technical specifications VOLKSWAGEN CORRADO 1990 Owners Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 277 of 906

* SUSPENSION UNIFORM INSPECTION GUIDELINES *

Article Text (p. 66)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:39PM

Cracked ³ A ³ Require replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDirectional/asymmetrical

³ B ³ Require remounting and/or

wheels mounted incorrectly

³ ³ repositioning.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄLoad capacity less than

³ B ³ Require replacement.

OEM specifications

³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄOffset mismatched on same

³ B ³ Require replacement.

axle

³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄRivets leaking

³ A ³ Require replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄRun-out beyond OEM specs

³ B ³ Require replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄStud holes elongated

³ A ³ Require replacement. See note (1)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄWelded or brazed repair

³ B,2 ³ Suggest replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄWelds leaking

³ A ³ Require replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄWheel hub centering (pilot)

³ B ³ Require replacement.

hole incorrect

³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄNOTE: (1) Inspect wheel attaching hardware for damage.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 294 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

shift as necessary. Evenly tighten mount bolts in reverse order of

loosening. Fill fluids to proper level. Adjust clutch pedal (if

equipped). Tighten all bolts and nuts to specifications.

ENGINE R & I (FOX)

REMOVAL (FOX)

1) Disconnect negative battery cable. Open heater valve,

coolant expansion tank and drain radiator through lower radiator hose.

Mark and disconnect all heater hoses. Disconnect electric cooling fan

and thermo switch. Remove lower and side radiator mounting bolts.

Remove fan, shroud and radiator. Remove M/T clutch cable (if

equipped).

2) Mark and disconnect electrical wiring and vacuum hoses (as

necessary). Disconnect throttle, cruise and kickdown linkage (if

equipped). Remove fuel injectors and install protective caps and

plugs. Leave fuel lines attached and remove cold start valve. Remove

charcoal canister and set aside.

3) Remove 3 upper engine-to-transaxle bolts. Remove intake

air duct. Remove left and right engine mount nuts. Disconnect and

remove starter assembly. Remove 2 lower engine-to-transaxle bolts.

Remove transaxle inspection cover plate. Disconnect exhaust inlet pipe

support and separate inlet pipe from exhaust manifold.

4) Support transaxle. Attach engine sling to engine lifting

hooks. Raise engine/transaxle until engine clears engine mounts.

Ensure transaxle is supported. Remove remaining engine-to-transaxle

bolts. Lift and separate engine from vehicle without transaxle.

INSTALLATION

Lubricate transaxle main shaft splines and contact area

between clutch release bearing and clutch pressure plate with MoS2

grease. DO NOT lubricate guide sleeve for clutch release bearing. To

complete installation, reverse removal procedure. DO NOT reuse self-

locking nuts. Ensure engine mounts are installed to original location.

Tighten engine mounts and subframe bolts with engine running at idle.

