lock TOYOTA SUPRA 2023 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2023, Model line: SUPRA, Model: TOYOTA SUPRA 2023Pages: 372, PDF Size: 6.32 MB

Page 283 of 372

2835-1. MOBILITY

5

MOBILITY

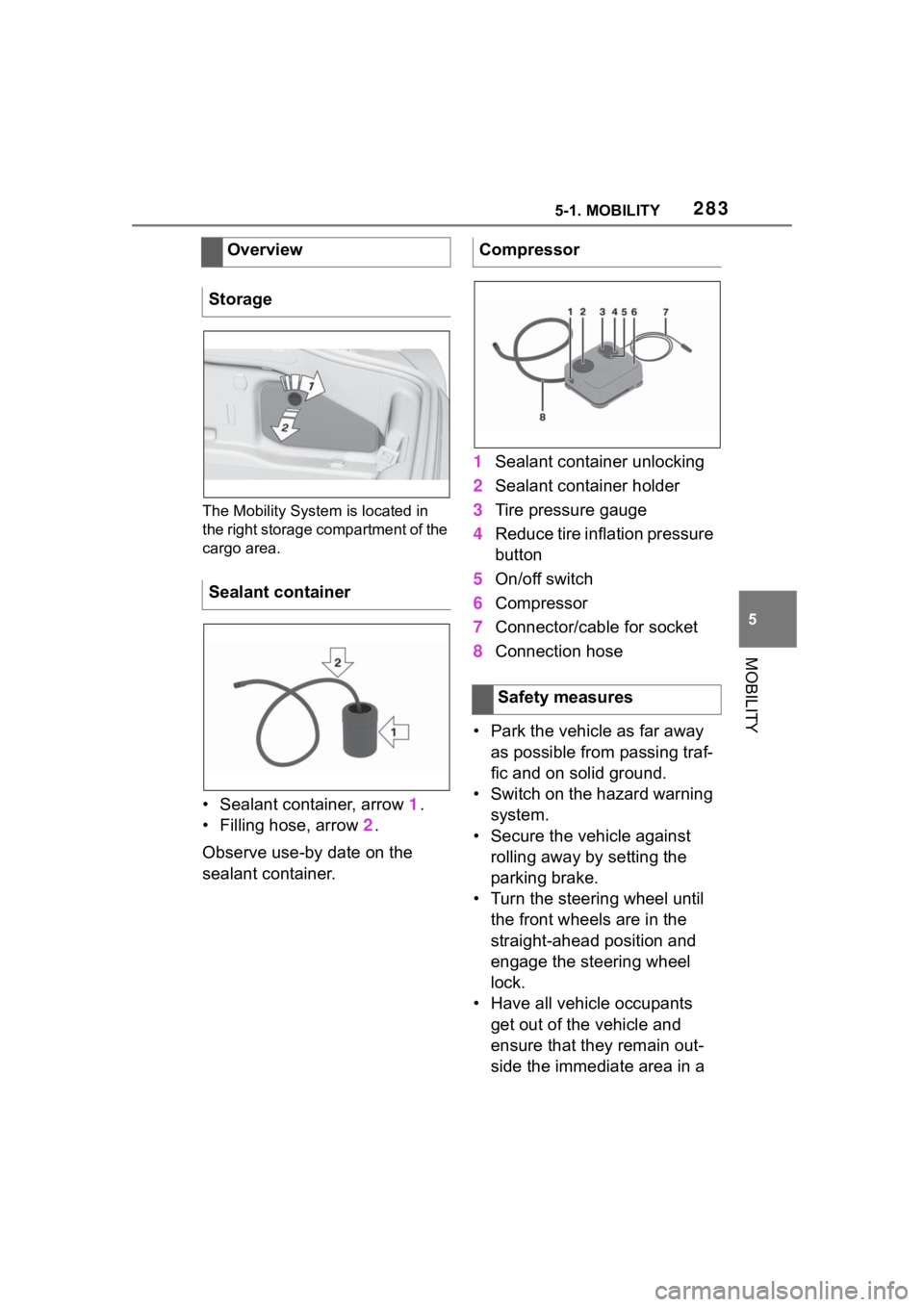

The Mobility System is located in

the right storage compartment of the

cargo area.

• Sealant container, arrow 1.

• Filling hose, arrow 2.

Observe use-by date on the

sealant container. 1

Sealant container unlocking

2 Sealant container holder

3 Tire pressure gauge

4 Reduce tire inflation pressure

button

5 On/off switch

6 Compressor

7 Connector/cable for socket

8 Connection hose

• Park the vehicle as far away as possible from passing traf-

fic and on solid ground.

• Switch on the hazard warning system.

• Secure the vehicle against rolling away by setting the

parking brake.

• Turn the steering wheel until the front wheels are in the

straight-ahead position and

engage the steering wheel

lock.

• Have all vehicle occupants get out of the vehicle and

ensure that they remain out-

side the immediate area in a

Overview

Storage

Sealant container

Compressor

Safety measures

Page 284 of 372

2845-1. MOBILITY

safe place, such as behind a

guardrail.

