VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 431 of 920

B - EMISSION APPLICATION

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

2.0L 4-Cyl. CIS-E Motronic

Major Control Systems & Devices ............. PCV, EVAP, TWC, FR,

(2) EGR, SPK, AP,

(1) O2, CEC, (2) MIL

Components & Other Related Devices ........ (4) EVAP-PV, EVAP-CV,

EGR-VA, EGR-TVV, SPK-CC

2.8L VR6 Motronic MFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, EGR,

SPK, AP, (1) O2, CEC, (2) MIL

Components & Other Related Devices ...... AP-EAP, AP-ERLY, AP-SV,

AP-SOV, EVAP-PV, EVAP-VC,

EGR-CV, EGR-TS, SPK-CC

(1) - Heated O2 sensor.

(2) - California only.

(3) - Digifant II only.

(4) - Two required.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ABBREVIATION DEFINITIONS

ABBREVIATION DEFINITION TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄAbbreviation Definition

AP ............................. Air Pump Injection System

AP-EAP .............................. AP Electric Air Pump

AP-ERLY ....................... AP Electric Air Pump Relay

AP-SV .......................... AP Solenoid (Inlet) Valve

AP-SOV ................................. AP Shut Off Valve

CEC ......................... Computerized Engine Controls

EGR ............................ Exhaust Gas Recirculation

EGR-CV ..................... EGR Control (Frequency) Valve

EGR-TS ............................ EGR Temperature Sensor

EGR-TVV ......................... EGR Thermal Vacuum Valve

EGR-VA .............................. EGR Vacuum Amplifier

EVAP ............................. Fuel Evaporative System

EVAP-CS ............................ EVAP Control Solenoid

EVAP-PV ................................. EVAP Purge Valve

EVAP-VC .............................. EVAP Vapor Canister

FR .................................. Fill Pipe Restrictor

HAI ....................................... Hot Air Intake

MIL ........... Malfunction Indicator (CHECK ENGINE) Light

MFI ............................. Multiport Fuel Injection

O2 ......................................... Oxygen Sensor

PCV ....................... Positive Crankcase Ventilation

SPK ................................. Spark Control System

SPK-CC ........................... SPK Computer Controlled

TWC ................................... Three-Way Catalyst

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 432 of 920

BRAKE SYSTEM

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

ARTICLE BEGINNING

1992-93 BRAKES

Volkswagen Disc & Drum

Corrado SLC

DESCRIPTION

All models are equipped with front disc brakes. Rear brakes

are either disc or drum. Parking brake acts on rear brakes and is

cable-actuated. All models use pressure regulator between front and

rear brake circuits to avoid rear wheel lock-up during hard braking.

A vacuum power-assist servo is used to ease brake pedal

application. A vacuum check valve, located in vacuum supply hose,

prevents vacuum leakdown when engine is off.

SERVICING

Manufacturer recommends replacing brake fluid every 2 years.

BLEEDING BRAKE SYSTEM

CAUTION: Ensure fluid level in master cylinder is adequate at all

times during bleeding procedure. Use only DOT 4 brake fluid.

DO NOT use DOT 5 silicone brake fluid.

BLEEDING PROCEDURES

NOTE: Manufacturer recommends bleeding brake system using Pressure

Bleeder (US 1116). If a pressure bleeder is not available,

use standard bleeding procedure.

1) Exhaust vacuum reserve from power unit by depressing brake

pedal several times. On ABS-equipped vehicles, depress brake pedal at

least 20 times to relieve system pressure.

2) On all vehicles, fill master cylinder with clean brake

fluid. If master cylinder was replaced, bleed master cylinder before

bleeding wheel calipers. Connect bleeder hose to appropriate caliper

bleeder valve. See BRAKE BLEEDING SEQUENCE table.

BRAKE BLEEDING SEQUENCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication (1) Sequence

Corrado SLC .................. Either Front Caliper First,

Either Rear Caliper First

(1) - Push lever of pressure regulator in direction of rear

axle when bleeding rear brakes.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 433 of 920

BRAKE SYSTEM

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

3) Submerge other end of hose in clean glass jar partially

filled with clean brake fluid. Pump brake pedal several times, then

hold down. Open bleeder valve. Holding pedal down, close bleeder

valve. Release brake pedal.

4) Repeat procedure until brake fluid shows no signs of air

bubbles. When bleeding rear brakes, push lever of pressure regulator

in direction of rear axle.

5) After bleeding ABS vehicles, turn ignition on. Allow pump

to run until it shuts off. If pump runs longer than 2 minutes, allow

pump to cool for 10 minutes. On all vehicles, ensure master cylinder

reservoir is full.

ADJUSTMENTS

BRAKE PRESSURE REGULATOR

CAUTION: DO NOT adjust pressure regulator with brake pedal depressed.

1) Depress brake pedal once firmly. Release brake pedal

quickly, watching for regulator lever to move when pedal is released.

If regulator lever does not move when pedal is released, replace

regulator. If regulator lever moved, go to next step.