Page 295 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

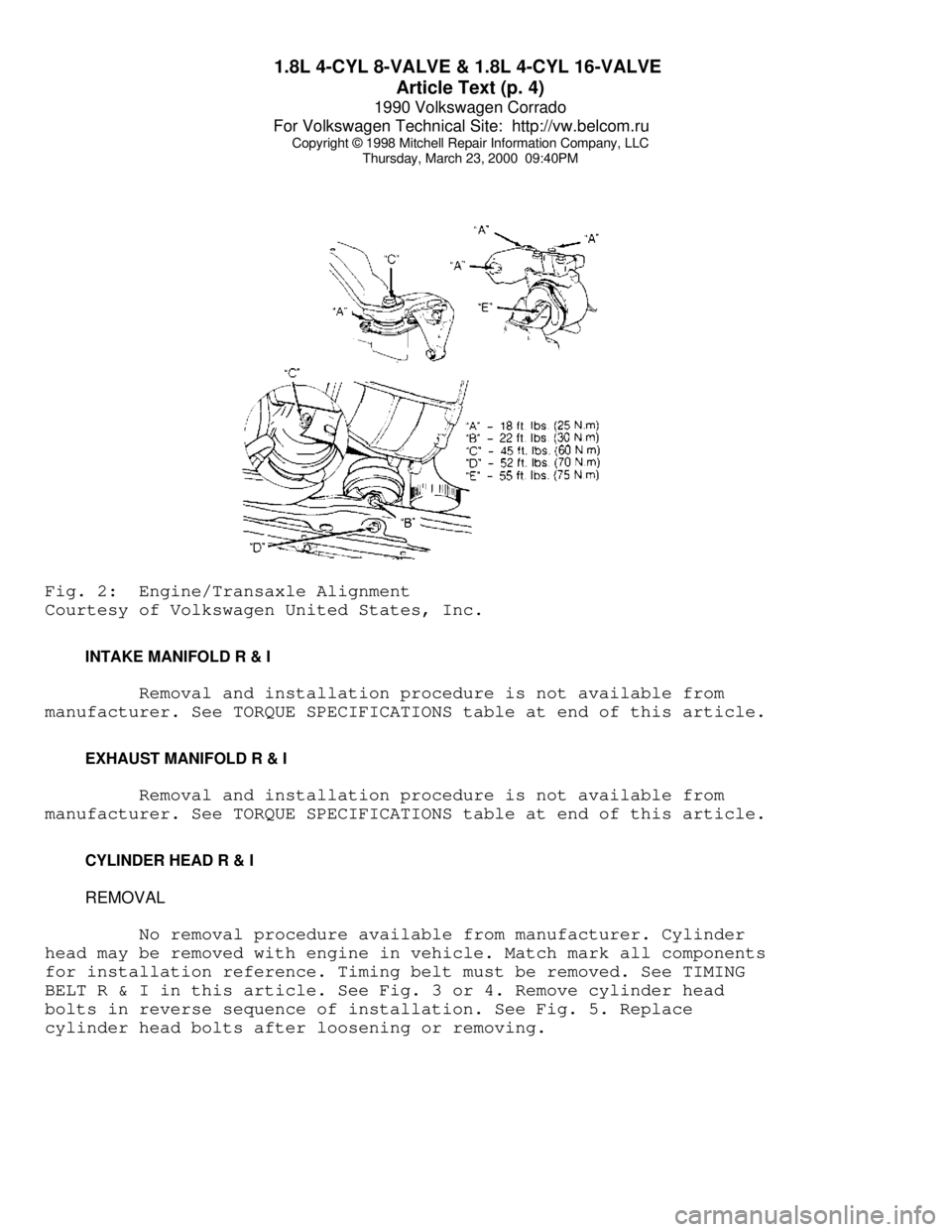

Thursday, March 23, 2000 09:40PMFig. 2: Engine/Transaxle Alignment

Courtesy of Volkswagen United States, Inc.

INTAKE MANIFOLD R & I

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of this article.

EXHAUST MANIFOLD R & I

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of this article.

CYLINDER HEAD R & I

REMOVAL

No removal procedure available from manufacturer. Cylinder

head may be removed with engine in vehicle. Match mark all components

for installation reference. Timing belt must be removed. See TIMING

BELT R & I in this article. See Fig. 3 or 4. Remove cylinder head

bolts in reverse sequence of installation. See Fig. 5. Replace

cylinder head bolts after loosening or removing.

Page 297 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

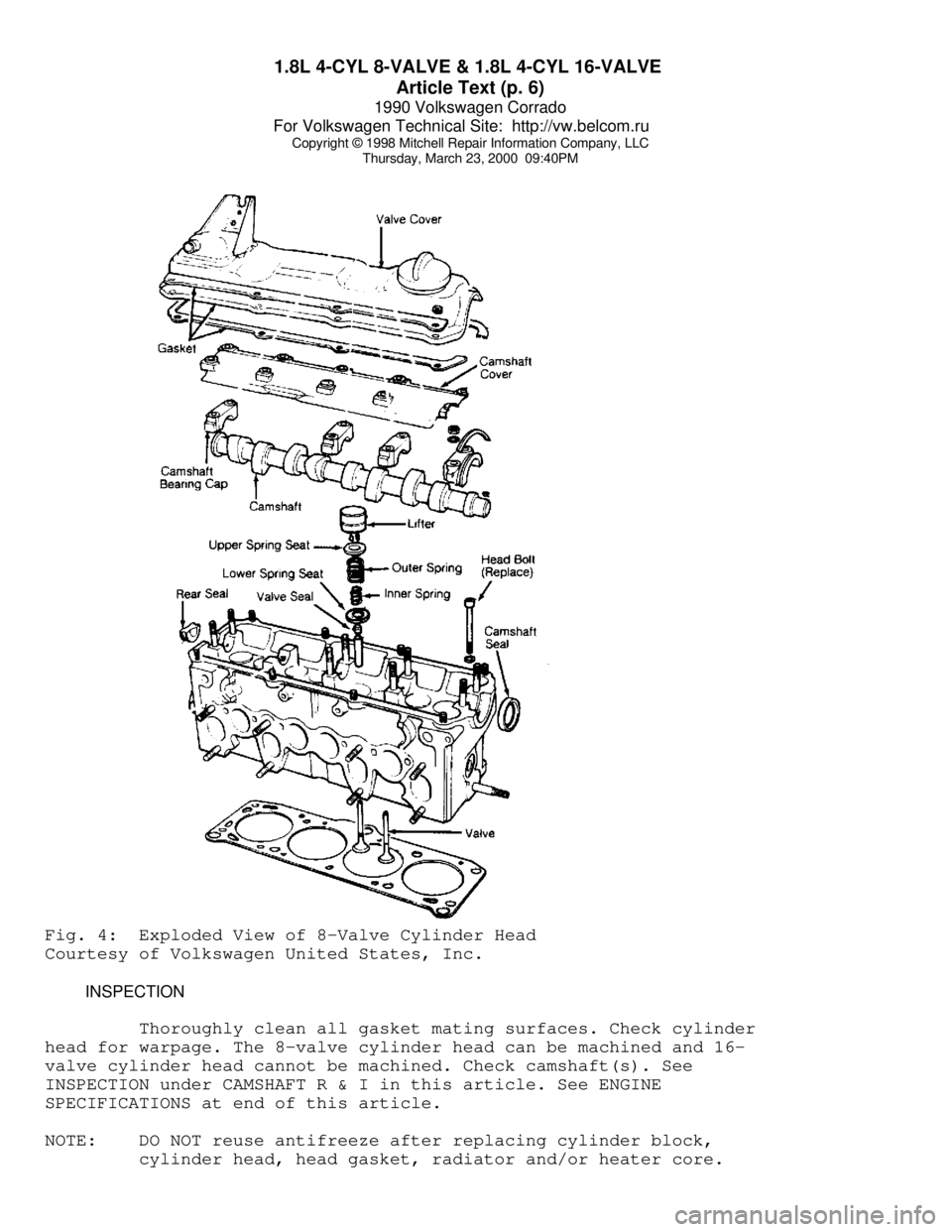

Thursday, March 23, 2000 09:40PMFig. 4: Exploded View of 8-Valve Cylinder Head

Courtesy of Volkswagen United States, Inc.

INSPECTION

Thoroughly clean all gasket mating surfaces. Check cylinder

head for warpage. The 8-valve cylinder head can be machined and 16-

valve cylinder head cannot be machined. Check camshaft(s). See

INSPECTION under CAMSHAFT R & I in this article. See ENGINE

SPECIFICATIONS at end of this article.

NOTE: DO NOT reuse antifreeze after replacing cylinder block,

cylinder head, head gasket, radiator and/or heater core.

