technical specifications VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 435 of 906

C - SPECIFICATIONS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

INJECTOR RESISTANCE SPECS TABLE

INJECTOR RESISTANCE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ohms

Vanagon ............................................. 16.0-16.4

All Other Models .................................. (1) 3.7-5.0

(1) - Resistance measured at main electrical connector on the end

of fuel rail.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ IDLE SPEED & MIXTURE SPECS TABLE

IDLE SPEED & CO LEVEL TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level

Cabriolet .......... 850-1000 ............ 0.3-1.2%

Fox ................ 800-1000 ............ 0.3-1.2%

Golf ............... 800-1000 ............ 0.3-1.2%

Golf GT ............. 800-900 ............ 0.3-1.2%

GTI ................ 800-1000 ............ 0.3-1.2%

Jetta .............. 800-1000 ............ 0.3-1.2%

Vanagon ............. 830-930 ............ 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 438 of 906

D - ADJUSTMENTS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

On-Vehicle Adjustments

Volkswagen; Cabriolet, Corrado, Fox, Golf GL/GTI,

Jetta, Vanagon

ENGINE COMPRESSION

Check engine compression with engine at normal operating

temperature at specified cranking speed, all spark plugs removed and

throttle wide open.

ENGINE COMPRESSION TESTÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄModel Standard Minimum

psi (kg/cm

ý) psi (kg/cmý)

Cabriolet ............. 131-174 (9.0-12.0) ............. 109 (7.5)

Corrado ............... 116-174 (8.0-12.0) .............. 87 (6.0)

Fox ................... 131-174 (9.0-12.0) ............. 102 (7.0)

Golf GL/GTI 1.8L ...... 131-174 (9.0-12.0) ............. 102 (7.0)

Jetta ................. 131-174 (9.0-12.0) ............. 102 (7.0)

Jetta GLi 2.0L ........ 145-190 (10.0-13.0) ............ 109 (7.5)

Vanagon ............... 87-131 (6.1-9.2) ................ 87 (6.0)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VALVE CLEARANCE

NOTE: All models use hydraulic lifters. No adjustments are

required.

IGNITION TIMING

NOTE: Basic timing readings are only valid when engine idle speed

and idle mixture are within specifications. For best

results, the manufacturer recommends ignition timing, idle

CO and idle speed be checked and adjusted in that order.

NOTE: Off idle timing is computer controlled on models with knock

sensor(s). Only idle ignition timing can be set.

ALL MODELS EXCEPT VANAGON

1) Warm engine to normal operating temperature (cooling fan

should cycle at least once). Remove the 27 mm plastic plug from timing

check hole on transaxle bellhousing.

2) With ignition off, connect a tachometer and timing light

to vehicle. Start engine, raise speed above 2100 RPM a few times, and

allow engine to idle normally. With distributor vacuum hoses

Page 442 of 906

D - ADJUSTMENTS

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

8) Connect adapter between connector and regulator. Connect

multimeter to adapter and turn switch to DCA 200 milliamp-range. Read

and compare current (4-16 milliamps) and CO values to specifications.

Turn engine off.

9) If CO reading is more than 1.2% at current reading of 4-16

milliamps, check for exhaust system leaks, ignition timing, injector

inserts for leaks, and fuel distributor for uneven fuel distribution.

If required, seal injector inserts with sealing compound and tighten

to 15 ft. lbs. (20 N.m).