2) Ensure vehicle fuel tank is full, luggage compartment is

empty and a driver is in driver seat. Raise and support vehicle. Using

Pressure Gauges (US 1016), attach one gauge to right rear brake

cylinder or caliper. If vehicle is ABS-equipped, go to next step. If

vehicle is not ABS-equipped, go to step 4).

3) Using Distributor "T" (803 611 755) and an additional 8"

(203 mm) of brakeline, connect one gauge in front of pressure

regulator. Bleed pressure gauge and hoses through valve on gauges.

Lower vehicle. Bounce rear of vehicle several times. Go to step 5).

4) Attach Pressure Gauges (US 1016) to left front brake

caliper. Bleed pressure gauge and hoses through valve on gauges. Lower

vehicle. Bounce rear of vehicle several times.

5) Pump brake pedal several times. Press on brake pedal until

reading on front gauge shows pressure given for first reading in the

BRAKE PRESSURES table. Hold brake pressure to specification. Rear

gauge reading should be within specification given for first reading

in the BRAKE PRESSURES table.

6) Increase pressure on brake pedal until reading on front

gauge shows pressure given for second reading in the BRAKE PRESSURES

table. Hold brake pressure to specification. Rear gauge reading should

be within specification given for second reading in BRAKE PRESSURES

table. If pressures are within specification, brake pressure regulator

is functioning properly. If pressures are not within specification, go

to next step.

7) If pressure is too high, decrease spring pressure on

regulator. If pressure is too low, increase spring pressure on

regulator. If adjusting spring pressure on regulator does not bring

pressures within specification, replace pressure regulator. Disconnect

gauges, and bleed brakes.

Page 434 of 920

BRAKE SYSTEM

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

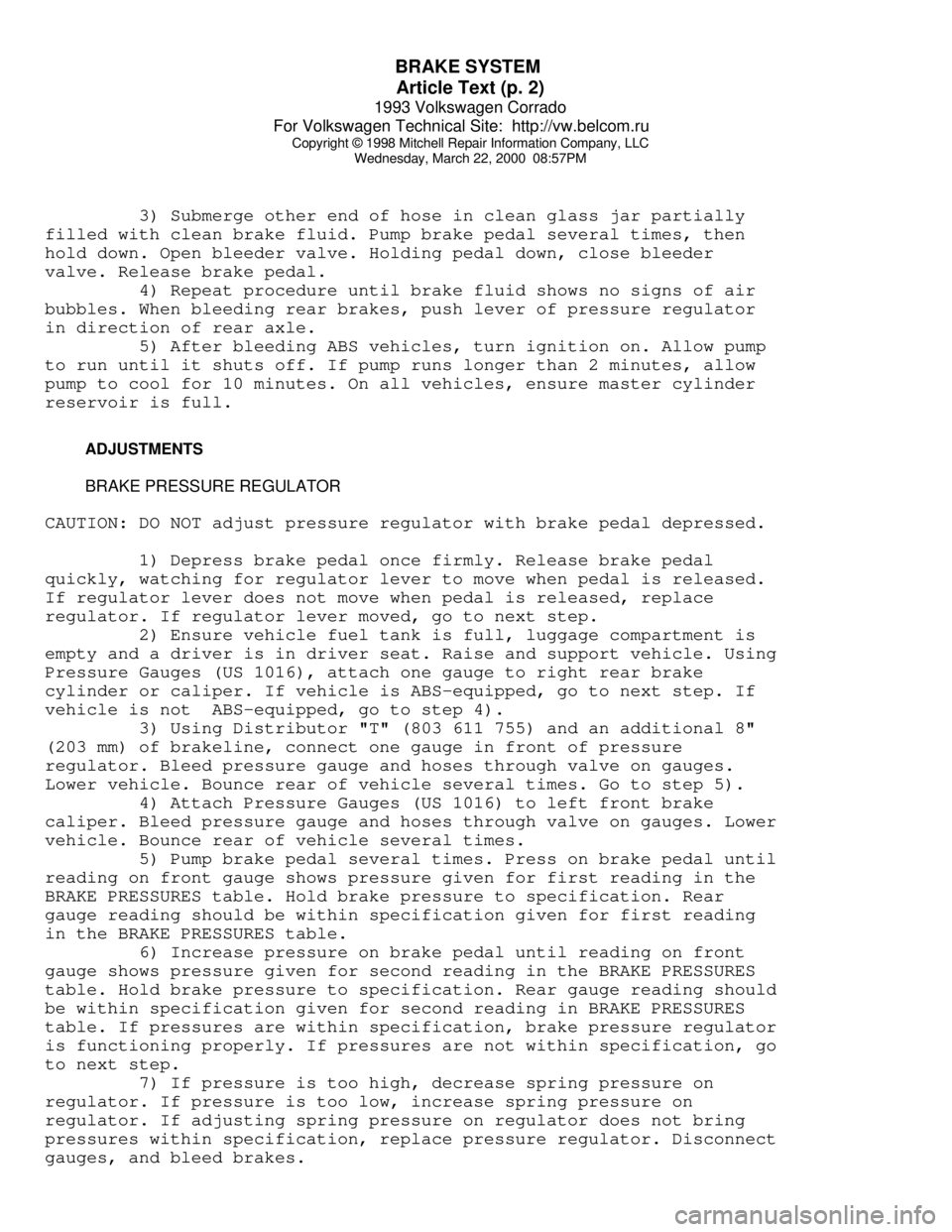

Wednesday, March 22, 2000 08:57PMFig. 1: Identifying Brake Pressure Regulator Components (Typical)

Courtesy of Volkswagen United States, Inc.

