technical specifications VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 551 of 906

F - BASIC TESTING

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ALL EXCEPT CORRADO & VANAGON

1) Remove fuel return line located near left strut tower.

Remove fuel tank cap. Attach a piece of hose between return line and a

1 qt. (.95 liter) graduated container.

2) Activate fuel pump for 30 seconds by removing fuel pump

relay and attaching jumper wire between terminals No. 30 and No. 87.

Remove fuel pump relay from fuse/relay block. Compare volume with

specifications.

CORRADO

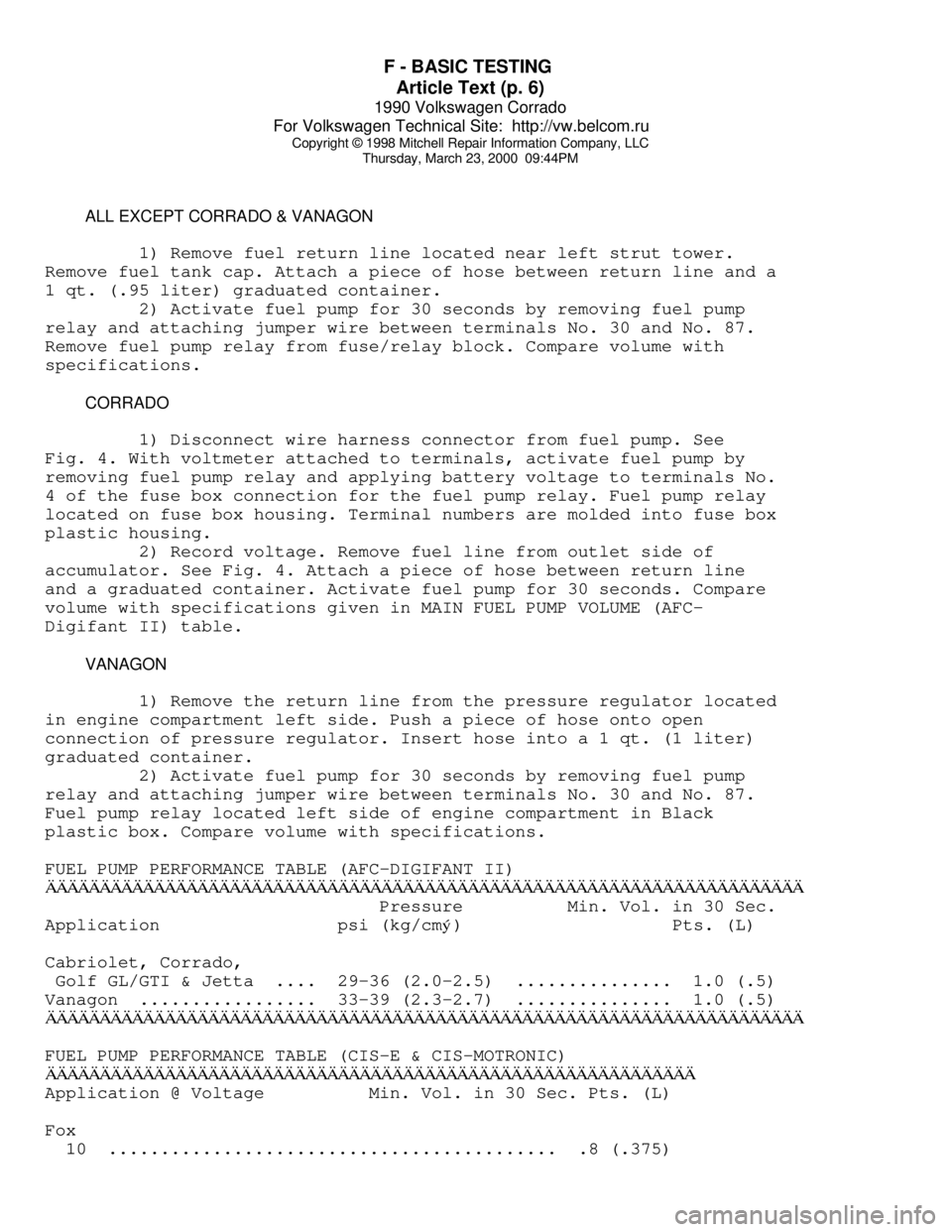

1) Disconnect wire harness connector from fuel pump. See

Fig. 4. With voltmeter attached to terminals, activate fuel pump by

removing fuel pump relay and applying battery voltage to terminals No.

