VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 411 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ARTICLE BEGINNING

1993 BRAKES

Volkswagen Anti-Lock

Corrado SLC

ANTI-LOCK BRAKE SAFETY PRECAUTIONS

* NEVER open a bleeder valve or loosen a hydraulic line while

ABS is pressurized

* NEVER disconnect or reconnect any electrical connectors while

ignition is on. Damage to ABS control unit may result.

* DO NOT attempt to bleed hydraulic system without first

referring to the appropriate article.

* Only use specially designed brake hoses/lines on ABS-equipped

vehicles.

* DO NOT tap on speed sensor components (sensor, sensor rings).

Speed rings must be pressed, NOT hammered into hubs. Striking

these components can cause demagnetization or a loss of

polarization, affecting the accuracy of the speed signal

returning to the ABS control unit.

* DO NOT mix tire sizes. Increasing the width, as long as tires

remain close to the original diameter, is acceptable. Rolling

diameter must be identical for all 4 tires. Some

manufacturers recommend tires of the same brand, style and

type. Failure to follow this precaution may cause inaccurate

wheel speed readings.

* DO NOT contaminate speed sensor components with grease. Only

use recommended anti-corrosion coating.

* When speed sensor components have been removed, ALWAYS check

sensor-to-ring air gaps when applicable. These specifications

can be found in each appropriate article.

* ONLY use recommended brake fluids. DO NOT use silicone brake

fluids in an ABS-equipped vehicle.

* When installing transmitting devices (CB's, telephones, etc.)

on ABS-equipped vehicles, DO NOT locate the antenna near the

ABS control unit (or any control unit).

* Disconnect all on-board computers, when using electric

welding equipment.

* DO NOT expose the ABS control unit to prolonged periods of

high heat (185øF/85øC for 2 hours is generally considered a

maximum limit).