BRAKE PRESSURES TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Front Gauge Rear Gauge

Application psi (kg/cm

ý) psi (kg/cmý)

1st Reading ......... 725 (51) ......... 391-478 (28-34)

2nd Reading ........ 1450 (102) ........ 696-783 (49-55)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ STOPLIGHT SWITCH

NOTE: Stoplight switches mounted on master cylinder are

non-adjustable.

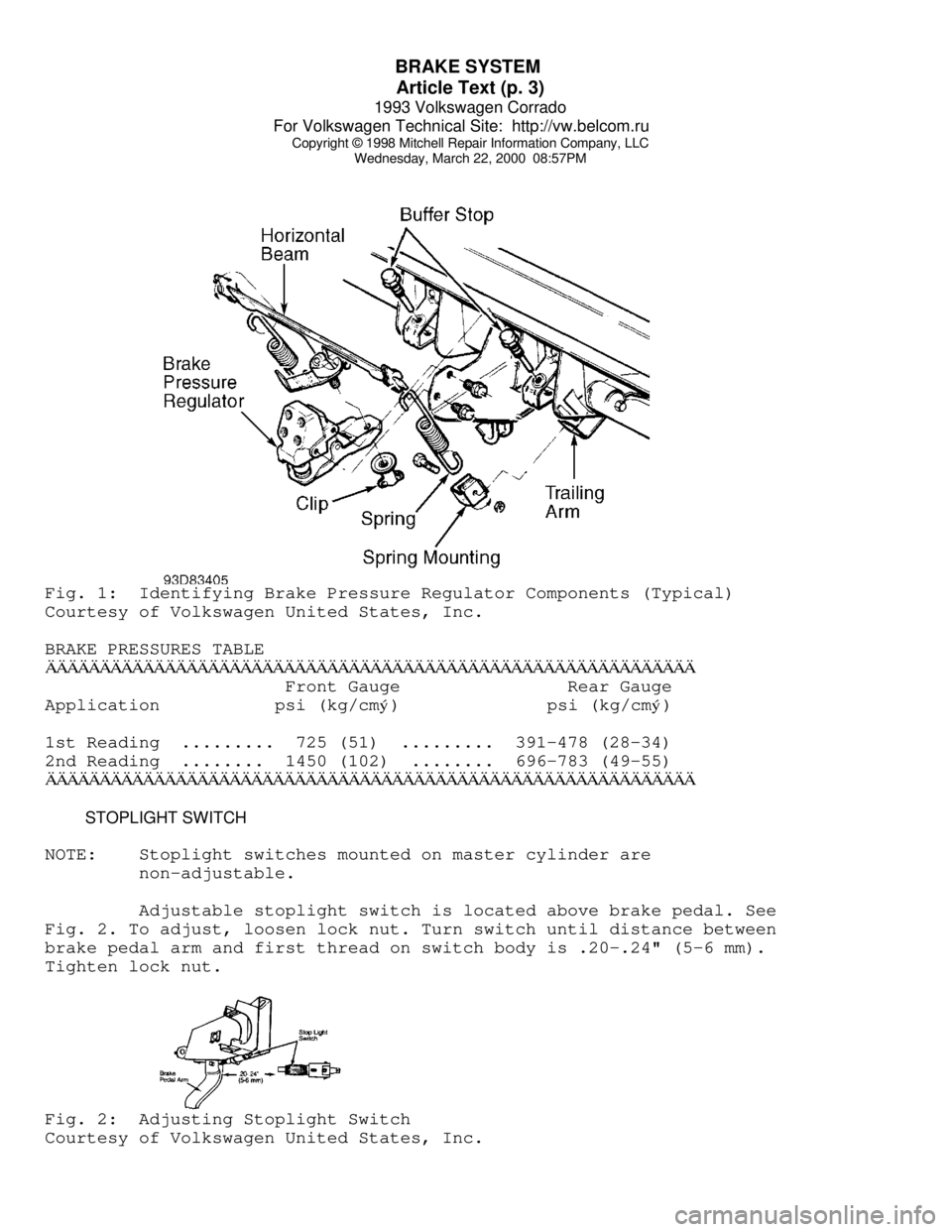

Adjustable stoplight switch is located above brake pedal. See

Fig. 2. To adjust, loosen lock nut. Turn switch until distance between

brake pedal arm and first thread on switch body is .20-.24" (5-6 mm).

Tighten lock nut.Fig. 2: Adjusting Stoplight Switch

Courtesy of Volkswagen United States, Inc.