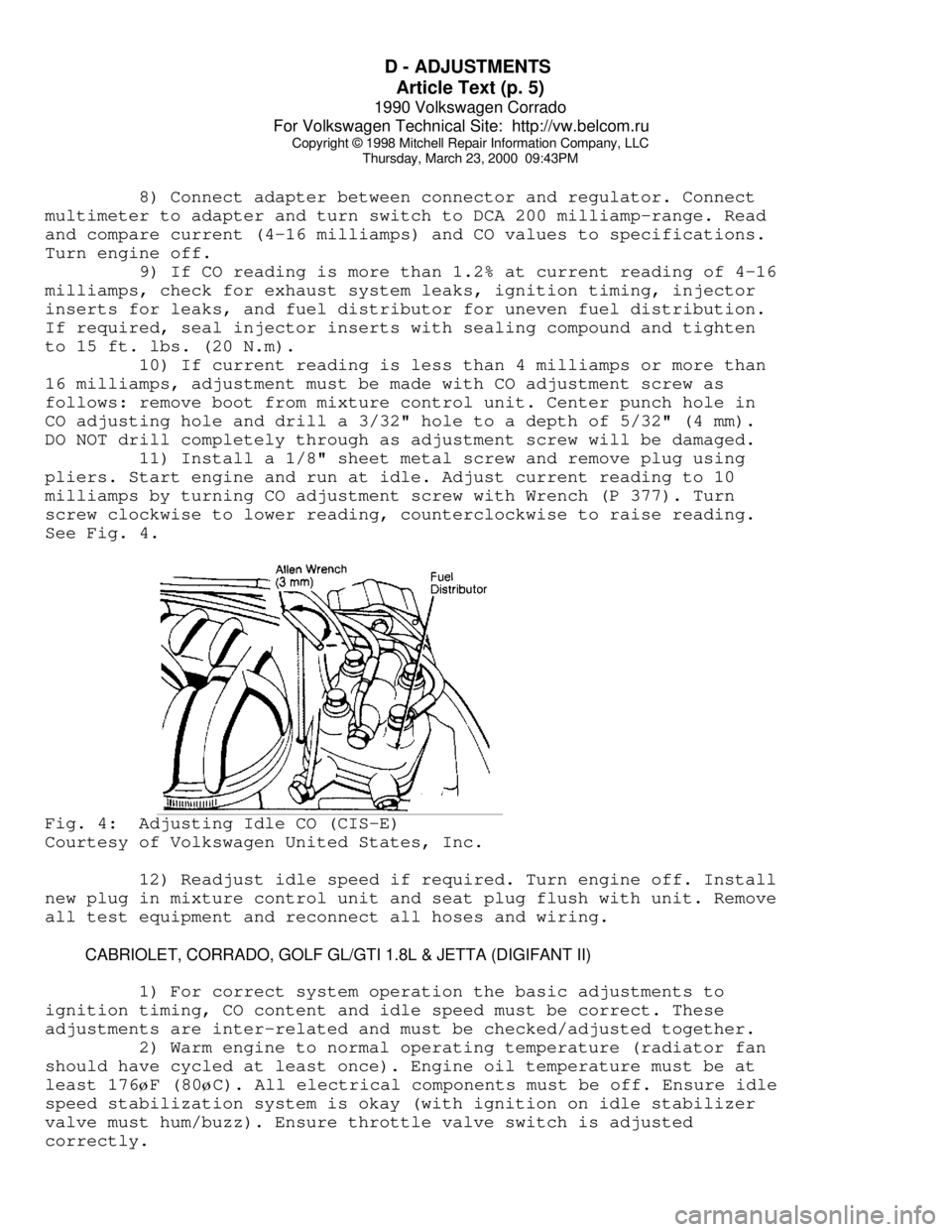

10) If current reading is less than 4 milliamps or more than

16 milliamps, adjustment must be made with CO adjustment screw as

follows: remove boot from mixture control unit. Center punch hole in

CO adjusting hole and drill a 3/32" hole to a depth of 5/32" (4 mm).

DO NOT drill completely through as adjustment screw will be damaged.

11) Install a 1/8" sheet metal screw and remove plug using

pliers. Start engine and run at idle. Adjust current reading to 10

milliamps by turning CO adjustment screw with Wrench (P 377). Turn

screw clockwise to lower reading, counterclockwise to raise reading.

See Fig. 4.Fig. 4: Adjusting Idle CO (CIS-E)

Courtesy of Volkswagen United States, Inc.

12) Readjust idle speed if required. Turn engine off. Install

new plug in mixture control unit and seat plug flush with unit. Remove

all test equipment and reconnect all hoses and wiring.

CABRIOLET, CORRADO, GOLF GL/GTI 1.8L & JETTA (DIGIFANT II)

1) For correct system operation the basic adjustments to

ignition timing, CO content and idle speed must be correct. These

adjustments are inter-related and must be checked/adjusted together.

2) Warm engine to normal operating temperature (radiator fan

should have cycled at least once). Engine oil temperature must be at

least 176øF (80øC). All electrical components must be off. Ensure idle

speed stabilization system is okay (with ignition on idle stabilizer

valve must hum/buzz). Ensure throttle valve switch is adjusted

correctly.

Page 446 of 906

D - ADJUSTMENTS

Article Text (p. 9)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

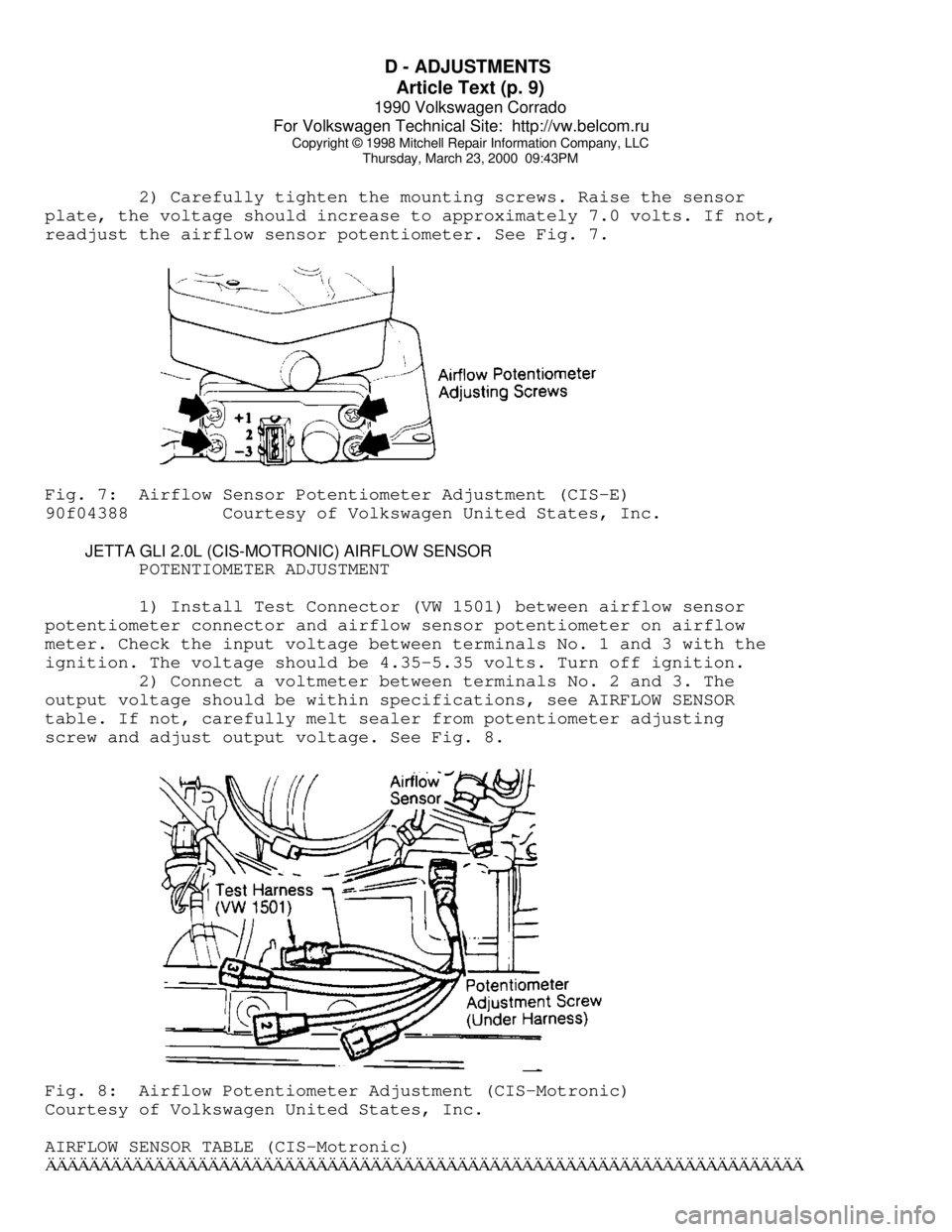

2) Carefully tighten the mounting screws. Raise the sensor

plate, the voltage should increase to approximately 7.0 volts. If not,

readjust the airflow sensor potentiometer. See Fig. 7.Fig. 7: Airflow Sensor Potentiometer Adjustment (CIS-E)

90f04388 Courtesy of Volkswagen United States, Inc.

