light VAUXHALL ADAM 2018.5 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018.5, Model line: ADAM, Model: VAUXHALL ADAM 2018.5Pages: 245, PDF Size: 7.4 MB

Page 177 of 245

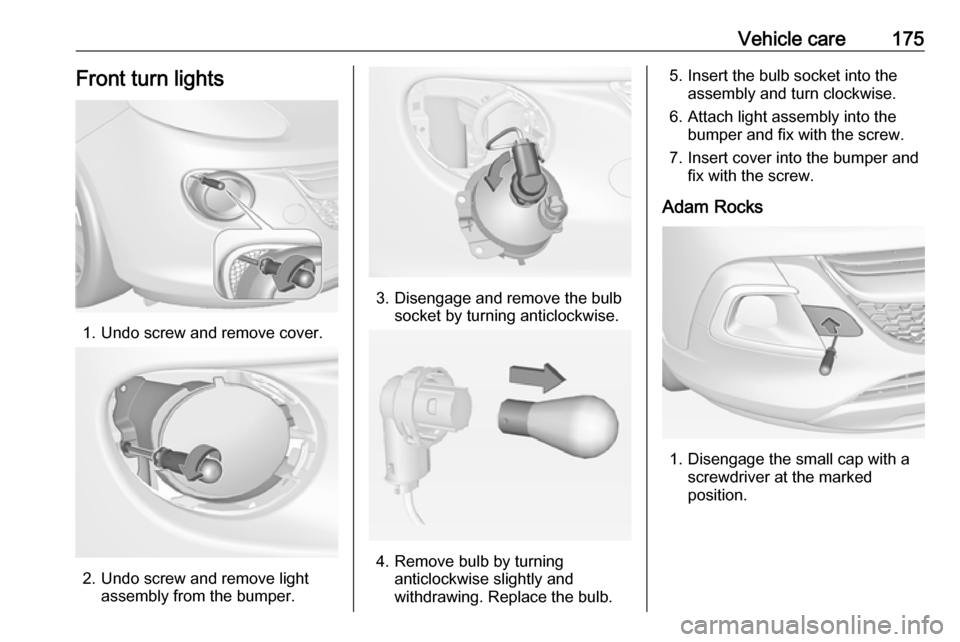

Vehicle care175Front turn lights

1. Undo screw and remove cover.

2. Undo screw and remove lightassembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

4. Remove bulb by turninganticlockwise slightly and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Attach light assembly into the bumper and fix with the screw.

7. Insert cover into the bumper and fix with the screw.

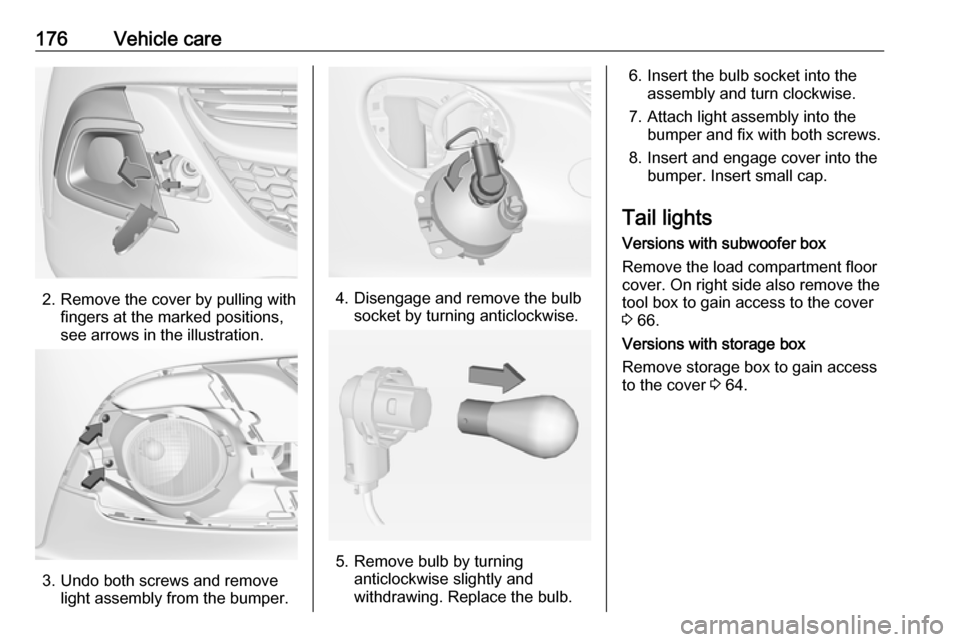

Adam Rocks

1. Disengage the small cap with a screwdriver at the marked

position.

Page 178 of 245

176Vehicle care

2. Remove the cover by pulling withfingers at the marked positions,

see arrows in the illustration.

3. Undo both screws and remove light assembly from the bumper.

4. Disengage and remove the bulbsocket by turning anticlockwise.

5. Remove bulb by turninganticlockwise slightly and

withdrawing. Replace the bulb.

6. Insert the bulb socket into the assembly and turn clockwise.

7. Attach light assembly into the bumper and fix with both screws.

8. Insert and engage cover into the bumper. Insert small cap.

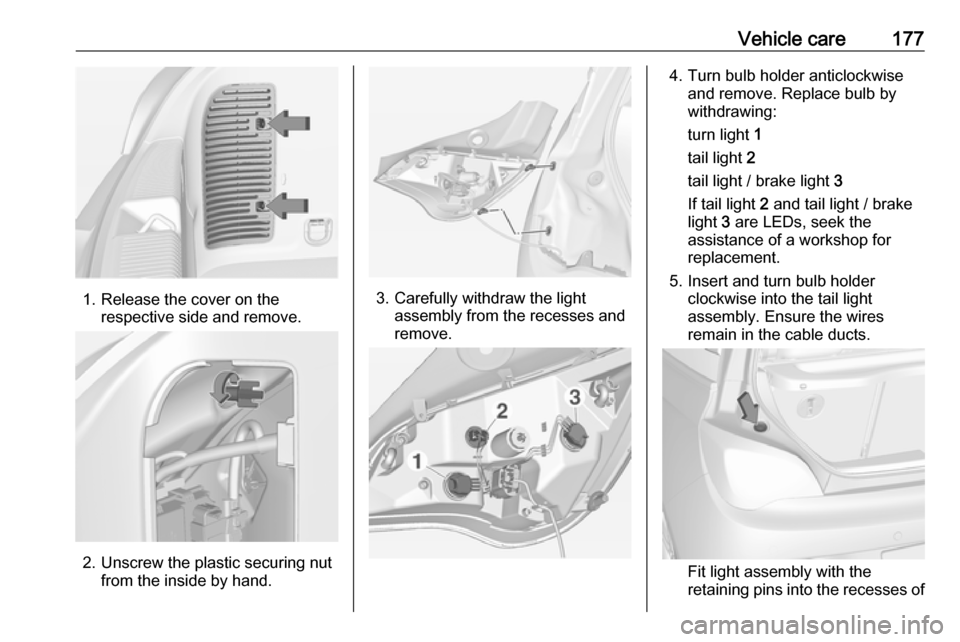

Tail lights Versions with subwoofer box

Remove the load compartment floor

cover. On right side also remove the

tool box to gain access to the cover

3 66.

Versions with storage box

Remove storage box to gain access

to the cover 3 64.

Page 179 of 245

Vehicle care177

1. Release the cover on therespective side and remove.

2. Unscrew the plastic securing nut from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Turn bulb holder anticlockwise and remove. Replace bulb by

withdrawing:

turn light 1

tail light 2

tail light / brake light 3

If tail light 2 and tail light / brake

light 3 are LEDs, seek the

assistance of a workshop for

replacement.

5. Insert and turn bulb holder clockwise into the tail light

assembly. Ensure the wires

remain in the cable ducts.

Fit light assembly with the

retaining pins into the recesses of

Page 180 of 245

178Vehicle carethe vehicle body and tighten the

plastic securing nut from inside

the load compartment. Pull the

circular gasket over the recess in

the lamp housing.

Close cover and engage.

Reversing light / rear fog light Reversing light is located on the left

side of the bumper, and the rear fog

light is located on the right side of the

bumper.

The description of bulb replacement

is the same for both lights.

1. Undo screw and remove cover.

2. Undo screw and remove light assembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

4. Remove bulb by turninganticlockwise slightly and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Replace light assembly in the bumper and fix with the screw.

7. Insert cover into the bumper and fix with the screw.

Page 181 of 245

Vehicle care179Adam Rocks

1. Remove the cover by pulling byhand at the marked position, see

arrow in the illustration.

2. Undo both screws and remove light assembly from the bumper.

3. Disengage and remove the bulb socket by turning anticlockwise.

4. Remove bulb by turninganticlockwise slightly and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Attach light assembly into the bumper and fix with both screws.

7. Insert and engage cover into the bumper.

Side turn lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

Page 182 of 245

180Vehicle care

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder andreplace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

2. Remove lamp downwards, taking care not to pull on the cable.

3. Remove bulb holder from lamp housing by turning anticlockwise.

Page 183 of 245

Vehicle care1814. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and allow

it to engage.

Interior lights

Have the following bulbs replaced by

a workshop:

● courtesy light, reading lights

● load compartment light

● dome light

● ambient light

● starlight panel

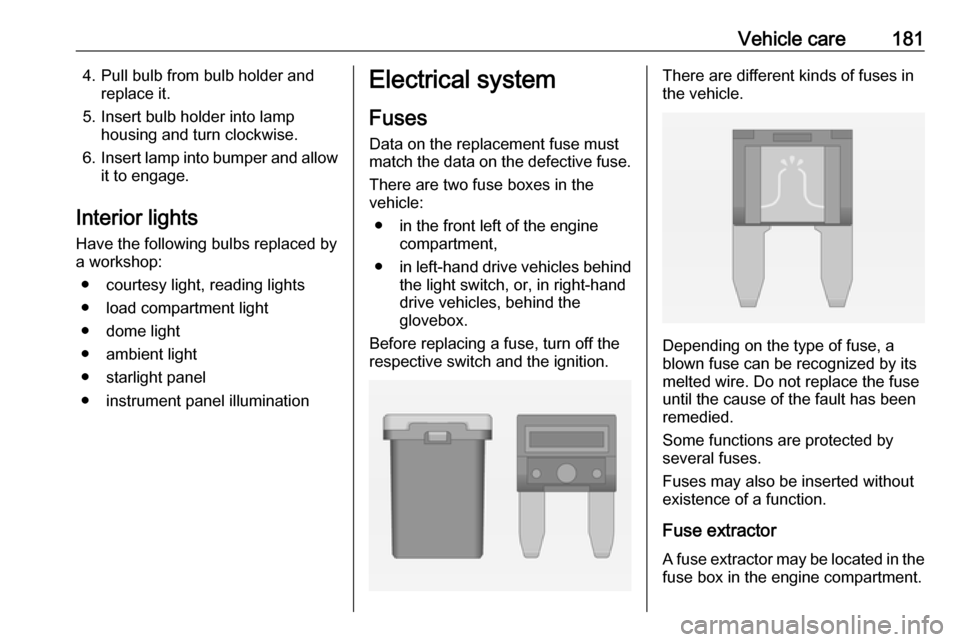

● instrument panel illuminationElectrical system

Fuses Data on the replacement fuse mustmatch the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● in the front left of the engine compartment,

● in left-hand drive vehicles behind

the light switch, or, in right-hand

drive vehicles, behind the

glovebox.

Before replacing a fuse, turn off the

respective switch and the ignition.There are different kinds of fuses in

the vehicle.

Depending on the type of fuse, a

blown fuse can be recognized by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Fuse extractorA fuse extractor may be located in the

fuse box in the engine compartment.

Page 185 of 245

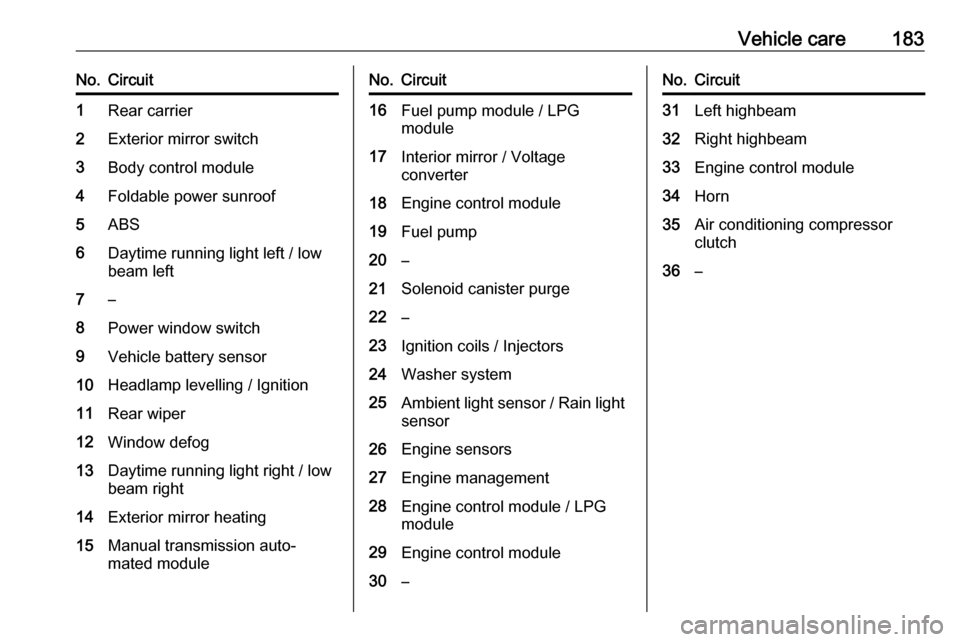

Vehicle care183No.Circuit1Rear carrier2Exterior mirror switch3Body control module4Foldable power sunroof5ABS6Daytime running light left / low

beam left7–8Power window switch9Vehicle battery sensor10Headlamp levelling / Ignition11Rear wiper12Window defog13Daytime running light right / low

beam right14Exterior mirror heating15Manual transmission auto‐

mated moduleNo.Circuit16Fuel pump module / LPG

module17Interior mirror / Voltage

converter18Engine control module19Fuel pump20–21Solenoid canister purge22–23Ignition coils / Injectors24Washer system25Ambient light sensor / Rain light sensor26Engine sensors27Engine management28Engine control module / LPG

module29Engine control module30–No.Circuit31Left highbeam32Right highbeam33Engine control module34Horn35Air conditioning compressor

clutch36–

Page 188 of 245

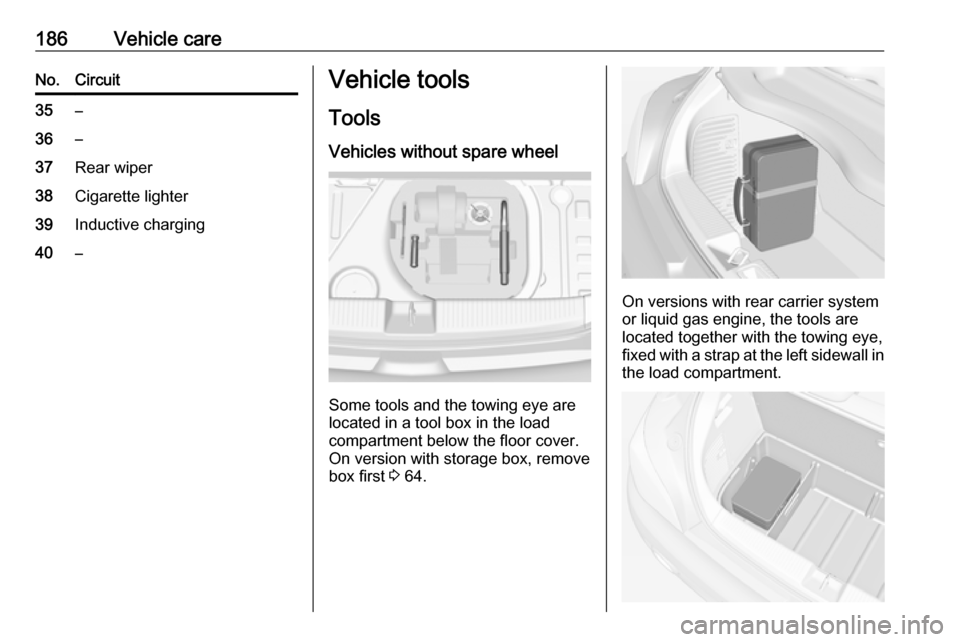

186Vehicle careNo.Circuit35–36–37Rear wiper38Cigarette lighter39Inductive charging40–Vehicle tools

Tools

Vehicles without spare wheel

Some tools and the towing eye are

located in a tool box in the load

compartment below the floor cover.

On version with storage box, remove

box first 3 64.

On versions with rear carrier system

or liquid gas engine, the tools are

located together with the towing eye,

fixed with a strap at the left sidewall in

the load compartment.

Page 193 of 245

Vehicle care191illuminates. For the further three

tyres, the system remains

operational.

The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 227, and

select the appropriate setting in the

menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 92 . This setting is

the reference for the tyre pressure

warnings.The Tyre Load menu only appears if

the vehicle is at a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Select:

● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full loading.

Tyre pressure sensor matching

process

Each pressure sensor has a unique

identification code. The identification

code must be matched to a new tyre /

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more pressure sensors

were replaced. The pressure sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the

pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn light at the current active position

is illuminated until sensor is matched.

Consult a workshop for service. There are 2 minutes to match the first wheelposition, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.