Page 435 of 920

BRAKE SYSTEM

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

PARKING BRAKE

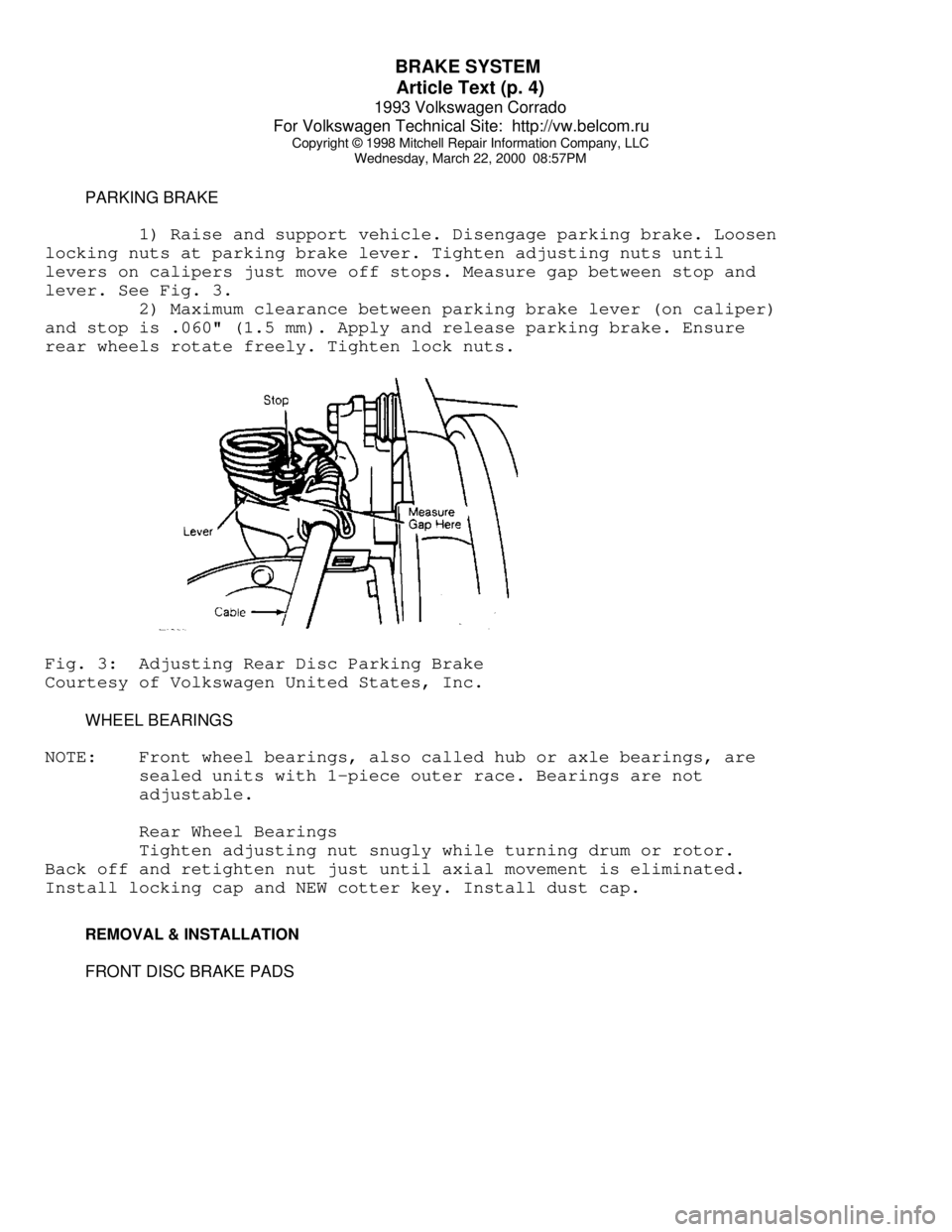

1) Raise and support vehicle. Disengage parking brake. Loosen

locking nuts at parking brake lever. Tighten adjusting nuts until

levers on calipers just move off stops. Measure gap between stop and

lever. See Fig. 3.

2) Maximum clearance between parking brake lever (on caliper)

and stop is .060" (1.5 mm). Apply and release parking brake. Ensure

rear wheels rotate freely. Tighten lock nuts.Fig. 3: Adjusting Rear Disc Parking Brake

Courtesy of Volkswagen United States, Inc.

WHEEL BEARINGS

NOTE: Front wheel bearings, also called hub or axle bearings, are

sealed units with 1-piece outer race. Bearings are not

adjustable.

Rear Wheel Bearings

Tighten adjusting nut snugly while turning drum or rotor.

Back off and retighten nut just until axial movement is eliminated.

Install locking cap and NEW cotter key. Install dust cap.