Page 298 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

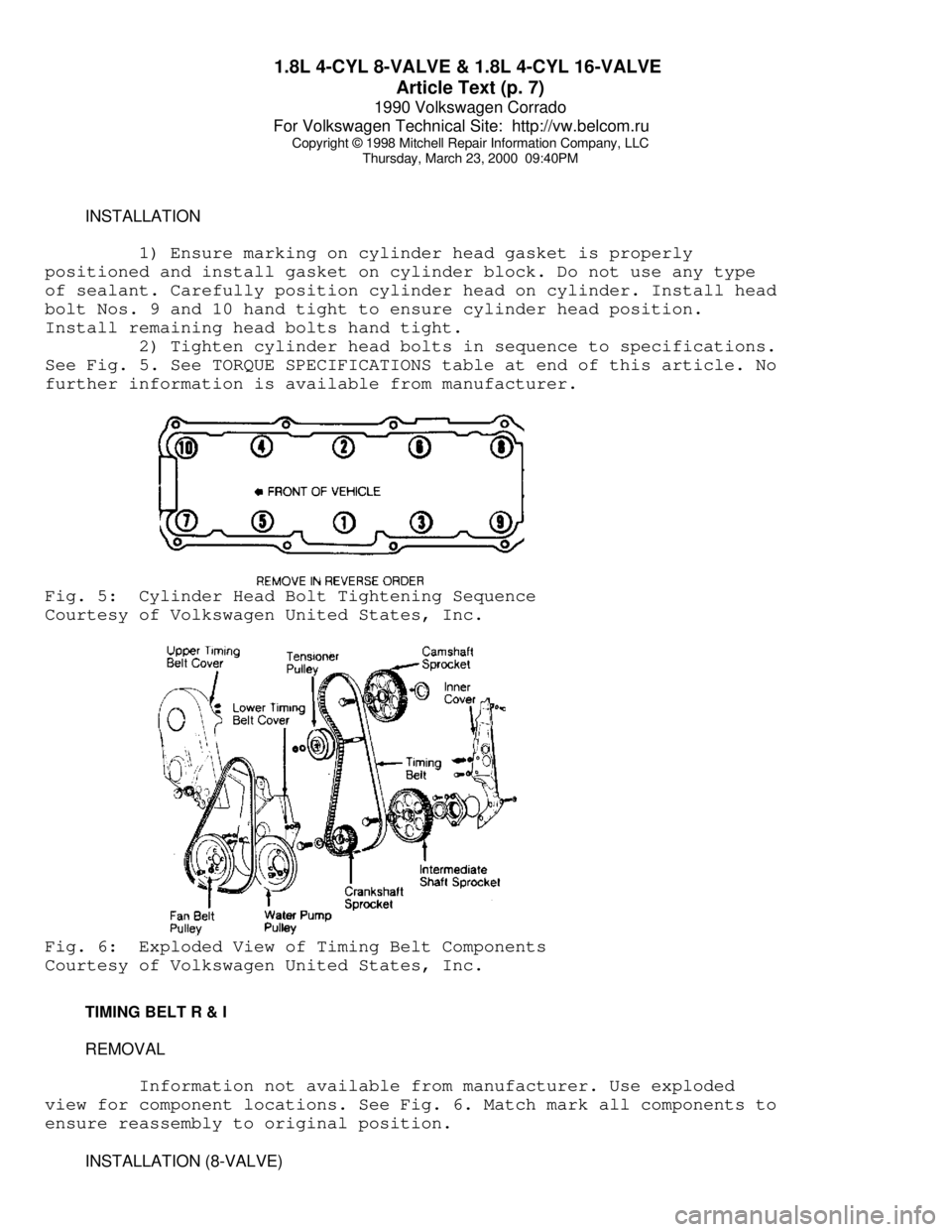

INSTALLATION

1) Ensure marking on cylinder head gasket is properly

positioned and install gasket on cylinder block. Do not use any type

of sealant. Carefully position cylinder head on cylinder. Install head

bolt Nos. 9 and 10 hand tight to ensure cylinder head position.

Install remaining head bolts hand tight.

2) Tighten cylinder head bolts in sequence to specifications.

See Fig. 5. See TORQUE SPECIFICATIONS table at end of this article. No

further information is available from manufacturer.Fig. 5: Cylinder Head Bolt Tightening Sequence

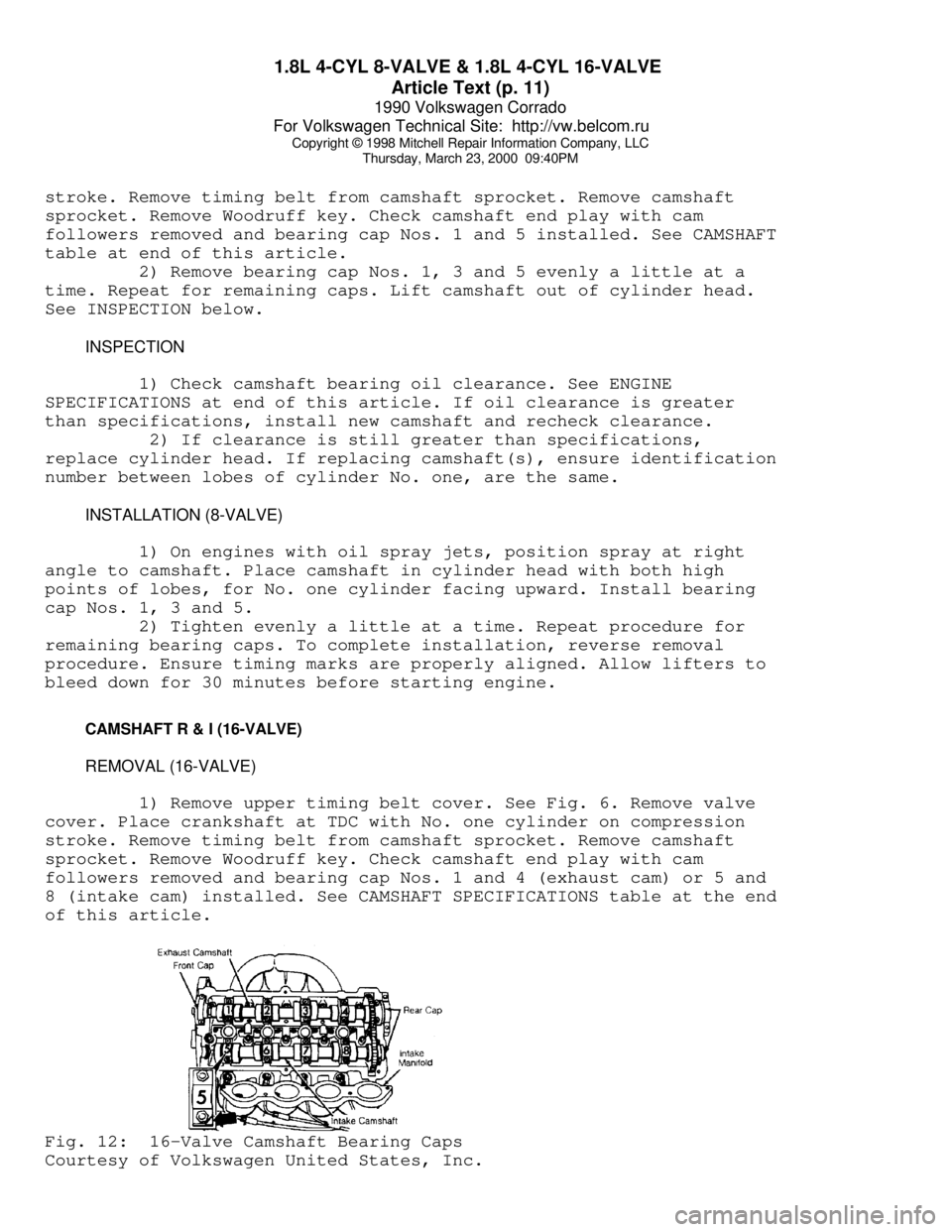

Courtesy of Volkswagen United States, Inc.Fig. 6: Exploded View of Timing Belt Components

Courtesy of Volkswagen United States, Inc.