DESCRIPTION

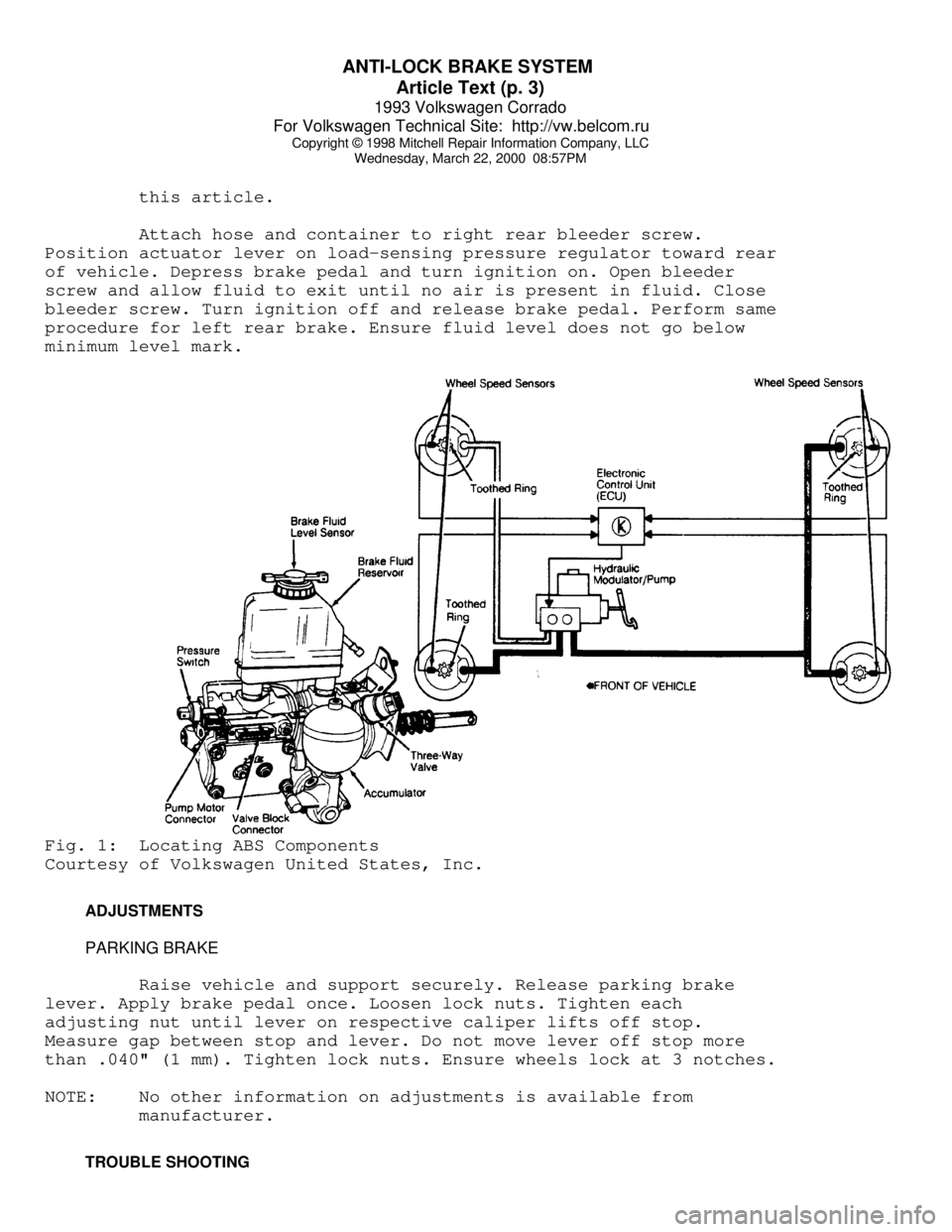

A Teves Anti-Lock Brake System (ABS) is used. See Fig. 1.

This system reduces the chance of wheel lock-up during heavy braking.

The system consists of 4 wheel speed sensors, Electronic Control Unit

(ECU), hydraulic modulator/pump and solenoid valves, ANTILOCK and

BRAKE warning lights. There are 2 relays located at fuse/relay panel,

Page 412 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

to protect the hydraulic modulator and ECU.

NOTE: For more brake system information, see BRAKE SYSTEM

article in the BRAKES section.

OPERATION

When pressure is applied to brake pedal, ECU monitors input

signals from each wheel speed sensor. If ECU measures a rate of

reduction greater than what is programmed in ECU, the ECU will output

a signal to appropriate solenoid valve. Each solenoid valve allows

hydraulic pressure to increase or decrease to the appropriate wheel

cylinder.

If a system failure occurs, ANTILOCK warning light, located

on instrument panel, will come on. System will be deactivated, but

conventional brake system will still operate. If brake fluid level

drops too low, BRAKE warning light, located on instrument panel, will

come on.

CAUTION: See ANTI-LOCK BRAKE SAFETY PRECAUTIONS in this article.

CAUTION: The ABS system is under extremely high pressure. Depressurize

the brake system before loosening or removing any hydraulic

component.

DEPRESSURIZING BRAKE SYSTEM

Turn ignition off. Depress and release brake pedal 25-35

times, or until there is a noticeable increase in the effort to

depress the brake pedal. DO NOT turn ignition on until all hydraulic

lines and components are fully tighten.

BLEEDING BRAKE SYSTEM

FRONT BRAKES

Depressurize brake system. See DEPRESSURIZING BRAKE SYSTEM.

Connect a container with hose to left front bleeder screw. Have

assistant depress and release brake pedal a few times. Holding brake

pedal down, open bleeder screw and allow fluid to enter container.

Close bleeder screw and then release brake pedal. Continue this method

until no air is present in fluid. Check master cylinder fluid level to

make sure it does not go below minimum level mark. Use same procedure

for right front brake.

REAR BRAKES

CAUTION: When bleeding rear brakes, accumulator pressure (about 3100

psi) is used to assist in procedure. Use eye protection when

performing this procedure. DO NOT allow pump to run longer

than 2 minutes. See ANTI-LOCK BRAKE SAFETY PRECAUTIONS in

Page 413 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

this article.

Attach hose and container to right rear bleeder screw.

