engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 405 of 920

ALTERNATOR & REGULATOR

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:56PM

ARTICLE BEGINNING

1993 ELECTRICAL

Volkswagen Alternators & Regulators - Bosch

Volkswagen; Cabriolet, Corrado SLC, EuroVan,

Fox, Golf, GTI, Jetta, Passat

DESCRIPTION

Bosch alternators are conventional 3-phase, self-rectifying

type alternators. Bosch 65 to 75-amp alternators use 3 positive and 3

negative diodes connected to stator windings to rectify current. Bosch

90-amp alternators use 14 diodes.

All alternators use 3 exciter diodes connected to stator

windings. These diodes turn off the alternator indicator light and

supply power to the voltage regulator while the engine is running.

Bosch regulators are transistorized and integral with alternator.

TROUBLE SHOOTING

NOTE: See TROUBLE SHOOTING - BASIC PROCEDURES article in

GENERAL INFORMATION.

ADJUSTMENTS

BELT TENSION

BELT ADJUSTMENT TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

A/C Compressor

Cabriolet

New ...................................... (1) 54 INCH Lbs. (6 N.m)

Used ..................................... (1) 36 INCH Lbs. (4 N.m)

Fox .......................................... 13/64-3/8" (5-10 mm)

Passat GL

New ...................................... (1) 72 INCH Lbs. (8 N.m)

Used ..................................... (1) 36 INCH Lbs. (4 N.m)

Alternator

Cabriolet

New .................................................. 5/16" (8 mm)

Used ................................................. 5/32" (4 mm)

Fox .......................................... 3/8-9/16" (10-15 mm)

Passat GL ............................ (1) (2) 72 INCH Lbs. (8 N.m)

Power Steering

Passat GL ........................................... 13/64" (5 mm)

Serpentine Belt

Corrado SLC, EuroVan,

Golf, GTI, Jetta & Passat GLX ................................. (3)

Page 406 of 920

ALTERNATOR & REGULATOR

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:56PM

(1) - Turn tensioning nut on toothed rack with Torque Wrench

(VAG1410) and Ring Insert (SW VAG 1410-2).

(2) - Start engine and let it idle for 5 minutes. Loosen bolts and

retighten belt to specification.

(3) - Serpentine belt tension automatically adjusted by tensioner.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ON-VEHICLE TESTING

WIRING CONTINUITY TEST

1) With ignition off, connect a voltmeter between alternator

B+ terminal and ground. Voltmeter should indicate battery voltage. If

battery voltage is not present, check wiring between alternator and

battery.

2) Turn ignition on and ensure alternator indicator light

comes on. If light does not come on, check wiring between alternator

and warning light, including indicator bulb.

OUTPUT TEST

CAUTION: DO NOT load electrical system for more than 15-20 seconds

during output test or possible system damage may occur.

1) Ensure connections at battery, alternator, and starter

(most vehicles) are clean and tight. Ensure alternator, engine and

body are properly grounded. Ensure alternator drive belt is tight and

in good condition.

2) Turn off all accessories. Start engine and allow to idle.

Connect ammeter following manufacturer's instructions. Run engine at

2000 RPM. Adjust carbon pile on tester to obtain maximum alternator

output. DO NOT allow battery voltage to drop to less than 12.6 volts.

3) Alternator output should equal alternator rated output,

minus 16-20 amps. If reading is more than 20 amps less than alternator

rating, replace regulator and retest. If output is still low, repair

or replace alternator.

REGULATOR CONTROL VOLTAGE TEST

1) Connect ammeter following manufacturer's instructions.

Connect voltmeter leads to battery terminals. Start engine and run at

3000 RPM.

2) Run engine until voltage stops rising. Voltage should be

13.5-14.5 volts. If reading is incorrect, remove regulator and ensure

brushes are longer than 3/16" (5 mm). Replace if necessary.

3) If brushes are okay and regulator fails to keep voltage

within specified limits, replace regulator and retest. If voltage is

still incorrect, repair or replace alternator.

BENCH TESTING

Page 414 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

HYDRAULIC MODULATOR/PUMP

Depressurize brake system. See DEPRESSURIZING BRAKE SYSTEM.

Turn ignition on. Hydraulic modulator/pump should operate for 60

seconds maximum and then stop. Depress brake pedal a few times; pump

should operate again for a few seconds. If pump motor does not

operate, check electrical system. If pump motor operates for more than

60 seconds, internal or external hydraulic leak may be indicated.

Check for external leaks. If external leak is not found, further

testing may be needed to check for internal leaks.

ANTILOCK WARNING LIGHT

Start engine. ANTILOCK warning light should come on, then

turn off after a few seconds. If light does not come on when engine is

started, check electrical system. If light comes on and stays on,

fault has been detected by the ECU and testing will be needed. See

SYSTEM TESTING under DIAGNOSIS & TESTING.

DIAGNOSIS & TESTING

SYSTEM TESTING

NOTE: Check battery condition, brake fluid level, electrical

connections and wiring for damage. If fluid level is

incorrect or battery and/or electrical connections are

faulty, correct problem before preceding. Perform each step,

in sequence, to test entire system, except for ECU. If

faulty ECU is suspected, replace with a known good one, and

retest system. Unplug ECU connector for all test steps.

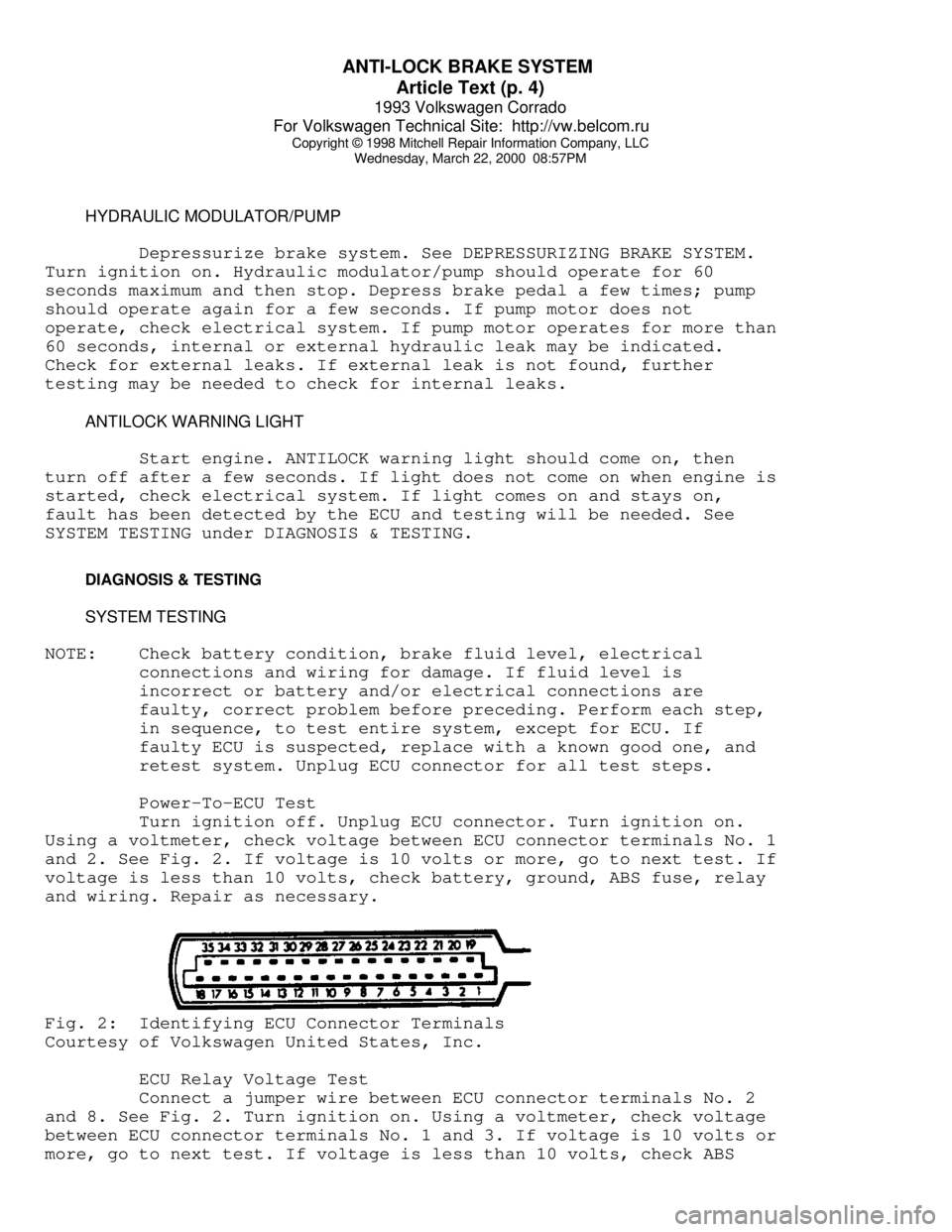

Power-To-ECU Test

Turn ignition off. Unplug ECU connector. Turn ignition on.

Using a voltmeter, check voltage between ECU connector terminals No. 1

and 2. See Fig. 2. If voltage is 10 volts or more, go to next test. If

voltage is less than 10 volts, check battery, ground, ABS fuse, relay

and wiring. Repair as necessary.Fig. 2: Identifying ECU Connector Terminals

Courtesy of Volkswagen United States, Inc.

ECU Relay Voltage Test

Connect a jumper wire between ECU connector terminals No. 2

and 8. See Fig. 2. Turn ignition on. Using a voltmeter, check voltage

between ECU connector terminals No. 1 and 3. If voltage is 10 volts or

more, go to next test. If voltage is less than 10 volts, check ABS

Page 425 of 920

ANTI-THEFT SYSTEM

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

positive lead to anti-theft control module 10-pin wiring harness

connector terminal No. "7" (Red/Yellow wire for Corrado SLC;

Yellow/Red wire for Passat). Insert key in driver's door lock. Turn

key against stop and hold momentarily. Voltmeter should register 12

volts. Repeat procedure for passengers door. If voltage is correct for

each door, go to next step. If voltage is correct, repair door switch

or open circuit.

3) Door Lock Switch Check

Connect voltmeter negative lead to ground. Connect positive

lead to anti-theft control module 10-pin wiring harness connector

terminal No. "6" (Red/Black wire). Insert key in driver's door lock.

Turn key against stop and hold momentarily. Voltmeter should register

12 volts. Repeat procedure for passengers door. If voltage is correct

for each door, replace control module. If voltage is not correct,

repair door switch or open circuit.

ALARM HORN INOPERATIVE

1) Alarm Horn Check

Ensure battery is fully charged. Obtain radio security code.

Disconnect battery cable terminals. Disconnect anti-theft control

module 6-pin and 10-pin wiring harness connector. See ANTI-THEFT

CONTROL MODULE LOCATION table.

2) Connect ohmmeter negative lead to ground. Connect positive

lead to anti-theft control module 6-pin wiring harness connector

terminal No. "4" (Black/Yellow wire). If continuity is present,

replace anti-theft control module. If continuity is not present, check

for open circuit and repair as necessary. If circuit is okay, replace

alarm horn.

LIGHTS DO NOT FLASH

1) Alarm Horn Check

Ensure battery is fully charged and emergency flasher system

is functional. Obtain radio security code. Disconnect battery cable

terminals. Disconnect anti-theft control module 6-pin and 10-pin

wiring harness connector. See ANTI-THEFT CONTROL MODULE LOCATION

table.

2) Connect voltmeter negative lead to ground. Connect

positive lead to anti-theft control module 6-pin wiring harness

connector terminal No. "1" (Black/White wire for Corrado SLC; Black

Yellow wire for Passat). Turn emergency flashers on. When lights flash

on, battery voltage should be present.

3) Remove voltmeter positive from terminal No. "1" and

connect to terminal No. "2" (Black/Green wire for Corrado SLC;

Green/Black wire for Passat). Turn emergency flashers on. When lights

flash on, battery voltage should be present. If voltage is correct,

replace anti-theft control module. If voltage is not correct, repair

open circuit in wiring harness between anti-theft control module and

lights.

ENGINE DOES NOT CRANK WITH ALARM SYSTEM OFF

Page 427 of 920

AXLE SHAFTS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ARTICLE BEGINNING

1993-94 DRIVE AXLES

Volkswagen Axle Shafts - FWD

Corrado SLC, Passat

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the

GENERAL TROUBLE SHOOTING section.

REMOVAL, DISASSEMBLY, REASSEMBLY & INSTALLATION

NOTE: Clean bolts and nuts to ensure tightening torque is correct.

AXLE SHAFT

Removal

1) Remove axle shaft nut. Remove wheel. Remove brake caliper,

and secure aside. Remove tie rod end bolts.

2) Remove 2 bolts attaching spindle assembly to strut

assembly. Remove lower ball joint bolt or nut if necessary. Remove

spindle assembly. Loosen inner CV joint from transaxle flange. On

models with V6 engine, use Axle Press (3283) to press axle from wheel

housing. Clean old locking compound from splines. Remove axle shaft

assembly. See Fig. 1.

Disassembly & Reassembly

1) Remove axle shaft boot(s). Using a drift, remove

protective cap from CV joint. Remove circlip from inner CV joint.

Support CV joint with axle assembly on Support Stand (VW 402).

2) Using Driver (VW 408A), press inner CV joint off axle

shaft. DO NOT disassemble inner CV joint, replace complete unit. To

remove outer CV joint, use a driver and hammer to drive CV joint off

axle shaft.

3) Rotate inner race and remove balls. Inspect for galling or

wear. Cover balls with grease and reinstall in race.

4) To reassemble, reverse disassembly procedure. Refer to the

AXLE SHAFT LENGTH table. Use new circlips and boot clamps during

assembly.

Installation

To install, reverse removal procedure. Install new axle shaft

nut. On models with V6 engine, apply locking compound to splines. See

the TORQUE SPECIFICATIONS table.

Page 430 of 920

B - EMISSION APPLICATION

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Emission Applications

Cabriolet, Corrado, Eurovan, Golf, GTI, Jetta, Passat

EMISSION APPLICATIONS

EMISSION APPLICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEngine & Fuel System Emission Control Systems & Devices

Cabriolet

1.8L Digifant PFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, SPK,

(1) O2, CEC, (2) MIL

Components & Other Related Devices ............ EVAP-PV, EVAP-VC,

SPK-CC, (3) HAI

Corrado SLC

2.8L VR6 Motronic MFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, EGR,

SPK AP, (1) O2, CEC, MIL

Components & Other Related Devices ...... AP-EAP, AP-ERLY, AP-SV,

AP-SOV, EVAP-PV, EVAP-VC,

EGR-CV, EGR-TS, SPK-CC

Eurovan

2.5L 5-Cyl. Digifant MFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, SPK,

(1) O2, CEC, (2) MIL

Components & Other Related Devices ............ EVAP-CS, EVAP-VC,

SPK-CC, HAI

Fox

1.8L 4-Cyl. Digifant MFI

Major Control Systems & Devices ............. PCV, EVAP, TWC, FR,

(2) EGR, SPK, (1) O2,

CEC, (2) MIL

Components & Other Related Devices ... EVAP-PV, EVAP-VC, EGR-TVV,

EGR-VA, SPK-CC, (3) HAI

Golf, GTI & Jetta

2.0L 4-Cyl. Motronic MFI

Major Control Systems & Devices ............. PVC, EVAP, TWC, FR,

(2) EGR, SPK, (1) O2,

CEC, (2) MIL

Components & Other Related Devices .... EVAP-PV, EVAP-VC, EGR-CV,

EGR-TS, HAI

Passat

Page 431 of 920

B - EMISSION APPLICATION

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

2.0L 4-Cyl. CIS-E Motronic

Major Control Systems & Devices ............. PCV, EVAP, TWC, FR,

(2) EGR, SPK, AP,

(1) O2, CEC, (2) MIL

Components & Other Related Devices ........ (4) EVAP-PV, EVAP-CV,

EGR-VA, EGR-TVV, SPK-CC

2.8L VR6 Motronic MFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, EGR,

SPK, AP, (1) O2, CEC, (2) MIL

Components & Other Related Devices ...... AP-EAP, AP-ERLY, AP-SV,

AP-SOV, EVAP-PV, EVAP-VC,

EGR-CV, EGR-TS, SPK-CC

(1) - Heated O2 sensor.

(2) - California only.

(3) - Digifant II only.

(4) - Two required.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ABBREVIATION DEFINITIONS

ABBREVIATION DEFINITION TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄAbbreviation Definition

AP ............................. Air Pump Injection System

AP-EAP .............................. AP Electric Air Pump

AP-ERLY ....................... AP Electric Air Pump Relay

AP-SV .......................... AP Solenoid (Inlet) Valve

AP-SOV ................................. AP Shut Off Valve

CEC ......................... Computerized Engine Controls

EGR ............................ Exhaust Gas Recirculation

EGR-CV ..................... EGR Control (Frequency) Valve

EGR-TS ............................ EGR Temperature Sensor

EGR-TVV ......................... EGR Thermal Vacuum Valve

EGR-VA .............................. EGR Vacuum Amplifier

EVAP ............................. Fuel Evaporative System

EVAP-CS ............................ EVAP Control Solenoid

EVAP-PV ................................. EVAP Purge Valve

EVAP-VC .............................. EVAP Vapor Canister

FR .................................. Fill Pipe Restrictor

HAI ....................................... Hot Air Intake

MIL ........... Malfunction Indicator (CHECK ENGINE) Light

MFI ............................. Multiport Fuel Injection

O2 ......................................... Oxygen Sensor

PCV ....................... Positive Crankcase Ventilation

SPK ................................. Spark Control System

SPK-CC ........................... SPK Computer Controlled

TWC ................................... Three-Way Catalyst

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 432 of 920

BRAKE SYSTEM

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ARTICLE BEGINNING

1992-93 BRAKES

Volkswagen Disc & Drum

Corrado SLC

DESCRIPTION

All models are equipped with front disc brakes. Rear brakes

are either disc or drum. Parking brake acts on rear brakes and is

cable-actuated. All models use pressure regulator between front and

rear brake circuits to avoid rear wheel lock-up during hard braking.

A vacuum power-assist servo is used to ease brake pedal

application. A vacuum check valve, located in vacuum supply hose,

prevents vacuum leakdown when engine is off.

SERVICING

Manufacturer recommends replacing brake fluid every 2 years.

BLEEDING BRAKE SYSTEM

CAUTION: Ensure fluid level in master cylinder is adequate at all

times during bleeding procedure. Use only DOT 4 brake fluid.

DO NOT use DOT 5 silicone brake fluid.

BLEEDING PROCEDURES

NOTE: Manufacturer recommends bleeding brake system using Pressure

Bleeder (US 1116). If a pressure bleeder is not available,

use standard bleeding procedure.

1) Exhaust vacuum reserve from power unit by depressing brake

pedal several times. On ABS-equipped vehicles, depress brake pedal at

least 20 times to relieve system pressure.

2) On all vehicles, fill master cylinder with clean brake

fluid. If master cylinder was replaced, bleed master cylinder before

bleeding wheel calipers. Connect bleeder hose to appropriate caliper

bleeder valve. See BRAKE BLEEDING SEQUENCE table.

BRAKE BLEEDING SEQUENCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication (1) Sequence

Corrado SLC .................. Either Front Caliper First,

Either Rear Caliper First

(1) - Push lever of pressure regulator in direction of rear

axle when bleeding rear brakes.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 441 of 920

C - SPECIFICATIONS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Service & Adjustment Specifications

Corrado SLC

INTRODUCTION

Use this article to quickly find specifications related to

servicing and on-vehicle adjustments. This is a quick-reference

article to use when you are familiar with an adjustment procedure and

only need a specification.

CAPACITIES

BATTERY SPECIFICATIONSÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Amp Hr. Rating

Corrado SLC ...................................... 63

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFLUID CAPACITIES

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Quantity

Auto. Trans. (Dexron-II)

Dry Fill ...................................... (1)

Refill (Oil Change) ........................... (1)

Cooling System (Includes Heater) .... 9.1 Qts. (8.6L)

Crankcase (Includes Filter) ......... 6.3 Qts. (6.0L)

Man. Transaxle (SAE 75-80/API

GL-4 Or SAE 75W-90, G50

Synthetic Gear Oil) ............... 2.1 Qts. (2.0L)

(1) - Information is not available from manufacturer.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Miles

Air Filter ................................... 30,000

Coolant ...................................... 30,000

Fuel Filter (1) .............................. 15,000

Oil & Filter ................................... 7500

Page 442 of 920

C - SPECIFICATIONS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:58PM

Spark Plugs .................................. 30,000

(1) - Discard mini-fuel filter at 1000-mile maintenance

interval. Install new copper gaskets.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄBELT ADJUSTMENT

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

Serpentine Belt ................................. (1)

(1) - Serpentine belt tension is automatically adjusted

by the tensioner.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ MECHANICAL CHECKS

ENGINE COMPRESSION

COMPRESSION SPECIFICATIONS

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

Compression Ratio ............................ 10.0:1

Compression

Pressure ........... 157-186 psi (11.0-13.0 kg/cm

ý)

Minimum Compression Pressure ... 106 psi (7.5 kg/cm

ý)

Maximum Variation

Between Cylinders ............. 43 psi (3.0 kg/cm

ý)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VALVE CLEARANCE

NOTE: All models are equipped with hydraulic lifters. No

adjustments are required.

IGNITION SYSTEM

IGNITION COIL

IGNITION COIL RESISTANCE - Ohms @ 68

øF (20øC)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Primary Secondary

Corrado SLC (1) ........ ..... .............. .....

(1) - Ignition coil pack, new for 1993, is located on

left side of cylinder head. When ignition coil is

triggered, spark is supplied to 2 spark plugs at

one time. One spark plug fires during compression

stroke and the other plug fires during exhaust