engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 506 of 920

E - THEORY/OPERATION

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Theory & Operation - Motronic

Corrado SLC

INTRODUCTION

This article covers basic description and operation of engine

performance-related systems and components. Read this article before

diagnosing vehicles or systems with which you are not completely

familiar.

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL UNIT

The Motronic engine management system uses a single

Electronic Control Module (ECM) for fuel injection, idle speed

control, ignition, and emission controls. The Electronic Control

Module (ECM) continually corrects air/fuel mixture based on signals

from various signals. The ECM is located underneath center of

windshield cowl, directly behind engine compartment firewall.

NOTE: Components are grouped into 2 categories. The first category

covers INPUT DEVICES, which control or produce voltage

signals monitored by the control unit. The second category

covers OUTPUT SIGNALS, which are components controlled by

the control unit.

INPUT DEVICES

Engine Coolant Temperature (ECT) Sensor

Sensor is located on thermostat housing. As engine coolant

temperature increases, the resistance of the sensor decreases. Engine

coolant temperature sensor signals are used for control of ignition

timing, injector pulse width, and idle speed stabilization. In

addition, knock sensors, idle speed control, oxygen sensor and fuel

tank venting are activated based on coolant temperature.

Engine Speed (RPM)/Reference Sensor

Engine speed (RPM) and crankshaft position are registered by

a single sensor located on side of engine block. The sensor reads a

toothed wheel mounted on the crankshaft. The wheel has a 2-tooth gap

which is used as a reference point for crankshaft position. The engine

speed/reference signal is used to monitor engine RPM and to identify

TDC position of cylinder No. 1.

Hall Effect Sensor

See ELECTRONIC IGNITION SYSTEM under IGNITION SYSTEM in this

Page 508 of 920

E - THEORY/OPERATION

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

Mass Airflow Sensor

A hot-wire air mass sensor is used to measure airflow into

the engine. The sensor is attached to air filter housing. The hot-wire

in sensor is kept at 356øF (180øC) above air temperature.

As airflow increases, the wire is cooled and the resistance

of the sensor changes. The resulting current change is converted to a

voltage signal and is used by the ECM to calculate the volume of air

taken in.

If a fault develops with mass airflow sensor signal, the

signal from throttle valve potentiometer is used as a substitute in

order for the car to be driveable.

Throttle Valve Potentiometer

Throttle valve potentiometer (throttle position sensor) is

connected to throttle valve shaft. It informs the ECM about the power

requested by the driver (throttle opening). Idle and full throttle

switches are NOT used in potentiometer. Idle speed and full throttle

applications are recognized by the ECM from the voltage output of the

potentiometer.

Throttle valve potentiometer signals are used for idle speed

stabilization, idle air volume control, fuel after-run shut-off, and

full throttle enrichment. The ECM uses mass airflow sensor signal and

engine RPM signals as substitute values if the potentiometer fails.

NOTE: On automatic transmission equipped vehicles, the throttle

valve potentiometer is combined in the housing with the

potentiometer for transmission control.

Oxygen (O2) Sensor

The heated oxygen sensor is made from zirconium dioxide,

while the inner and outer surfaces are coated with platinum. If fuel

mixture is lean (excess oxygen), the oxygen sensor will send a low

voltage signal (about 100 millivolts) to the ECM. If fuel mixture is

rich (lack of oxygen), the oxygen sensor will send a high voltage

signal (about 900 millivolts) to the ECM.

OUTPUT SIGNALS

NOTE: Vehicles are equipped with different combinations of

computer-controlled components. Not all components listed

below are used on every vehicle. For theory and operation on

each output component, refer to the system indicated after

component.

EGR Frequency Valve

See EXHAUST GAS RECIRCULATION (EGR) SYSTEM under EMISSION

SYSTEMS in this article.

Fuel Evaporative (Frequency) Valve

See FUEL EVAPORATIVE EMISSIONS SYSTEM under EMISSION SYSTEMS

in this article.

Page 509 of 920

E - THEORY/OPERATION

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

Fuel Injectors

See FUEL CONTROL under FUEL SYSTEM in this article.

