VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 561 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 32)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

zero. Rotate camshaft gear in opposite direction as far as possible

and note reading.

To determine timing gear runout, mount dial indicator with

tip resting on face edge of camshaft gear. Adjust indicator to zero.

Rotate camshaft gear 360 degrees and note reading. If backlash or

runout exceed specifications, replace camshaft and/or crankshaft

gear.

REAR MAIN OIL SEAL

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

INSTALLATION

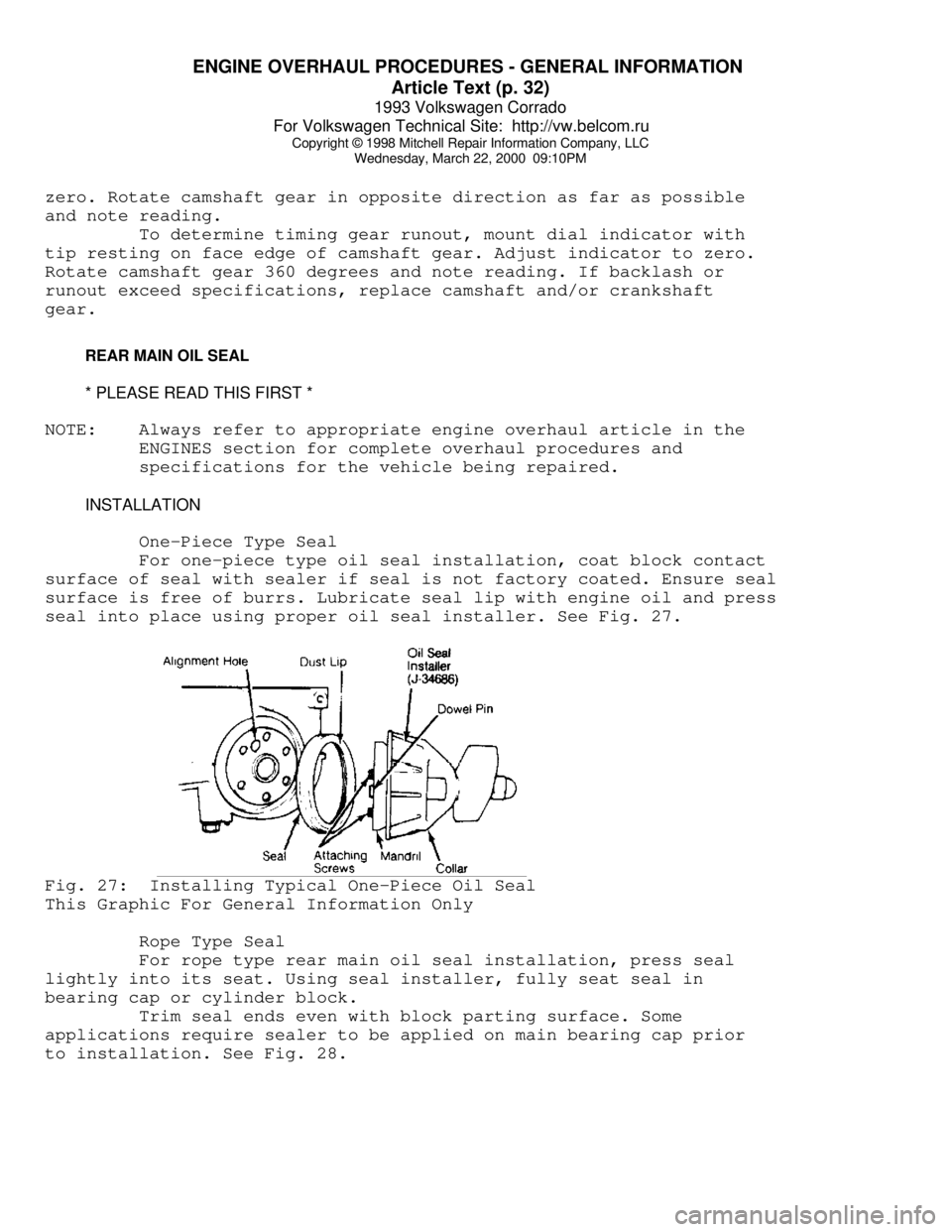

One-Piece Type Seal

For one-piece type oil seal installation, coat block contact

surface of seal with sealer if seal is not factory coated. Ensure seal

surface is free of burrs. Lubricate seal lip with engine oil and press

seal into place using proper oil seal installer. See Fig. 27.Fig. 27: Installing Typical One-Piece Oil Seal

This Graphic For General Information Only

Rope Type Seal

For rope type rear main oil seal installation, press seal

lightly into its seat. Using seal installer, fully seat seal in

bearing cap or cylinder block.

Trim seal ends even with block parting surface. Some

applications require sealer to be applied on main bearing cap prior

to installation. See Fig. 28.