4 of the fuse box connection for the fuel pump relay. Fuel pump relay

located on fuse box housing. Terminal numbers are molded into fuse box

plastic housing.

2) Record voltage. Remove fuel line from outlet side of

accumulator. See Fig. 4. Attach a piece of hose between return line

and a graduated container. Activate fuel pump for 30 seconds. Compare

volume with specifications given in MAIN FUEL PUMP VOLUME (AFC-

Digifant II) table.

VANAGON

1) Remove the return line from the pressure regulator located

in engine compartment left side. Push a piece of hose onto open

connection of pressure regulator. Insert hose into a 1 qt. (1 liter)

graduated container.

2) Activate fuel pump for 30 seconds by removing fuel pump

relay and attaching jumper wire between terminals No. 30 and No. 87.

Fuel pump relay located left side of engine compartment in Black

plastic box. Compare volume with specifications.

FUEL PUMP PERFORMANCE TABLE (AFC-DIGIFANT II)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Pressure Min. Vol. in 30 Sec.

Application psi (kg/cm

ý) Pts. (L)

Cabriolet, Corrado,

Golf GL/GTI & Jetta .... 29-36 (2.0-2.5) ............... 1.0 (.5)

Vanagon ................. 33-39 (2.3-2.7) ............... 1.0 (.5)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFUEL PUMP PERFORMANCE TABLE (CIS-E & CIS-MOTRONIC)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication @ Voltage Min. Vol. in 30 Sec. Pts. (L)

Fox

10 ........................................... .8 (.375)

Page 552 of 906

F - BASIC TESTING

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

11 .......................................... 1.1 (.520)

12 .......................................... 1.4 (.675)

Jetta GLi

10 .......................................... 1.0 (.460)

11 .......................................... 1.3 (.620)

12 .......................................... 1.6 (.750)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 4: Identifying Main Fuel Pump (Fox & Jetta GLi)

Courtesy of Volkswagen United States, Inc.

IGNITION CHECKS (CIS-E)

NOTE: Ignition checks are divided according to fuel system.

SPARK TEST

1) Using an ohmmeter, check resistance of each spark plug

wire. See HIGH TENSION WIRE RESISTANCE table. Check for a strong Blue

spark at coil wire and each spark plug wire by holding wire terminal

5/16" ground while cranking engine.

2) Disconnect and inspect all related ignition system

connectors and harness. Clean or repair as necessary. If okay, remove

negative battery cable. Disconnect secondary lead from coil Remove

primary leads from ignition coil.

3) Using ohmmeter, check resistance between primary terminals

of coil. Check secondary resistance between coil secondary terminal

and primary positive terminal. Replace coil if readings are not within

specifications. See IGNITION COIL RESISTANCE table.

HIGH TENSION WIRE RESISTANCE TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ohms

Page 554 of 906

F - BASIC TESTING

Article Text (p. 9)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

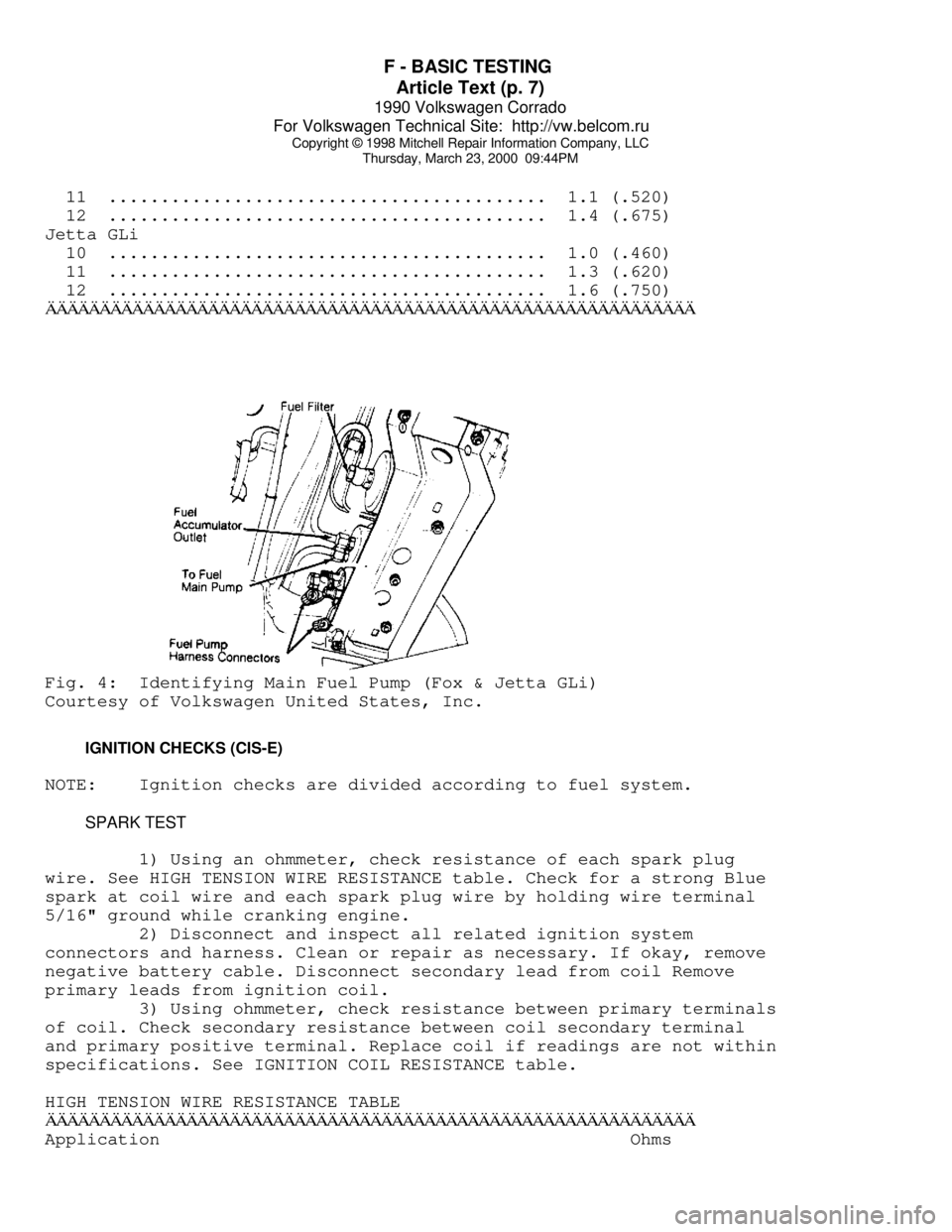

1) Perform SPARK TEST check. If secondary spark is present,

ignition control unit is okay. If not, turn ignition off. Disconnect

ignition control unit wire harness connector. Turn ignition on. Using

a voltmeter, measure voltage between terminal No. 2 (-) and terminal

No. 4 (+) of connector. See Fig. 6.

2) Voltage should be present. If not, ensure continuity

exists between terminal No. 2 and ground. Continuity must also exist

between terminal No. 4 and ignition coil positive terminal. Repair

wiring if necessary. If wiring is okay, replace ignition control unit.Fig. 6: Checking Typical Ignition Control Unit Voltage

Courtesy of Volkswagen United States, Inc.

NOTE: These tests require a high-impedance volt-ohmmeter.

IGNITION CHECKS (CIS-MOTRONIC)

SPARK

1) Using an ohmmeter, check resistance of each spark plug

wire. See HIGH TENSION WIRE RESISTANCE table. Check for a strong Blue

spark at coil wire and each spark plug wire by holding wire terminal

5/16" ground while cranking engine.

2) Disconnect and inspect all related ignition system

connectors and harness. Clean or repair as necessary. If okay, remove

negative battery cable. Disconnect secondary and primary leads from

ignition coil.

3) Using ohmmeter, check resistance between primary terminals

of coil. Check secondary resistance between coil secondary terminal

and primary positive terminal. Replace coil if readings are not within

specifications. See IGNITION COIL RESISTANCE table.

HIGH TENSION WIRE RESISTANCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ohms

Jetta GLi

Coil Wire With Connectors .................... 1600-2400

Spark Plug Wire With Connectors .............. 4800-7200

Spark Plug Connector ......................... 4000-6000

Suppressor (1) ................................ 800-1200

(1) - Suppressor is located between ignition wire and

Page 557 of 906

F - BASIC TESTING

Article Text (p. 12)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

No. 1 and No. 15 of the coil.

2) Turn the ignition on, using a jumper wire, briefly connect

the center terminal of the Hall Effect sender connector to ground. The

voltage should briefly increase to at least 2 volts then drop to zero.

If not, either the ECU or coil power stage are defective.

IGNITION CHECKS (AFC-DIGIFANT II)

SPARK TEST

1) Using an ohmmeter, check resistance of each spark plug

wire. See HIGH TENSION WIRE RESISTANCE table. Check for a strong Blue

spark at coil wire and each spark plug wire by holding wire terminal

5/16" ground while cranking engine.

2) Disconnect and inspect all related ignition system

connectors and harness. Clean or repair as necessary. If okay, remove

negative battery cable. Disconnect secondary and primary leads from

ignition coil.

3) Using ohmmeter, check resistance between primary terminals

of coil. Check secondary resistance between coil secondary terminal

and primary positive terminal. Replace coil if readings are not within

specifications. See IGNITION COIL RESISTANCE table.

HIGH TENSION WIRE RESISTANCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ohms

Vanagon

Coil Wire With Connectors ................... 1200-2800

Spark Plug Wire/Connector ................... 4600-7400

Spark Plug Connector ........................ 4000-6000

Suppressor (1) ............................... 600-1400

All Other Models

Coil Wire Only .................................... (1)

Coil Wire With Connector .................... 1600-2400

Spark Plug Wire/ Connector .................. 4000-6000

Suppressor (2) ............................... 600-1400

(1) - Check for continuity.

(2) - Suppressor is located between ignition wire and

distributor cap.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ IGNITION COIL

IGNITION COIL RESISTANCE TABLE - Ohms @ 68

øF (20øC)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Primary Secondary

Jetta GLi 2.0L ......... .60-.70 ............. 6900-8500

All Other Models ....... .52-.76 ............. 2400-3500

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 568 of 906

GEAR TOOTH CONTACT PATTERNS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

ARTICLE BEGINNING

GENERAL INFORMATION

Gear Tooth Contact Patterns

* PLEASE READ THIS FIRST *

The following article is for GENERAL INFORMATION purposes

only. Information does not SPECIFICALLY apply to all years, makes and

models, but is to be used as a general reference guide.

INSPECTION

PRELIMINARY INSPECTION

Wipe lubricant from internal parts. Rotate gears and inspect

for wear or damage. Mount dial indicator to housing, and check

backlash at several points around ring gear. Backlash must be within

specifications at all points. If no defects are found, check gear

tooth contact pattern.

GEAR TOOTH CONTACT PATTERN

NOTE: Drive pattern should be well centered on ring gear teeth.

Coast pattern should be centered, but may be slightly toward

toe of ring gear teeth.

1) Paint ring gear teeth with marking compound. Wrap cloth or

rope around drive pinion flange to act as brake. Rotate ring gear

until clear tooth contact pattern is obtained.

2) Contact pattern will indicate whether correct pinion

bearing mounting shim has been installed and if drive gear backlash

has been set properly. Backlash between drive gear and pinion must be

maintained within specified limits, until correct tooth pattern is

obtained.

Page 574 of 906

H - TESTS W/O CODES

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Trouble Shooting - No Codes

Volkswagen; Cabriolet, Corrado, Fox, Golf GL/GTI,

Jetta, Vanagon

INTRODUCTION

Before diagnosing symptoms or intermittent faults, perform

steps in F - BASIC TESTING article. Use this article to diagnose

driveability problems existing when a hard fault code is not present

or vehicle is not equipped with a self-diagnostic system.

NOTE: Some driveability problems may have been corrected by

manufacturer with a revised computer calibration chip or

computer control unit. Check with manufacturer for latest

chip or computer application.

Symptom checks can direct the technician to malfunctioning

component(s) for further diagnosis. A symptom should lead to a

specific component, system test or an adjustment.

Use intermittent test procedures to locate driveability

problems that DO NOT occur when the vehicle is being tested. These

test procedures should also be used if a soft (intermittent) trouble

code was present, but no problem was found during self-diagnostic

testing.

NOTE: For specific testing procedures, see I - SYSTEM/COMP

TESTS article. For specifications, see D - ADJUSTMENTS

or C - SPECIFICATIONS articles.

SYMPTOM DIAGNOSIS

Symptom checks cannot be used properly unless the problem is

actually happening while the vehicle is being tested. To reduce

diagnostic time, ensure steps in F - BASIC TESTING article have been

performed before attempting to diagnose a symptom. Symptoms available

for diagnosis include the following:

* Will Not Start or Starts Hard Cold (Cranks Okay)

* Will Not Start or Starts Hard Hot (Cranks Okay)

* Engine Stalls or Idles Rough

* Engine Misfires or Hesitates

* Excessive Fast Idle

* Engine Hesitates On Acceleration

* Engine Lacks Power

* Poor Fuel Mileage

* Engine Diesels

* Failed Emissions Test

Page 578 of 906

H - TESTS W/O CODES

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

* Ensure there are no vacuum leaks.

* Check idle stabilizer operation (if equipped).

* Ensure fuel system pressure and volume are correct.

* Check auxiliary air by-pass regulator.

* Check cold start valve for leaking (engine warm).

ENGINE HESITATES ON ACCELERATION

* Inspect intake air components for leaking hoses

* Check injector spray pattern. Check for faulty injectors.

* Check cold start valve for leaking (engine warm).

* Check airflow sensor plate movement. Replace fuel distributor

as necessary.

* Check airflow sensor plate position. Adjust as necessary.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Test airflow sensor plate potentiometer. Adjust or replace

as necessary.

* Perform system electrical checks.

* Check idle mixture CO adjustment. Adjust as necessary.

ENGINE LACKS POWER

* Test coolant temperature sensor and wiring. Repair or

replace as required.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Check throttle cable adjustment.

* Check throttle switch. Adjust or replace as necessary.

* Check airflow sensor screen for damage or incorrect installation

(if equipped).

* Check ignition timing and knock sensor control (if equipped).

Adjust as necessary.

* Check EGR system for correct operation (if equipped).

* Ensure base timing is correct and timing advance system

is functional.

* Check transmission for correct downshift (auto. trans.)

* Check fuel tank filler tube for tampering of restrictor. If

tampering has occurred, check catalytic converter for lead

contamination and exhaust system restriction.

* Check for use of poor quality fuel containing insufficient

cleaning additives. Prolonged use of poor quality fuel can

cause injector clogging and carbon build-up on intake system.

* Inspect intake air element, housing, and preheating system.

* Check airflow sensor plate movement. Replace if necessary.

POOR FUEL MILEAGE

* Ensure idle speed, base timing and timing advance are

set to specifications.

* Check cold start valve for leaking (engine warm).

Page 579 of 906

H - TESTS W/O CODES

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

* Check fuel system and control system pressure. Replace

pressure regulator if necessary.

* Check thermo time switch operation.

* Check airflow sensor voltage output.

* Check air induction system for leaks.

* Check fuel injector operation.

* Check coolant temperature sensor operation.

* Check Oxygen (O2) sensor operation.

ENGINE DIESELING

CIS-E & CIS-E MOTRONIC

* Ensure ignition timing and timing advance are set to

specifications.

* Check for engine overheating.

* Check cold start valve for leaking (engine warm).

* Check for leaking injectors.

* Check airflow sensor plate/control plunger rest position.

Adjust as necessary.

* Check carbon canister solenoid valve.

* Verify no leaks in exhaust system.

FAILED EMISSIONS TEST

* Test lambda control system. Replace if faulty.

* Check air/fuel mixture. Adjust if necessary.

* Ensure air intake system is not restricted.

* Ensure engine is at normal operating temperature.

* Ensure fuel system pressure is correct.

* Check cold start valve for leaking (engine warm).

* Check thermo time switch operation.

* Verify base timing is correct.

* Check for correct PCV valve operation.

* Check crankcase for gasoline contamination.

* Check idle stabilizer operation.

* Check EGR system for correct operation (if equipped).

* Check vapor recovery system operation.

* Check operation of coolant temperature sensor.

* Check fuel tank filler tube for tampering of restrictor.

If tampering has occurred, check catalytic converter for

lead contamination and exhaust system restriction.

* Check for use of poor quality fuel containing insufficient

cleaning additives. Prolonged use of poor quality fuel can

cause injector clogging and carbon build-up on intake system.

INTERMITTENT PROBLEM DIAGNOSIS

Intermittent fault testing requires duplicating circuit or

component failure to identify the problem. If necessary, monitor

voltage or resistance values using a DVOM while attempting to

Page 594 of 906

I - SYSTEM/COMPONENT TESTS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

1) Disconnect throttle valve switch connector. With ohmmeter

set on 200-ohm scale, attach probes to male terminals. Ensure throttle

valve switch is completely closed. With throttle valve closed, meter

reading should be zero.

2) Position throttle valve to 1/2 open position. Ohmmeter

reading should be infinite. Position throttle to fully open position.

Ohmmeter reading should be zero. If any reading is incorrect, perform

throttle valve switch adjustment. See D - ADJUSTMENTS article.

3) If correct specifications cannot be obtained, check

throttle shaft play, accelerator cable adjustment and throttle switch

actuating cam. If okay, replace throttle valve switch.

RELAYS

FUEL PUMP RELAY (CABRIOLET, GOLF GL/GTI & JETTA)

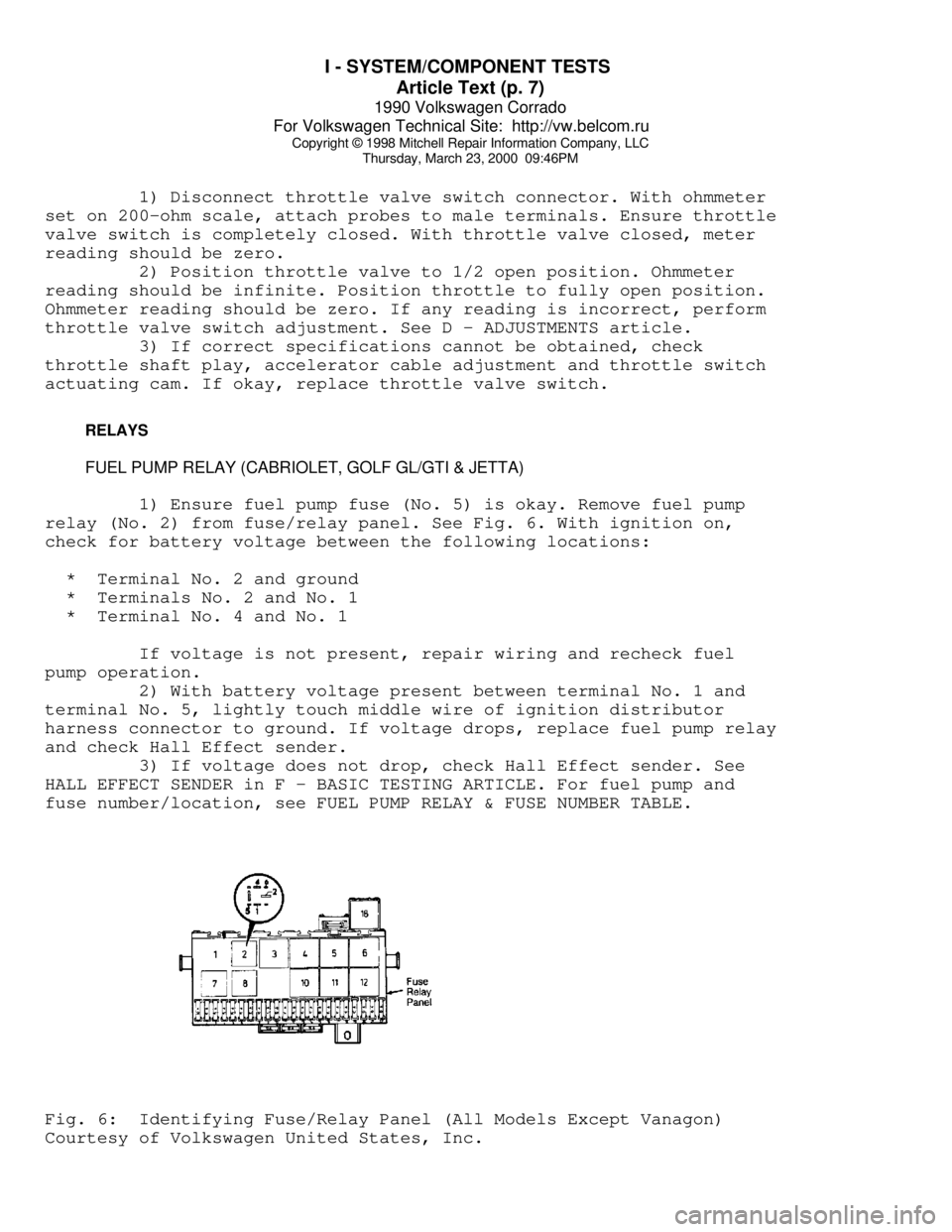

1) Ensure fuel pump fuse (No. 5) is okay. Remove fuel pump

relay (No. 2) from fuse/relay panel. See Fig. 6. With ignition on,

check for battery voltage between the following locations:

* Terminal No. 2 and ground

* Terminals No. 2 and No. 1

* Terminal No. 4 and No. 1

If voltage is not present, repair wiring and recheck fuel

pump operation.

2) With battery voltage present between terminal No. 1 and

terminal No. 5, lightly touch middle wire of ignition distributor

harness connector to ground. If voltage drops, replace fuel pump relay

and check Hall Effect sender.

3) If voltage does not drop, check Hall Effect sender. See

HALL EFFECT SENDER in F - BASIC TESTING ARTICLE. For fuel pump and

fuse number/location, see FUEL PUMP RELAY & FUSE NUMBER TABLE.Fig. 6: Identifying Fuse/Relay Panel (All Models Except Vanagon)

Courtesy of Volkswagen United States, Inc.

Page 603 of 906

INSTRUMENT PANEL

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

ARTICLE BEGINNING

1989-90 ACCESSORIES & EQUIPMENT

Volkswagen Instrument Panels

Cabriolet, Fox, Golt, GTI, Jetta, Jetta GLI, Vanagon

DESCRIPTION & OPERATION

Instrument cluster for most models includes speedometer, fuel

gauge and temperature gauge. Optional instruments include clock,

tachometer, voltmeter and oil temperature gauge.

Printed circuit provides voltage to gauges. A voltage

regulator attached to the printed circuit controls voltage to fuel and

temperature gauges. Light Emitting Diodes (LEDs) are used for most

warning lights. To replace diodes, pull from printed circuit sockets.

NOTE: Volkswagen Tester (1301) is required for resistance tests.

Tester settings are numerical. Settings do not indicate

resistance in ohms. Manufacturer does not supply resistance

value in ohms.

TESTING

FUEL & TEMPERATURE GAUGE

1) Disconnect wire from fuel tank or temperature sending

unit. Connect VW tester between wire and ground. Turn ignition on and

allow 2 minutes for gauge reading to stabilize. Use FUEL GAUGE TESTING

or TEMPERATURE GAUGE TESTING table to compare gauge reading. Gauge

should be within one pointer width of specification.

2) If gauge needle does not move, check continuity between

sender wire and gauge. If needle moves, but does not match

specifications, replace gauge. If gauge works correctly with tester,

but not sending unit, replace sending unit.

FUEL GAUGE TESTINGÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Dial Setting Indicator

Cabriolet & Fox .......... 55 ................ Full

560 ................Empty

Golf, GTI, Jetta

& Jetta GLI .............. 52 ................ Full

550 ................Empty

Vanagon .................. 50 ................ Full

320 ................Empty

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTEMPERATURE GAUGE TESTING

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