Fuel Pump

See FUEL DELIVERY under FUEL SYSTEM in this article.

Idle Air Control/Stabilizer Valve

See IDLE SPEED under FUEL SYSTEM in this article.

Ignition Coil & Output Stage

See DISTRIBUTORLESS IGNITION SYSTEM (DIS) under IGNITION

SYSTEM in this article.

Malfunction Indicator (CHECK ENGINE) Light

See MALFUNCTION INDICATOR (CHECK ENGINE) LIGHT under SELF-

DIAGNOSTIC SYSTEM in this article.

FUEL SYSTEM

FUEL DELIVERY

Fuel Pump

A 2-stage fuel pump, located in fuel tank, is used (one motor

drives two separate pumps). The stage one vane-type pump draws fuel,

through a screen, from bottom of fuel tank and into an accumulator.

The vane-type pump acts as a transfer pump. The stage two gear-type

pump draws fuel from bottom of accumulator and out fuel lines.

Fuel Pressure Regulator

The diaphragm-type fuel pressure regulator is attached to

fuel return side of fuel rail. Fuel pressure is regulated depending on

intake manifold pressure. As intake manifold pressure changes, the

pressure regulator will increase or decrease fuel system pressure.

FUEL CONTROL

Fuel Injectors

Fuel injectors are supplied with battery (system) voltage

through power supply relay and are controlled (grounded) by the ECM.

Injectors are opened sequentially in cylinder firing order. Fuel

quantity is determined by injector on time (duty cycle).

IDLE SPEED

Idle Air Control/Stabilizer Valve

The idle air control/stabilizer valve is actuated by the ECM

thorough the valve's ground control circuit. When a defect in circuit

is recognized, both output stages are shut-off and the valve rotates

to a fixed potion. This permits engine to idle at a warm engine idle

speed.

IGNITION SYSTEM

Page 510 of 920

E - THEORY/OPERATION

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

NOTE: Corrado SLC models are equipped with a Distributorless

Ignition System (DIS).

ELECTRONIC IGNITION SYSTEM

The electronic ignition system consists of ECM, power output

stage, ignition coil, distributor, mass airflow sensor, throttle valve

potentiometer, engine coolant temperature sensor, and Hall Effect

sensor.

Ignition system uses engine speed, engine load, and throttle

valve potentiometer signals to calculate ignition timing. Engine

coolant temperature signal is used to correct ignition timing when

engine is cold and to activate knock sensor circuit. See KNOCK

SENSOR(S) under IGNITION TIMING CONTROL in this article.

Hall Effect Sensor

On Corrado SLC, this sensor is mounted on end of camshaft

(near ignition coil). Sensor consists of a magnetic enclosure and

integrated semi-conductor circuit. A voltage signal is generated when

trigger wheel, turning at camshaft speed, interrupts magnetic field

created by the semi-conductor. Hall Effect sensor and engine

speed/reference signals are used to identify TDC position of cylinder

No. 1 for sequential fuel injection and spark knock regulation.

DISTRIBUTORLESS IGNITION SYSTEM (DIS)

Hall Effect Sensor

See HALL EFFECT SENSOR under ELECTRONIC IGNITION SYSTEM in

this article.

Ignition Coil & Output Stage

The distributorless (direct) ignition system consists of ECM,

power output stage, 3 double-ended ignition coils and secondary

ignition wires. The ECM operates each ignition coil through the power

output stage. The power output stage and heat sink are located behind

ignition coils. The ignition coils are located on left side of

cylinder head. When the power output stage fires an ignition coil, a

spark is supplied to 2 spark plugs at one time. One spark plug fires

during the compression stroke, and the other spark plug fires during

the exhaust stroke (waste spark).

IGNITION TIMING CONTROL

Knock Sensor(s)

The knock sensor(s) work(s) like a microphone to "listen" for

spark knock (detonation). When detonation occurs, ignition timing is

retarded until the knock is eliminated.

On Corrado SLC, 2 knock sensors are mounted on side of engine

block. Knock sensor I monitors cylinders No. 1, 3 and 5. Knock sensor

II monitors cylinders No. 2, 4 and 6.

Page 511 of 920

E - THEORY/OPERATION

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

EMISSION SYSTEMS

AIR INJECTION SYSTEM

The air injection system consists of electrically operated

air pump, inlet valve, shut-off valve (mounted between intake ports

for cylinders No. 2 and 4), and air pump control relay.

The Electronic Control Module (ECM) control operation of air

injection system air pump by completing the ground circuit of the air

pump control relay (located above brake master cylinder). In addition,

the relay operates the secondary air injection inlet valve.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

The EGR system consist of EGR valve, EGR frequency valve, and

EGR temperature sensor. All Corrado SLC models are equipped with the

EGR system. The EGR system is switched on when engine coolant

temperature reaches 122øF (50øC). The system recirculates a small

portion of exhaust gas into the intake air/fuel mixture to reduce

nitrous oxide emissions (NOx).

EGR Frequency Valve

The EGR frequency valve is mounted on back of intake

manifold. The frequency valve controls the amount of vacuum supplied

to the EGR valve. The ECM, depending on engine speed and load,

controls the frequency valve's ground circuit. In doing so, the ECM

controls the amount of recirculated exhaust gas entering the engine.

EGR Temperature Sensor

Sensor is located in EGR valve exhaust gas recirculation

channel. The EGR temperature sensor measures exhaust gas temperature.

The electrical resistance of the sensor decreases as the temperature

of the exhaust gas increases. The signal generated by the EGR

temperature sensor is ONLY used for diagnosis of the EGR system.

FUEL EVAPORATIVE EMISSIONS SYSTEM

Fuel Evaporative (Frequency) Valve

The ECM determines the duty cycle of the frequency valve to

regulate the flow of fuel vapors from fuel evaporative (carbon)

canister into engine. When no current is supplied to valve, it remains

in the open position. The valve is closed (100% duty cycle) when the

engine is started cold. A spring operated check valve inside the

frequency valve closes when the engine is off. This prevents fuel

vapors from entering intake manifold and causing a rich mixture during

engine restart.

Fuel Tank Venting

The engine speed, engine load, engine coolant temperature,

and throttle valve potentiometer input signals are used by the ECM to

control fuel tank venting. Fuel vapors from fuel tank are vented to

fuel evaporative (carbon) canister. When engine is warm and above idle

Page 512 of 920

E - THEORY/OPERATION

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

speed, the vapors will be drawn into intake manifold. Depending on

engine load and oxygen sensor signal, the fuel evaporative (frequency)

valve will regulate the amount of vapors entering the intake manifold.

SELF-DIAGNOSTIC SYSTEM

The Electronic Control Module (ECM) recognizes faults (open

circuits, short circuits, missing signals, or a continuously applied

signal voltage) in the following circuits/components.

* EGR Frequency Valve

* EGR Temperature Sensor

* Engine Coolant Temperature Sensor

* Engine Speed (RPM)/Reference Sensor

* Fuel Evaporative (Frequency) Valve

* Hall Effect Sensor

* Idle Air Control/Stabilizer Valve

* Intake Air Temperature Sensor

* Knock Sensor(s)

* Throttle Valve Potentiometer

* Oxygen Sensor

MALFUNCTION INDICATOR (CHECK ENGINE) LIGHT

All California models are equipped with a malfunction

indicator (CHECK ENGINE) light. If CHECK ENGINE light comes on and

remains on during vehicle operation, cause of malfunction must be

determined. See the G - TESTS W/CODES article.

END OF ARTICLE

Page 515 of 920

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

ARTICLE BEGINNING

GENERAL INFORMATION

All Makes Emission Control Visual Inspection Procedures

All Models

PLEASE READ THIS FIRST

This article is provided for general information only. Not

all information applies to all makes and models. For more complete

information, see appropriate article(s) in the ENGINE PERFORMANCE

Section.

EMISSION CONTROL LABELS

The vehicle manufacturer's emission control label, also known

as the underhood tune-up label or Vehicle's Underhood Emission Control

System (VECI) label, is located in the engine compartment. Information

regarding year model of vehicle, engine size, number of cylinders,

emission equipment or type, engine tune-up specifications, whether

vehicle was manufactured for sale in California or is a Federal

vehicle, vacuum hose routing schematic, etc., can be found on this

label. See Fig. 1.

In addition to the VECI label, some emission control

inspection and maintenance programs may require an additional label to

be affixed to the vehicle in special circumstances. For example, in

California, a Bureau Of Automotive Repair (BAR) engine label may be

affixed to the left door post. A BAR engine label is only used when

the vehicle has an engine change, approved modification or is a

Specially Constructed (SPCN) or an acceptable Gray market vehicle.

Check your state's emission control inspection and maintenance laws to

determine if a similar label is used.Fig. 1: Typical Emission Control Label

Courtesy of General Motors Corp.

EMISSION CONTROL VISUAL INSPECTION

Page 516 of 920

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

NOTE: The following emission control visual inspection procedures

should be used as a guide only. When performing a visual

inspection, always follow your state's recommended

inspection procedures.

A visual inspection is made to determine if any required

emission control devices are missing, modified or disconnected.

Missing, modified or disconnected systems must be made fully

operational before a vehicle can be certified.

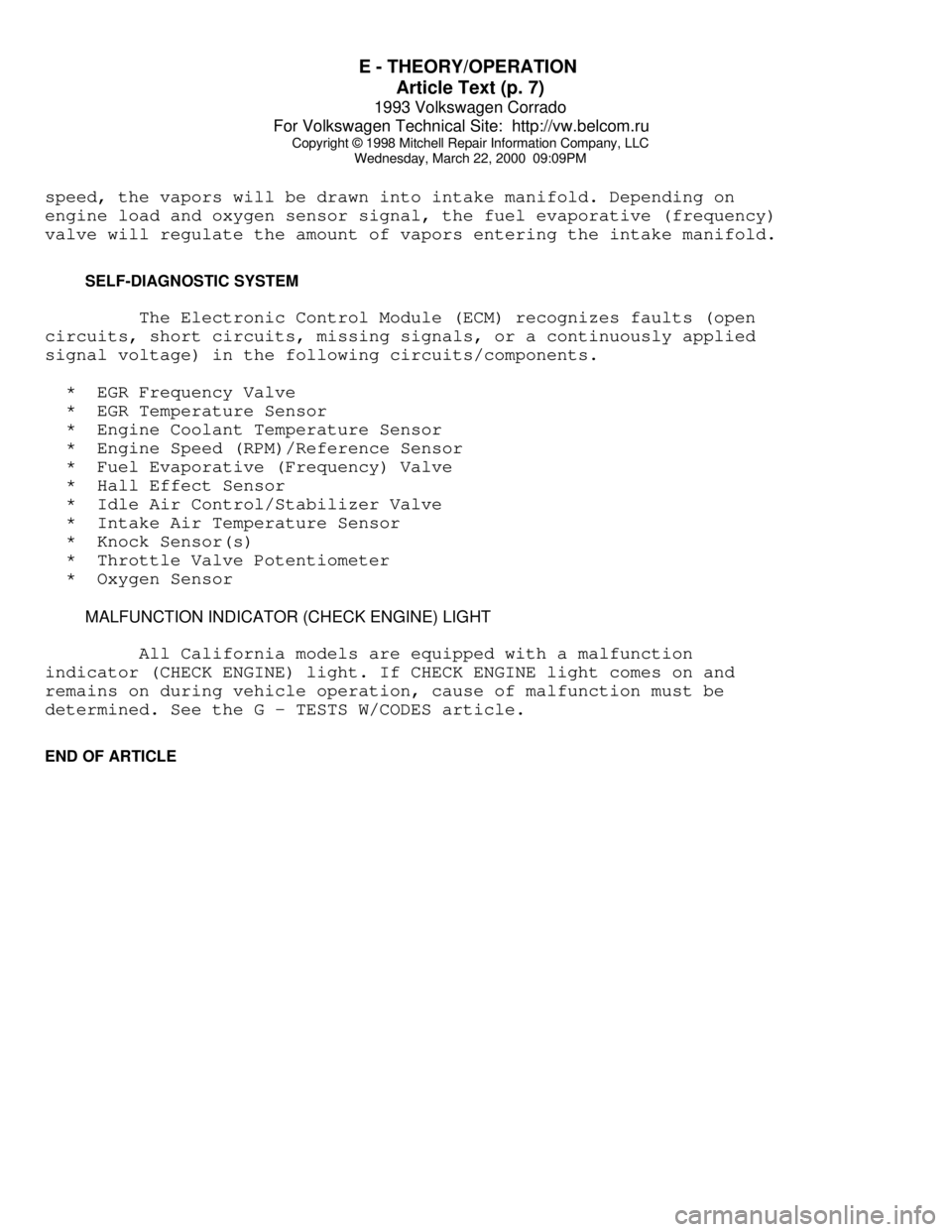

POSITIVE CRANKCASE VENTILATION (PCV)

PCV controls the flow of crankcase fumes into the intake

manifold while preventing gases and flames from traveling in the

opposite direction. PCV is either an open or closed system. See

Fig. 2.

Ensure PCV system is installed as required. Verify valve,

required hoses, connections, flame arresters, etc., are present,

routed properly and in serviceable condition.Fig. 2: Typical Open & Closed Type PCV System

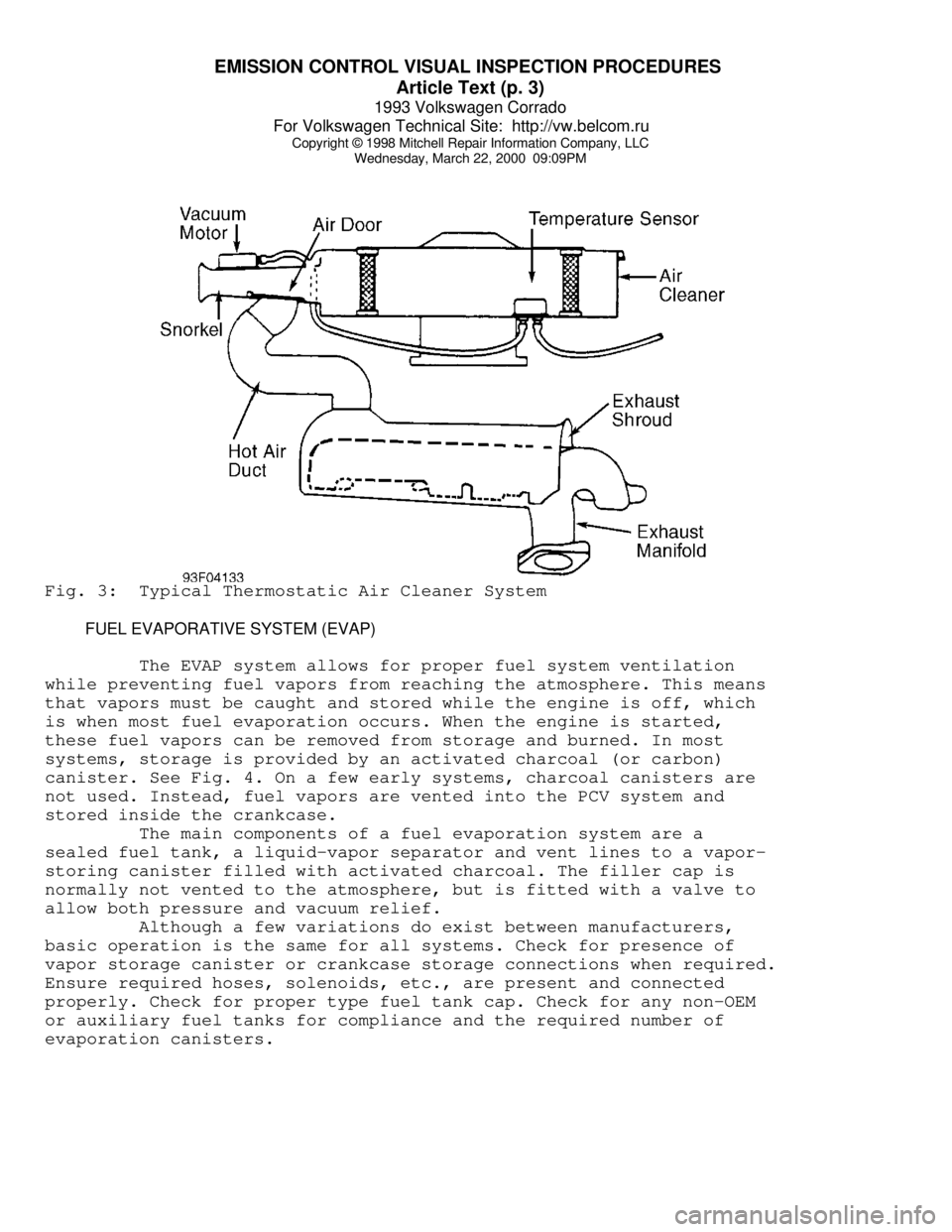

THERMOSTATIC AIR CLEANER (TAC)

The TAC supplies warm air to air intake during cold engine

operation. This system is active during cold engine warm-up only.

Under all other operating conditions, air cleaner function is the same

as any non-thermostatic unit.

Ensure required exhaust shroud, hot air duct, vacuum hoses

and air cleaner components are present and installed properly. See

Fig. 3. Ensure any required thermostatic vacuum switches are in place

and vacuum hoses are installed and in serviceable condition. Also

ensure air cleaner lid is installed right side up. Check for oversized

air filter elements and for additional holes in the air cleaner

housing.

Page 517 of 920

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMFig. 3: Typical Thermostatic Air Cleaner System

FUEL EVAPORATIVE SYSTEM (EVAP)

The EVAP system allows for proper fuel system ventilation

while preventing fuel vapors from reaching the atmosphere. This means

that vapors must be caught and stored while the engine is off, which

is when most fuel evaporation occurs. When the engine is started,

these fuel vapors can be removed from storage and burned. In most

systems, storage is provided by an activated charcoal (or carbon)

canister. See Fig. 4. On a few early systems, charcoal canisters are

not used. Instead, fuel vapors are vented into the PCV system and

stored inside the crankcase.

The main components of a fuel evaporation system are a

sealed fuel tank, a liquid-vapor separator and vent lines to a vapor-

storing canister filled with activated charcoal. The filler cap is

normally not vented to the atmosphere, but is fitted with a valve to

allow both pressure and vacuum relief.

Although a few variations do exist between manufacturers,

basic operation is the same for all systems. Check for presence of

vapor storage canister or crankcase storage connections when required.

Ensure required hoses, solenoids, etc., are present and connected

properly. Check for proper type fuel tank cap. Check for any non-OEM

or auxiliary fuel tanks for compliance and the required number of

evaporation canisters.

Page 520 of 920

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

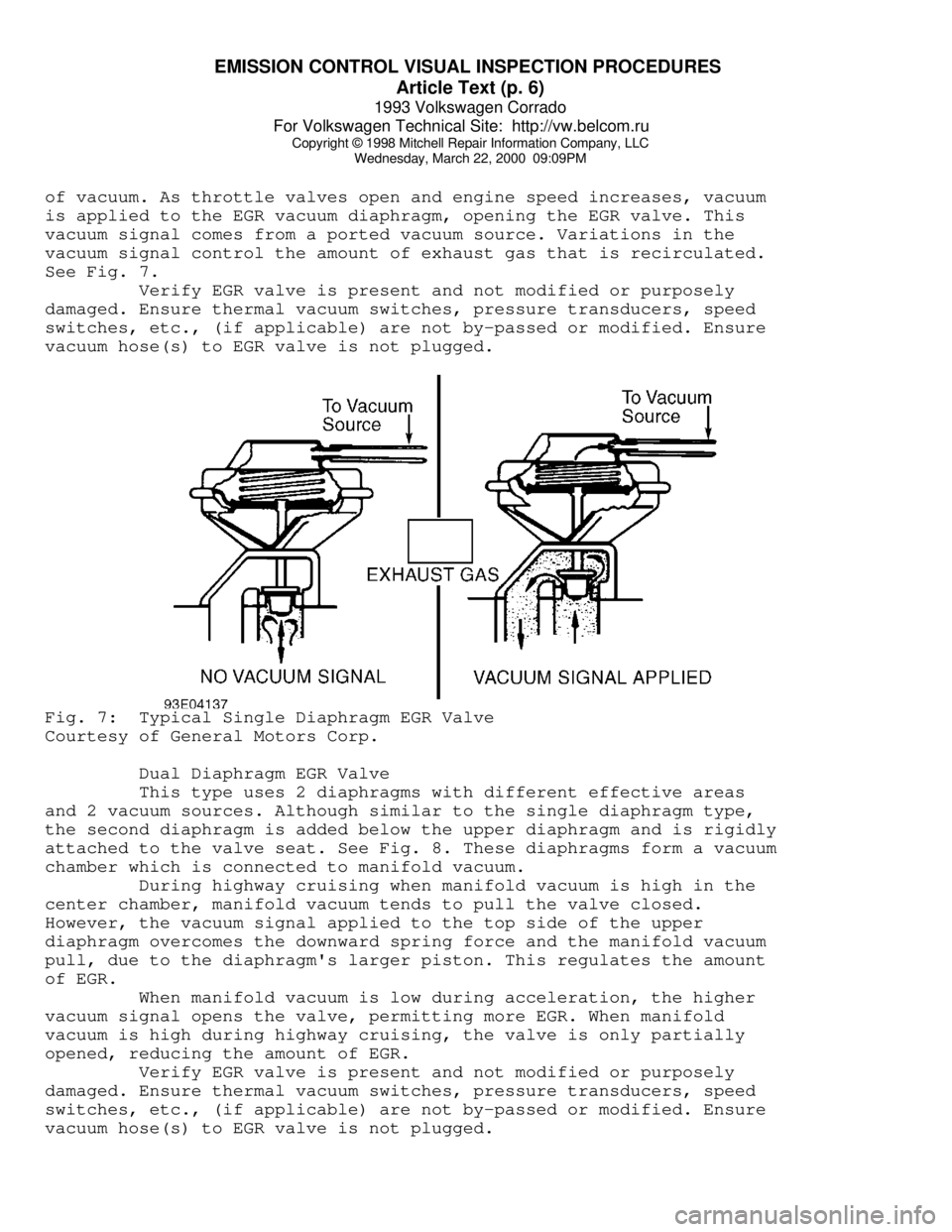

of vacuum. As throttle valves open and engine speed increases, vacuum

is applied to the EGR vacuum diaphragm, opening the EGR valve. This

vacuum signal comes from a ported vacuum source. Variations in the

vacuum signal control the amount of exhaust gas that is recirculated.

See Fig. 7.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.Fig. 7: Typical Single Diaphragm EGR Valve

Courtesy of General Motors Corp.

Dual Diaphragm EGR Valve

This type uses 2 diaphragms with different effective areas

and 2 vacuum sources. Although similar to the single diaphragm type,

the second diaphragm is added below the upper diaphragm and is rigidly

attached to the valve seat. See Fig. 8. These diaphragms form a vacuum

chamber which is connected to manifold vacuum.

During highway cruising when manifold vacuum is high in the

center chamber, manifold vacuum tends to pull the valve closed.

However, the vacuum signal applied to the top side of the upper

diaphragm overcomes the downward spring force and the manifold vacuum

pull, due to the diaphragm's larger piston. This regulates the amount

of EGR.

When manifold vacuum is low during acceleration, the higher

vacuum signal opens the valve, permitting more EGR. When manifold

vacuum is high during highway cruising, the valve is only partially

opened, reducing the amount of EGR.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.