Page 562 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 33)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PMFig. 28: Typical Rope Seal Installation

This Graphic For General Information Only

Split-Rubber Type Seal

Follow manufacturers procedures when installing split-rubber

type rear main oil seals. Installation procedures vary with engine

type. See appropriate ENGINE article in this section. See Fig. 29.Fig. 29: Typical Split-Rubber Seal Installation

This Graphic For General Information Only

OIL PUMP

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

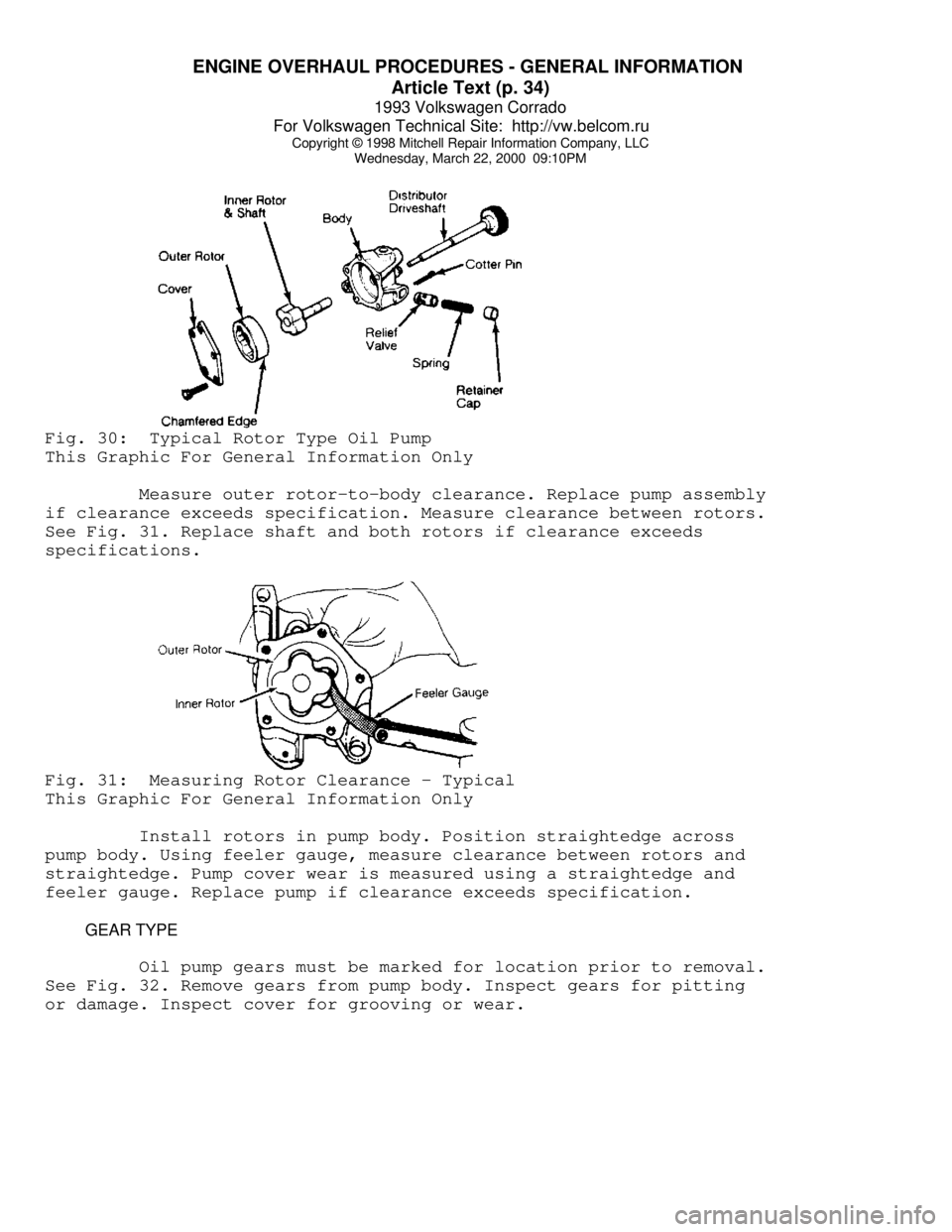

ROTOR-TYPE

Oil pump rotors must be marked for location prior to removal.

See Fig. 30. Remove outer rotor and measure thickness and diameter.

Measure inner rotor thickness. Inspect shaft for scoring or wear.

Inspect rotors for pitting or damage. Inspect cover for grooving or

wear. Replace components if worn or damaged.

Page 563 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 34)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PMFig. 30: Typical Rotor Type Oil Pump

This Graphic For General Information Only

Measure outer rotor-to-body clearance. Replace pump assembly

if clearance exceeds specification. Measure clearance between rotors.

See Fig. 31. Replace shaft and both rotors if clearance exceeds

specifications.Fig. 31: Measuring Rotor Clearance - Typical

This Graphic For General Information Only

Install rotors in pump body. Position straightedge across

pump body. Using feeler gauge, measure clearance between rotors and

straightedge. Pump cover wear is measured using a straightedge and

feeler gauge. Replace pump if clearance exceeds specification.