REMOVAL & INSTALLATION

FRONT DISC BRAKE PADS

Page 436 of 920

BRAKE SYSTEM

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

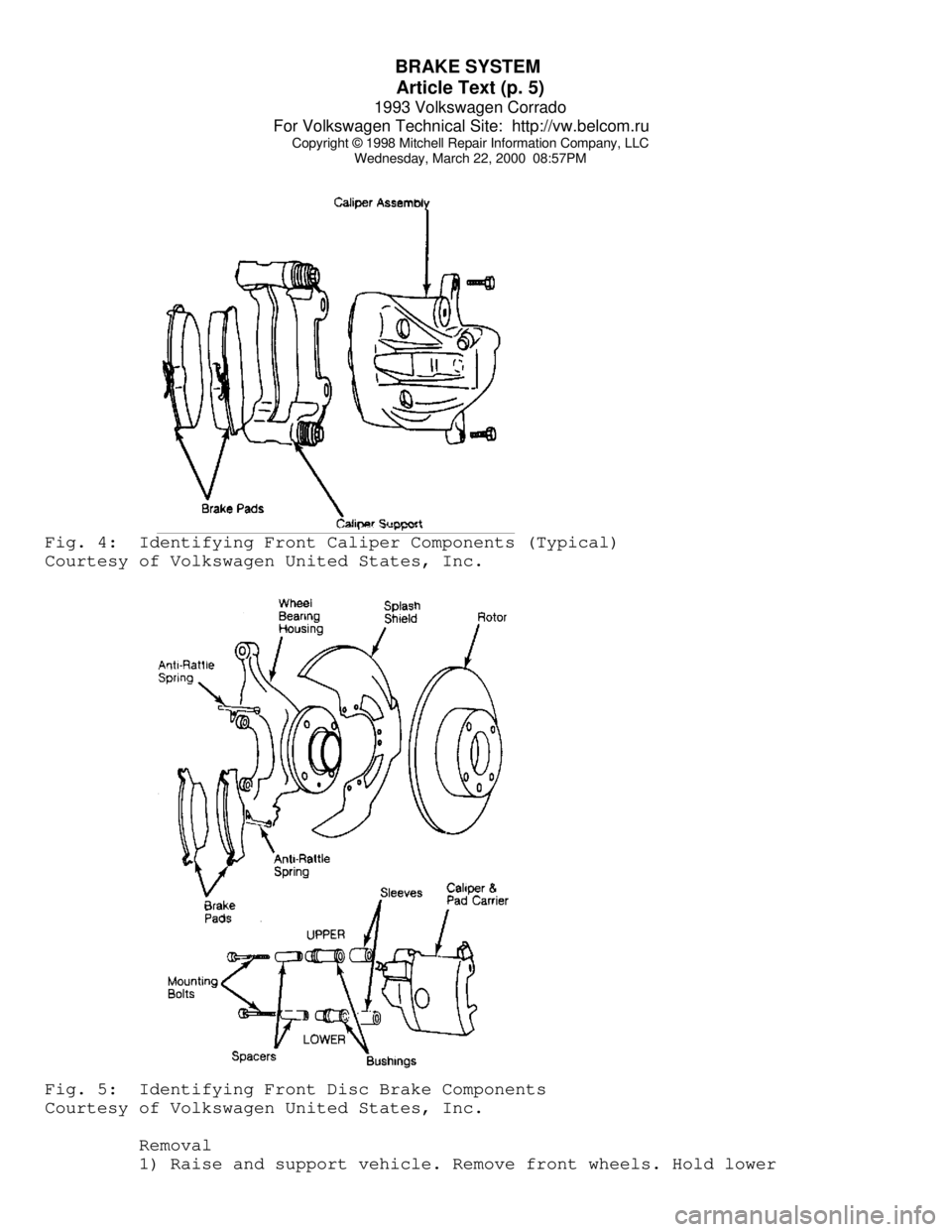

Wednesday, March 22, 2000 08:57PMFig. 4: Identifying Front Caliper Components (Typical)