Position actuator lever on load-sensing pressure regulator toward rear

of vehicle. Depress brake pedal and turn ignition on. Open bleeder

screw and allow fluid to exit until no air is present in fluid. Close

bleeder screw. Turn ignition off and release brake pedal. Perform same

procedure for left rear brake. Ensure fluid level does not go below

minimum level mark.Fig. 1: Locating ABS Components

Courtesy of Volkswagen United States, Inc.

ADJUSTMENTS

PARKING BRAKE

Raise vehicle and support securely. Release parking brake

lever. Apply brake pedal once. Loosen lock nuts. Tighten each

adjusting nut until lever on respective caliper lifts off stop.

Measure gap between stop and lever. Do not move lever off stop more

than .040" (1 mm). Tighten lock nuts. Ensure wheels lock at 3 notches.

NOTE: No other information on adjustments is available from

manufacturer.

TROUBLE SHOOTING

Page 414 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

HYDRAULIC MODULATOR/PUMP

Depressurize brake system. See DEPRESSURIZING BRAKE SYSTEM.

Turn ignition on. Hydraulic modulator/pump should operate for 60

seconds maximum and then stop. Depress brake pedal a few times; pump

should operate again for a few seconds. If pump motor does not

operate, check electrical system. If pump motor operates for more than

60 seconds, internal or external hydraulic leak may be indicated.

Check for external leaks. If external leak is not found, further

testing may be needed to check for internal leaks.

ANTILOCK WARNING LIGHT

Start engine. ANTILOCK warning light should come on, then

turn off after a few seconds. If light does not come on when engine is

started, check electrical system. If light comes on and stays on,

fault has been detected by the ECU and testing will be needed. See

SYSTEM TESTING under DIAGNOSIS & TESTING.

DIAGNOSIS & TESTING

SYSTEM TESTING

NOTE: Check battery condition, brake fluid level, electrical

connections and wiring for damage. If fluid level is

incorrect or battery and/or electrical connections are

faulty, correct problem before preceding. Perform each step,

in sequence, to test entire system, except for ECU. If

faulty ECU is suspected, replace with a known good one, and

retest system. Unplug ECU connector for all test steps.