TIMING BELT R & I

REMOVAL

Information not available from manufacturer. Use exploded

view for component locations. See Fig. 6. Match mark all components to

ensure reassembly to original position.

INSTALLATION (8-VALVE)

Page 302 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 11)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

stroke. Remove timing belt from camshaft sprocket. Remove camshaft

sprocket. Remove Woodruff key. Check camshaft end play with cam

followers removed and bearing cap Nos. 1 and 5 installed. See CAMSHAFT

table at end of this article.

2) Remove bearing cap Nos. 1, 3 and 5 evenly a little at a

time. Repeat for remaining caps. Lift camshaft out of cylinder head.

See INSPECTION below.

INSPECTION

1) Check camshaft bearing oil clearance. See ENGINE

SPECIFICATIONS at end of this article. If oil clearance is greater

than specifications, install new camshaft and recheck clearance.

2) If clearance is still greater than specifications,

replace cylinder head. If replacing camshaft(s), ensure identification

number between lobes of cylinder No. one, are the same.

INSTALLATION (8-VALVE)

1) On engines with oil spray jets, position spray at right

angle to camshaft. Place camshaft in cylinder head with both high

points of lobes, for No. one cylinder facing upward. Install bearing

cap Nos. 1, 3 and 5.

2) Tighten evenly a little at a time. Repeat procedure for

remaining bearing caps. To complete installation, reverse removal

procedure. Ensure timing marks are properly aligned. Allow lifters to

bleed down for 30 minutes before starting engine.

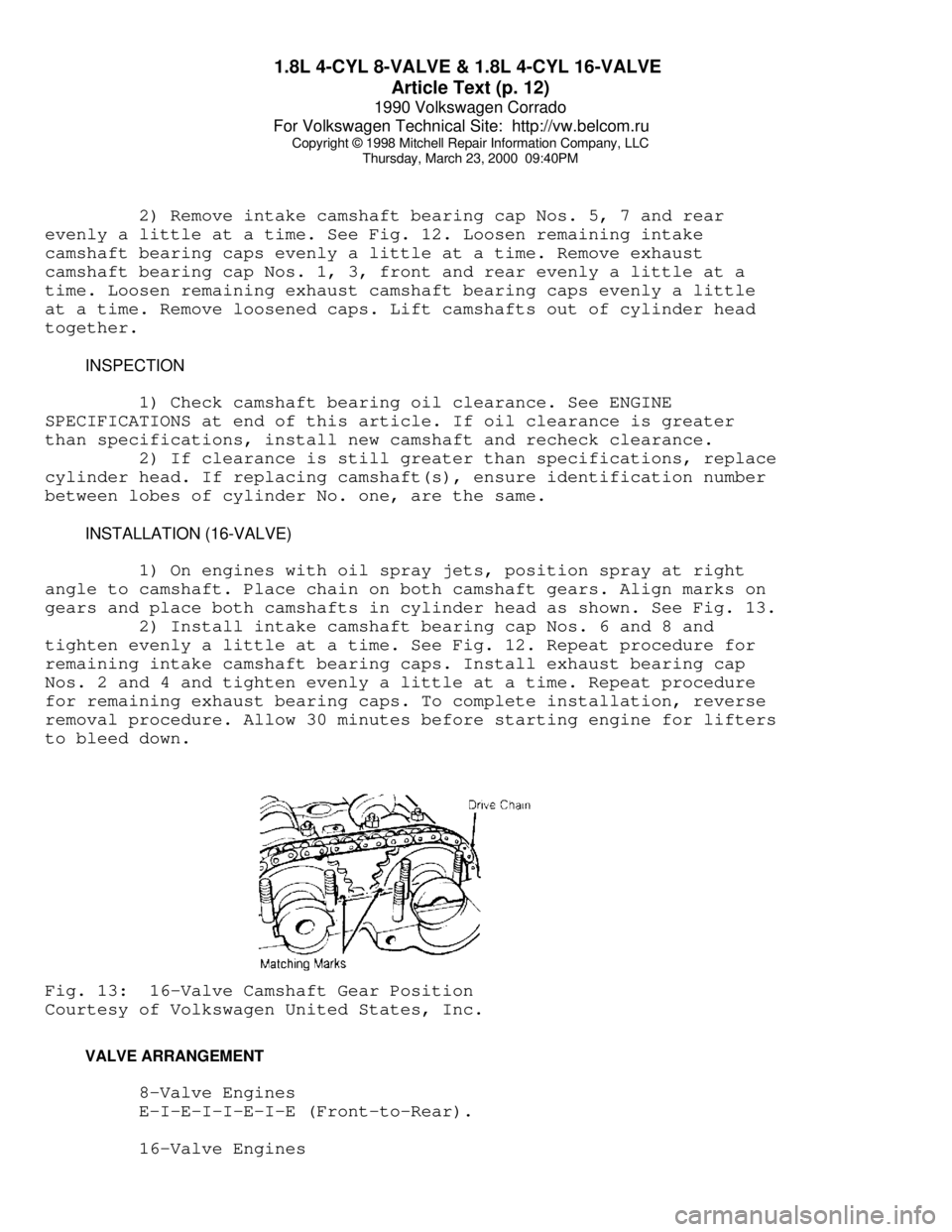

CAMSHAFT R & I (16-VALVE)