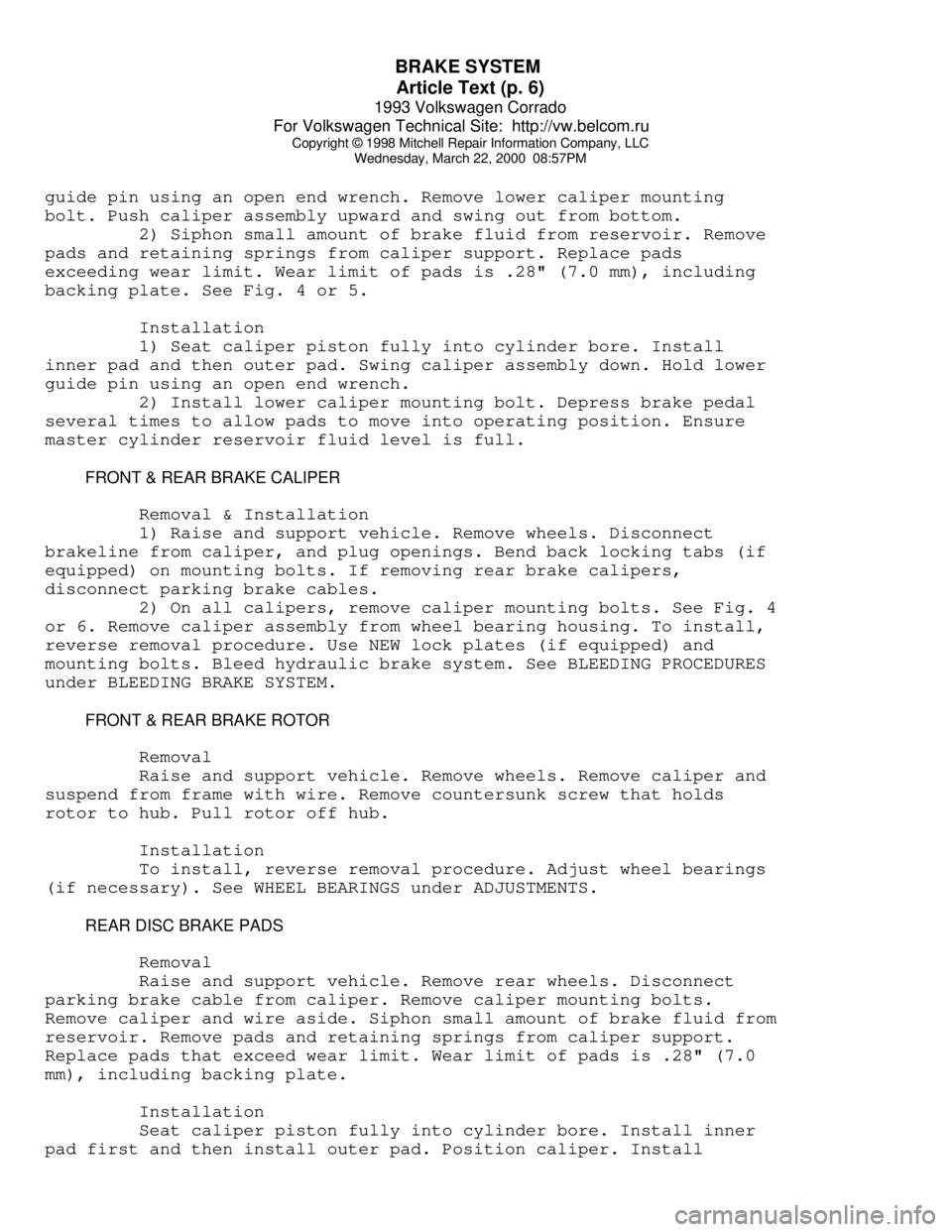

Courtesy of Volkswagen United States, Inc.Fig. 5: Identifying Front Disc Brake Components

Courtesy of Volkswagen United States, Inc.

Removal

1) Raise and support vehicle. Remove front wheels. Hold lower

Page 437 of 920

BRAKE SYSTEM

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

guide pin using an open end wrench. Remove lower caliper mounting

bolt. Push caliper assembly upward and swing out from bottom.

2) Siphon small amount of brake fluid from reservoir. Remove

pads and retaining springs from caliper support. Replace pads

exceeding wear limit. Wear limit of pads is .28" (7.0 mm), including

backing plate. See Fig. 4 or 5.

Installation

1) Seat caliper piston fully into cylinder bore. Install

inner pad and then outer pad. Swing caliper assembly down. Hold lower

guide pin using an open end wrench.

2) Install lower caliper mounting bolt. Depress brake pedal

several times to allow pads to move into operating position. Ensure

master cylinder reservoir fluid level is full.

FRONT & REAR BRAKE CALIPER

Removal & Installation

1) Raise and support vehicle. Remove wheels. Disconnect

brakeline from caliper, and plug openings. Bend back locking tabs (if

equipped) on mounting bolts. If removing rear brake calipers,

disconnect parking brake cables.

2) On all calipers, remove caliper mounting bolts. See Fig. 4

or 6. Remove caliper assembly from wheel bearing housing. To install,

reverse removal procedure. Use NEW lock plates (if equipped) and

mounting bolts. Bleed hydraulic brake system. See BLEEDING PROCEDURES

under BLEEDING BRAKE SYSTEM.

FRONT & REAR BRAKE ROTOR

Removal

Raise and support vehicle. Remove wheels. Remove caliper and

suspend from frame with wire. Remove countersunk screw that holds

rotor to hub. Pull rotor off hub.

Installation

To install, reverse removal procedure. Adjust wheel bearings

(if necessary). See WHEEL BEARINGS under ADJUSTMENTS.

REAR DISC BRAKE PADS

Removal

Raise and support vehicle. Remove rear wheels. Disconnect

parking brake cable from caliper. Remove caliper mounting bolts.

Remove caliper and wire aside. Siphon small amount of brake fluid from

reservoir. Remove pads and retaining springs from caliper support.

Replace pads that exceed wear limit. Wear limit of pads is .28" (7.0

mm), including backing plate.

Installation

Seat caliper piston fully into cylinder bore. Install inner

pad first and then install outer pad. Position caliper. Install

Page 438 of 920

BRAKE SYSTEM

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

caliper mounting bolts. Depress brake pedal several times to allow

pads to move into operating position. Ensure master cylinder reservoir

fluid level is full.