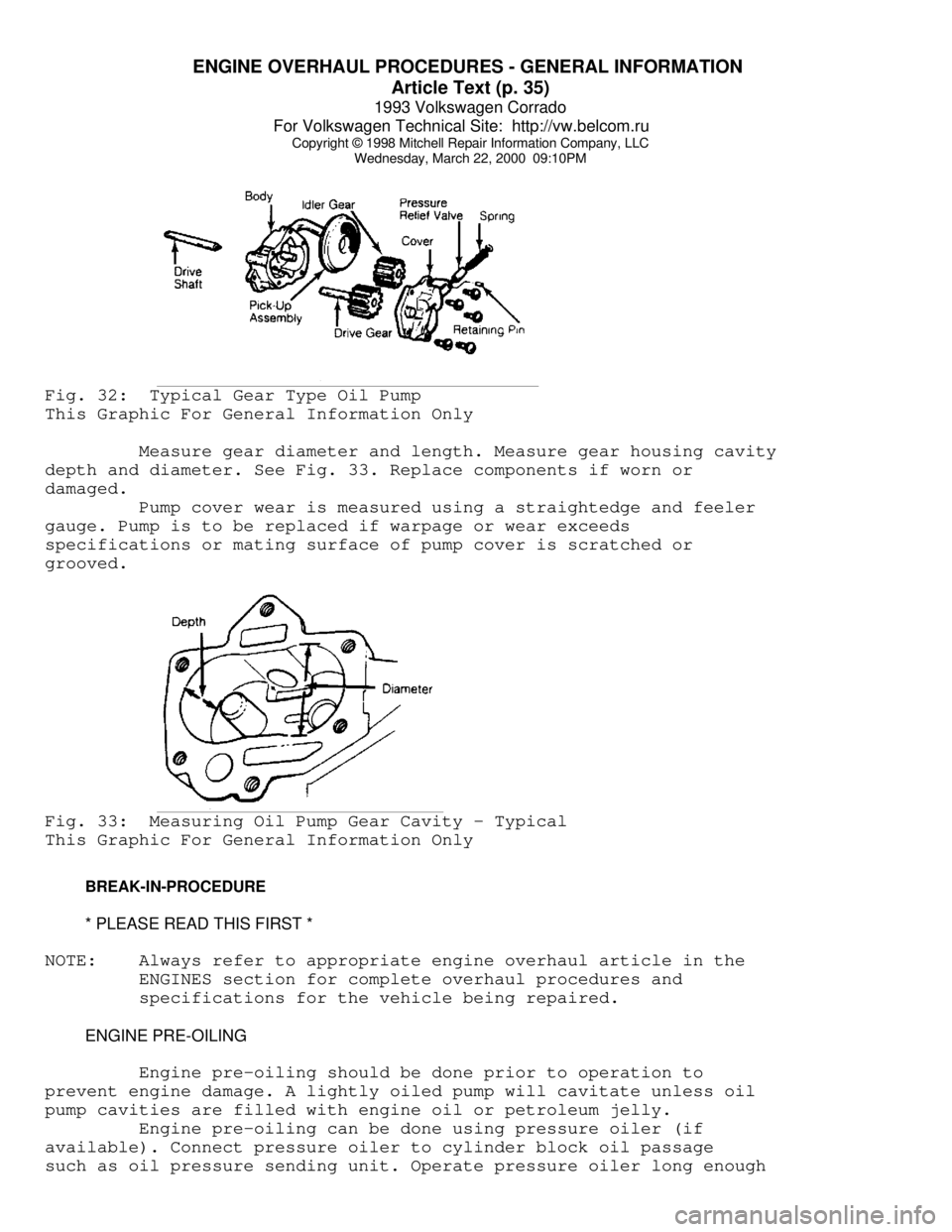

GEAR TYPE

Oil pump gears must be marked for location prior to removal.

See Fig. 32. Remove gears from pump body. Inspect gears for pitting

or damage. Inspect cover for grooving or wear.

Page 564 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 35)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PMFig. 32: Typical Gear Type Oil Pump

This Graphic For General Information Only

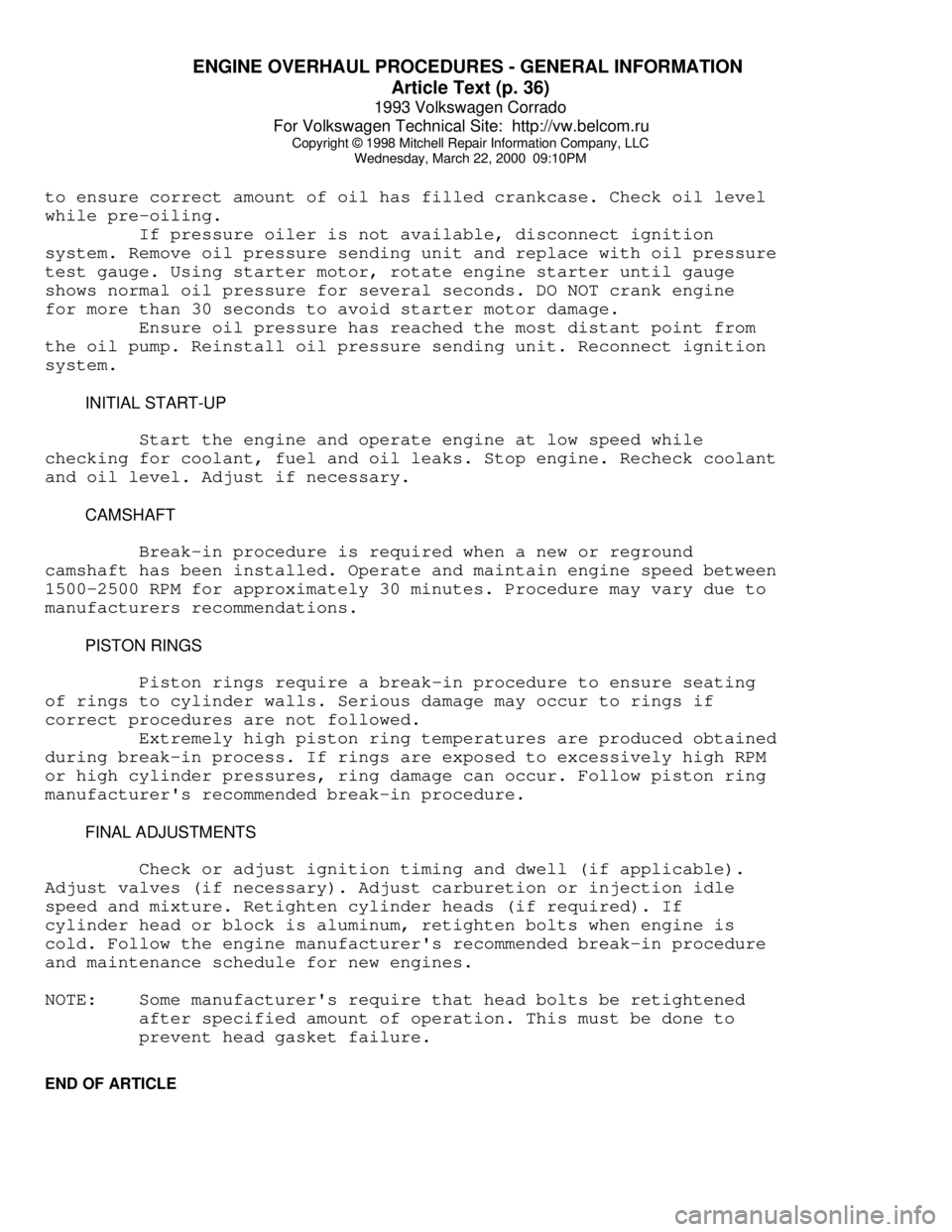

Measure gear diameter and length. Measure gear housing cavity

depth and diameter. See Fig. 33. Replace components if worn or

damaged.

Pump cover wear is measured using a straightedge and feeler

gauge. Pump is to be replaced if warpage or wear exceeds

specifications or mating surface of pump cover is scratched or

grooved.Fig. 33: Measuring Oil Pump Gear Cavity - Typical

This Graphic For General Information Only

BREAK-IN-PROCEDURE

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

ENGINE PRE-OILING

Engine pre-oiling should be done prior to operation to

prevent engine damage. A lightly oiled pump will cavitate unless oil

pump cavities are filled with engine oil or petroleum jelly.

Engine pre-oiling can be done using pressure oiler (if

available). Connect pressure oiler to cylinder block oil passage

such as oil pressure sending unit. Operate pressure oiler long enough

Page 565 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 36)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

to ensure correct amount of oil has filled crankcase. Check oil level

while pre-oiling.

If pressure oiler is not available, disconnect ignition

system. Remove oil pressure sending unit and replace with oil pressure

test gauge. Using starter motor, rotate engine starter until gauge

shows normal oil pressure for several seconds. DO NOT crank engine

for more than 30 seconds to avoid starter motor damage.

Ensure oil pressure has reached the most distant point from

the oil pump. Reinstall oil pressure sending unit. Reconnect ignition

system.

INITIAL START-UP

Start the engine and operate engine at low speed while

checking for coolant, fuel and oil leaks. Stop engine. Recheck coolant

and oil level. Adjust if necessary.

CAMSHAFT

Break-in procedure is required when a new or reground

camshaft has been installed. Operate and maintain engine speed between

1500-2500 RPM for approximately 30 minutes. Procedure may vary due to

manufacturers recommendations.

PISTON RINGS

Piston rings require a break-in procedure to ensure seating

of rings to cylinder walls. Serious damage may occur to rings if

correct procedures are not followed.

Extremely high piston ring temperatures are produced obtained

during break-in process. If rings are exposed to excessively high RPM

or high cylinder pressures, ring damage can occur. Follow piston ring

manufacturer's recommended break-in procedure.

FINAL ADJUSTMENTS

Check or adjust ignition timing and dwell (if applicable).

Adjust valves (if necessary). Adjust carburetion or injection idle

speed and mixture. Retighten cylinder heads (if required). If

cylinder head or block is aluminum, retighten bolts when engine is

cold. Follow the engine manufacturer's recommended break-in procedure

and maintenance schedule for new engines.

NOTE: Some manufacturer's require that head bolts be retightened

after specified amount of operation. This must be done to

prevent head gasket failure.

END OF ARTICLE

Page 566 of 920

F - BASIC TESTING

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Basic Diagnostic Procedures

Cabriolet, Corrado SLC, EuroVan, Fox, Golf,

GTI, Jetta, Passat GL, Passat GLX

INTRODUCTION

The following diagnostic steps will help prevent overlooking

a simple problem. This is also where to begin diagnosis for a no-start

condition.

The first step in diagnosing any driveability problem is

verifying the customer's complaint with a test drive under the

conditions the problem reportedly occurred.

Before entering self-diagnostics (if equipped), perform a

careful and complete visual inspection. Most engine control problems

result from mechanical breakdowns, poor electrical connections, or

damaged/misrouted vacuum hoses. Before condemning the computerized

system, perform each test listed in this article.

NOTE: Perform all voltage tests with a Digital Volt-Ohmmeter

(DVOM) with a minimum 10-megohm input impedance, unless

stated otherwise in test procedure.

PRELIMINARY INSPECTION & ADJUSTMENTS

VISUAL INSPECTION

Visually inspect all electrical wiring, looking for chafed,

stretched, cut or pinched wiring. Ensure electrical connectors fit

tightly and are not corroded. Ensure vacuum hoses are properly routed

and are not pinched or cut. See M - VACUUM DIAGRAMS article in this

section to verify routing and connections (if necessary). Inspect air

induction system for possible vacuum leaks.

MECHANICAL INSPECTION

Compression

Check engine mechanical condition with a compression gauge,

vacuum gauge, or an engine analyzer. See engine analyzer manual for

specific instructions.

WARNING: DO NOT use ignition switch during compression tests on fuel

injected vehicles. Use a remote starter to crank engine. Fuel

injectors on many models are triggered by ignition switch

during cranking mode, which can create a fire hazard or

contaminate the engine's oiling system.

COMPRESSION SPECIFICATION TABLE

Page 567 of 920

F - BASIC TESTING

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Compression

Pressure Compression

Application psi (kg/cm

ý) Ratio

Cabriolet ............. 131-174 (9.2-12.2) ........... 10.0:1

Corrado SLC ........... 157-186 (11.0-13.0) .......... 10.0:1

EuroVan ............... 128-170 (9.0-12.0) ........... 8.5:1

Fox ................... 128-170 (9.0-12.0) ............ 9.0:1

Golf & GTI ............ 142-186 (10.0-13.0) .......... 10.0:1

Jetta ................. 142-186 (10.0-13.0) .......... 10.0:1

Passat GL (2.0L) ...... 142-186 (10.0-13.0) .......... 10.8:1

Passat GLX (2.8L) ..... 142-186 (10.0-13.0) .......... 10.0:1

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Exhaust System Backpressure

The exhaust system can be checked with a vacuum or pressure

gauge. Remove O2 sensor or air injection check valve (if equipped).

Connect a 0-5 psi pressure gauge and operate engine at 2500 RPM. If

exhaust system backpressure is greater than 2 psi, exhaust system or

catalytic converter is plugged.

If a vacuum gauge is used, connect vacuum gauge hose to

intake manifold vacuum port and start engine. Observe vacuum gauge.

Open throttle part way and hold steady. If vacuum gauge reading slowly

drops after stabilizing, check exhaust system for restriction.

FUEL SYSTEM

FUEL SYSTEM APPLICATION

FUEL SYSTEM APPLICATION TABLE

ÚÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

³

³ ³Engine³ ³

³ Model

³ Engine ³ ID ³ Fuel System ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Cabriolet

³ 1.8L ³ 2H ³ Digifant II MFI ³

³

³ 8-Valve ³ ³ (1) ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Corrado SLC

³ 2.8L VR6³ AAA ³ Motronic MFI (2)³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ EuroVan

³ 2.5L ³ AAF ³ Digifant MFI ³

³

³10-Valve ³ ³ ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Fox

³ 1.8L ³ ABG ³ Digifant II MFI ³

³

³ 8-Valve ³ ³ (1) ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Golf

³ 2.0L ³ ABA ³ Motronic MFI (2)³

³

³ 8-Valve ³ ³ ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ GTI

³ 2.0L ³ ABA ³ Motronic MFI (2)³

³

³ 8-Valve ³ ³ ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

Page 568 of 920

F - BASIC TESTING

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM³ Jetta ³ 2.0L ³ ABA ³ Motronic MFI (2)³

³

³ 8-Valve ³ ³ ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Passat GL

³ 2.0L ³ 9A ³ CIS-E Motronic ³

³

³16-Valve ³ ³ MFI (2) ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³ Passat GLX

³ 2.8L VR6³ AAA ³ Motronic MFI (2)³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³(1) - California vehicles are equipped with

³

³ Digifant I.

³

³(2) - Sequential Multiport Fuel Injection.

³

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ FUEL PRESSURE

Basic diagnosis of fuel system should begin with determining

fuel system pressure.

WARNING: ALWAYS relieve fuel pressure before disconnecting any fuel

injection-related component. DO NOT allow fuel to contact

engine or electrical components.

CIS-E Motronic

1) Ensure ignition is off. Wrap a cloth around fuel

distributor port near cold start valve. Slowly loosen distributor port

near cold start valve to release fuel pressure. Connect fuel pressure

gauge between fuel distributor port and end of fuel line to cold start

valve. Disconnect differential pressure regulator harness connector.

2) Start engine and let it run. System fuel pressure should

89-96 psi (6.3-6.7 kg/cm

ý). If system fuel pressure is lower than

specification, perform fuel volume check. If fuel volume is okay,

replace fuel pressure regulator.

3) If fuel pressure is greater than specification, remove

return hose from pressure regulator and place in a container. Repeat

test. If system pressure is okay, check for restricted fuel return

line. If pressure is incorrect, replace fuel pressure regulator.

4) Turn ignition off. After 10 minutes, residual pressure

should be 48 psi (3.4 kg/cm

ý). After 20 minutes, residual pressure

should be 46 psi (3.2 kg/cm

ý). If system fuel pressure is low, check

fuel pump check valve, sensor plate free play, fuel distributor "O"

rings and seats. Replace if necessary. If these components are okay,

replace fuel pressure regulator.

Digifant

1) Ensure ignition is off. Wrap a cloth around service port

on fuel plenum. Slowly loosen service port on fuel plenum to release

fuel pressure. Install fuel pressure gauge at service port on fuel

plenum. Fuel pressure gauge must have reading range of 0-50 psi. Start

engine and allow it to idle. System fuel pressure should be

approximately 36 psi (2.5 kg/cm

ý).

2) Disconnect vacuum hose from top of fuel pressure

regulator. Fuel pressure should increase to approximately 44 psi (3

Page 569 of 920

F - BASIC TESTING

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

kg/cmý). Turn engine off. After 10 minutes, residual pressure should

be 29 psi (2 kg/cm

ý). If system pressure is too high, replace fuel

pressure regulator.

