check engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 601 of 920

H - TESTS W/O CODES

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ENGINE STALLS WHILE DRIVING

* Check fuel pump.

* Check auxiliary air intake system.

* Check injector fuel pressure and volume.

* Check idle and full throttle switches.

* Check intake air preheating system.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

POOR PERFORMANCE

* Check fuel pump.

* Check throttle cable adjustment.

* Check auxiliary air intake system.

* Check airflow sensor lever adjustment and control plunger.

* Check throttle potentiometer.

* Check fuel system differential and residual pressures.

* Check injector fuel pressure and volume.

* Check full throttle switch.

* Check mass airflow sensor (if equipped).

* Check intake air preheating system.

* Check catalytic converter.

* Check ignition timing.

ENGINE RUN-ON (DIESELING)

* Check fuel evaporative frequency solenoid(s).

* Check fuel system for leaks.

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check airflow sensor lever adjustment and control plunger.

HIGH FUEL CONSUMPTION

* Check fuel system for leaks.

* Check oxygen sensor control circuit.

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check airflow sensor lever adjustment and control plunger.

* Check throttle potentiometer.

* Check injector fuel pressure and volume.

* Check full throttle switch.

* Check mass airflow sensor (if equipped).

* Check intake air preheating system.

* Check exhaust system for leaks (between cylinder and

oxygen (O2) sensor).

* Check ignition timing.

ENGINE KNOCK

* Check knock sensors (if equipped).

Page 602 of 920

H - TESTS W/O CODES

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

* Check full throttle switch.

* Check ignition timing.

ENGINE RUNS UNEVENLY OVER ENTIRE SPEED RANGE

* Check auxiliary air intake system.

* Check injector fuel pressure and volume.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

INTERMITTENTS

INTERMITTENT PROBLEM DIAGNOSIS

Intermittent fault testing requires duplicating circuit or

component failure to identify the problem. These procedures may lead

to the computer setting a fault code (on some systems) which may help

in diagnosis.

If problem vehicle does not produce fault codes, monitor

voltage or resistance values using a DVOM while attempting to

reproduce conditions causing intermittent fault. A status change on

DVOM indicates a fault has been located.

Use a DVOM to pinpoint faults. When monitoring voltage,

ensure ignition switch is in ON position or engine is running. Ensure

ignition switch is in OFF position or negative battery cable is

disconnected when monitoring circuit resistance. Status changes on

DVOM during test procedures indicate area of fault.

TEST PROCEDURES

Intermittent Simulation

To reproduce the conditions creating an intermittent fault,

use the following methods:

* Lightly vibrate component.

* Heat component.

* Wiggle or bend wiring harness.

* Spray component with water.

* Remove/apply vacuum source.

Monitor circuit/component voltage or resistance while

simulating intermittent. If engine is running, monitor for self-

diagnostic codes. Use the test results to identify a faulty component

or circuit. For system or component testing refer to the appropriate

I - SYS/COMP TESTS article in this section. See the menu below:

* For Cabriolet, see: I - SYSTEM/COMPONENT TESTS

* For Corrado SLC, see: I - SYSTEM/COMPONENT TESTS

* For EuroVan, see: I - SYSTEM/COMPONENT TESTS

* For Fox, see: I - SYSTEM/COMPONENT TESTS

* For Golf, GTI, Jetta, see: I - SYSTEM/COMPONENT TESTS

* For Passat GL 2.0L 4-Cylinder, see:

Page 614 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL MODULE (ECM)

Ground & Power Circuits

Check ECM ground and power circuits using the values in the

appropriate J - PIN VOLTAGE CHARTS article.

ENGINE SENSORS & SWITCHES

ENGINE COOLANT TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever. Start engine and allow it to idle.

2) With scan tester in READ TEST VALUE BLOCK function, select

group No. 01 and read coolant temperature value in field No. 2 of scan

tester. Temperature value must increase uniformly without

interruption. If value increases as specified, select END OUTPUT

function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ENGINE

COOLANT TEMPERATURE SENSOR RESISTANCE table.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature

øF (øC) Ohms

68 (20) ......................... 3000-2000

86 (30) ......................... 2000-1500

104 (40) ........................ 1500-1000

122 (50) ......................... 1000-800

140 (60) .......................... 700-500

158 (70) .......................... 500-375

176 (80) .......................... 375-275

194 (90) .......................... 275-225

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ INTAKE AIR TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Turn ignition off. Disconnect intake air temperature

sensor. Remove sensor from intake manifold and plug opening in

manifold. Reconnect sensor to wiring harness.

2) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. Start engine

and allow it to idle. With scan tester in READ TEST VALUE BLOCK

function, select group 03 and read intake air temperature sensor value

in field No. 4 of scan tester.

3) Spray sensor with cooling spray and observe value on scan

Page 615 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

tester. Scan tester value must decrease. If temperature value does not

change, repair intake air temperature sensor circuit or replace sensor

as necessary. After repairs, erase Diagnostic Trouble Code (DTC)

memory (if applicable) and select END OUTPUT function.

HALL EFFECT SENSOR

Corrado SLC (2.8L)

Testing information is not available from manufacturer. These

vehicles are equipped with a distributorless ignition system.

FUEL SYSTEM

ACCELERATION/FULL THROTTLE ENRICHMENT & DECELERATION FUEL

CUT-OFF

Corrado SLC (2.8L)

1) Ensure engine coolant temperature is at least 176øF

(80

øC). Connect Scan Tester (VAG 1551) to Data Link Connectors (DLC)

located in center console, in front of shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 04 and read value in

field No. 4 of scan tester. Display value must be 00010 at idle.

3) Using accelerator pedal, increase engine speed to 3000 RPM

and observe scan tester. Display value in field No. 4 of scan tester

must briefly be 10100. Release accelerator pedal and observe scan

tester.

4) Display value in field No. 4 of scan tester must briefly

be 00011, then return to 00010 at idle. If values are not as

specified, see THROTTLE POSITION (TP) SENSOR ADJUSTMENT procedures in

the D - ADJUSTMENTS article. If values are as specified, select END

OUTPUT function on scan tester.

FUEL INJECTORS & CIRCUIT

Corrado SLC (2.8L)