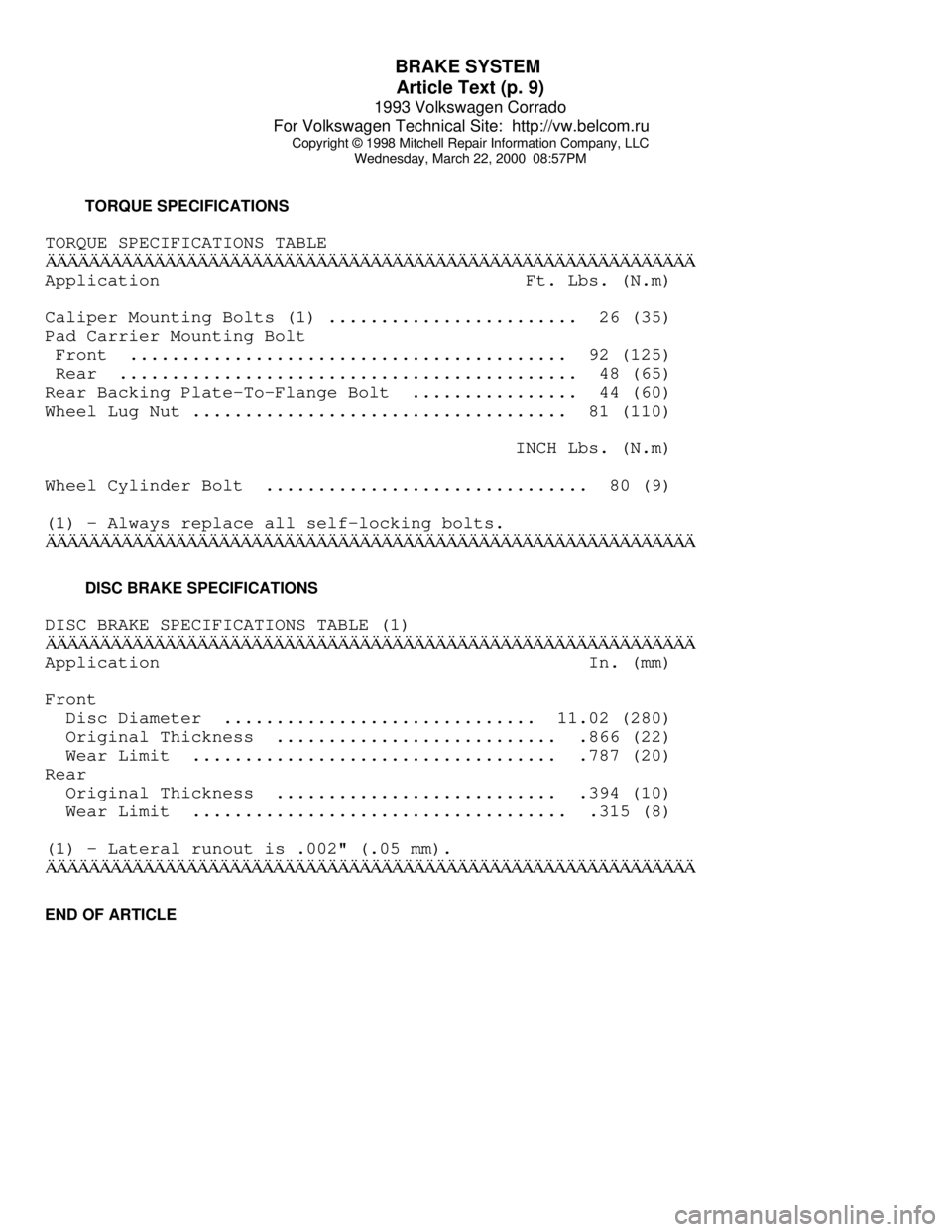

MASTER CYLINDER

Removal

1) Drain master cylinder reservoir. Remove cover plate (if

equipped). Disconnect brakelines and wiring at master cylinder.

2) On models without power assist servo, disconnect brake

push rod at brake pedal. On models equipped with power assist servo,

remove master cylinder from servo. Be careful to keep any spacers used

on attaching bolts for proper installation.

Installation

To install, reverse removal procedure. Always use NEW "O"

ring between master cylinder and power assist servo. Bleed hydraulic

system.

VACUUM POWER ASSIST SERVO

Removal

Remove master cylinder from power assist servo. Disconnect

brake push rod from brake pedal. Disconnect vacuum hose from servo.

Remove servo from vehicle.

NOTE: Not all vehicles have all components.

Installation

To install, reverse removal procedure. Before attaching brake

push rod to brake pedal, check and adjust push rod length. Always use

NEW damping ring, washer, filter and "O" ring (as equipped). Slots in

damping washer and filter must be offset 180 degrees (if equipped).

Complete installation, and bleed hydraulic system.