REMOVAL (16-VALVE)

1) Remove upper timing belt cover. See Fig. 6. Remove valve

cover. Place crankshaft at TDC with No. one cylinder on compression

stroke. Remove timing belt from camshaft sprocket. Remove camshaft

sprocket. Remove Woodruff key. Check camshaft end play with cam

followers removed and bearing cap Nos. 1 and 4 (exhaust cam) or 5 and

8 (intake cam) installed. See CAMSHAFT SPECIFICATIONS table at the end

of this article.Fig. 12: 16-Valve Camshaft Bearing Caps

Courtesy of Volkswagen United States, Inc.

Page 303 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 12)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

2) Remove intake camshaft bearing cap Nos. 5, 7 and rear

evenly a little at a time. See Fig. 12. Loosen remaining intake

camshaft bearing caps evenly a little at a time. Remove exhaust

camshaft bearing cap Nos. 1, 3, front and rear evenly a little at a

time. Loosen remaining exhaust camshaft bearing caps evenly a little

at a time. Remove loosened caps. Lift camshafts out of cylinder head

together.

INSPECTION

1) Check camshaft bearing oil clearance. See ENGINE

SPECIFICATIONS at end of this article. If oil clearance is greater

than specifications, install new camshaft and recheck clearance.

2) If clearance is still greater than specifications, replace

cylinder head. If replacing camshaft(s), ensure identification number

between lobes of cylinder No. one, are the same.

INSTALLATION (16-VALVE)

1) On engines with oil spray jets, position spray at right

angle to camshaft. Place chain on both camshaft gears. Align marks on

gears and place both camshafts in cylinder head as shown. See Fig. 13.

2) Install intake camshaft bearing cap Nos. 6 and 8 and

tighten evenly a little at a time. See Fig. 12. Repeat procedure for

remaining intake camshaft bearing caps. Install exhaust bearing cap

Nos. 2 and 4 and tighten evenly a little at a time. Repeat procedure

for remaining exhaust bearing caps. To complete installation, reverse

removal procedure. Allow 30 minutes before starting engine for lifters

to bleed down.Fig. 13: 16-Valve Camshaft Gear Position

Courtesy of Volkswagen United States, Inc.

VALVE ARRANGEMENT

8-Valve Engines

E-I-E-I-I-E-I-E (Front-to-Rear).

16-Valve Engines

Page 304 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 13)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

Right Side - Exhaust Valves.

Left Side - Intake Valves.

NOTE: "Right" and "Left" refer to right and left side of engine

NOT vehicle.

VALVE SEALS & SPRINGS R & I

Valve seals and springs may be removed with cylinder head

installed in vehicle. Remove camshaft as previously described. Mark

and remove lifters. Use compressed air to hold valves closed.

Installation Bar (2036), Spring Compressor (VW 541/1) and Valve Seal

Replacer/Sleeve (10-204/A) are necessary tools for replacing. DO NOT

install valve seal without using sleeve.

VALVE GUIDE R & I

If valve-to-guide clearance is not within specifications,

replace guide(s). See ENGINE SPECIFICATIONS tables at end of this

article. To replace valve guide, press guide out from combustion

chamber side. Press guide in cold cylinder head as far as guide will

go. DO NOT exceed one ton pressure. Ream guides by hand to achieve

proper valve-to-guide clearance.

