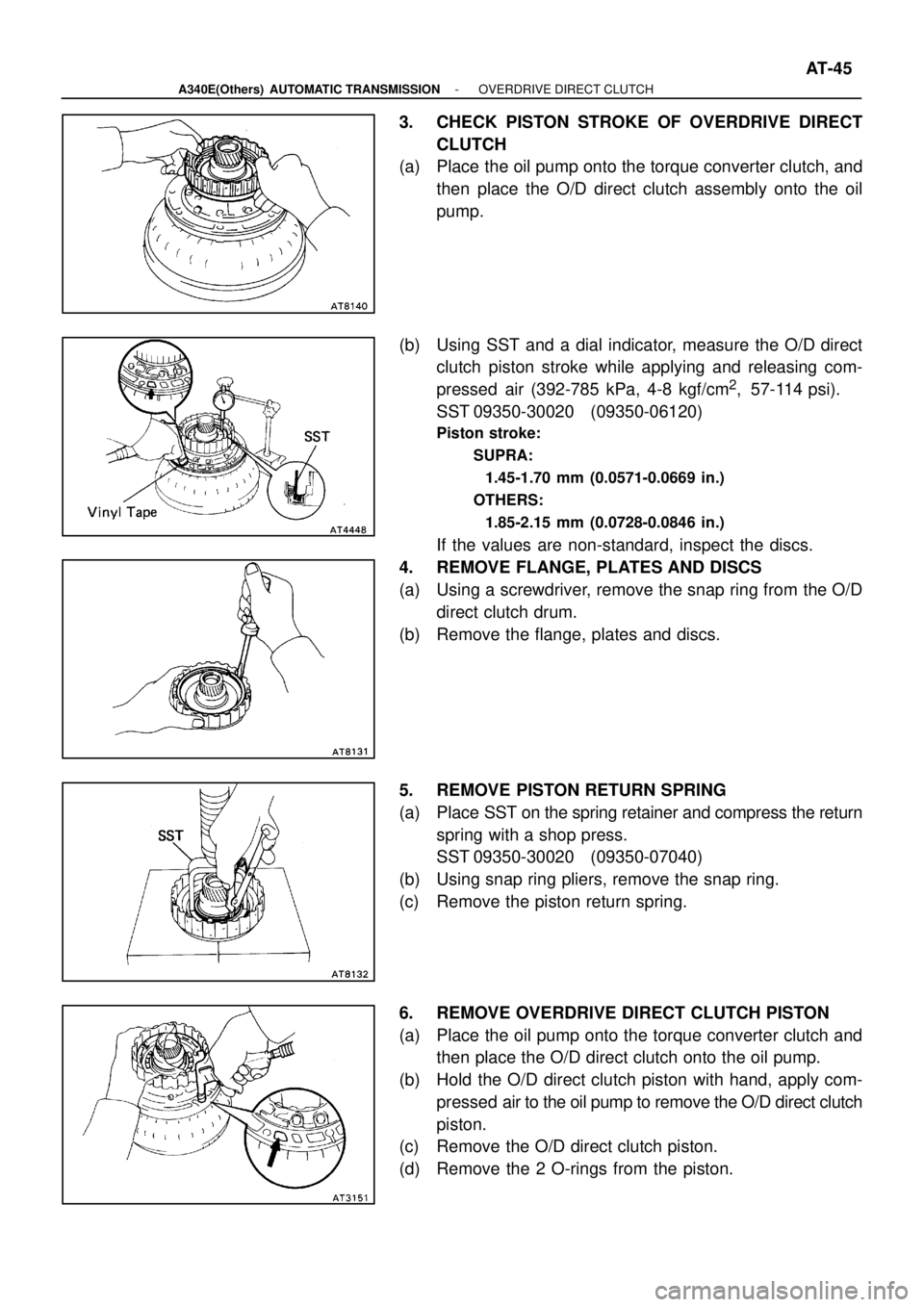

9. INSTALL OVERDRIVE DIRECT CLUTCH ASSEMBLY

(a) Align the flukes of the discs in the direct clutch.

(b) Install the direct clutch assembly onto the O/D planetary

gear.

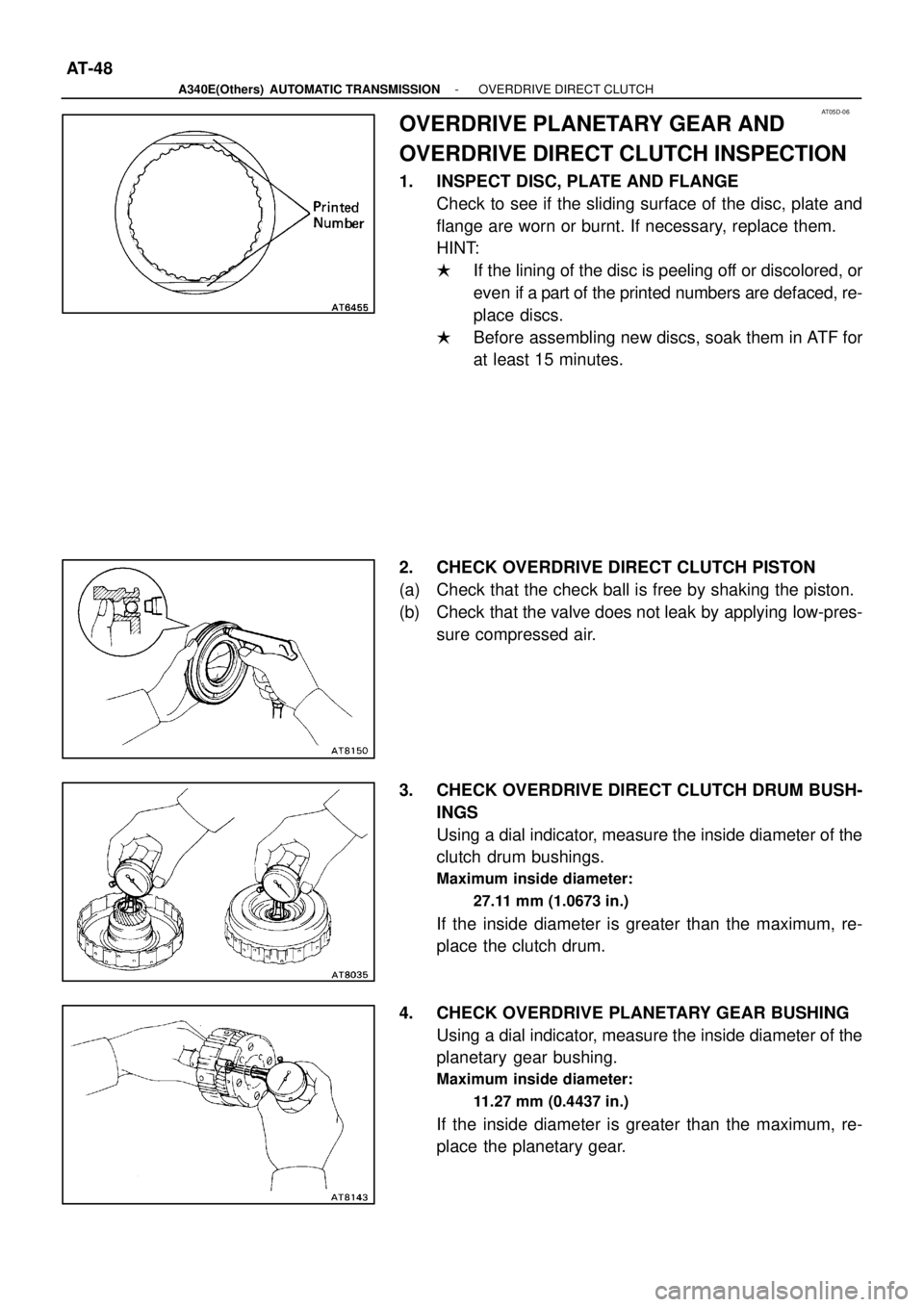

10. CHECK OPERATION OF ONE-WAY CLUTCH

Hold the O/D direct clutch drum and turn the input shaft.

Check that the input shaft must be able to turn freely

clockwise and locks counterclockwise.

Page 310 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOVERDRIVE BRAKE -

AT-53

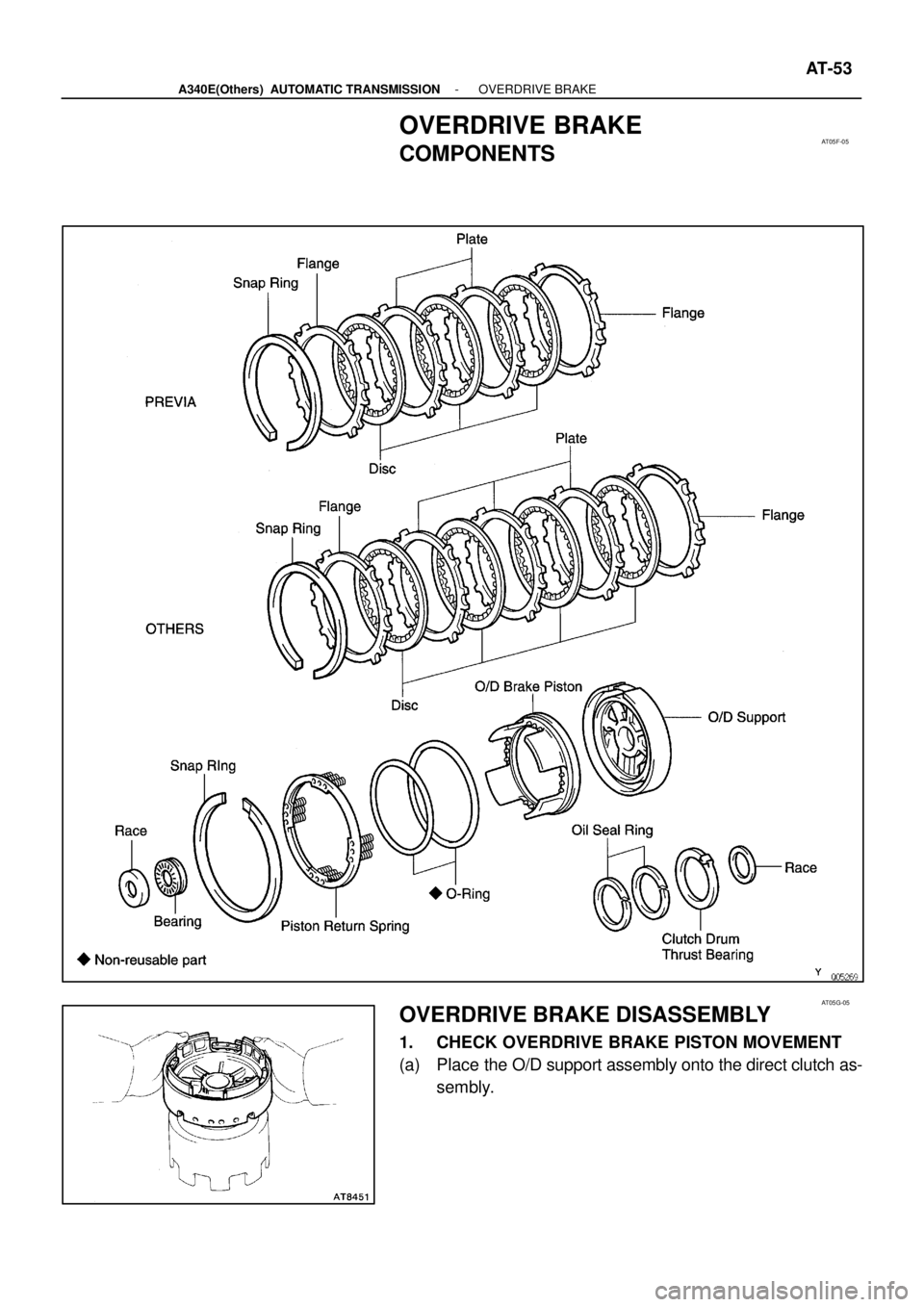

OVERDRIVE BRAKE

COMPONENTS

OVERDRIVE BRAKE DISASSEMBLY

1. CHECK OVERDRIVE BRAKE PISTON MOVEMENT

(a) Place the O/D support assembly onto the direct clutch as-

sembly.

AT05F-05

AT05G-05

Trending: overheating, roof rack, instrument cluster, trailer, driver seat adjustment, oil level, fold seats