OVERHAUL

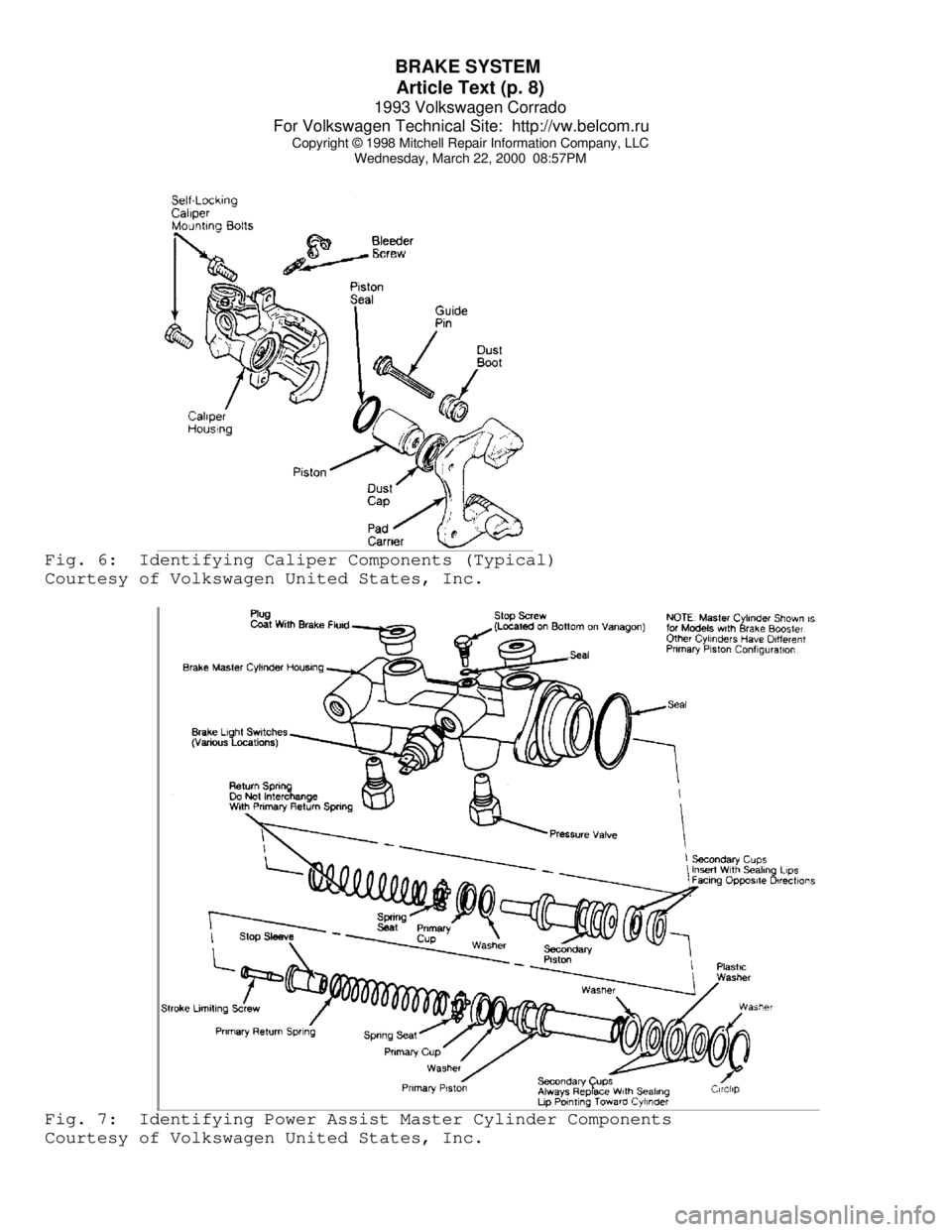

NOTE: Black staining from piston seal wear may show on caliper

bore walls and piston. This staining is normal. DO NOT

disassemble power assist servo as parts are not available.

Refer to appropriate illustration for caliper and master

cylinder overhaul. See Figs. 6 and 7.

Page 439 of 920

BRAKE SYSTEM

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PMFig. 6: Identifying Caliper Components (Typical)

Courtesy of Volkswagen United States, Inc.Fig. 7: Identifying Power Assist Master Cylinder Components

Courtesy of Volkswagen United States, Inc.

Page 440 of 920

BRAKE SYSTEM

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ft. Lbs. (N.m)

Caliper Mounting Bolts (1) ........................ 26 (35)

Pad Carrier Mounting Bolt

Front .......................................... 92 (125)

Rear ............................................ 48 (65)

Rear Backing Plate-To-Flange Bolt ................ 44 (60)

Wheel Lug Nut .................................... 81 (110)

INCH Lbs. (N.m)

Wheel Cylinder Bolt ............................... 80 (9)

(1) - Always replace all self-locking bolts.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ DISC BRAKE SPECIFICATIONS

DISC BRAKE SPECIFICATIONS TABLE (1)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

Front

Disc Diameter .............................. 11.02 (280)

Original Thickness ........................... .866 (22)

Wear Limit ................................... .787 (20)

Rear

Original Thickness ........................... .394 (10)

Wear Limit .................................... .315 (8)

(1) - Lateral runout is .002" (.05 mm).

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE