engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 444 of 920

C - SPECIFICATIONS

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

IGNITION TIMING

NOTE: Always refer to underhood label for latest specifications.

IGNITION TIMING (Degrees BTDC @ RPM)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Checking Adjusting

Corrado SLC ............... (1) ............... (1)

(1) - Ignition timing is computer controlled.

Information is not available from manufacturer.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄIGNITION TIMING ADVANCE (Degrees BTDC @ RPM)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

Corrado SLC ..................................... (1)

(1) - Ignition timing advance is computer controlled.

Information is not available from manufacturer.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ FUEL SYSTEM

FUEL PUMP

NOTE: Fuel pump performance measures fuel pressure and volume

availability, not regulated fuel pressure.

FUEL PUMP PERFORMANCE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Pressure Min. Vol. In 30 Sec.

Application psi (kg/cm(

ý) Pts. (L)

Corrado SLC (1) .......... 58 (4.0) ....... 1.0-1.4 (0.5-0.7)

(1) - Using Adapter Cable (VAG 1348/3-2) between battery positive

terminal and terminal No. 4 of fuel pump relay socket. Fuel

pump energized, with 10-12 volts at fuel pump and engine off.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄREGULATED FUEL PRESSURE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ At Idle At Idle

w/Vacuum w/o Vacuum

Application psi (kg/cm

ý) (1) psi (kg/cmý)

Corrado SLC ............ 50 (3.5) .................. 58 (4.0)

(1) - With vacuum hose disconnected from fuel pressure regulator.

Page 447 of 920

CLUTCH

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

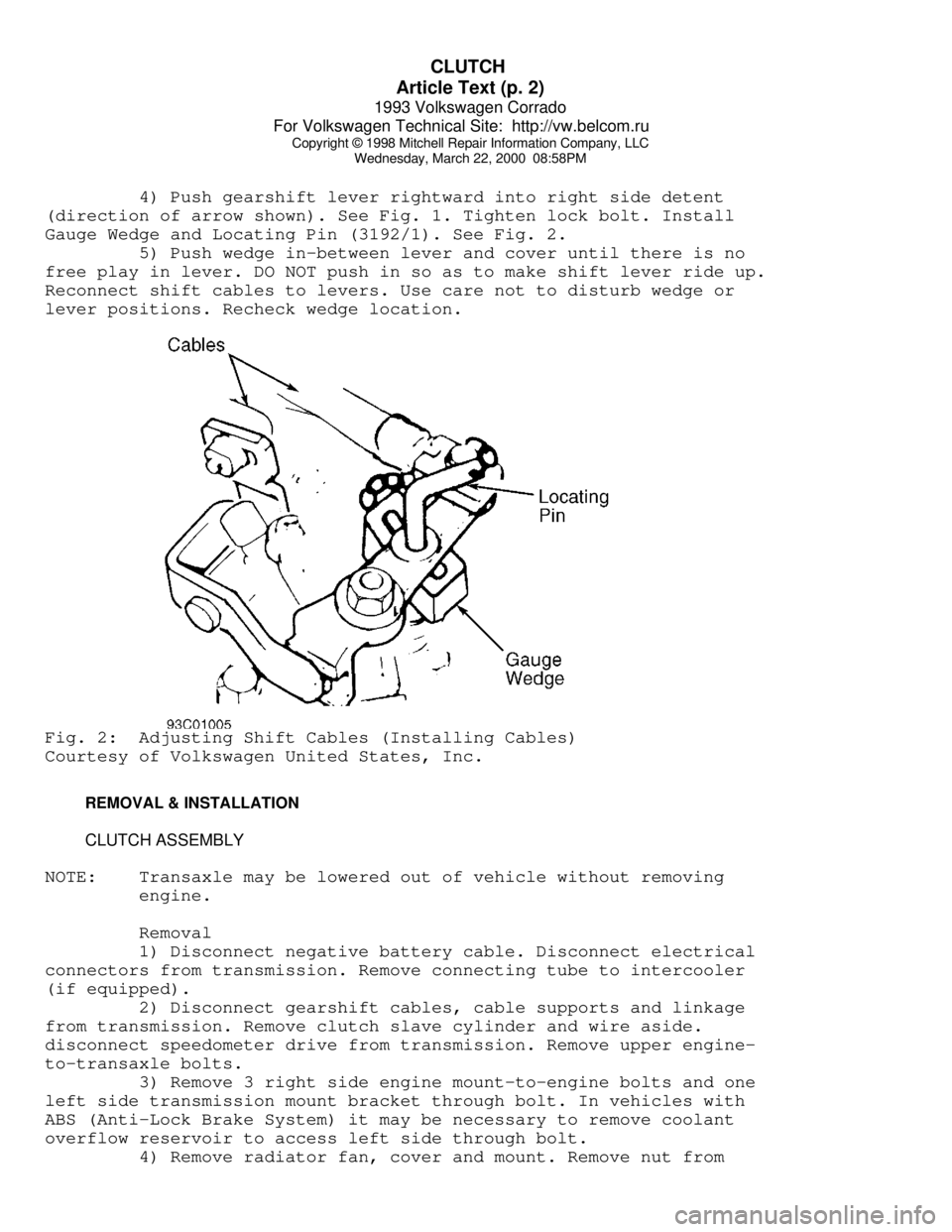

4) Push gearshift lever rightward into right side detent

(direction of arrow shown). See Fig. 1. Tighten lock bolt. Install

Gauge Wedge and Locating Pin (3192/1). See Fig. 2.

5) Push wedge in-between lever and cover until there is no

free play in lever. DO NOT push in so as to make shift lever ride up.

Reconnect shift cables to levers. Use care not to disturb wedge or

lever positions. Recheck wedge location.Fig. 2: Adjusting Shift Cables (Installing Cables)

Courtesy of Volkswagen United States, Inc.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

NOTE: Transaxle may be lowered out of vehicle without removing

engine.

Removal

1) Disconnect negative battery cable. Disconnect electrical

connectors from transmission. Remove connecting tube to intercooler

(if equipped).

2) Disconnect gearshift cables, cable supports and linkage

from transmission. Remove clutch slave cylinder and wire aside.

disconnect speedometer drive from transmission. Remove upper engine-

to-transaxle bolts.

3) Remove 3 right side engine mount-to-engine bolts and one

left side transmission mount bracket through bolt. In vehicles with

ABS (Anti-Lock Brake System) it may be necessary to remove coolant

overflow reservoir to access left side through bolt.

4) Remove radiator fan, cover and mount. Remove nut from

Page 448 of 920

CLUTCH

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

front transmission mount. Attach Engine Support (10-222A) with Bases

(10-222A/1) to engine. Slightly tighten engine support and remove

starter. Remove left transaxle mount bracket.

5) Remove long left side transmission support bracket. Remove

balance weight from mount. Remove heat shield for right side inner CV

(constant velocity) joint.

6) Disconnect axle shafts at flanges and wire aside. Remove

left side transaxle mount from transaxle. It will be necessary to push

rearward on mount for clearance to remove long transaxle mount bolt.

7) Push transaxle mount to right and pull down to remove from

vehicle. Remove small gear carrier housing cover. Support transaxle

with floor jack. Remove rear transaxle mount. Remove lower transaxle-

to-engine bolts. Carefully pry transaxle from engine and lower.

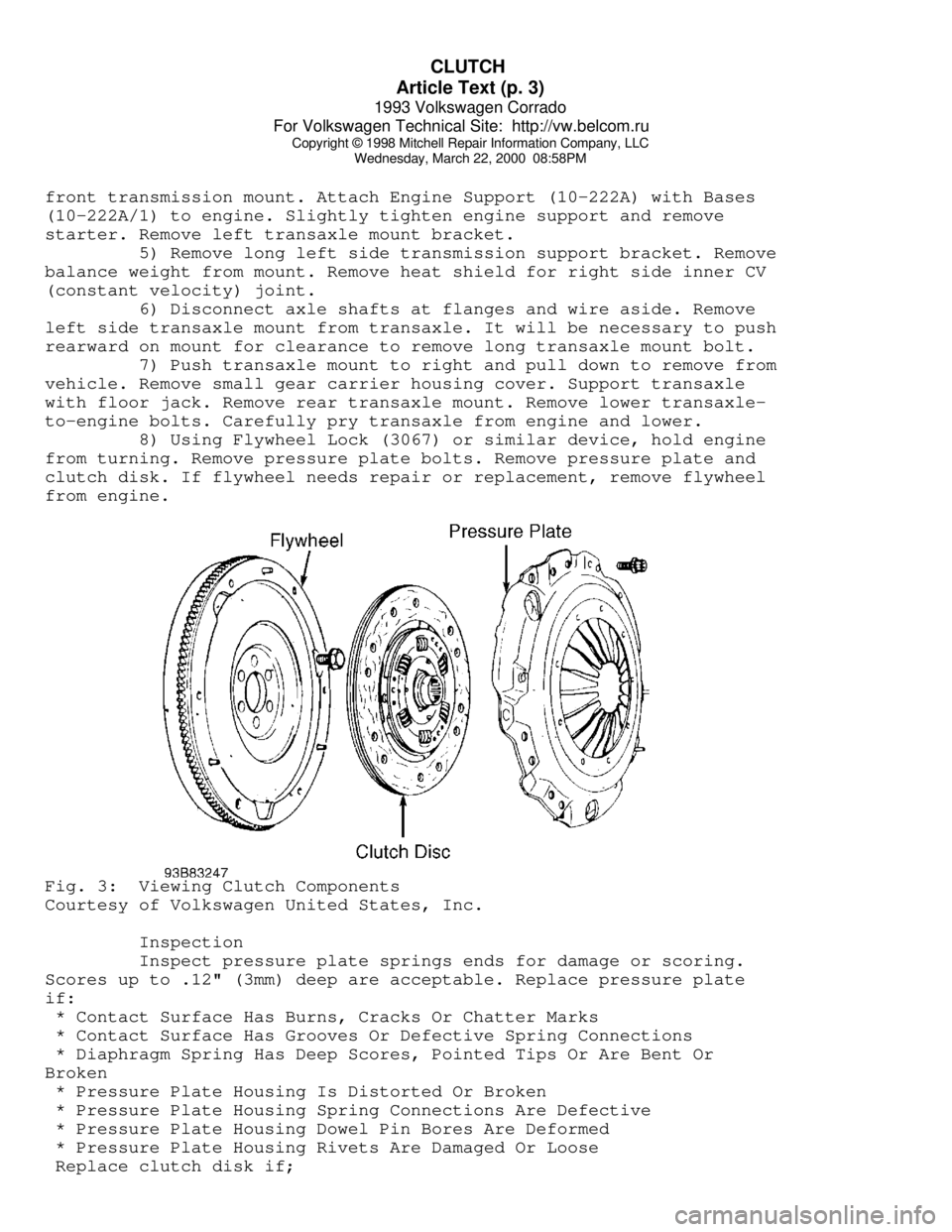

8) Using Flywheel Lock (3067) or similar device, hold engine

from turning. Remove pressure plate bolts. Remove pressure plate and

clutch disk. If flywheel needs repair or replacement, remove flywheel

from engine.Fig. 3: Viewing Clutch Components

Courtesy of Volkswagen United States, Inc.

Inspection

Inspect pressure plate springs ends for damage or scoring.

Scores up to .12" (3mm) deep are acceptable. Replace pressure plate

if:

* Contact Surface Has Burns, Cracks Or Chatter Marks

* Contact Surface Has Grooves Or Defective Spring Connections

* Diaphragm Spring Has Deep Scores, Pointed Tips Or Are Bent Or

Broken

* Pressure Plate Housing Is Distorted Or Broken

* Pressure Plate Housing Spring Connections Are Defective

* Pressure Plate Housing Dowel Pin Bores Are Deformed

* Pressure Plate Housing Rivets Are Damaged Or Loose

Replace clutch disk if;

Page 449 of 920

CLUTCH

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

* Worn To Surface Of Rivet Heads

* Rivets Are Loose, Missing Or Damaged

* Friction Material Is Oil Or Grease Soaked

* Friction Material Is Loose, Cracked Or Grooved

* Hub Is Rusted Or Damaged

* Springs Are Rusted Solid, Broken, Cracked Or Loose

* Torsion Damper Spring Guide Is Broken

* Torsion Damper Cover Damaged

* Torsion Damper Grooved Or Not Functioning

NOTE: Pressure plate has a protective grease coating. Remove

contact surface grease only. Service life will be shortened

if remaining portions of pressure plate protective grease

are removed.

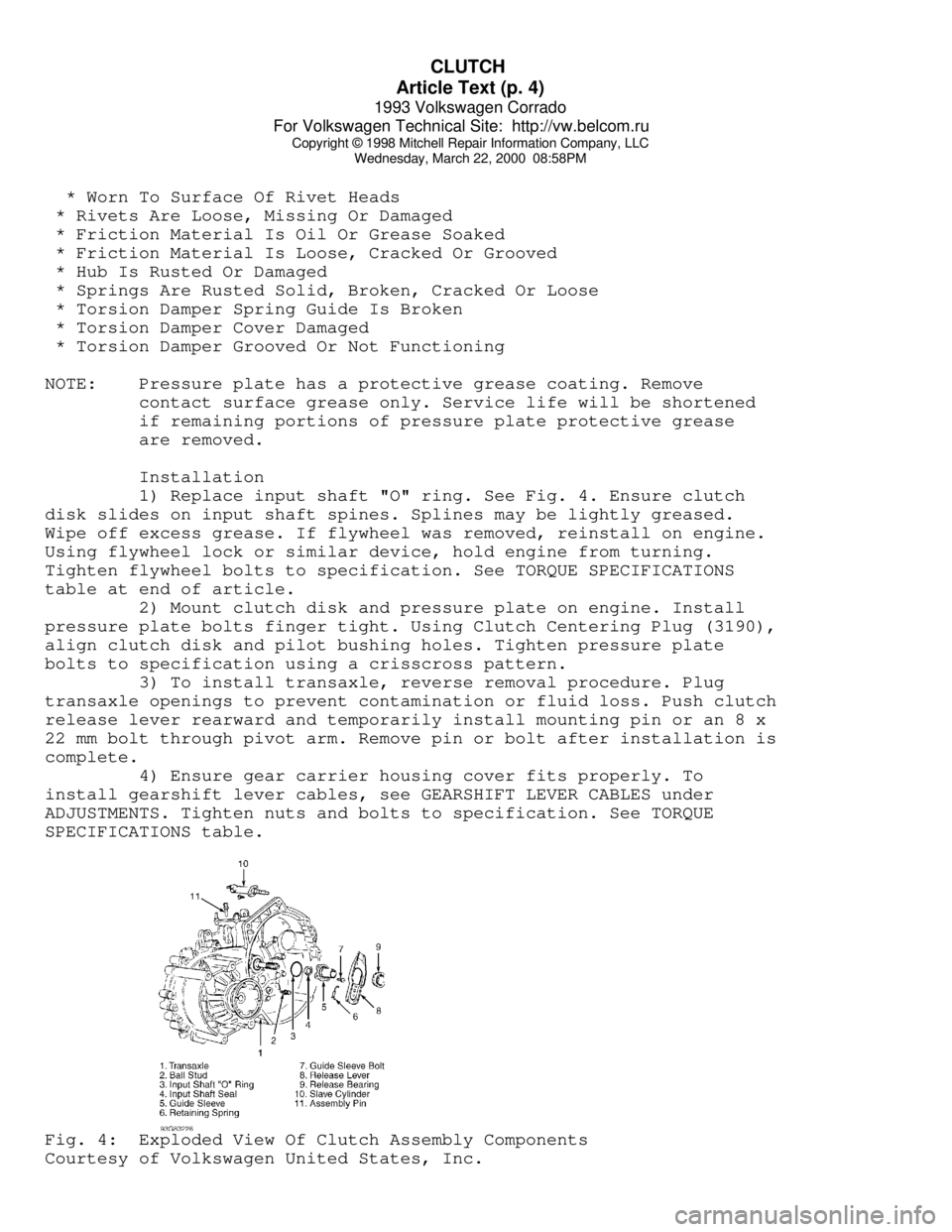

Installation

1) Replace input shaft "O" ring. See Fig. 4. Ensure clutch

disk slides on input shaft spines. Splines may be lightly greased.

Wipe off excess grease. If flywheel was removed, reinstall on engine.

Using flywheel lock or similar device, hold engine from turning.

Tighten flywheel bolts to specification. See TORQUE SPECIFICATIONS

table at end of article.

2) Mount clutch disk and pressure plate on engine. Install

pressure plate bolts finger tight. Using Clutch Centering Plug (3190),

align clutch disk and pilot bushing holes. Tighten pressure plate

bolts to specification using a crisscross pattern.

3) To install transaxle, reverse removal procedure. Plug

transaxle openings to prevent contamination or fluid loss. Push clutch

release lever rearward and temporarily install mounting pin or an 8 x

22 mm bolt through pivot arm. Remove pin or bolt after installation is

complete.

4) Ensure gear carrier housing cover fits properly. To

install gearshift lever cables, see GEARSHIFT LEVER CABLES under

ADJUSTMENTS. Tighten nuts and bolts to specification. See TORQUE

SPECIFICATIONS table.Fig. 4: Exploded View Of Clutch Assembly Components

Courtesy of Volkswagen United States, Inc.

Page 450 of 920

CLUTCH

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

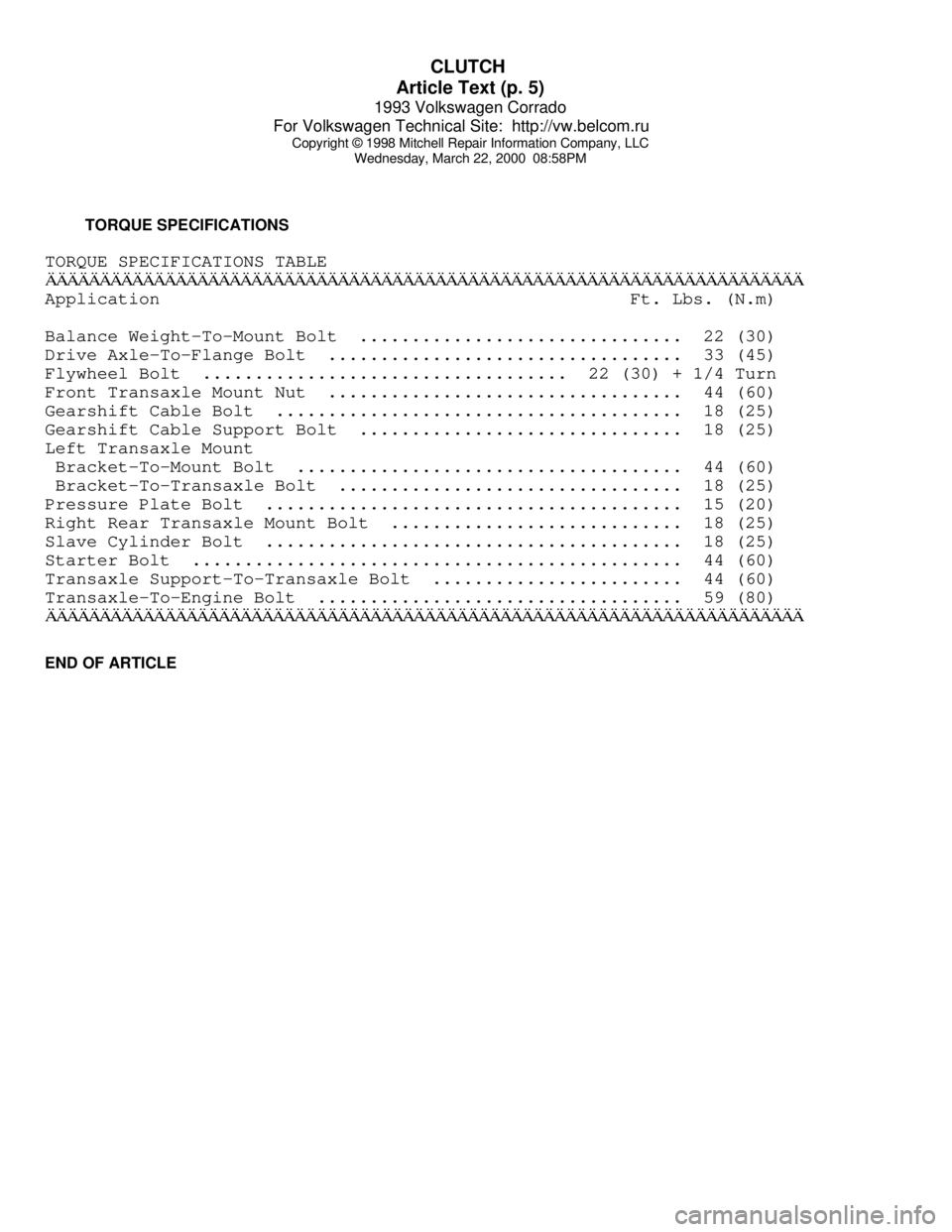

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ft. Lbs. (N.m)

Balance Weight-To-Mount Bolt ............................... 22 (30)

Drive Axle-To-Flange Bolt .................................. 33 (45)

Flywheel Bolt ................................... 22 (30) + 1/4 Turn

Front Transaxle Mount Nut .................................. 44 (60)

Gearshift Cable Bolt ....................................... 18 (25)

Gearshift Cable Support Bolt ............................... 18 (25)

Left Transaxle Mount

Bracket-To-Mount Bolt ..................................... 44 (60)

Bracket-To-Transaxle Bolt ................................. 18 (25)

Pressure Plate Bolt ........................................ 15 (20)

Right Rear Transaxle Mount Bolt ............................ 18 (25)

Slave Cylinder Bolt ........................................ 18 (25)

Starter Bolt ............................................... 44 (60)

Transaxle Support-To-Transaxle Bolt ........................ 44 (60)

Transaxle-To-Engine Bolt ................................... 59 (80)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 451 of 920

COMPUTER RELEARN PROCEDURES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

ARTICLE BEGINNING

GENERAL INFORMATION

Computer Relearn Procedures

All Models

* PLEASE READ THIS FIRST *

The following general procedures are to be used if

driveability problems are encountered after power loss or battery has

been disconnected. These procedures may provide an aid in eliminating

these problems.

To reduce the possibility of complaints, after any service

which requires battery power to be disconnected, vehicle should be

road tested.

COMPUTER RELEARN PROCEDURES

Vehicles equipped with engine or transmission computers may

require a relearn procedure after vehicle battery is disconnected.

Many vehicle computers memorize and store vehicle operation patterns

for optimum driveability and performance. When vehicle battery is

disconnected, this memory is lost. The computer will use default data

until new data from each key start is stored. As computer memorizes

vehicle operation for each new key start, driveability is restored.

Vehicle computers may memorize vehicles operation patterns for 40 of

more key starts.

Customers often complain of driveability problems during

relearn stage because vehicle acts differently then before being

serviced. Depending on type and make of vehicle and how it is

equipped, the following complaints (driveability problems) may exist:

* Harsh Or Poor Shift Quality

* Rough Or Unstable Idle

* Hesitation Or Stumble

* Rich Or Lean Running

* Poor Fuel Mileage

These symptoms and complaints should disappear after a number

of drive cycles have been memorized. To reduce the possibility of

complaints, after any service which requires battery power to be

disconnected, vehicle should be road tested. If a specific relearn

procedure is not available, the following procedure may be used:

Automatic Transmission

* Set parking brake, start engine in "P" or "N" position.

Warm-up vehicle to normal operating temperature or until

cooling fan cycles.

* Allow vehicle to idle for one minute in "N" position. Select

Page 452 of 920

COMPUTER RELEARN PROCEDURES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

"D" and allow engine to idle for one minute.

* Accelerate at normal throttle position (20-50%) until vehicle

shifts into top gear.

* Cruise at light to medium throttle.

* Decelerate to a stop, allowing vehicle to downshift, and use

brakes normally.

* Process may be repeated as necessary.

Manual Transmission

* Place transmission in Neutral position.

* Ensure emergency brake has been set and all accessories

are turned off.

* Start engine and bring to normal operating temperature.

* Allow vehicle to idle in Neutral for one minute.

* Initial relearn is complete: process will be completed during

normal driving.

Some manufacturers identify a specific relearn procedure

which will help establish suitable driveability during relearn stage.

These procedures are especially important if vehicle is equipped with

and electronically controlled automatic transmission or transaxle.

Always complete procedure before returning vehicle to customer.

END OF ARTICLE

Page 465 of 920

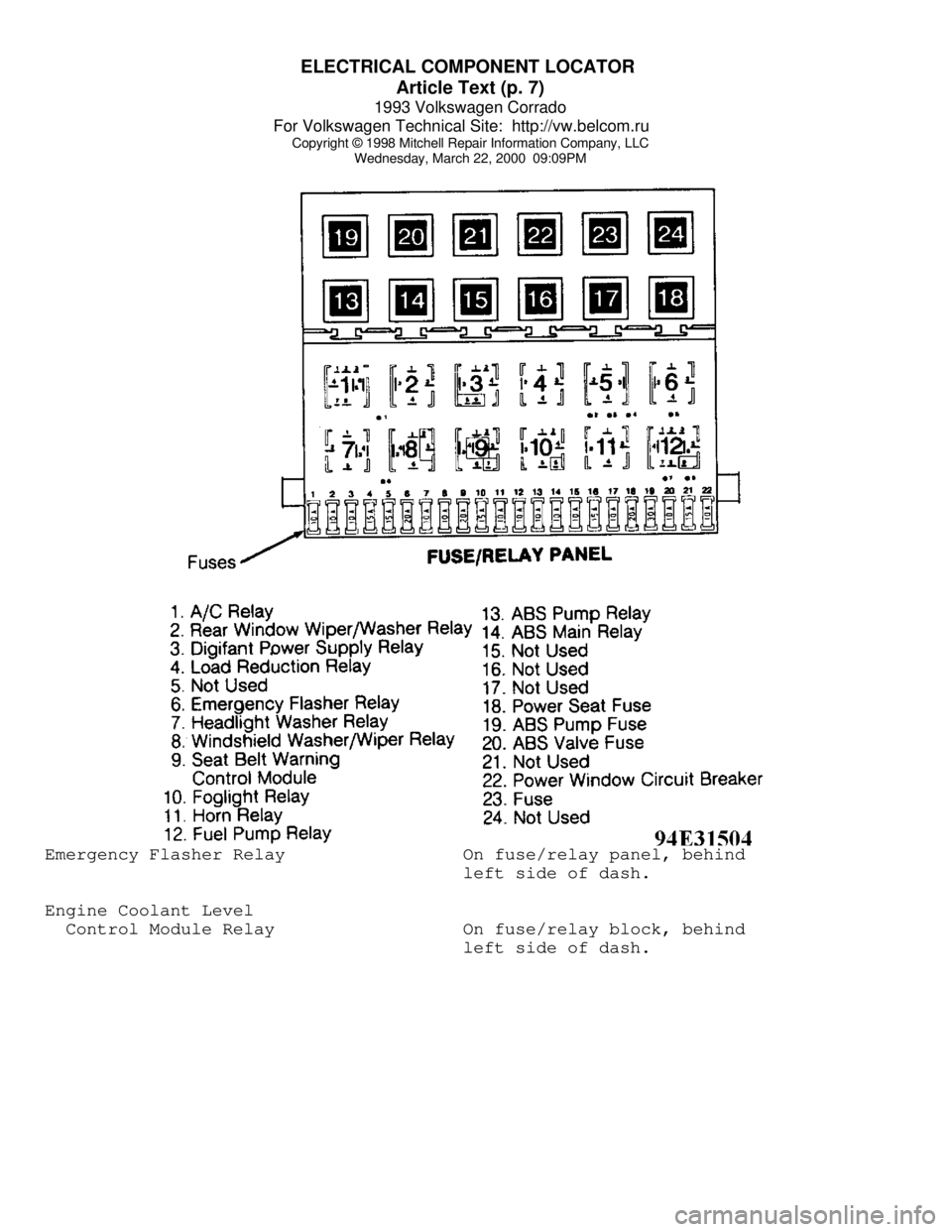

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMEmergency Flasher Relay On fuse/relay panel, behind

left side of dash.

Engine Coolant Level

Control Module Relay On fuse/relay block, behind

left side of dash.

Page 475 of 920

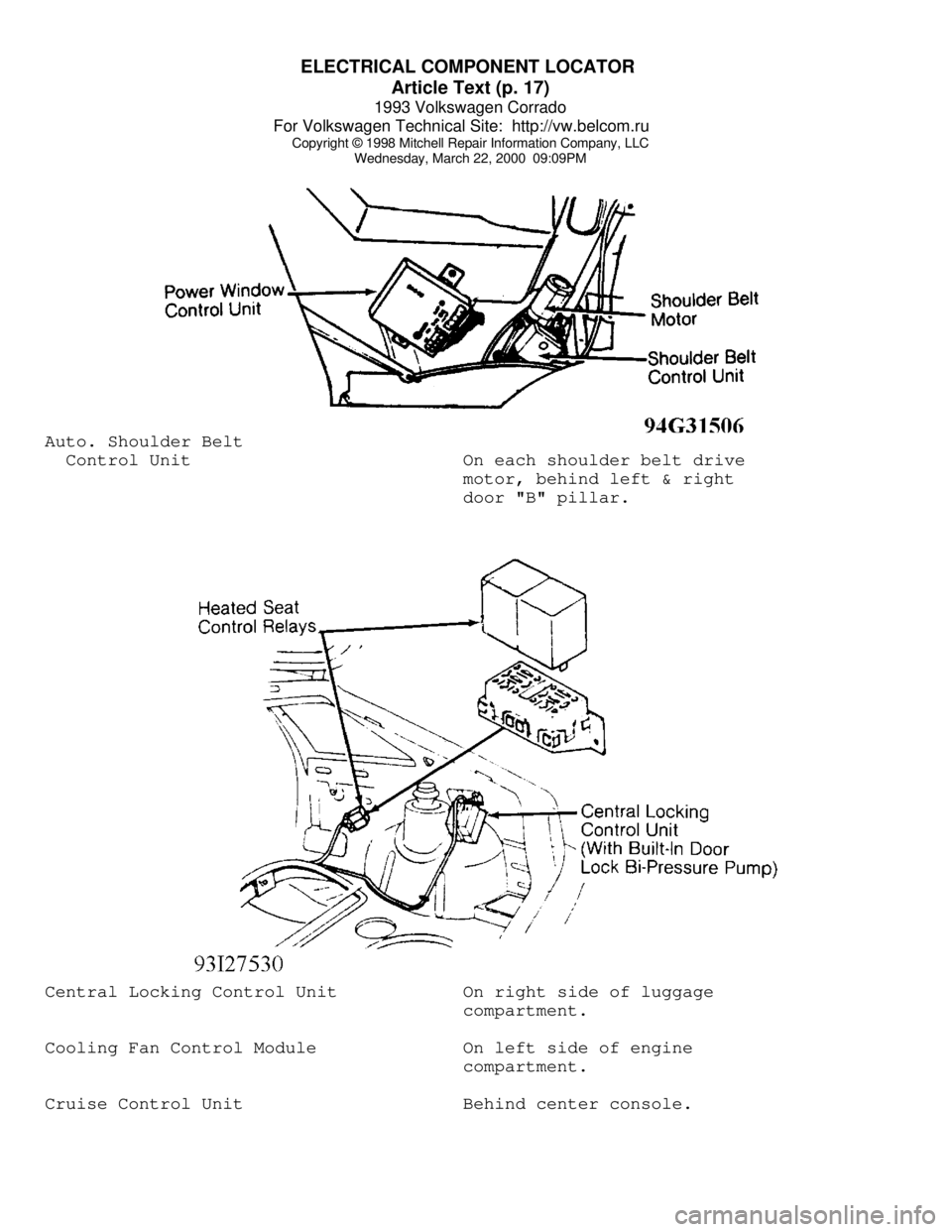

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 17)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMAuto. Shoulder Belt

Control Unit On each shoulder belt drive

motor, behind left & right

door "B" pillar.Central Locking Control Unit On right side of luggage

compartment.

Cooling Fan Control Module On left side of engine

compartment.

Cruise Control Unit Behind center console.

Page 476 of 920

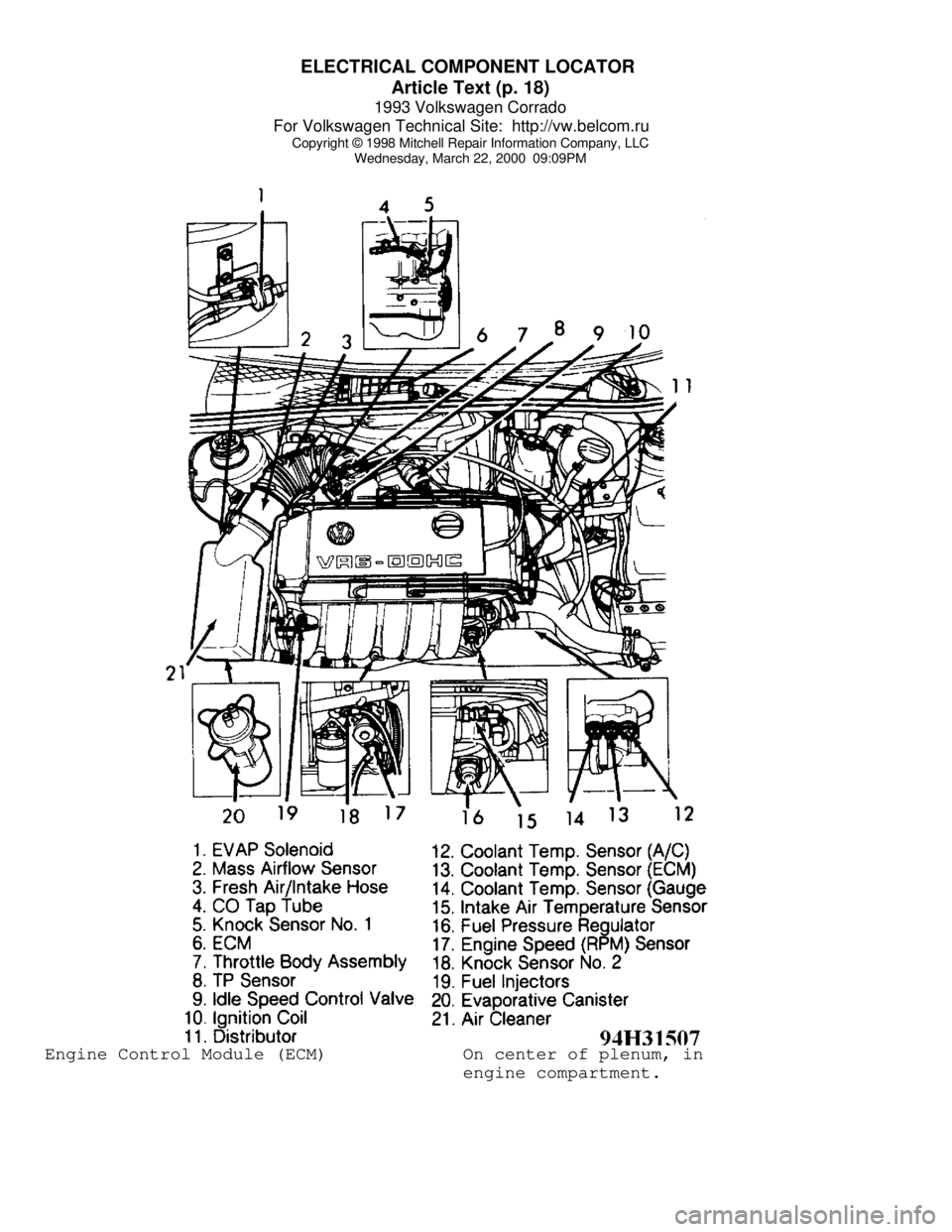

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 18)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMEngine Control Module (ECM) On center of plenum, in

engine compartment.