JETTA GLI 2.0L (CIS-MOTRONIC) AIRFLOW SENSOR

POTENTIOMETER ADJUSTMENT

1) Install Test Connector (VW 1501) between airflow sensor

potentiometer connector and airflow sensor potentiometer on airflow

meter. Check the input voltage between terminals No. 1 and 3 with the

ignition. The voltage should be 4.35-5.35 volts. Turn off ignition.

2) Connect a voltmeter between terminals No. 2 and 3. The

output voltage should be within specifications, see AIRFLOW SENSOR

table. If not, carefully melt sealer from potentiometer adjusting

screw and adjust output voltage. See Fig. 8.Fig. 8: Airflow Potentiometer Adjustment (CIS-Motronic)

Courtesy of Volkswagen United States, Inc.

AIRFLOW SENSOR TABLE (CIS-Motronic)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 448 of 906

DRIVE AXLE - GEAR TOOTH CONTACT PATTERNS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

ARTICLE BEGINNING

1983-93 DRIVE AXLES

Gear Tooth Contact Patterns

All Models

INSPECTION

PRELIMINARY INSPECTION

Wipe lubricant from internal parts. Rotate gears and inspect

for wear or damage. Mount dial indicator to housing, and check

backlash at several points around ring gear. Backlash must be within

specifications at all points. If no defects are found, check gear

tooth contact pattern.

GEAR TOOTH CONTACT PATTERN

NOTE: Drive pattern should be well centered on ring gear teeth.

Coast pattern should be centered, but may be slightly toward

toe of ring gear teeth.

1) Paint ring gear teeth with marking compound. Wrap cloth or

rope around drive pinion flange to act as brake. Rotate ring gear

until clear tooth contact pattern is obtained.

2) Contact pattern will indicate whether correct pinion

bearing mounting shim has been installed and if drive gear backlash

has been set properly. Backlash between drive gear and pinion must be

maintained within specified limits, until correct tooth pattern is

obtained.

Page 495 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ARTICLE BEGINNING

GENERAL INFORMATION

All Makes Emission Control Visual Inspection Procedures

All Models

PLEASE READ THIS FIRST

This article is provided for general information only. Not

all information applies to all makes and models. For more complete

information, see appropriate article(s) in the ENGINE PERFORMANCE

Section.