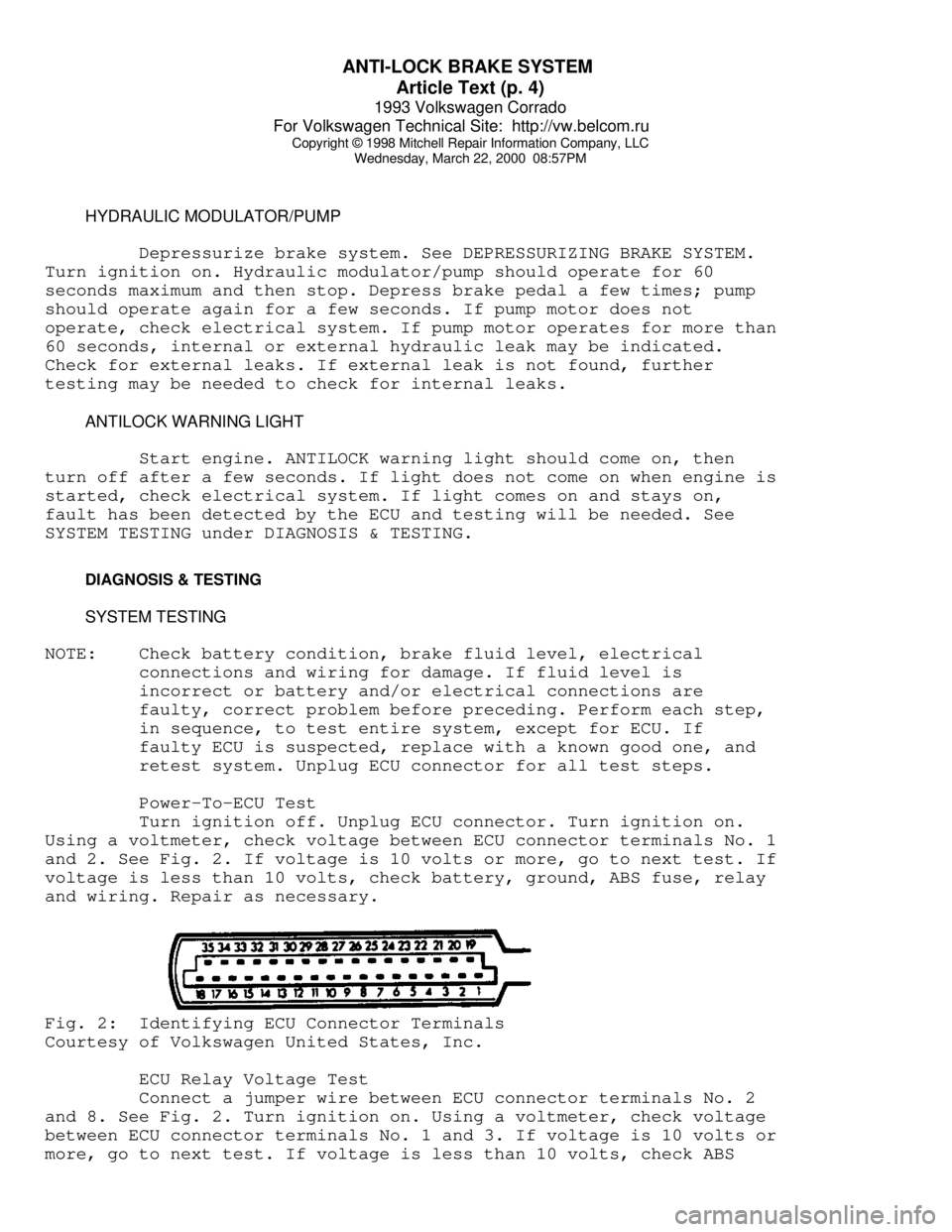

Power-To-ECU Test

Turn ignition off. Unplug ECU connector. Turn ignition on.

Using a voltmeter, check voltage between ECU connector terminals No. 1

and 2. See Fig. 2. If voltage is 10 volts or more, go to next test. If

voltage is less than 10 volts, check battery, ground, ABS fuse, relay

and wiring. Repair as necessary.Fig. 2: Identifying ECU Connector Terminals

Courtesy of Volkswagen United States, Inc.

ECU Relay Voltage Test

Connect a jumper wire between ECU connector terminals No. 2

and 8. See Fig. 2. Turn ignition on. Using a voltmeter, check voltage

between ECU connector terminals No. 1 and 3. If voltage is 10 volts or

more, go to next test. If voltage is less than 10 volts, check ABS

Page 415 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

fuse. If fuse is faulty, replace and retest. If fuse is okay, check

wiring. If wiring is faulty, repair and retest. If wiring is okay,

replace relay and retest.

Brakelight Switch

Turn ignition on. Apply brakes. Check for 12 volts between

terminals No. 12 and 1. If 12 volts are present, brakelight switch is

okay. If 12 volts are not present, check fuse, brakelight switch and

Black/Red wire from brakelight switch to ECU.

Hydraulic Modulator/Pump Relay Voltage Test

1) Turn ignition off. Unplug hydraulic modulator/pump

connector. Depress brake pedal 25 times. Turn ignition on. Using a

voltmeter, measure voltage between ECU connector terminals No. 1 and

32. See Fig. 2. If voltage is 10 volts or more, go to RIGHT REAR WHEEL

SPEED SENSOR VOLTAGE TEST under SYSTEM TESTING.

2) If voltage is less than 10 volts, check hydraulic

modulator/pump fuse. If fuse is okay, check wiring between ECU

connector terminal No. 32 and hydraulic modulator/pump connector

terminal No. 1 (large gauge Red/Black wire). See Figs. 2 and 4. If

wiring is not okay, repair wiring, and retest. If wiring is okay,

replace relay, and retest.