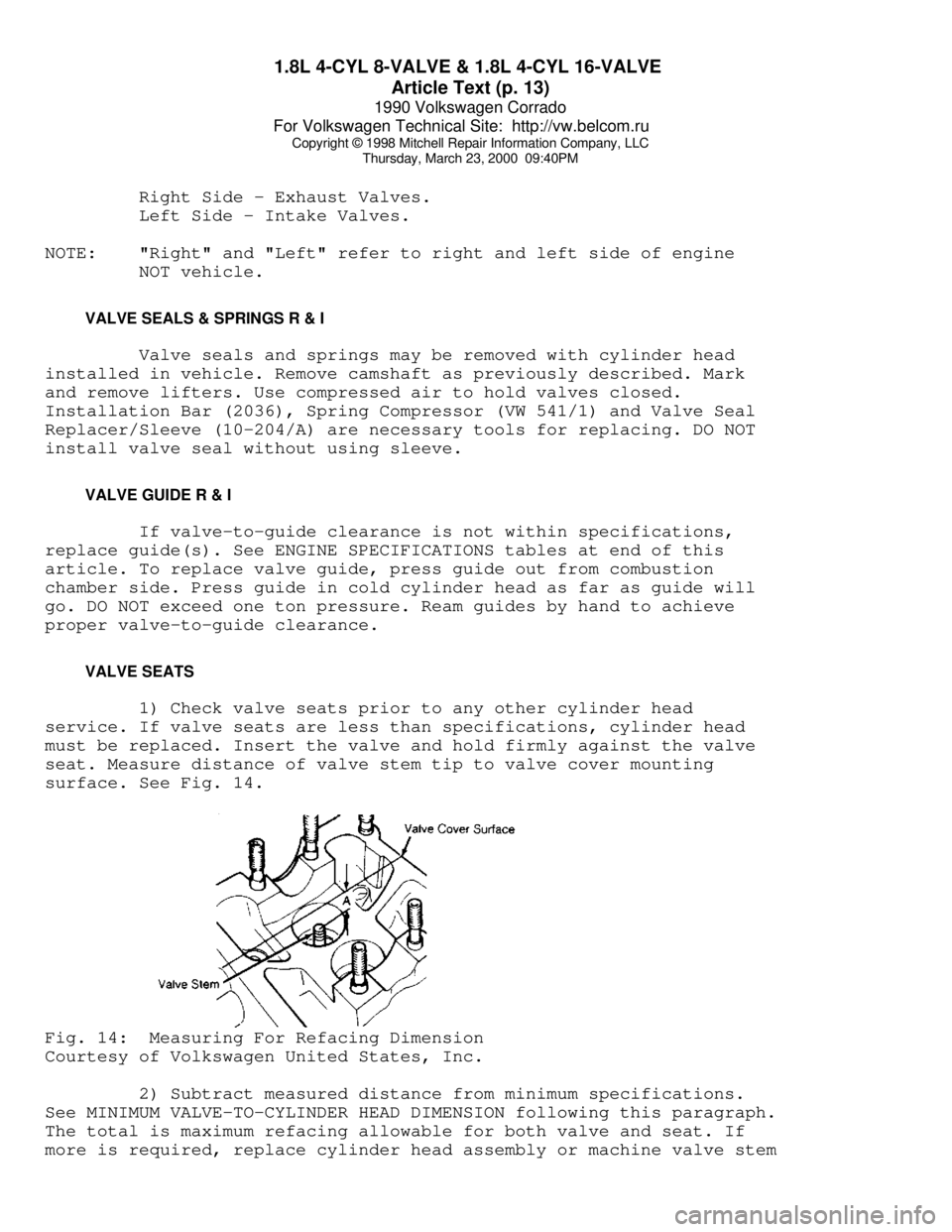

VALVE SEATS

1) Check valve seats prior to any other cylinder head

service. If valve seats are less than specifications, cylinder head

must be replaced. Insert the valve and hold firmly against the valve

seat. Measure distance of valve stem tip to valve cover mounting

surface. See Fig. 14.Fig. 14: Measuring For Refacing Dimension

Courtesy of Volkswagen United States, Inc.

2) Subtract measured distance from minimum specifications.

See MINIMUM VALVE-TO-CYLINDER HEAD DIMENSION following this paragraph.

The total is maximum refacing allowable for both valve and seat. If

more is required, replace cylinder head assembly or machine valve stem

Page 305 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

(Cabriolet only). If less than minimum dimension is used, valve

lifters will not function.

MINIMUM VALVE-TO-CYLINDER HEAD DIMENSIONÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

8-Valve

Intake Valve .............. 1.330 (33.78)

Exhaust Valve ............. 1.342 (34.09)

16-Valve

Intake Valve .............. 1.354 (34.39)

Exhaust Valve ............. 1.366 (34.70)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VALVES

1) With valves removed, measure dimension of valves. If not

within specifications, replace valves. DO NOT reface exhaust valves

with machine. Lap valves by hand or replace as necessary. See ENGINE

SPECIFICATIONS at end of this article.

CAUTION: On 16-valve engines, exhaust valves are sodium filled. Use

following procedure to dispose of valves properly.

2) To dispose of sodium filled valves, cut valve stem off

near head of valve with hacksaw. DO NOT allow water to contact valve

during cutting. Throw valve stem in bucket of water and move quickly

away. Once reaction with water has ceased, discard valve. Repeat

procedure as necessary.

VALVE CLEARANCE ADJUSTMENT

NOTE: Cylinder heads without shims between camshaft(s) and lifters

are not adjustable. See LIFTERS under VALVES in this article.

1) After any cylinder head repair, check and adjust valves

with engine cold. After 1000 miles (after repair) or at normal service

interval, adjust with engine warm. Shims are available in different

thicknesses. Etched side of shim must be installed away from camshaft.

2) Position camshaft lobes of cylinder to be check with high

points facing upward (valves closed). Measure clearance. See VALVE

ADJUSTMENT SPECIFICATIONS table in this article. If clearance cannot

be achieved with thinnest shim, shorter valves may be installed. If

clearance is greater than specifications, use appropriate shim to

acquire proper clearance.

3) To remove shim, rotate lifter (follower) so grooves face

inward towards each other (one cylinder at a time). Using Lifter

Compressor (2078) and Pliers (10-208), remove shim. To install,

reverse removal procedure.

Page 306 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 15)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

VALVE ADJUSTMENT SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

Cold

Intake .............. .006-.010 (.15-.25)

Exhaust ............. .014-.018 (.35-.45)

Warm

Intake .............. .008-.012 (.20-.30)

Exhaust ............. .016-.020 (.40-.50)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ LIFTERS

1) If equipped with hydraulic lifters, no adjustment is

possible. If lifter noise is present, start engine and allow to warm

until cooling fan engages. Increase engine speed to 2500 RPM for 2

minutes. If lifter noise is intermittent or continues, replace

necessary lifters.

2) To determine weak or noisy lifter, position camshaft so

No. 1 cylinder lobes high point faces upward. Using a piece of wood,

push down on lifter. If lifter can be pushed down more than .004" (.10

mm), replace lifter. Repeat procedure for remaining lifters (as

necessary).

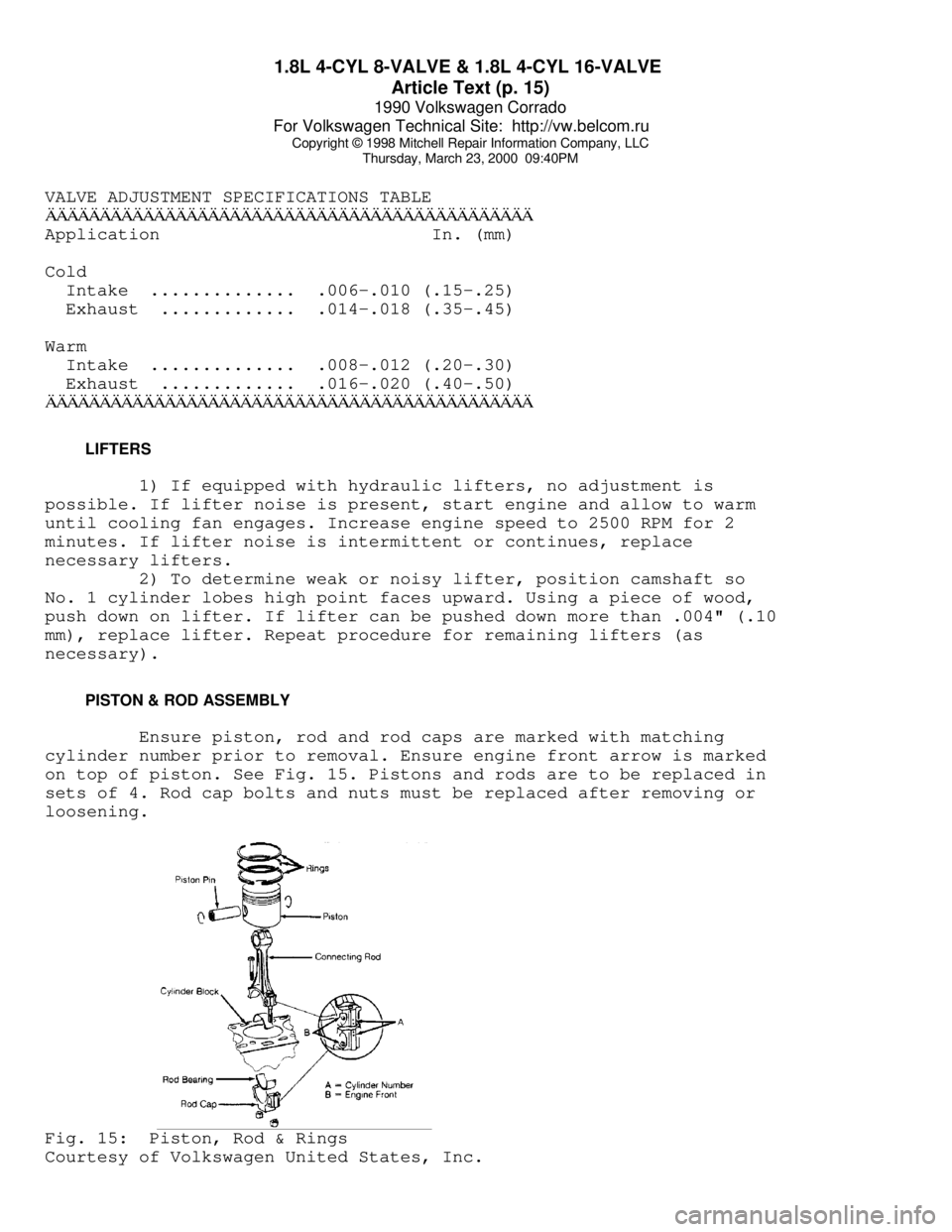

PISTON & ROD ASSEMBLY

Ensure piston, rod and rod caps are marked with matching

cylinder number prior to removal. Ensure engine front arrow is marked

on top of piston. See Fig. 15. Pistons and rods are to be replaced in

sets of 4. Rod cap bolts and nuts must be replaced after removing or

loosening.Fig. 15: Piston, Rod & Rings

Courtesy of Volkswagen United States, Inc.