EMISSION CONTROL LABELS

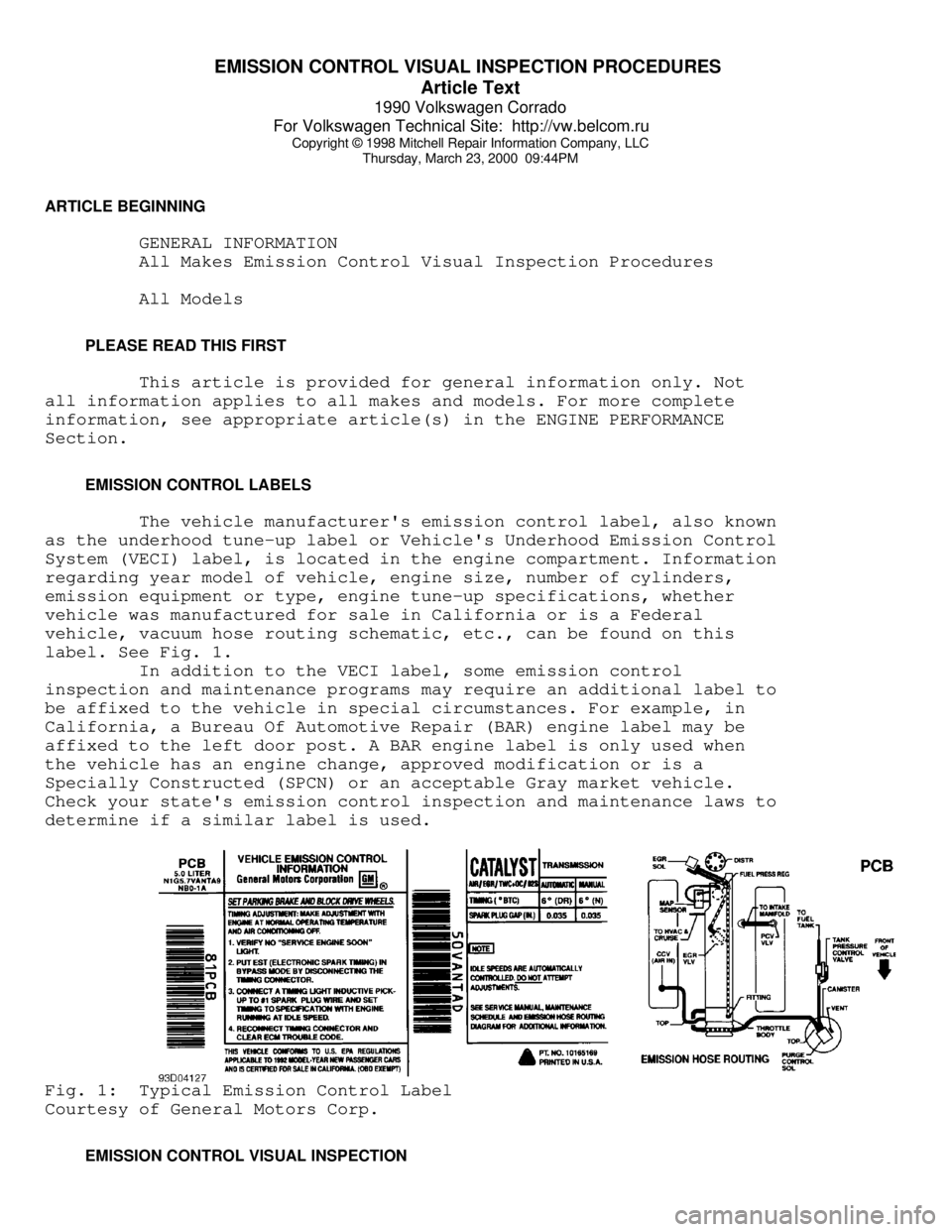

The vehicle manufacturer's emission control label, also known

as the underhood tune-up label or Vehicle's Underhood Emission Control

System (VECI) label, is located in the engine compartment. Information

regarding year model of vehicle, engine size, number of cylinders,

emission equipment or type, engine tune-up specifications, whether

vehicle was manufactured for sale in California or is a Federal

vehicle, vacuum hose routing schematic, etc., can be found on this

label. See Fig. 1.

In addition to the VECI label, some emission control

inspection and maintenance programs may require an additional label to

be affixed to the vehicle in special circumstances. For example, in

California, a Bureau Of Automotive Repair (BAR) engine label may be

affixed to the left door post. A BAR engine label is only used when

the vehicle has an engine change, approved modification or is a

Specially Constructed (SPCN) or an acceptable Gray market vehicle.

Check your state's emission control inspection and maintenance laws to

determine if a similar label is used.Fig. 1: Typical Emission Control Label

Courtesy of General Motors Corp.

EMISSION CONTROL VISUAL INSPECTION

Page 510 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ARTICLE BEGINNING

Engine Overhaul Procedures - General Information

ALL PISTON ENGINES

* PLEASE READ THIS FIRST *

Examples used in this article are general in nature and do

not necessarily relate to a specific engine or system. Illustrations

and procedures have been chosen to guide mechanic through engine

overhaul process. Descriptions of processes of cleaning, inspection,

assembly and machine shop practice are included.

Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and specifications

for the vehicle being repaired.

ENGINE IDENTIFICATION

The engine may be identified from its Vehicle Identification

Number (VIN) stamped on a metal tab. Metal tab may be located in

different locations depending on manufacturer. Engine identification

number or serial number is located on cylinder block. Location varies

with manufacturer.

INSPECTION PROCEDURES

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

GENERAL

Engine components must be inspected to meet manufacturer's

specifications and tolerances during overhaul. Proper dimensions and

tolerances must be met to obtain proper performance and maximum engine

life.

Micrometers, depth gauges and dial indicator are used for

checking tolerances during engine overhaul. Magnaflux, Magnaglo, dye-

check, ultrasonic and x-ray inspection procedures are used for parts

inspection.

MAGNETIC PARTICLE INSPECTION

Magnaflux & Magnaglo

Magnaflux is an inspection technique used to locate material

flaws and stress cracks. The part in question is subjected to a strong

magnetic field. The entire part, or a localized area, can be

magnetized. The part is coated with either a wet or dry material that

contains fine magnetic particles.

Page 512 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

GENERAL

All components of an engine do not have the same cleaning

requirements. Physical methods include bead blasting and manual

removal. Chemical methods include solvent blast, solvent tank, hot

tank, cold tank and steam cleaning of components.

BEAD BLASTING

Manual removal of deposits may be required prior to bead

blasting, followed by some other cleaning method. Carbon, paint and

rust may be removed using bead blasting method. Components must be

free of oil and grease prior to bead blasting. Beads will stick to

grease or oil soaked areas causing area not to be cleaned.

Use air pressure to remove all trapped residual beads from

components after cleaning. After cleaning internal engine parts made

of aluminum, wash thoroughly with hot soapy water. Component must be

thoroughly cleaned as glass beads will enter engine oil resulting in

bearing damage.

CHEMICAL CLEANING

Solvent tank is used for cleaning oily residue from

components. Solvent blasting sprays solvent through a siphon gun using

compressed air.

The hot tank, using heated caustic solvents, is used for

cleaning ferrous materials only. DO NOT clean aluminum parts such as

cylinder heads, bearings or other soft metals using the hot tank.

After cleaning, flush parts with hot water.

A non-ferrous part will be ruined and caustic solution will

be diluted if placed in the hot tank. Always use eye protection and

gloves when using the hot tank.

Use of a cold tank is for cleaning of aluminum cylinder

heads, carburetors and other soft metals. A less caustic and unheated

solution is used. Parts may be lift in the tank for several hours

without damage. After cleaning, flush parts with hot water.

Steam cleaning, with boiling hot water sprayed at high

pressure, is recommended as the final cleaning process when using

either hot or cold tank cleaning.

COMPONENT CLEANING

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

Page 513 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

specifications for the vehicle being repaired.

SHEET METAL PARTS

Examples of sheet metal parts are the rocker covers, front

and side covers, oil pan and bellhousing dust cover. Glass bead

blasting or hot tank may be used for cleaning.

Ensure all mating surfaces are flat. Deformed surfaces should

be straightened. Check all sheet metal parts for cracks and dents.

INTAKE & EXHAUST MANIFOLDS

Using solvent cleaning or bead blasting, clean manifolds for

inspection. If the intake manifold has an exhaust crossover, all

carbon deposits must be removed. Inspect manifolds for cracks, burned

or eroded areas, corrosion and damage to fasteners.

Exhaust heat and products of combustion cause threads of

fasteners to corrode. Replace studs and bolts as necessary. On "V"

type intake manifolds, the sheet metal oil shield must be removed for

proper cleaning and inspection. Ensure that all manifold parting

surfaces are flat and free of burrs.

CYLINDER HEAD REPLACEMENT

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

REMOVAL

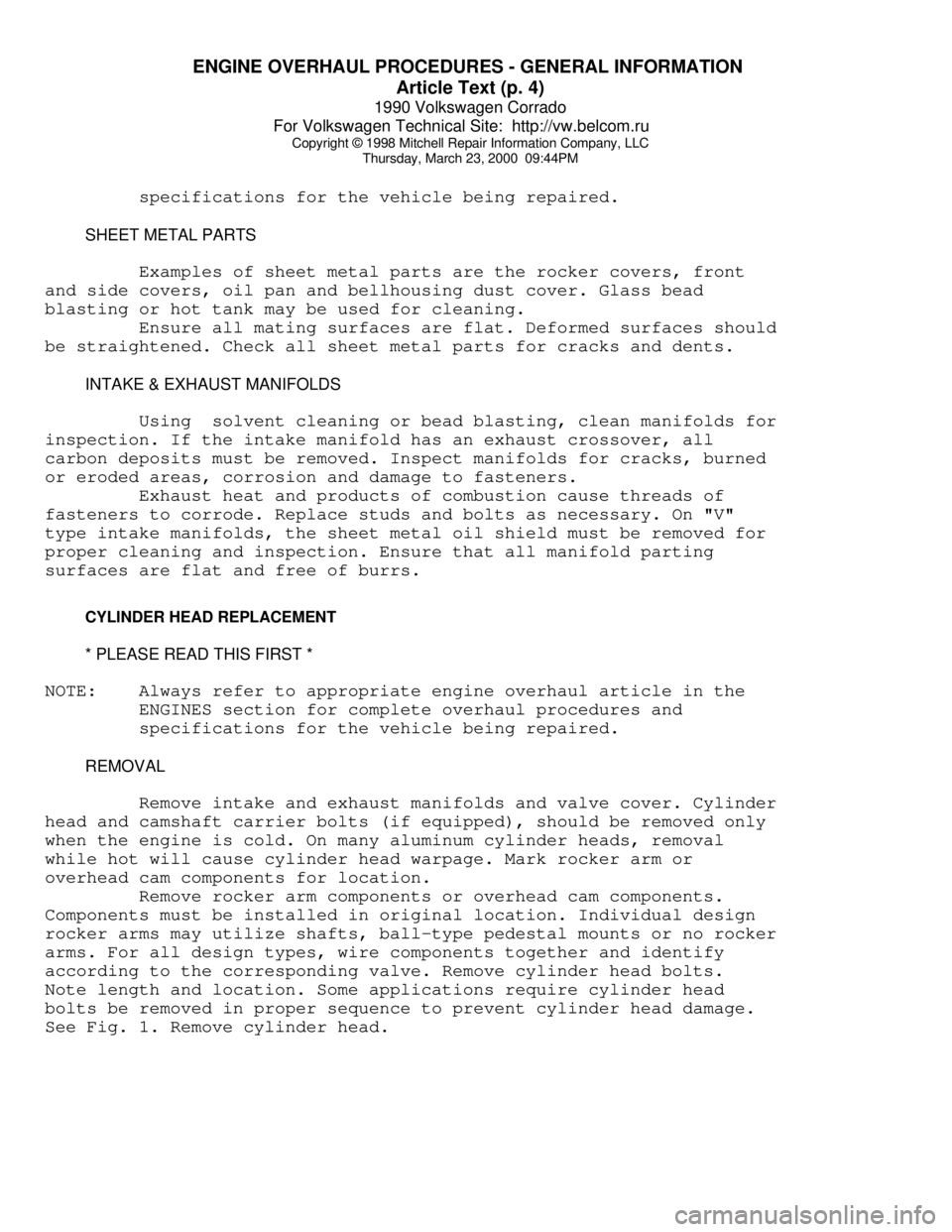

Remove intake and exhaust manifolds and valve cover. Cylinder

head and camshaft carrier bolts (if equipped), should be removed only

when the engine is cold. On many aluminum cylinder heads, removal

while hot will cause cylinder head warpage. Mark rocker arm or

overhead cam components for location.

Remove rocker arm components or overhead cam components.

Components must be installed in original location. Individual design

rocker arms may utilize shafts, ball-type pedestal mounts or no rocker

arms. For all design types, wire components together and identify

according to the corresponding valve. Remove cylinder head bolts.

Note length and location. Some applications require cylinder head

bolts be removed in proper sequence to prevent cylinder head damage.

See Fig. 1. Remove cylinder head.

Page 514 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

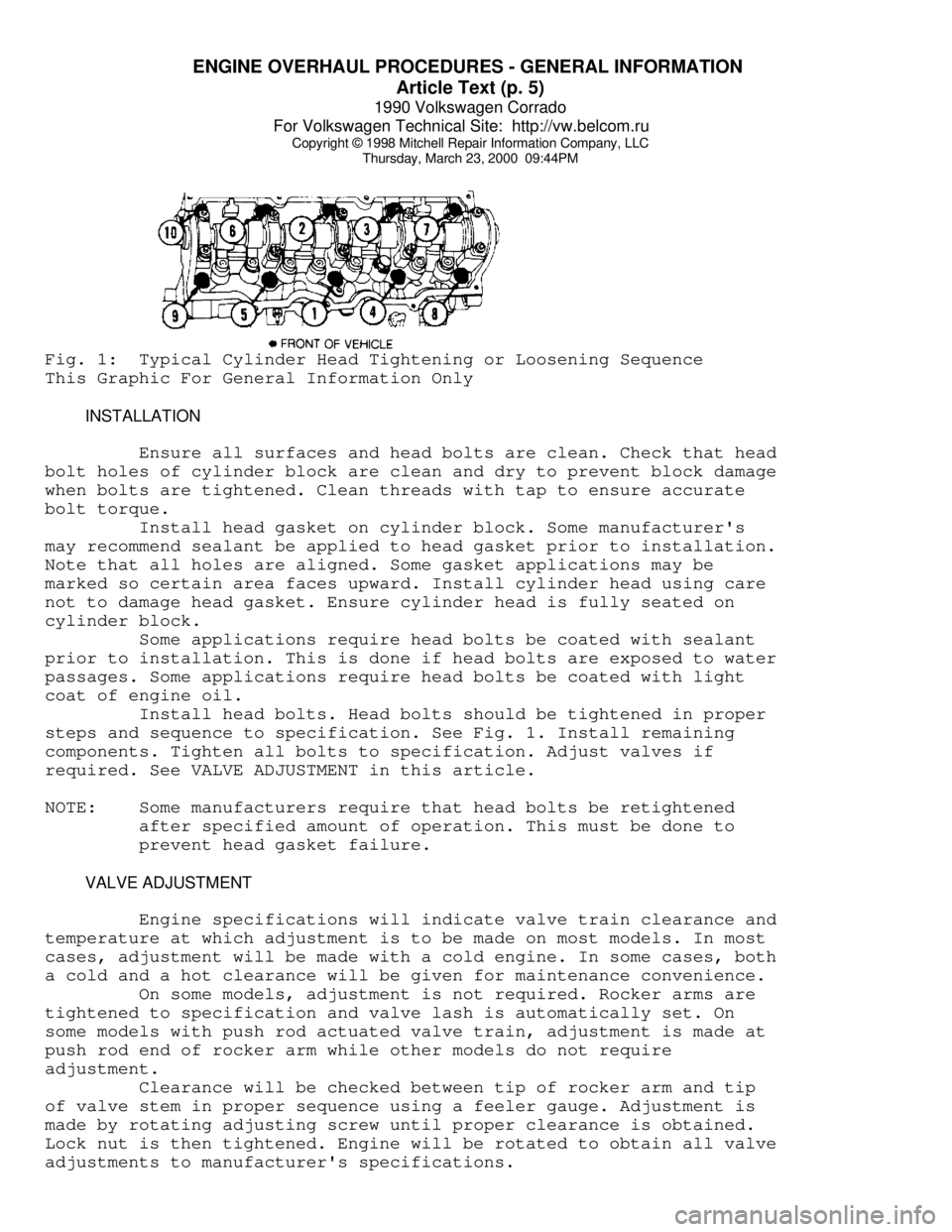

Thursday, March 23, 2000 09:44PMFig. 1: Typical Cylinder Head Tightening or Loosening Sequence

This Graphic For General Information Only

INSTALLATION

Ensure all surfaces and head bolts are clean. Check that head

bolt holes of cylinder block are clean and dry to prevent block damage

when bolts are tightened. Clean threads with tap to ensure accurate

bolt torque.

Install head gasket on cylinder block. Some manufacturer's

may recommend sealant be applied to head gasket prior to installation.

Note that all holes are aligned. Some gasket applications may be

marked so certain area faces upward. Install cylinder head using care

not to damage head gasket. Ensure cylinder head is fully seated on

cylinder block.

Some applications require head bolts be coated with sealant

prior to installation. This is done if head bolts are exposed to water

passages. Some applications require head bolts be coated with light

coat of engine oil.

Install head bolts. Head bolts should be tightened in proper

steps and sequence to specification. See Fig. 1. Install remaining

components. Tighten all bolts to specification. Adjust valves if

required. See VALVE ADJUSTMENT in this article.

NOTE: Some manufacturers require that head bolts be retightened

after specified amount of operation. This must be done to

prevent head gasket failure.

VALVE ADJUSTMENT

Engine specifications will indicate valve train clearance and

temperature at which adjustment is to be made on most models. In most

cases, adjustment will be made with a cold engine. In some cases, both

a cold and a hot clearance will be given for maintenance convenience.

On some models, adjustment is not required. Rocker arms are

tightened to specification and valve lash is automatically set. On

some models with push rod actuated valve train, adjustment is made at

push rod end of rocker arm while other models do not require

adjustment.

Clearance will be checked between tip of rocker arm and tip

of valve stem in proper sequence using a feeler gauge. Adjustment is

made by rotating adjusting screw until proper clearance is obtained.

Lock nut is then tightened. Engine will be rotated to obtain all valve

adjustments to manufacturer's specifications.