Right Rear Wheel Speed Sensor Voltage Test

Connect an AC voltmeter between ECU connector terminals No. 4

and 22. See Fig. 2. Rotate right rear wheel at one revolution per

second. Measure voltage with wheel rotating. If voltage is 0.075 volt

or more, go to next test. If voltage is less than 0.075 volt, check

wheel speed sensor and/or toothed ring for damage, wear and proper

installation. If damage or wear is found, replace faulty component and

retest. If components are not properly installed, reposition and

retest. If components are okay, replace wheel speed sensor and retest.

Left Rear Wheel Speed Sensor Voltage Test

Connect an AC voltmeter between ECU connector terminals No. 6

and 24. See Fig. 2. Rotate left rear wheel at one revolution per

second. Measure voltage with wheel rotating. If voltage is 0.075 volt

or more, go to next test. If voltage is less than 0.075 volt, check

wheel speed sensor and/or toothed ring for damage, wear and proper

installation. If damage or wear is found, replace faulty component and

retest. If components are not properly installed, reposition and

retest. If components are okay, replace wheel speed sensor and retest.

Right Front Wheel Speed Sensor Voltage Test

Connect an AC voltmeter between ECU connector terminals No. 7

and 25. See Fig. 2. Rotate right front wheel at one revolution per

second. Measure voltage with wheel rotating. If voltage is 0.075 volt

or more, go to next test. If voltage is less than 0.075 volt, check

wheel speed sensor and/or toothed ring for damage, wear and improper

installation. If damage or wear is found, replace faulty component,

and retest. If components are improperly installed, reposition

component, and retest. If components are okay, replace wheel speed

Page 416 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

sensor, and retest.

Left Front Wheel Speed Sensor Voltage Test

Connect an AC voltmeter between ECU connector terminals No. 5

and 23. See Fig. 2. Rotate left front wheel at one revolution per

second. Measure voltage with wheel rotating. If voltage is 0.075 volt

or more, go to next test. If voltage is less than 0.075 volt, check

wheel speed sensor and/or toothed ring for damage, wear and proper

installation. If damage or wear is found, replace faulty component and

retest. If components are not properly installed, reposition and

retest. If components are okay, replace wheel speed sensor and retest.

ECU Relay Continuity Test

Turn ignition off. Using an ohmmeter, check for continuity

between ECU connector terminals No. 1 and 3, and between terminals No.

1 and 20. See Fig. 2. If there is continuity at both test points, go

to next test. If there is no continuity at either or both test points,

check wiring. If wiring is faulty, repair and retest. If wiring is

okay, replace relay and retest.

Solenoid Valves Ground Circuit Continuity Test

1) Turn ignition off. Remove jumper wire from previous test.

Using an ohmmeter, check for continuity between ECU connector

terminals No. 1 and 11. See Fig. 2. If there is continuity, go to step

3).

2) If continuity does not exist, check for continuity between

ECU connector terminal No. 1 and valve block housing and between

hydraulic modulator and valve block housing. If continuity does not

exist between ECU connector terminal No. 1 and valve block housing,

repair wiring, and retest. If continuity does not exist between

housings, repair as necessary.

3) Reconnect jumper wire between ECU connector terminals No.

1 and 11. Check for continuity between ECU connector terminal No. 11

and valve block connector terminal No. 1 (Brown wire). See Figs. 2 and

4. If there is no continuity, repair wiring and retest.

Hydraulic Modulator/Pump Relay Ground Circuit Test

Turn ignition off. Reconnect pressure switch connector.

Depress brake pedal 20 times. Using an ohmmeter, check for continuity

between ECU connector terminals No. 1 and 14. If continuity exists, go

to next test. If continuity does not exist, check for continuity

between pressure switch terminals No. 1 (Brown wire) and No. 4

(Red/Yellow or White wire). See Figs. 1 and 4. If continuity does not

exist, replace pressure switch, and retest. If continuity exists,

check wiring between ECU terminal No. 14 and pressure switch terminal

No. 4. Repair wiring, and retest.

Low Pressure Warning Switch Test

Turn ignition off. Ensure brake fluid level is okay and fluid

level sensor switch float is in correct position (switch is in closed

position). Ensure accumulator is fully charged and pump is not

operating. Using an ohmmeter, check for continuity between ECU

Page 417 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

connector terminals No. 9 and 10. See Fig. 2. If there is continuity,

switch is okay. If continuity does not exist, check wiring. If wiring

is okay, replace switch, and retest.