• If necessary, set up a warning triangle at an appropriate dis-

tance.

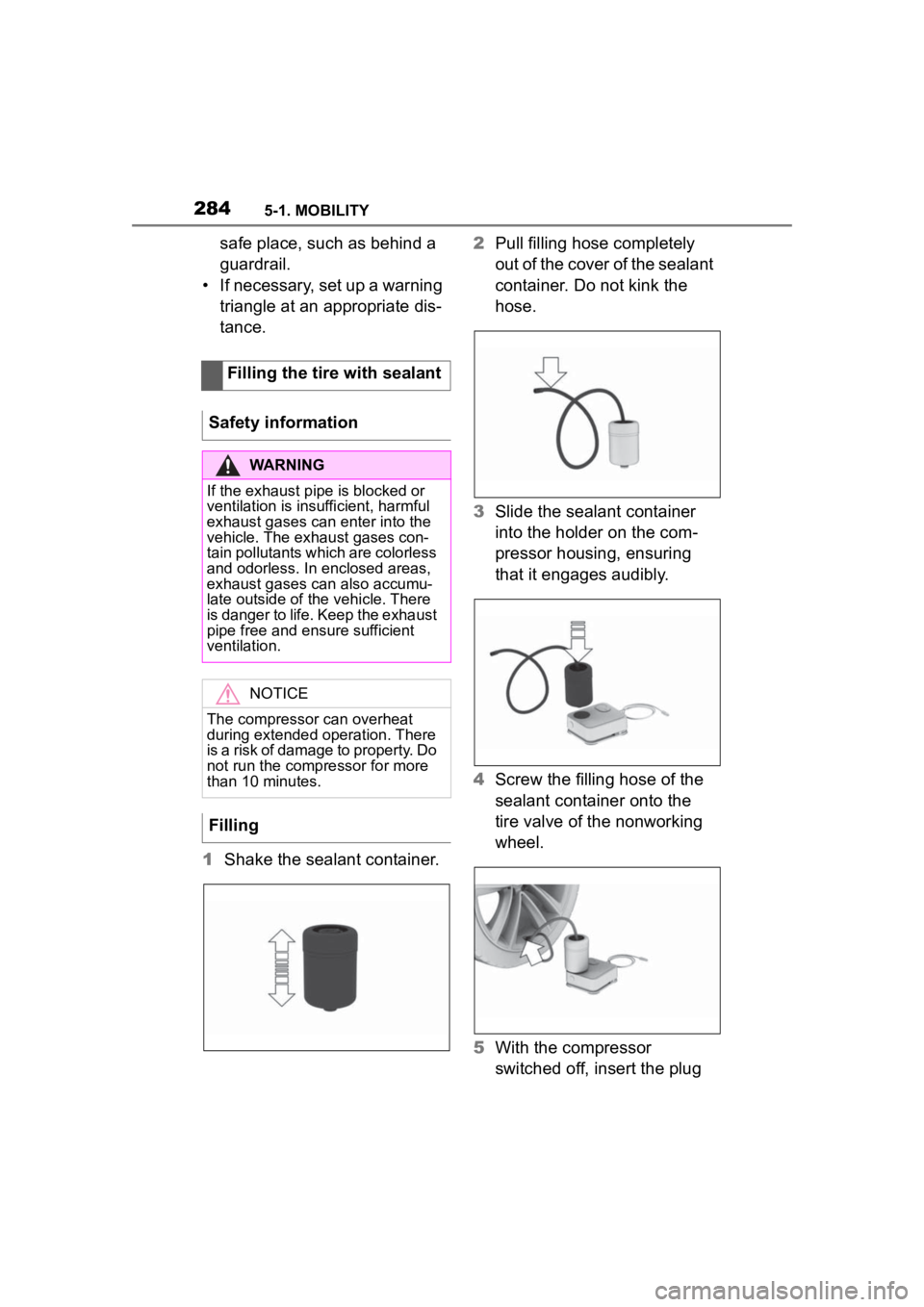

1 Shake the sealant container. 2

Pull filling hose completely

out of the cover of the sealant

container. Do not kink the

hose.

3 Slide the sealant container

into the holder on the com-

pressor housing, ensuring

that it engages audibly.

4 Screw the filling hose of the

sealant container onto the

tire valve of the nonworking

wheel.

5 With the compressor

switched off, insert the plug

Filling the tire with sealant

Safety information

WARNING

If the exhaust pipe is blocked or

ventilation is insufficient, harmful

exhaust gases can enter into the

vehicle. The exhaust gases con-

tain pollutants which are colorless

and odorless. In enclosed areas,

exhaust gases can also accumu-

late outside of the vehicle. There

is danger to life. Keep the exhaust

pipe free and ensure sufficient

ventilation.

NOTICE

The compressor can overheat

during extended operation. There

is a risk of damage to property. Do

not run the compressor for more

than 10 minutes.

Filling

Page 285 of 372

2855-1. MOBILITY

5

MOBILITY

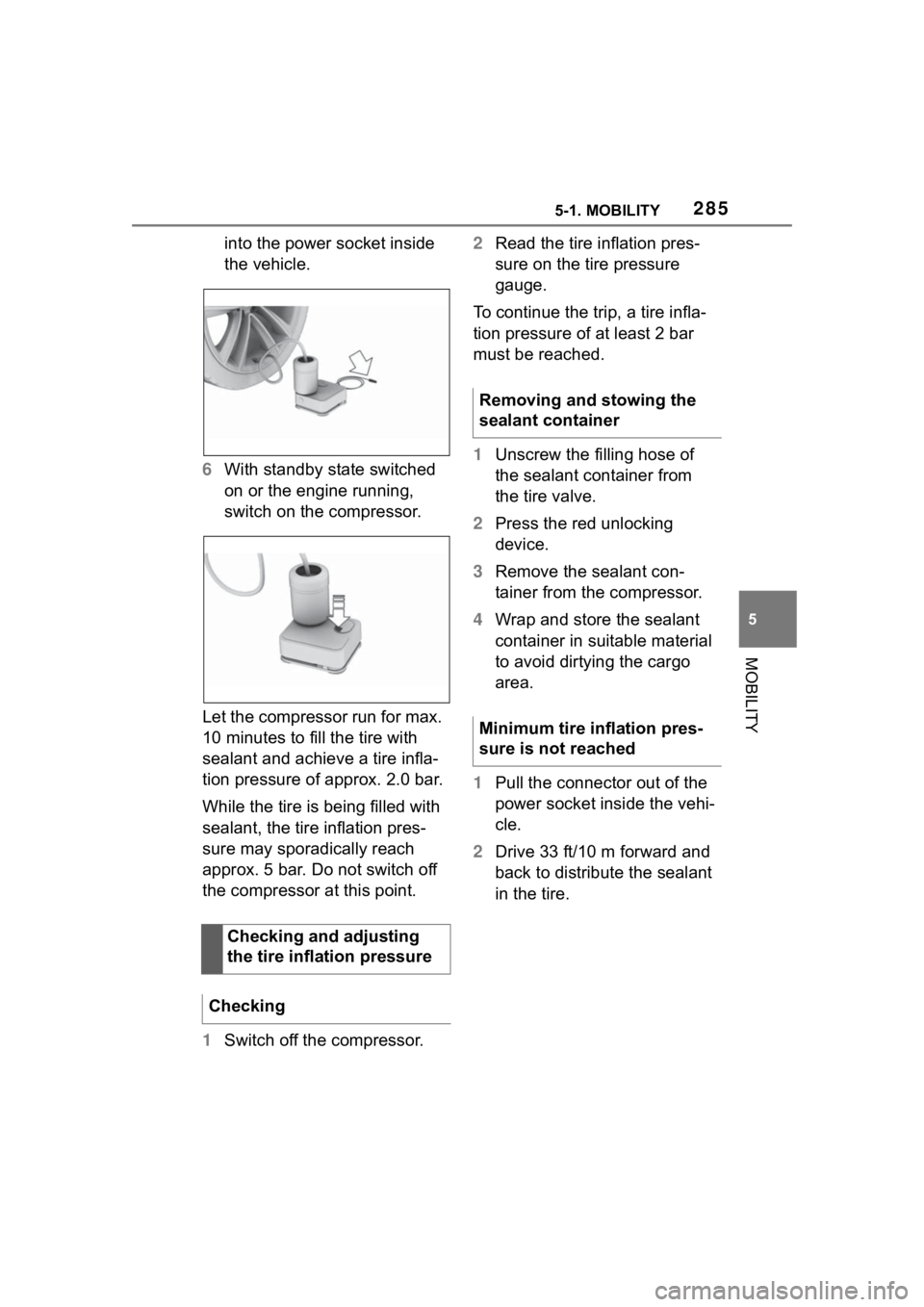

into the power socket inside

the vehicle.

6 With standby state switched

on or the engine running,

switch on the compressor.

Let the compressor run for max.

10 minutes to fill the tire with

sealant and achieve a tire infla-

tion pressure of approx. 2.0 bar.

While the tire is being filled with

sealant, the tire inflation pres-

sure may sporadically reach

approx. 5 bar. Do not switch off

the compressor at this point.

1 Switch off the compressor. 2

Read the tire inflation pres-

sure on the tire pressure

gauge.

To continue the trip, a tire infla-

tion pressure of at least 2 bar

must be reached.

1 Unscrew the filling hose of

the sealant container from

the tire valve.

2 Press the red unlocking

device.

3 Remove the sealant con-

tainer from the compressor.

4 Wrap and store the sealant

container in suitable material

to avoid dirtying the cargo

area.

1 Pull the connector out of the

power socket inside the vehi-

cle.

2 Drive 33 ft/10 m forward and

back to distribute the sealant

in the tire.

Checking and adjusting

the tire inflation pressure

Checking

Removing and stowing the

sealant container

Minimum tire inflation pres-

sure is not reached

Page 296 of 372

2965-1. MOBILITY

tioning properly. Always

check the TPMS malfunction

telltale after replacing one or

more tires or wheels on your

vehicle to ensure that the

replacement or alternate tires

and wheels allow the TPMS

to continue to function prop-

erly.

If a tire is punctured and loses

pressure, it is not necessary to

replace the tire immediately if a

tire repair kit (Mobility System) is

used.

If needed, the tools for changing

wheels are available as acces-

sories from your Toyota dealer.

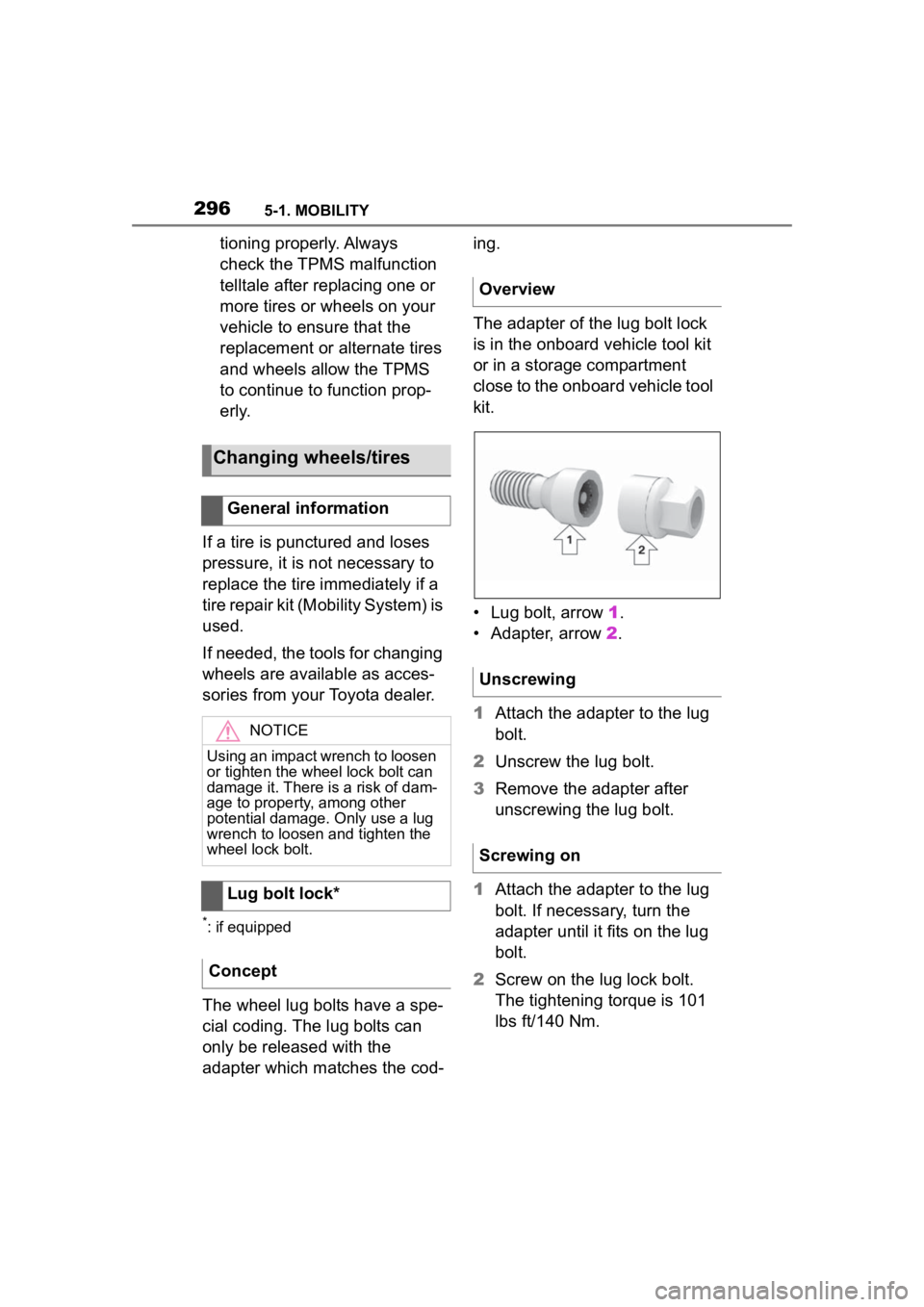

*: if equipped

The wheel lug bolts have a spe-

cial coding. The lug bolts can

only be released with the

adapter which matches the cod- ing.

The adapter of the lug bolt lock

is in the onboard vehicle tool kit

or in a storage compartment

close to the onboard vehicle tool

kit.

• Lug bolt, arrow

1.

• Adapter, arrow 2.

1 Attach the adapter to the lug

bolt.

2 Unscrew the lug bolt.

3 Remove the adapter after

unscrewing the lug bolt.

1 Attach the adapter to the lug

bolt. If necessary, turn the

adapter until it fits on the lug

bolt.

2 Screw on the lug lock bolt.

The tightening torque is 101

lbs ft/140 Nm.

Changing wheels/tires

General information

NOTICE

Using an impact wrench to loosen

or tighten the wheel lock bolt can

damage it. There is a risk of dam-

age to property, among other

potential damage. Only use a lug

wrench to loosen and tighten the

wheel lock bolt.

Lug bolt lock*

Concept

Overview

Unscrewing

Screwing on

Page 299 of 372

2995-1. MOBILITY

5

MOBILITY

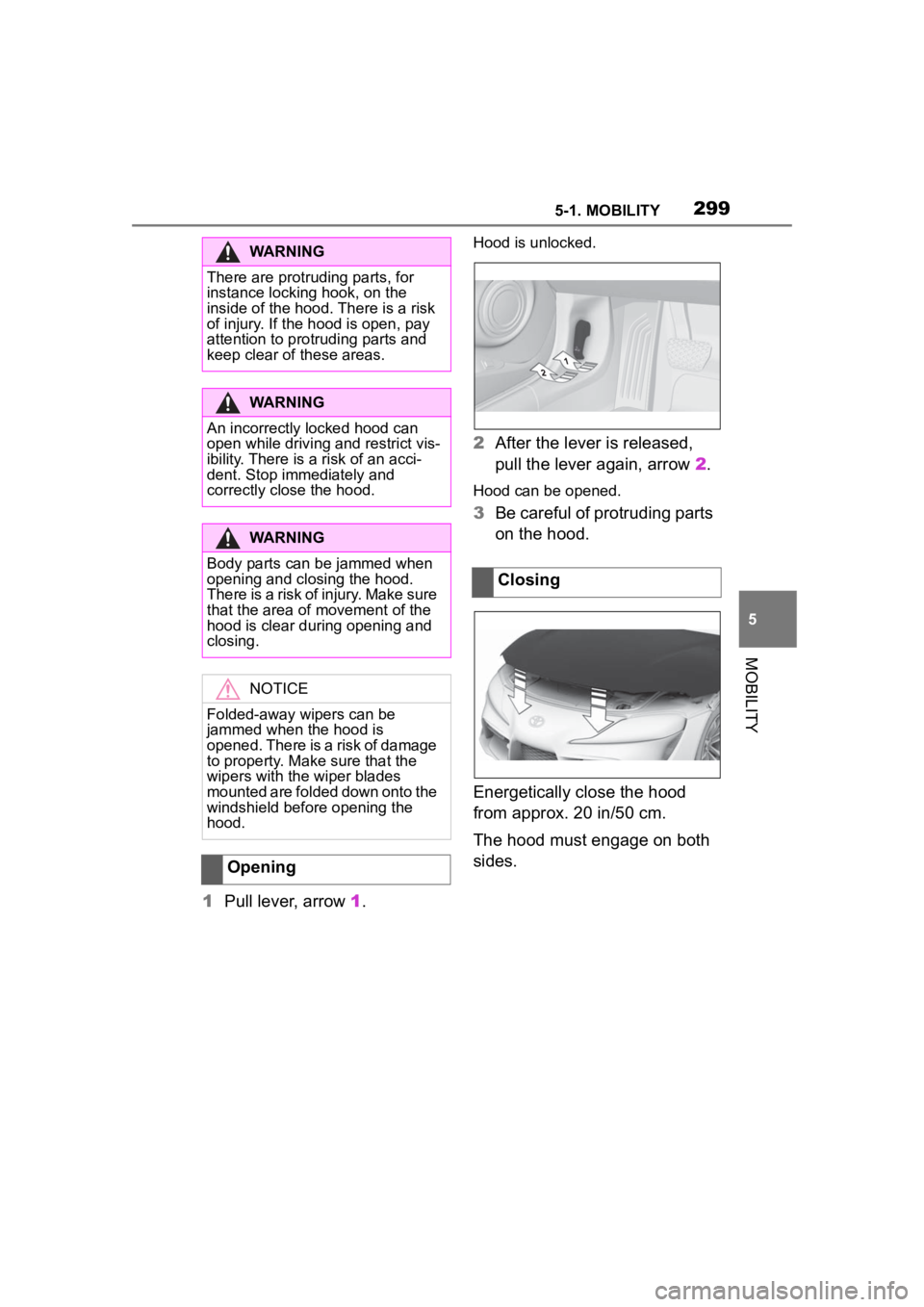

1Pull lever, arrow 1.

Hood is unlocked.

2After the lever is released,

pull the lever again, arrow 2.

Hood can be opened.

3Be careful of protruding parts

on the hood.

Energetically close the hood

from approx. 20 in/50 cm.

The hood must engage on both

sides.

WARNING

There are protruding parts, for

instance locking hook, on the

inside of the hood. There is a risk

of injury. If the hood is open, pay

attention to protruding parts and

keep clear of these areas.

WARNING

An incorrectly locked hood can

open while driving and restrict vis-

ibility. There is a risk of an acci-

dent. Stop immediately and

correctly close the hood.

WARNING

Body parts can be jammed when

opening and closing the hood.

There is a risk of injury. Make sure

that the area of movement of the

hood is clear during opening and

closing.

NOTICE

Folded-away wipers can be

jammed when the hood is

opened. There is a risk of damage

to property. Make sure that the

wipers with the wiper blades

mounted are folded down onto the

windshield before opening the

hood.

Opening

Closing

Page 304 of 372

3045-1. MOBILITY

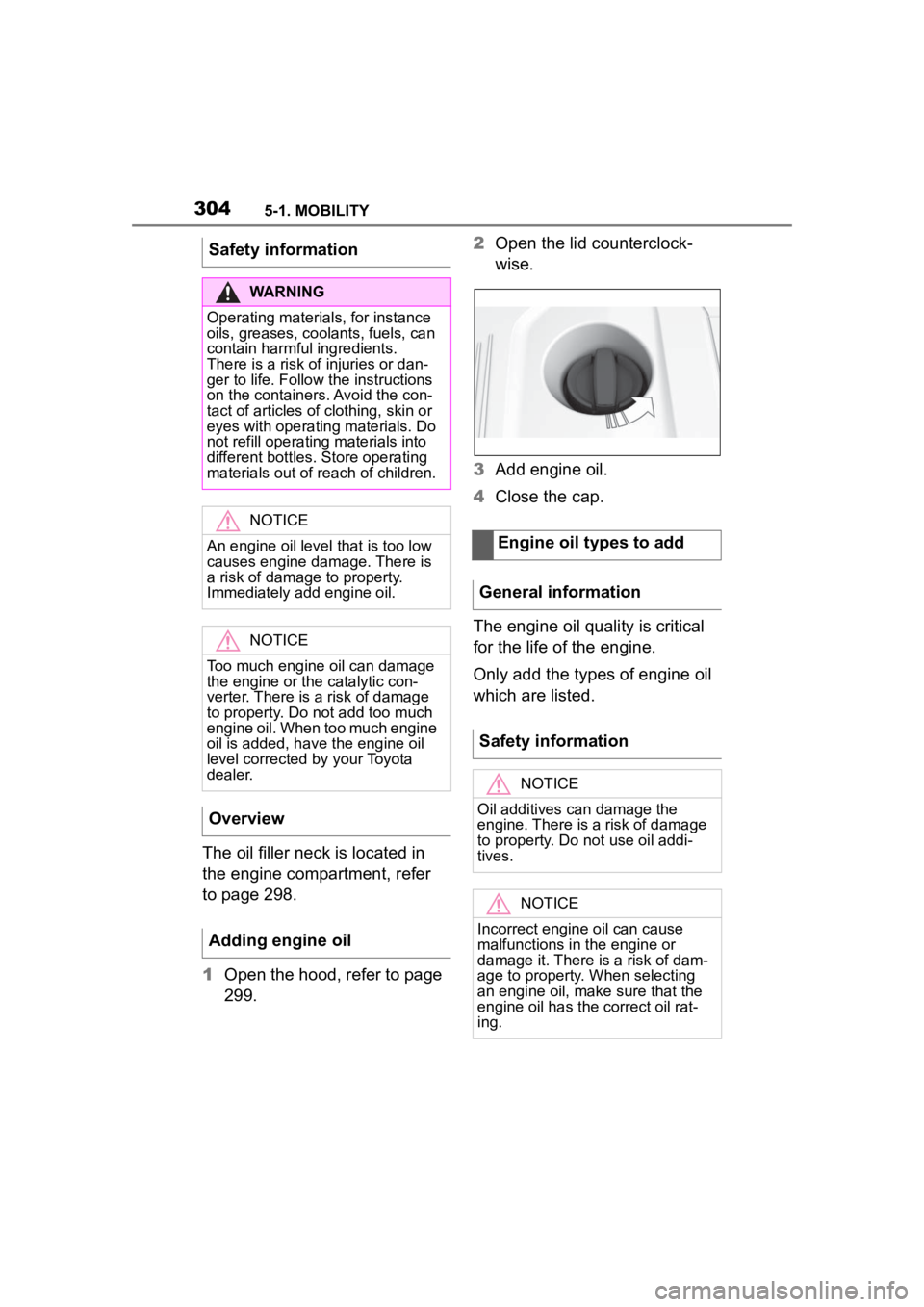

The oil filler neck is located in

the engine compartment, refer

to page 298.

1Open the hood, refer to page

299. 2

Open the lid counterclock-

wise.

3 Add engine oil.

4 Close the cap.

The engine oil quality is critical

for the life of the engine.

Only add the types of engine oil

which are listed.

Safety information

WARNING

Operating material

s, for instance

oils, greases, coolants, fuels, can

contain harmful ingredients.

There is a risk o f injuries or dan-

ger to life. Follow the instructions

on the containers. Avoid the con-

tact of articles of clothing, skin or

eyes with operating materials. Do

not refill operating materials into

different bottles. Store operating

materials out of reach of children.

NOTICE

An engine oil level that is too low

causes engine damage. There is

a risk of damage to property.

Immediately add engine oil.

NOTICE

Too much engine oil can damage

the engine or the catalytic con-

verter. There is a risk of damage

to property. Do not add too much

engine oil. When too much engine

oil is added, have the engine oil

level corrected by your Toyota

dealer.

Overview

Adding engine oil

Engine oil types to add

General information

Safety information

NOTICE

Oil additives can damage the

engine. There is a risk of damage

to property. Do not use oil addi-

tives.

NOTICE

Incorrect engine oil can cause

malfunctions in the engine or

damage it. There is a risk of dam-

age to property. When selecting

an engine oil, make sure that the

engine oil has the correct oil rat-

ing.

Page 306 of 372

3065-1. MOBILITY

mercially available additives are

suitable for the vehicle. The

vehicle manufacturer recom-

mends using coolant with the

BMW LC-18 specification. Do

not mix additives of different col-

ors. Observe the water - additive

mixture ratio of 50:50. Informa-

tion about suitable additives is

available from your Toyota

dealer.

Depending on the motorization,

there are up to two coolant res-

ervoirs in the engine compart-

ment. Check and top up the

coolant levels on a regular

basis.The coolant may be overfilled in

the coolant reservoir when the

vehicle is delivered from the fac-

tory. The normal coolant level is

achieved by operating the vehi-

cle for a longer period.

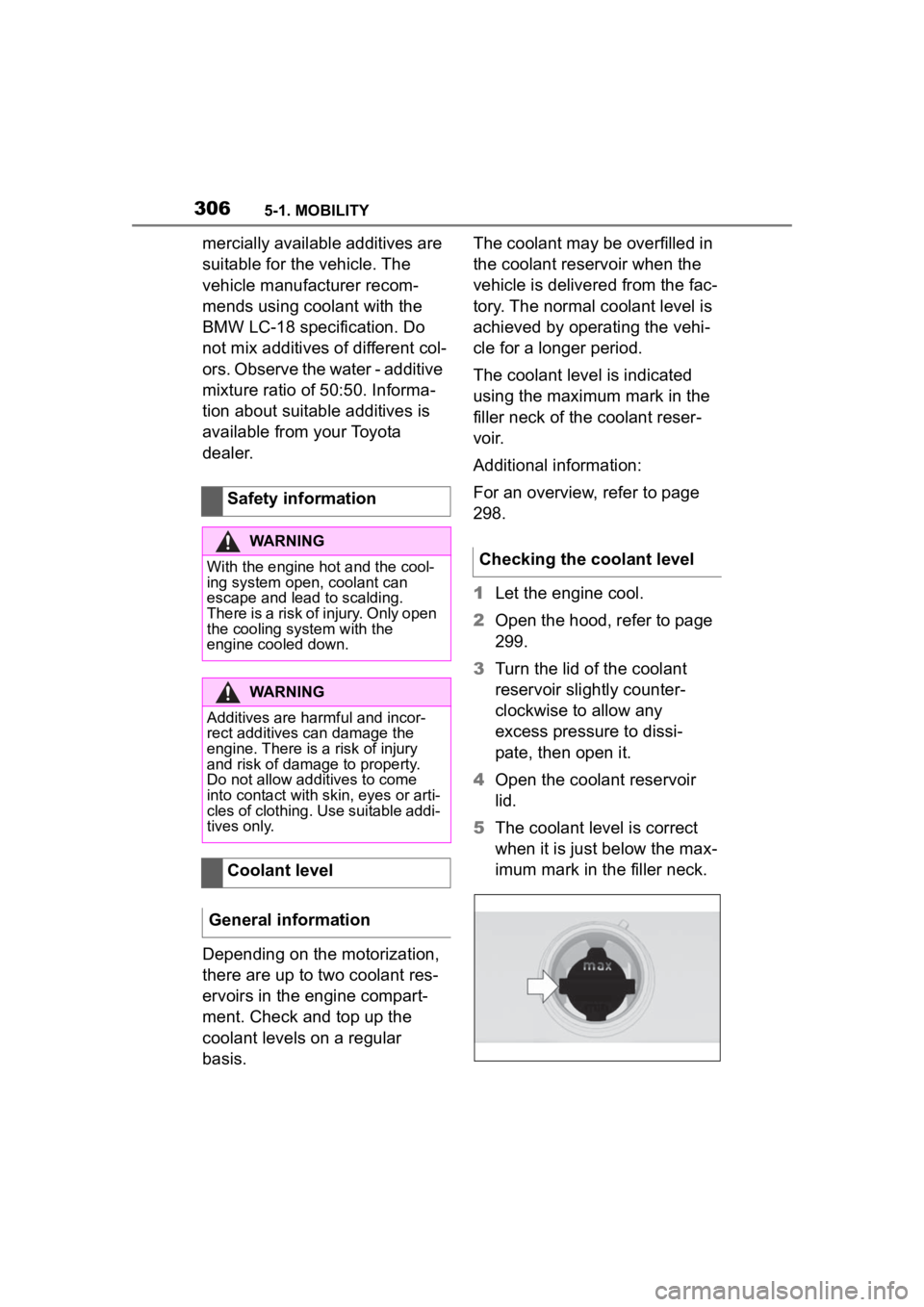

The coolant level is indicated

using the maximum mark in the

filler neck of the coolant reser-

voir.

Additional information:

For an overview, refer to page

298.

1

Let the engine cool.

2 Open the hood, refer to page

299.

3 Turn the lid of the coolant

reservoir slightly counter-

clockwise to allow any

excess pressure to dissi-

pate, then open it.

4 Open the coolant reservoir

lid.

5 The coolant level is correct

when it is just below the max-

imum mark in the filler neck.

Safety information

WARNING

With the engine hot and the cool-

ing system open, coolant can

escape and lead to scalding.

There is a risk of injury. Only open

the cooling system with the

engine cooled down.

WARNING

Additives are harmful and incor-

rect additives can damage the

engine. There is a risk of injury

and risk of damage to property.

Do not allow additives to come

into contact with skin, eyes or arti-

cles of clothing. Use suitable addi-

tives only.

Coolant level

General information

Checking the coolant level

Page 307 of 372

3075-1. MOBILITY

5

MOBILITY

6Close the cap.

1 Let the engine cool.

2 Open the hood, refer to page

299.

3 Turn the lid of the coolant

reservoir slightly counter-

clockwise to allow any

excess pressure to dissi-

pate, then open it.

4 Open the coolant reservoir

lid.

5 If the coolant is low, slowly

add coolant up to the speci-

fied level; do not overfill.

6 Close the cap.

7 Have the cause of the cool-

ant loss eliminated as soon

as possible.

Comply with the relevant envi-

ronmental protection regulations

when disposing of coolant and

coolant additives.

All washer nozzles are supplied

from one reservoir.

Use a mixture of tap water and windshield washer concentrate.

If desired, a windshield washer

concentrate containing anti-

freeze can be used.

Recommended minimum fill

quantity:0.2 US gal/1 liter.

Adding

Disposal

Washer fluid

General information

Safety information

WARNING

Some antifreeze agents can con-

tain harmful substances and are

flammable. There i s a risk of fire

and a risk of inj ury. Follow the

instructions on the containers.

Keep antifreeze away from igni-

tion sources. Do no t refill operat-

ing materials into different bottles.

Store operating materials out of

reach of children.

United States: th e washer fluid

mixture ratio is regulated by the

U.S. EPA and many individual

states; do not exceed the allow-

able washer fluid dilution ratio lim-

its that apply. Follow the usage

instructions on th e washer fluid

container.

WARNING

Washer fluid can ignite and catch

fire on contact with hot engine

parts. There is a risk of injury or

risk of damage to property. Only

add washer fluid when the engine

is cooled down. Next, fully close

the lid of the washer fluid reser-

v oi r.

Page 309 of 372

3095-1. MOBILITY

5

MOBILITY

Condition Based Service CBS

determines the maintenance

recommendation using sensors

and special algorithms that take

into account the driving condi-

tions of the vehicle.

The system makes it possible to

adapt the amount of mainte-

nance corresponding to your

user profile.

Information on service notifica-

tions, refer to page 147, can be

displayed on the Control Dis-

play.

Storage periods during which

the vehicle battery was discon-

nected are not taken into

account.

If this occurs, have a Toyota

dealer update the time-depen-

dent maintenance procedures,

such as checking brake fluid

and, if necessary, changing the

engine oil and the microfil-

ter/activated-charcoal filter.Please consult “Owner's War-

ranty Information Booklet” or

“Owner's Manual Supplement”

for additional information on ser-

vice and maintenance work.

The manufacturer of your vehi-

cle recommends that mainte-

nance and repair be performed

by a Toyota dealer. Records of

regular maintenance and repair

work should be retained.

Scheduled maintenance should

be performed at specified inter-

vals according to the mainte-

nance schedule.

For details about maintenance

items and schedules, refer to

the "Scheduled Maintenance

Guide" or "Owner's Manual Sup-

plement".

Devices connected to the OBD

socket trigger the alarm system

when the vehicle is locked.

Remove any devices con-

nected at the OBD socket

Condition Based Service

CBS

Concept

General information

Storage periods

"Owner's Warranty Infor-

mation Booklet" or

"Owner's Manual Supple-

ment"

Scheduled maintenance

Socket for OBD Onboard

Diagnosis

General information

Page 310 of 372

3105-1. MOBILITY

before locking the vehicle.

There is an OBD socket on the

driver's side for checking the pri-

mary components in the vehi-

cle's emissions.Safety information

NOTICE

The socket for Onboard Diagno-

sis is an intricate component

intended to be used in conjunction

with specialized equipment to

check the vehicle’s primary emis-

sions system. Improper use of the

socket for Onboard Diagnosis, or

contact with the socket for

Onboard Diagnosis for other than

its intended purpose, can cause

vehicle malfunctions and creates

risks of personal and property

damage. Given the foregoing, the

manufacture of your vehicle

strongly recommends that access

to the socket for Onboard Diagno-

sis be limited to your Toyota

dealer or other persons that have

the specialized

training and

equipment for purposes of prop-

erly utilizing the socket for

Onboard Diagnosis.

Position

Emissions

• The warning light

lights up:

Emissions are deterio-

rating. Have the vehi-

cle checked as soon

as possible.

• The warning light flashes under certain

circumstances:

This indicates that

there is excessive mis-

firing in the engine.

Reduce the vehicle

speed and have the

system checked imme-

diately; otherwise, seri-

ous engine misfiring

within a brief period

can seriously damage

emission control com-

ponents, in particular

the catalytic converter.