clock VAUXHALL ANTARA 2014 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: ANTARA, Model: VAUXHALL ANTARA 2014Pages: 217, PDF Size: 5.94 MB

Page 166 of 217

164Vehicle careSide turn signal lights

1. Using a suitable screwdriver, prylamp assembly away from wing.

2. Rotate bulb holder anticlockwise.

3. Remove bulb from lamp assembly

by pulling bulb straight out of bulb holder.

4. Insert new bulb into bulb holder by

pressing it in and rotating the bulb holder clockwise.

5. Push lamp assembly back into aperture.

Centre high-mounted

brake light Have bulbs replaced by a workshop.

Number plate light

1. Remove 4 screws (arrowed) and remove lamp covers.

2. Remove bulb holder from lamp assembly by rotating it

anticlockwise.

3. Pull bulb straight out of bulb holder.

4. Insert new bulb.

5. Reinstall bulb holder into lamp assembly, rotate bulb holder

clockwise and ensure it is secure.

6. Replace lamp covers using the 4 screws removed earlier.

Interior lights

Front reading lights

1. Using a suitable screwdriver, pry lamp lens away from roof lining.

2. Remove bulb.

3. Insert new bulb.

4. Reinstall lamp lens in roof lining.

Page 176 of 217

174Vehicle care

To remove the jack and vehicle tools,open the tailgate.

Push both levers on the floor cover

towards the handle and pull up the

cover by the handle.

Where present, hang the hook to the

upper part of the tailgate opening.

Remove wing bolt from the jack by

rotating it anticlockwise and remove

the jack and wheel wrench bag.

Remove straps holding the bag

containing the wheel wrench.

Remove wheel wrench from the bag.

Vehicles with tyre repair kit

In vehicles with a tyre repair kit, there may not be a jack and vehicle tool kit.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

Page 182 of 217

180Vehicle care9Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the electrical parking brake

3 136 and engage first gear, reverse

gear or P.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

To remove the tyre repair kit, open the

tailgate.

Pull the floor cover handle upwards

3 68.

Vehicle tools 3 173.

Caution

Do not allow objects to protrude

above the top of the rear floor

storage compartment, to avoid

damage to the storage area and

the load compartment floor.

1. Release the sealant filler hose 1

and the power plug 2.

2. Unscrew valve cap from defective

tyre.

Screw the sealant filler hose onto

the tyre valve.

3. Connect the power plug to the power outlet. Unplug all items

from other power outlets.

4. Switch on ignition. To avoid discharging the battery, werecommend running the engine.

5. Turn the selector switch anticlockwise to the sealant +

air position.

Page 184 of 217

182Vehicle care

not be driven. Seek the

assistance of a workshop.

12. To adjust tyre pressure, screw compressor air hose (arrowed)

directly onto tyre valve.

13. Turn the selector switch clockwise

to the air only position. Switch on

the compressor to inflate the tyre

with air only.

Notice

The driving characteristic of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

canister.

Replace the used sealant canister.

To remove sealant canister, release sealant filler hose and air hose, slide

canister out of housing and unscrew hose from canister. Dispose of thecanister as prescribed by applicable

laws.

The accessory adapter supplied can

be used to pump up other items

e.g. footballs, air mattresses,

inflatable dinghies etc. The adapter

is located on the underside of the

tyre repair kit.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 179.

Page 185 of 217

Vehicle care183

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The front wheels must be in the straight-ahead position.

■ Apply the electrical parking brake 3 136 and engage first gear,

reverse gear or P.

■ Remove the spare wheel 3 185.

■ Never change more than one wheel

at a time.

■ Block wheel diagonally opposite the wheel to be changed, by placing

wedge blocks or equivalent in front

and behind the wheel.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

changes.

■ Never exceed jack maximum working load (900 kg).

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.■ Do not raise the vehicle more than is necessary to change a wheel.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when it is raised on the jack.

■ Clean wheel nuts and thread before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Pull off the wheel cover.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel nut by one turn by

turning anticlockwise.

3. The location of front and rear jacking points is indicated by

notches on the bottom edge of the

vehicle, under the doors.

Page 186 of 217

184Vehicle care

4. Before positioning the jack, set itto the necessary height by

rotating the eye by hand.

Position jack at the jacking point

located nearest to the wheel concerned so that the jack claw

spans the vertical base. Ensure

the jack is positioned correctly.

The jack base must be on the

ground directly below the jacking

point in a manner that prevents it

from slipping.5. Attach wheel wrench to eye of threaded rod and rotate wrench

clockwise to raise vehicle.

If this is not the case, carefully

lower the vehicle immediately and

reposition the jack. Raise the

vehicle until the wheel is just clear of the ground.

6. Unscrew wheel nuts completely and wipe clean with a cloth.

Do not grease the threads. Put

wheel nuts somewhere where the threads will not be soiled.

7. Change the wheel. Notes on spare wheel 3 185.

8. Screw on the wheel nuts and

tighten slightly by hand by turning

clockwise until wheel is held

against the hub.

9. Rotate wrench anticlockwise and lower vehicle to the ground.

10. Install the wheel wrench ensuring that it locates securely and tighten

each wheel nut in a crosswise

sequence. Tightening torque is

140 Nm.

11. Stow the replaced wheel 3 185

and the vehicle tools 3 173.

12. Check the tyre pressure of the installed tyre as soon as possible.

Page 188 of 217

186Vehicle care

The temporary spare wheel is locatedin the load compartment below the

floor cover and is secured with a

screw-in retainer.

Push both levers on the floor cover

towards the handle and pull up the

cover by the handle. Hang the hook

to the upper part of the tailgate

opening.

Vehicle tools 3 173.

Remove the retainer by rotating it

anticlockwise and remove temporary

spare wheel from the spare wheel

well.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.

When the temporary spare wheel is

fitted, do not take the vehicle through an automatic vehicle wash with guide

rails. The temporary spare wheel may get caught on the rails, causing

damage to the tyre, wheel and other

vehicle parts.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre chains 3 179.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed as soon

as possible and have the wheel

balanced and fitted to the vehicle.■ Do not drive faster than 50 mph.

■ Drive particularly carefully on wet and snow-covered road surfaces.9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed in place

properly. During a sudden stop or

a collision, loose equipment could

cause personal injury or damage

to the vehicle.

Always store the jack and vehicle

tools in their respective storage

compartments and secure them properly.

Always place the damaged wheel

in the load compartment, secured

in the spare wheel well with the

screw-in retainer.

Page 192 of 217

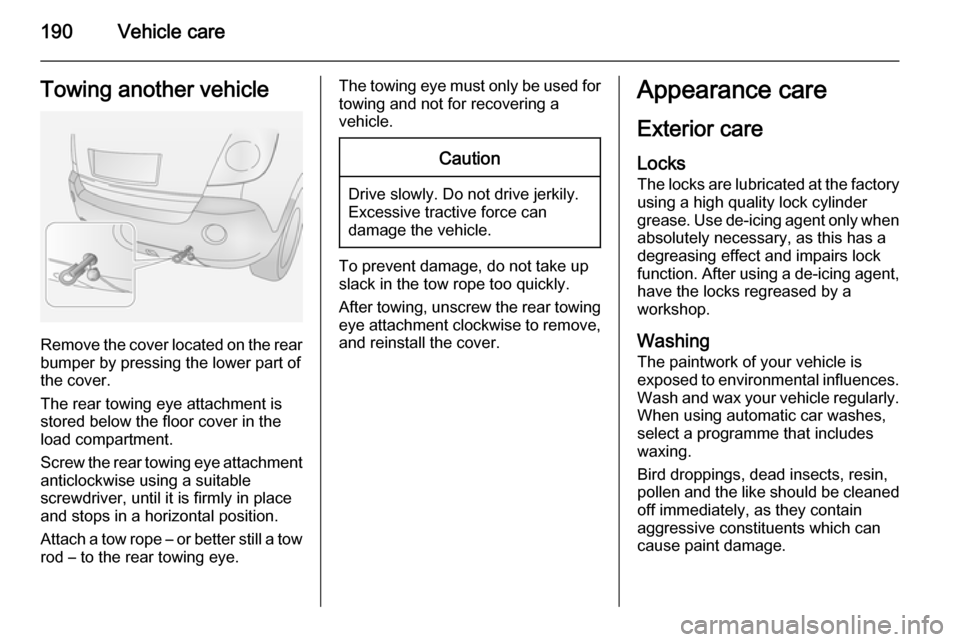

190Vehicle careTowing another vehicle

Remove the cover located on the rearbumper by pressing the lower part of

the cover.

The rear towing eye attachment is

stored below the floor cover in the

load compartment.

Screw the rear towing eye attachment

anticlockwise using a suitable

screwdriver, until it is firmly in place

and stops in a horizontal position.

Attach a tow rope – or better still a tow

rod – to the rear towing eye.

The towing eye must only be used for

towing and not for recovering a

vehicle.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

To prevent damage, do not take up slack in the tow rope too quickly.

After towing, unscrew the rear towing

eye attachment clockwise to remove,

and reinstall the cover.

Appearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has adegreasing effect and impairs lockfunction. After using a de-icing agent,

have the locks regreased by a

workshop.

Washing The paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly.

When using automatic car washes,

select a programme that includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

Page 213 of 217

211

Centre high-mounted brakelight.................................. 109, 164

Change engine oil .......................88

Changing tyre and wheel size ...178

Charging system .......................... 83

Check control................................ 99

Child locks ................................... 21

Child restraint installation locations ................................... 51

Child restraints.............................. 50

Child restraint systems ................50

Cleaning the vehicle ...................190

Climate control ............................. 14

Climate control systems .............114

Clock ............................................ 76

Clutch fluid ................................. 156

Coin storage ................................. 56

Console box.................................. 57

Console net .................................. 56

Control indicators.......................... 80

Control of the vehicle .................122

Controls ........................................ 72

Controls in steering wheel ............72

Convex shape .............................. 27

Coolant and antifreeze ...............195

Coupling ball bar ........................147

Cruise control ...................... 90, 140

Cupholders .................................. 55

Curtain airbag system .................. 48D

Danger, Warnings and Cautions ...3

Daytime running lights ...............107

Declaration of conformity ............208

Descent control system .......86, 138

Diesel fuel filter .......................... 158

Diesel fuel system bleeding .......159

Diesel particle filter .........84, 87, 127

Door open .................................... 90

Doors ............................................ 22

Drain fuel filter ............................. 89

Drink holders ................................ 55

Driver assistance systems ..........140

Driving characteristics and towing tips .............................. 146

Driving hints ................................ 122

E

Electric adjustment ......................27

Electrical parking brake .......85, 136

Electrical parking brake fault .......85

Electrical system......................... 165

Electronic climate control system 116

Electronic driving programmes ..130

Electronic Stability Control ..86, 137

Electronic Stability Control off ...... 87

End-of-life vehicle recovery .......151

Engine compartment fuse box ...167

Engine coolant ........................... 153Engine coolant temperature ........87

Engine data ............................... 202

Engine exhaust .......................... 127

Engine identification ...................198

Engine oil ................... 152, 195, 199

Engine oil life monitor ...................88

Engine oil pressure ......................87

Entry lighting .............................. 112

Event data recorders ..................208

Exhaust gases ............................ 127

Exit lighting ................................ 112

Exterior care .............................. 190

Exterior lighting ....................12, 105

Exterior mirrors ............................. 27

F

Fault ........................................... 131

Fire extinguisher ........................... 69

First aid kit ................................... 69

Fixed air vents ........................... 120

Flex-Fix system ............................ 57

Fog light ....................................... 89

Fog lights .................... 108, 109, 162

Folding mirrors ............................. 27

Front airbag system .....................46

Front fog lights ........................... 108

Front passenger seat undertray ...57

Front seats.................................... 34

Front storage ............................... 56

Fuel............................................. 143