Right Rear Wheel Speed Sensor Resistance Test

Turn ignition off. Using an ohmmeter, measure resistance

between ECU connector terminals No. 4 and 22. See Fig. 2. If

resistance is 800-1400 ohms, go to next test. If resistance is not as

specified, check resistance at right rear wheel speed sensor. If

resistance is correct, repair wiring and retest. If resistance is not

correct, replace wheel speed sensor and retest.

Left Rear Wheel Speed Sensor Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 6 and 24. See Fig. 2. If resistance is 800-1400 ohms, go

to next test. If resistance is not as specified, check resistance at

left rear wheel speed sensor. If resistance is correct, repair wiring

and retest. If resistance is not correct, replace wheel speed sensor,

and retest.

Right Front Wheel Speed Sensor Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 7 and 25. See Fig. 2. If resistance is 800-1400 ohms, go

to next test. If resistance is not as specified, check resistance at

right front wheel speed sensor. If resistance is correct, repair

wiring and retest. If resistance is not correct, replace wheel speed

sensor and retest.

Left Front Wheel Speed Sensor Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 5 and 23. See Fig. 2. If resistance is 800-1400 ohms, go

to next test. If resistance is not as specified, check resistance at

left front wheel speed sensor. If resistance is correct, repair

wiring, and retest. If resistance is not correct, replace wheel speed

sensor, and retest.

Right Rear Wheel Speed Sensor Shielding Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 1 and 4. See Fig. 2. If resistance is 20,000 ohms or

more, go to next test. If resistance is less than 20,000 ohms, check

shielding wire for damage. Replace harness if damage is found and

retest.

Left Rear Wheel Speed Sensor Shielding Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 1 and 6. See Fig. 2. If resistance is 20,000 ohms or

more, go to next test. If resistance is less than 20,000 ohms, check

shielding wire for damage. Replace harness if damage is found and

retest.

Right Front Wheel Speed Sensor Shielding Resistance Test

Using an ohmmeter, measure resistance between ECU connector

Page 418 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

terminals No. 1 and 7. See Fig. 2. If resistance is 20,000 ohms or

more, go to next test. If resistance is less than 20,000 ohms, check

shielding wire for damage. Replace harness if damaged, and retest.

Left Front Wheel Speed Sensor Shielding Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 1 and 5. See Fig. 2. If resistance is 20,000 ohms or

more, go to next test. If resistance is less than 20,000 ohms, check

shielding wire for damage. Replace harness if damaged, and retest.

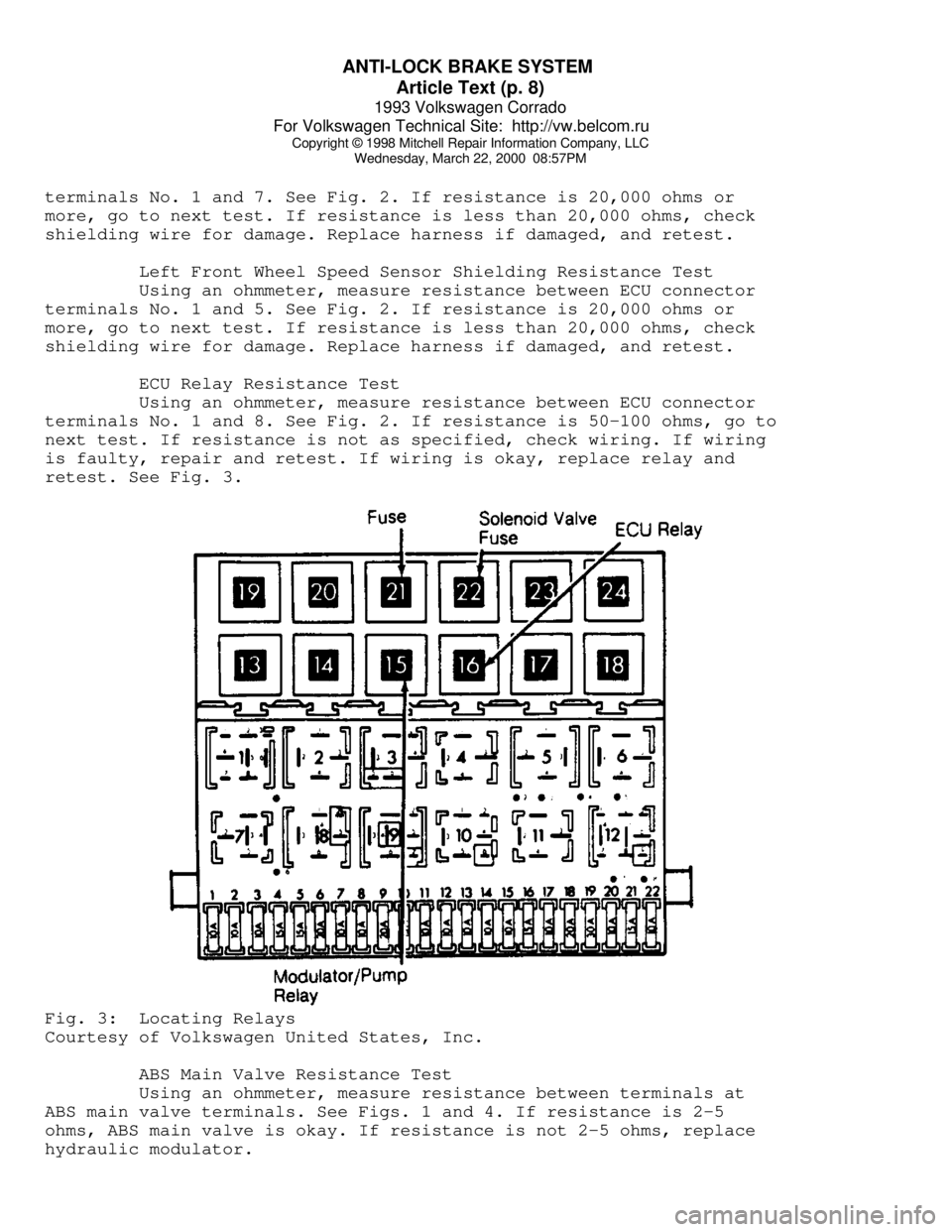

ECU Relay Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 1 and 8. See Fig. 2. If resistance is 50-100 ohms, go to

next test. If resistance is not as specified, check wiring. If wiring

is faulty, repair and retest. If wiring is okay, replace relay and

retest. See Fig. 3.Fig. 3: Locating Relays

Courtesy of Volkswagen United States, Inc.

ABS Main Valve Resistance Test

Using an ohmmeter, measure resistance between terminals at

ABS main valve terminals. See Figs. 1 and 4. If resistance is 2-5

ohms, ABS main valve is okay. If resistance is not 2-5 ohms, replace

hydraulic modulator.

Page 419 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ABS Main Valve Continuity Test

Using an ohmmeter, check for continuity between ABS main

valve terminal No. 1 (Black wire) and ECU connector terminal No. 18,

and between ABS main valve terminal No. 2 (Brown wire) and ground.

There should be continuity at both test points. If there is no

continuity at both test points, repair wiring and retest.

Rear Hydraulic Modulator Inlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 17. See Fig. 2. If resistance is 5-7 ohms, go to

next test. If resistance is not 5-7 ohms, measure between hydraulic

modulator block terminals No. 1 (Brown wire) and No. 5 (Gray wire).

See Fig. 4. If resistance is 5-7 ohms, check wiring between hydraulic

modulator and ECU for open circuit. If resistance is not 5-7 ohms,

replace hydraulic modulator.

Right Front Hydraulic Modulator Inlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 15. See Fig. 2. If resistance is 5-7 ohms, go to

next test. If resistance is not 5-7 ohms, measure between hydraulic

modulator terminals No. 1 (Brown wire) and No. 2 (Yellow wire). See

Fig. 4. If resistance is 5-7 ohms, check wiring between hydraulic

modulator and ECU for open circuit. If resistance is not 5-7 ohms,

replace hydraulic modulator.

Left Front Hydraulic Modulator Inlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 35. See Fig. 2. If resistance is 5-7 ohms, go to

next test. If resistance is not 5-7 ohms, measure between hydraulic

modulator terminals No. 1 (Brown wire) and No. 7 (Blue or Black/Green

wire). See Fig. 4. If resistance is 5-7 ohms, check wiring between

valve block and ECU for open circuit. If resistance is not 5-7 ohms,

replace hydraulic modulator.

Rear Hydraulic Modulator Outlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 33. See Fig. 2. If resistance is 3-5 ohms, go to

next test. If resistance is not 3-5 ohms, measure between valve block

terminals No. 1 (Brown wire) and No. 4 (White wire). See Fig. 4. If

resistance is 3-5 ohms, check wiring between hydraulic modulator and

ECU for open circuit. If resistance is not 3-5 ohms, replace hydraulic

modulator.

Right Hydraulic Modulator Block Outlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 34. See Fig. 2. If resistance is 3-5 ohms, go to

next test. If resistance is not 3-5 ohms, measure between hydraulic

modulator terminals No. 1 (Brown wire) and No. 3 (Green wire). See

Fig. 4. If resistance is 3-5 ohms, check wiring between hydraulic

modulator and ECU for open circuit. If resistance is not 3-5 ohms,

replace hydraulic modulator.

Page 420 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 10)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

Left Front Hydraulic Modulator Outlet Valve Resistance Test

Using an ohmmeter, measure resistance between ECU connector

terminals No. 11 and 16. See Fig. 2. If resistance is 3-5 ohms, go to

next test. If resistance is not 3-5 ohms, measure between hydraulic

modulator terminals No. 1 (Brown wire) and No. 6 (Black/Blue wire).

See Fig. 4. If resistance is 3-5 ohms, check wiring between hydraulic

modulator and ECU for open circuit. If resistance is not 3-5 ohms,

replace hydraulic modulator.

Hydraulic Modulator/Pump Relay Resistance Test

Turn ignition off. Unplug pressure switch connector from

hydraulic modulator. Using an ohmmeter, measure resistance between ECU

connector terminals No. 2 and 14. See Fig. 2. If resistance is 50-100

ohms, go to next test. If resistance is not 50-100 ohms, check wiring.

If wiring is faulty, repair wiring and retest. If wiring is okay,

replace relay and retest.

ABS Main Valve Function Test

Connect a jumper wire between ECU connector terminals No. 2

and 18. See Fig. 2. Depress brake pedal. Turn ignition on. Brake pedal

should rise slightly. If brake pedal did not rise slightly, check

wiring between terminals and hydraulic modulator. If wiring is okay,

replace hydraulic modulator.

Hydraulic Modulator/Pump Test

Turn ignition off. Depress brake pedal 25 times. Turn

ignition on. BRAKE and ANTILOCK lights should come on for 2-60

seconds. Pump should operate for 2-60 seconds, then turn off. If

lights do not come on, check wiring and warning light bulbs, and

retest. Also check bulb(s). If lights come on, then turn off, and pump

operates for 60 seconds maximum, then turns off, go to next test. If

pump does not operate and all other preceding tests have been

performed, replace hydraulic modulator/pump.

CAUTION: During VALVE BLOCK FUNCTION TESTS, DO NOT turn ignition on

longer than 60 seconds during any test.

Rear Valve Block Function Test

Connect a jumper wire ECU between ECU connector terminals No.

2, 17 and 33. See Fig. 2. Depress brake pedal. Rear wheels should be

locked up. Turn ignition on. Rear wheels should rotate. If wheels do

not rotate, replace hydraulic modulator. Turn ignition off.

Right Front Valve Block Function Test

Connect a jumper wire ECU between ECU connector terminals No.

2, 15 and 34. See Fig. 2. Depress brake pedal. Right front wheel

should be locked up. Turn ignition on. Right front wheel should

rotate. If wheel does not rotate, replace hydraulic modulator. Turn

ignition off.

Left Front Valve Block Function Test