3) If residual pressure is too low, operate engine until

system pressure builds up, then pinch off Blue fuel return line. If

pressure holds, replace the fuel regulator. If fuel pressure is low,

check for leaks at fuel lines, fuel injectors and fuel pump check

valve

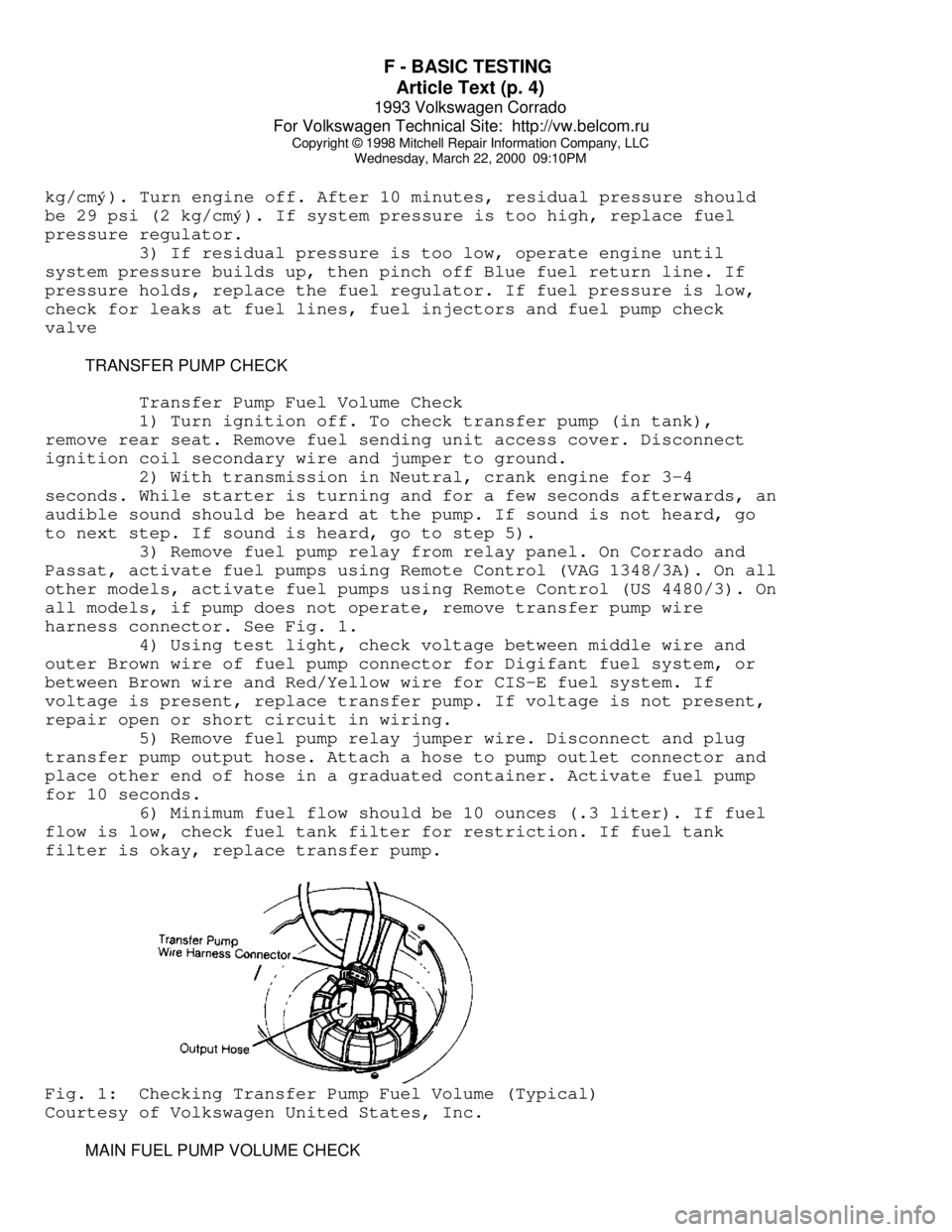

TRANSFER PUMP CHECK

Transfer Pump Fuel Volume Check

1) Turn ignition off. To check transfer pump (in tank),

remove rear seat. Remove fuel sending unit access cover. Disconnect

ignition coil secondary wire and jumper to ground.

2) With transmission in Neutral, crank engine for 3-4

seconds. While starter is turning and for a few seconds afterwards, an

audible sound should be heard at the pump. If sound is not heard, go

to next step. If sound is heard, go to step 5).

3) Remove fuel pump relay from relay panel. On Corrado and

Passat, activate fuel pumps using Remote Control (VAG 1348/3A). On all

other models, activate fuel pumps using Remote Control (US 4480/3). On

all models, if pump does not operate, remove transfer pump wire

harness connector. See Fig. 1.

4) Using test light, check voltage between middle wire and

outer Brown wire of fuel pump connector for Digifant fuel system, or

between Brown wire and Red/Yellow wire for CIS-E fuel system. If

voltage is present, replace transfer pump. If voltage is not present,

repair open or short circuit in wiring.

5) Remove fuel pump relay jumper wire. Disconnect and plug

transfer pump output hose. Attach a hose to pump outlet connector and

place other end of hose in a graduated container. Activate fuel pump

for 10 seconds.

6) Minimum fuel flow should be 10 ounces (.3 liter). If fuel

flow is low, check fuel tank filter for restriction. If fuel tank

filter is okay, replace transfer pump.Fig. 1: Checking Transfer Pump Fuel Volume (Typical)

Courtesy of Volkswagen United States, Inc.

MAIN FUEL PUMP VOLUME CHECK

Page 570 of 920

F - BASIC TESTING

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

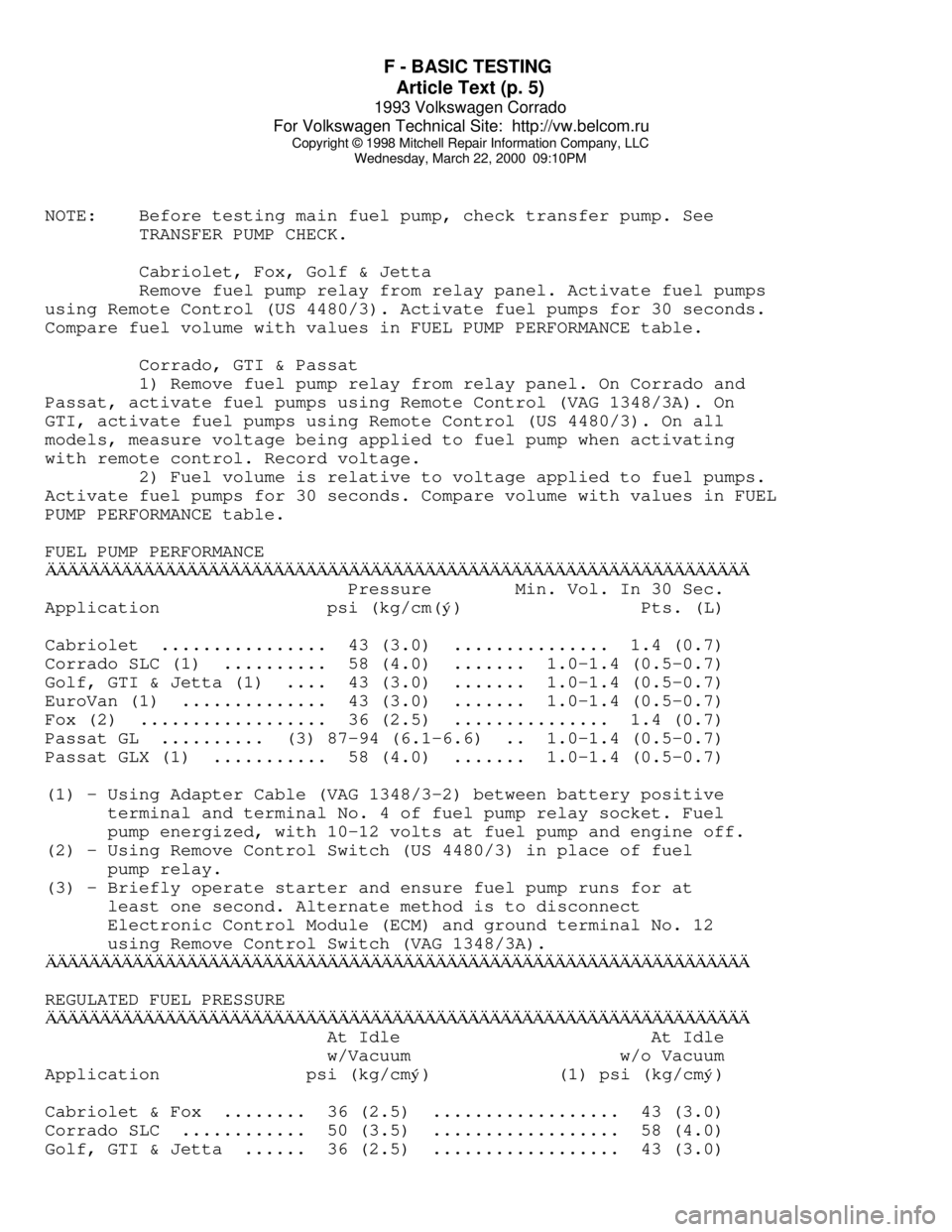

NOTE: Before testing main fuel pump, check transfer pump. See

TRANSFER PUMP CHECK.

Cabriolet, Fox, Golf & Jetta

Remove fuel pump relay from relay panel. Activate fuel pumps

using Remote Control (US 4480/3). Activate fuel pumps for 30 seconds.

Compare fuel volume with values in FUEL PUMP PERFORMANCE table.

Corrado, GTI & Passat

1) Remove fuel pump relay from relay panel. On Corrado and

Passat, activate fuel pumps using Remote Control (VAG 1348/3A). On

GTI, activate fuel pumps using Remote Control (US 4480/3). On all

models, measure voltage being applied to fuel pump when activating

with remote control. Record voltage.

2) Fuel volume is relative to voltage applied to fuel pumps.

Activate fuel pumps for 30 seconds. Compare volume with values in FUEL

PUMP PERFORMANCE table.

FUEL PUMP PERFORMANCEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Pressure Min. Vol. In 30 Sec.

Application psi (kg/cm(

ý) Pts. (L)

Cabriolet ................ 43 (3.0) ............... 1.4 (0.7)

Corrado SLC (1) .......... 58 (4.0) ....... 1.0-1.4 (0.5-0.7)

Golf, GTI & Jetta (1) .... 43 (3.0) ....... 1.0-1.4 (0.5-0.7)

EuroVan (1) .............. 43 (3.0) ....... 1.0-1.4 (0.5-0.7)

Fox (2) .................. 36 (2.5) ............... 1.4 (0.7)

Passat GL .......... (3) 87-94 (6.1-6.6) .. 1.0-1.4 (0.5-0.7)

Passat GLX (1) ........... 58 (4.0) ....... 1.0-1.4 (0.5-0.7)

(1) - Using Adapter Cable (VAG 1348/3-2) between battery positive

terminal and terminal No. 4 of fuel pump relay socket. Fuel

pump energized, with 10-12 volts at fuel pump and engine off.

(2) - Using Remove Control Switch (US 4480/3) in place of fuel

pump relay.

(3) - Briefly operate starter and ensure fuel pump runs for at

least one second. Alternate method is to disconnect

Electronic Control Module (ECM) and ground terminal No. 12

using Remove Control Switch (VAG 1348/3A).

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄREGULATED FUEL PRESSURE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ At Idle At Idle

w/Vacuum w/o Vacuum

Application psi (kg/cm

ý) (1) psi (kg/cmý)

Cabriolet & Fox ........ 36 (2.5) .................. 43 (3.0)

Corrado SLC ............ 50 (3.5) .................. 58 (4.0)

Golf, GTI & Jetta ...... 36 (2.5) .................. 43 (3.0)