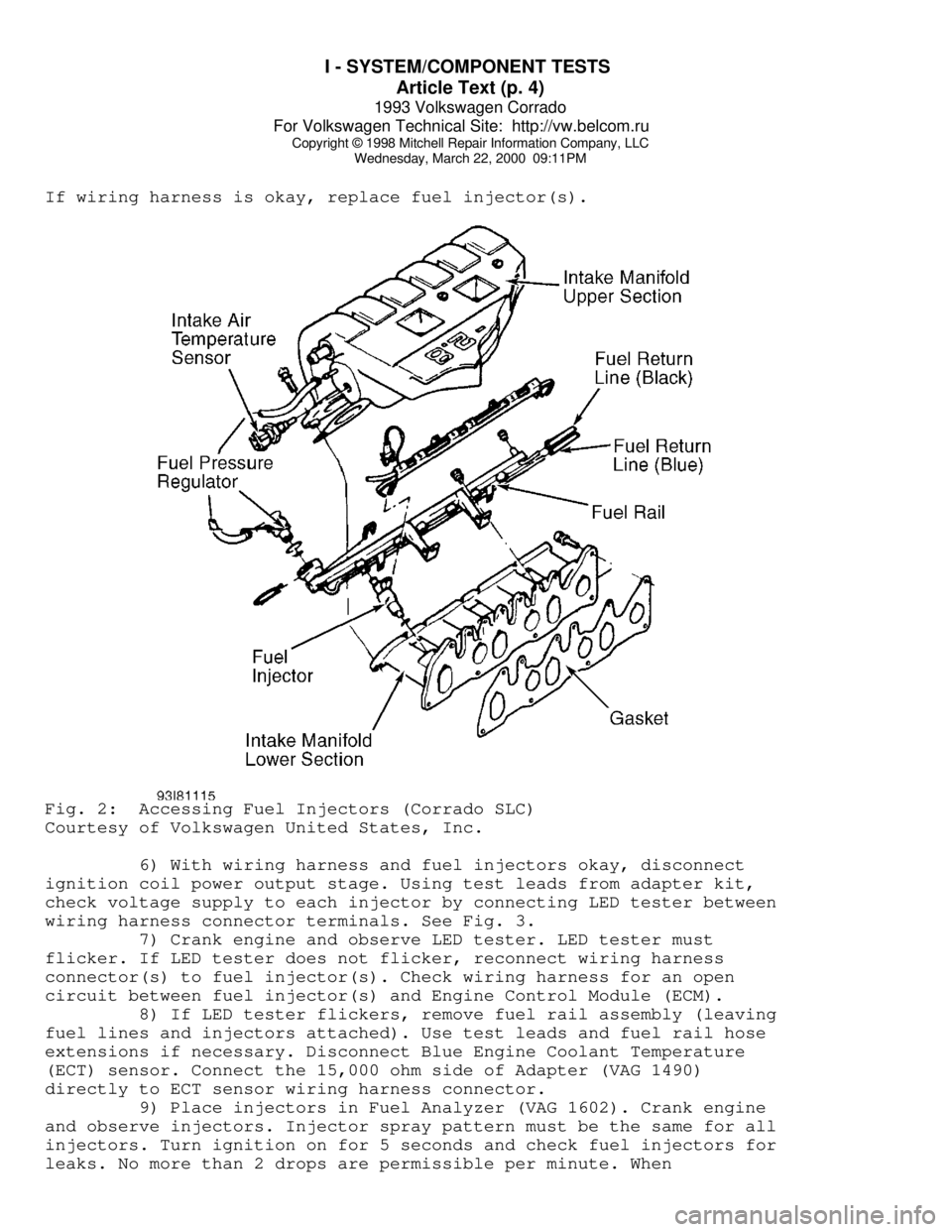

1) To access fuel injectors, remove ignition wires. Remove

hose from mass airflow sensor. Disconnect hose to fuel evaporative

(frequency) solenoid valve at throttle body.

2) Disconnect throttle position sensor and idle air control

valve. Disconnect accelerator cable from throttle body. Disconnect and

plug coolant hoses at throttle body.

3) Disconnect hose from air intake heated tube. Detach fuel

lines at cylinder head cover and remove from fuel rail. Disconnect

vacuum hose from fuel pressure regulator. Remove intake manifold upper

section. See Fig. 2.

4) With intake manifold upper section removed, disconnect

wiring harness from fuel injectors. Using a Digital Volt-Ohmmeter

(DVOM) and test leads from Adapter Kit (VW 1594), check fuel injector

resistance. See Fig. 3.

5) Fuel injector resistance should be 15.0-21.5 ohms. If

resistance is zero ohms, check for a short circuit in wiring harness.

Page 616 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

If wiring harness is okay, replace fuel injector(s).Fig. 2: Accessing Fuel Injectors (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

6) With wiring harness and fuel injectors okay, disconnect

ignition coil power output stage. Using test leads from adapter kit,

check voltage supply to each injector by connecting LED tester between

wiring harness connector terminals. See Fig. 3.

7) Crank engine and observe LED tester. LED tester must

flicker. If LED tester does not flicker, reconnect wiring harness

connector(s) to fuel injector(s). Check wiring harness for an open

circuit between fuel injector(s) and Engine Control Module (ECM).

8) If LED tester flickers, remove fuel rail assembly (leaving

fuel lines and injectors attached). Use test leads and fuel rail hose

extensions if necessary. Disconnect Blue Engine Coolant Temperature

(ECT) sensor. Connect the 15,000 ohm side of Adapter (VAG 1490)

directly to ECT sensor wiring harness connector.

9) Place injectors in Fuel Analyzer (VAG 1602). Crank engine

and observe injectors. Injector spray pattern must be the same for all

injectors. Turn ignition on for 5 seconds and check fuel injectors for

leaks. No more than 2 drops are permissible per minute. When

Page 618 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

IGNITION COIL

EMISSION SYSTEMS & SUB-SYSTEMS

NOTE: Other than EGR system, additional emission systems and

sub-system component testing information is not available

from manufacturer.

EXHAUST GAS RECIRCULATION (EGR)

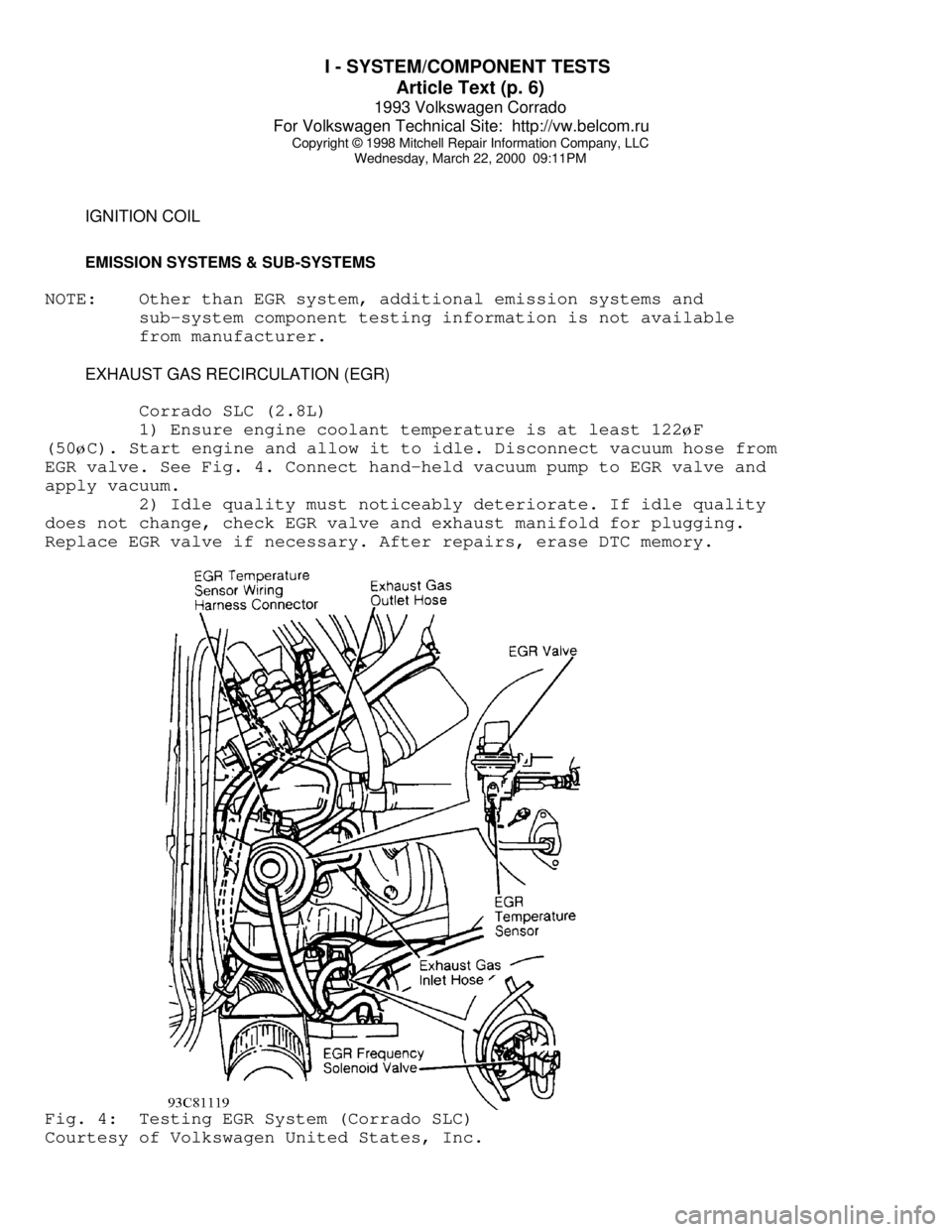

Corrado SLC (2.8L)

1) Ensure engine coolant temperature is at least 122øF

(50

øC). Start engine and allow it to idle. Disconnect vacuum hose from

EGR valve. See Fig. 4. Connect hand-held vacuum pump to EGR valve and

apply vacuum.

2) Idle quality must noticeably deteriorate. If idle quality

does not change, check EGR valve and exhaust manifold for plugging.

Replace EGR valve if necessary. After repairs, erase DTC memory.Fig. 4: Testing EGR System (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

Page 626 of 920

INTERFERENCE VERIFICATION CHECK FOR OHC ENGINE

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:12PM

ARTICLE BEGINNING

Maintenance & Service Information

1974-96 Volkswagen - Timing Belt Information

Cabrio, Cabriolet, Corrado, Dasher, Eurovan (Canadian), Fox,

Golf, Golf (Canadian), GTI, GTI (Canadian), Jetta, Jetta GLI,

Passat, Passat (Canadian), Pickup, Quantum, Rabbit, Scirocco,

Scirocco (Canadian), Transporter (Canadian), Vanagon

TIMING BELT INTERFERENCE VERIFICATION INFORMATION

TIMING BELT INTERFERENCE CAUTION

NOTE: CAMSHAFT DRIVE BELTS OR TIMING BELTS - The condition of

camshaft drive belts should always be checked on vehicles

which have more than 50,000 miles. Although some

manufacturers do not recommend replacement at a specified

mileage, others require it at 60,000-100,000 miles. A

camshaft drive belt failure may cause extensive damage to

internal engine components on most engines, although some

designs do not allow piston-to-valve contact. These designs

are often called "Free Wheeling". Many manufacturers changed

their maintenance and warranty schedules in the mid-1980's to

reflect timing belt inspection and/or replacement at

50,000-60,000 miles. Most service interval schedules shown in

this section reflect these changes. Belts or components

should be inspected and replaced if any of the following

conditions exist:

* Crack Or Tears In Belt Surface

* Missing, Damaged, Cracked Or Rounded Teeth

* Oil Contamination

* Damaged Or Faulty Tensioners

* Incorrect Tension Adjustment

TIMING BELT INTERFERENCE CHECK MENU

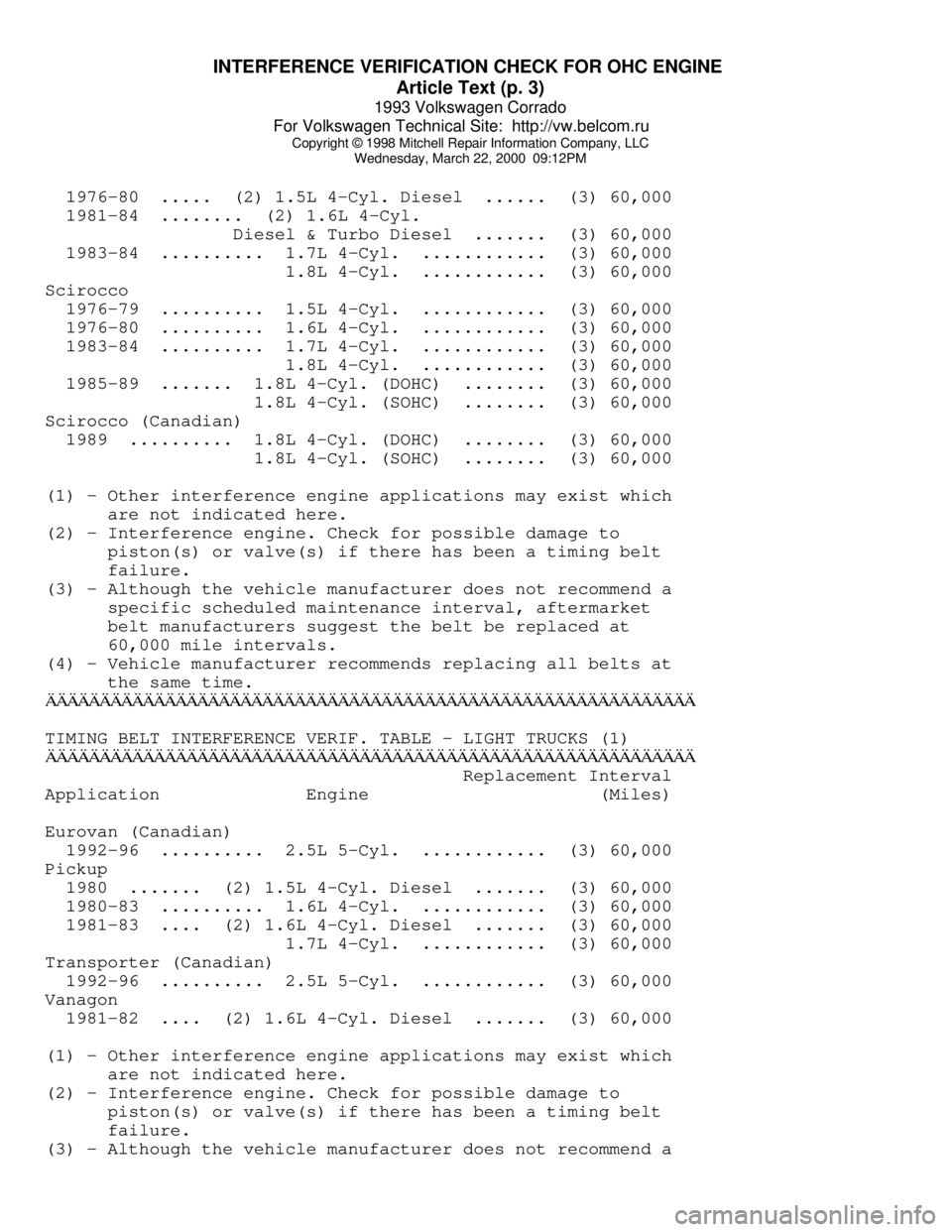

TIMING BELT INTERFERENCE VERIF. TABLE - PASSENGER CARS (1)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Replacement Interval

Application Engine (Miles)

Cabrio

1995-96 .......... 2.0L 4-Cyl. ............ (3) 60,000

Cabriolet

1985-89 ....... 1.8L 4-Cyl. (DOHC) ........ (3) 60,000

1.8L 4-Cyl. (SOHC) ........ (3) 60,000

1990-93 .......... 1.8L 4-Cyl. ............ (3) 60,000

Corrado

1990-92 .......... 1.8L 4-Cyl. ............ (3) 60,000

Dasher

Page 627 of 920

INTERFERENCE VERIFICATION CHECK FOR OHC ENGINE

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:12PM

1976-80 ..... (2) 1.5L 4-Cyl. Diesel ...... (3) 60,000

1974-80 .......... 1.6L 4-Cyl. ............ (3) 60,000

1981-80 ......... (2) 1.6L 4-Cyl.

Diesel & Turbo Diesel ...... (3) 60,000

Fox

1987-93 .......... 1.8L 4-Cyl. ............ (3) 60,000

Golf

1985-88 ..... (2) 1.6L 4-Cyl. Diesel ...... (3) 60,000

1985-89 ....... 1.8L 4-Cyl. (DOHC) ........ (3) 60,000

1985-93 ....... 1.8L 4-Cyl. (SOHC) ........ (3) 60,000

1990-92 .......... 1.8L 4-Cyl. ............ (3) 60,000

1993-96 .......... 2.0L 4-Cyl. ............ (3) 60,000

Golf (Canadian)

1985-92 ..... (2) 1.6L 4-Cyl. Diesel ...... (3) 60,000

1993 ............. 1.8L 4-Cyl. ............ (3) 60,000

GTI

1983-84 ..... (2) 1.6L 4-Cyl. Diesel ...... (3) 60,000

(2) 1.6L 4-Cyl. Turbo Diesel ... (3) 60,000

1.7L 4-Cyl. ............ (3) 60,000

1.8L 4-Cyl. ............ (3) 60,000

1985-89 .......... 1.8L 4-Cyl. (DOHC) ..... (3) 60,000

1983-92 .......... 1.8L 4-Cyl. (SOHC) ..... (3) 60,000

1990-92 .......... 1.8L 4-Cyl. ............ (3) 60,000

1990-96 .......... 2.0L 4-Cyl. ............ (3) 60,000

GTI (Canadian)

1993 ............. 2.0L 4-Cyl. ............ (3) 60,000

Jetta

1980 ............. 1.6L 4-Cyl. ............ (3) 60,000

1981-92 ........ (2) 1.6L 4-Cyl.

Diesel & Turbo Diesel ....... (3) 60,000

1983-84 .......... 1.7L 4-Cyl. ............ (3) 60,000

1.8L 4-Cyl. ............ (3) 60,000

1985-89 ....... 1.8L 4-Cyl. (DOHC) ........ (3) 60,000

1983-92 ....... 1.8L 4-Cyl. (SOHC) ........ (3) 60,000

1990-92 .......... 1.8L 4-Cyl. ............ (3) 60,000

1993-96 .......... 2.0L 4-Cyl. ............ (3) 60,000

Jetta GLI

1990-92 .......... 2.0L 4-Cyl. ............ (3) 60,000

Passat

1990-96 .......... 2.0L 4-Cyl. ............ (3) 60,000

Passat (Canadian)

1993 ............. 1.8L 4-Cyl. ............ (3) 60,000

Quantum

1981-86 ........ (2) 1.6L 4-Cyl.

Diesel & Turbo Diesel ....... (3) 60,000

1981-84 .......... 1.7L 4-Cyl. ............ (3) 60,000

1984-85 .......... 2.1L 5-Cyl. ............ (3) 60,000

1983-88 .......... 2.2L 5-Cyl. ............ (3) 60,000

1985-86 .......... 1.8L 4-Cyl. ............ (3) 60,000

Rabbit

1974-79 .......... 1.5L 4-Cyl. ............ (3) 60,000

1.6L 4-Cyl. ............ (3) 60,000

Page 628 of 920

INTERFERENCE VERIFICATION CHECK FOR OHC ENGINE

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:12PM

1976-80 ..... (2) 1.5L 4-Cyl. Diesel ...... (3) 60,000

1981-84 ........ (2) 1.6L 4-Cyl.

Diesel & Turbo Diesel ....... (3) 60,000

1983-84 .......... 1.7L 4-Cyl. ............ (3) 60,000

1.8L 4-Cyl. ............ (3) 60,000

Scirocco

1976-79 .......... 1.5L 4-Cyl. ............ (3) 60,000

1976-80 .......... 1.6L 4-Cyl. ............ (3) 60,000

1983-84 .......... 1.7L 4-Cyl. ............ (3) 60,000

1.8L 4-Cyl. ............ (3) 60,000

1985-89 ....... 1.8L 4-Cyl. (DOHC) ........ (3) 60,000

1.8L 4-Cyl. (SOHC) ........ (3) 60,000

Scirocco (Canadian)

1989 .......... 1.8L 4-Cyl. (DOHC) ........ (3) 60,000

1.8L 4-Cyl. (SOHC) ........ (3) 60,000

(1) - Other interference engine applications may exist which

are not indicated here.

(2) - Interference engine. Check for possible damage to

piston(s) or valve(s) if there has been a timing belt

failure.

(3) - Although the vehicle manufacturer does not recommend a

specific scheduled maintenance interval, aftermarket

belt manufacturers suggest the belt be replaced at

60,000 mile intervals.

(4) - Vehicle manufacturer recommends replacing all belts at

the same time.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTIMING BELT INTERFERENCE VERIF. TABLE - LIGHT TRUCKS (1)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Replacement Interval

Application Engine (Miles)

Eurovan (Canadian)

1992-96 .......... 2.5L 5-Cyl. ............ (3) 60,000

Pickup

1980 ....... (2) 1.5L 4-Cyl. Diesel ....... (3) 60,000

1980-83 .......... 1.6L 4-Cyl. ............ (3) 60,000

1981-83 .... (2) 1.6L 4-Cyl. Diesel ....... (3) 60,000

1.7L 4-Cyl. ............ (3) 60,000

Transporter (Canadian)

1992-96 .......... 2.5L 5-Cyl. ............ (3) 60,000

Vanagon

1981-82 .... (2) 1.6L 4-Cyl. Diesel ....... (3) 60,000

(1) - Other interference engine applications may exist which

are not indicated here.

(2) - Interference engine. Check for possible damage to

piston(s) or valve(s) if there has been a timing belt

failure.

(3) - Although the vehicle manufacturer does not recommend a

Page 629 of 920

INTERFERENCE VERIFICATION CHECK FOR OHC ENGINE

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:12PM

specific scheduled maintenance interval, aftermarket

belt manufacturers suggest the belt be replaced at

60,000 mile intervals.

(4) - Vehicle manufacturer recommends replacing all belts at

the same time.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE