engine VOLKSWAGEN CORRADO 1993 Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 213 of 920

* SUSPENSION UNIFORM INSPECTION GUIDELINES *

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:43PM

The Motorist Assurance Program continues to work

cooperatively and proactively with government agencies and consumer

groups toward solutions that both benefit the customer and are

mutually acceptable to both regulators and industry. We maintain the

belief that industry must retain control over how we conduct our

business, and we must be viewed as part of the solution and not part

of the problem. Meetings with state and other government officials

concerned with auto repair and/or consumer protection are conducted.

Feedback from these representatives are brought back to members, and

the program adjusted as needed.

To assure auto repair customers recourse if they were not

satisfied with a repair transaction, the Motorist Assurance Program

offers arbitration through MAP/BBB-CARE in cooperation with the

Council of Better Business Bureaus and individual participating

Bureaus. MAP "piloted" in Indianapolis and Pittsburgh during spring,

1996 - and publicized "roll-outs" in New Jersey, Detroit (MI), Chicago

(IL) and Richmond (VA) were conducted. To put some "teeth" in the

program, and accreditation requirement for shops was initiated. The

requirements are stringent and a self-policing method has been

incorporated which includes the "mystery shopping" of outlets. In

addition, a committee of service providers had been working diligently

developing standards for newspaper, television and Internet

advertising.

We welcome you to join us as we continue our outreach ...

with your support, both the automotive repair industry and your

customers will reap the benefits. Please visit MAP at our Internet

site: www.hunter.com/map.htm or contact us at:

808 17th Street, NW Suite 200

Washington, D.C. 20006

Ph. (202) 466-7050 Fax (202) 223-9569

OVERVIEW OF SERVICE REQUIREMENTS & SUGGESTIONS

It is MAP policy that all exhaust, brake, ABS, steering and

suspension, wheel alignment, tires and wheels, driveline, engine

performance and maintenance and heating, ventilation and air

conditioning services be offered and performed under the guidelines

and procedures specified in these sections.

Before any service is performed on a vehicle, an inspection

of the appropriate system must be performed. The results of this

inspection must be explained to the customer and documented on an

inspection form. The condition of the vehicle and its components will

indicate what services/part replacements may be required or suggested.

In addition, suggestions may be made to satisfy the needs expressed by

the customer.

This section lists the various parts and conditions that

indicate required or suggested service or part replacement. Although

this list is extensive, it is not inclusive. In addition to this list,

a technician may make a suggestion. This suggestion must be based on

substantial and informed experience or the vehicle manufacturer's

recommended service interval.

Page 285 of 920

* SYMPTOM CHECK LIST *

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:45PM

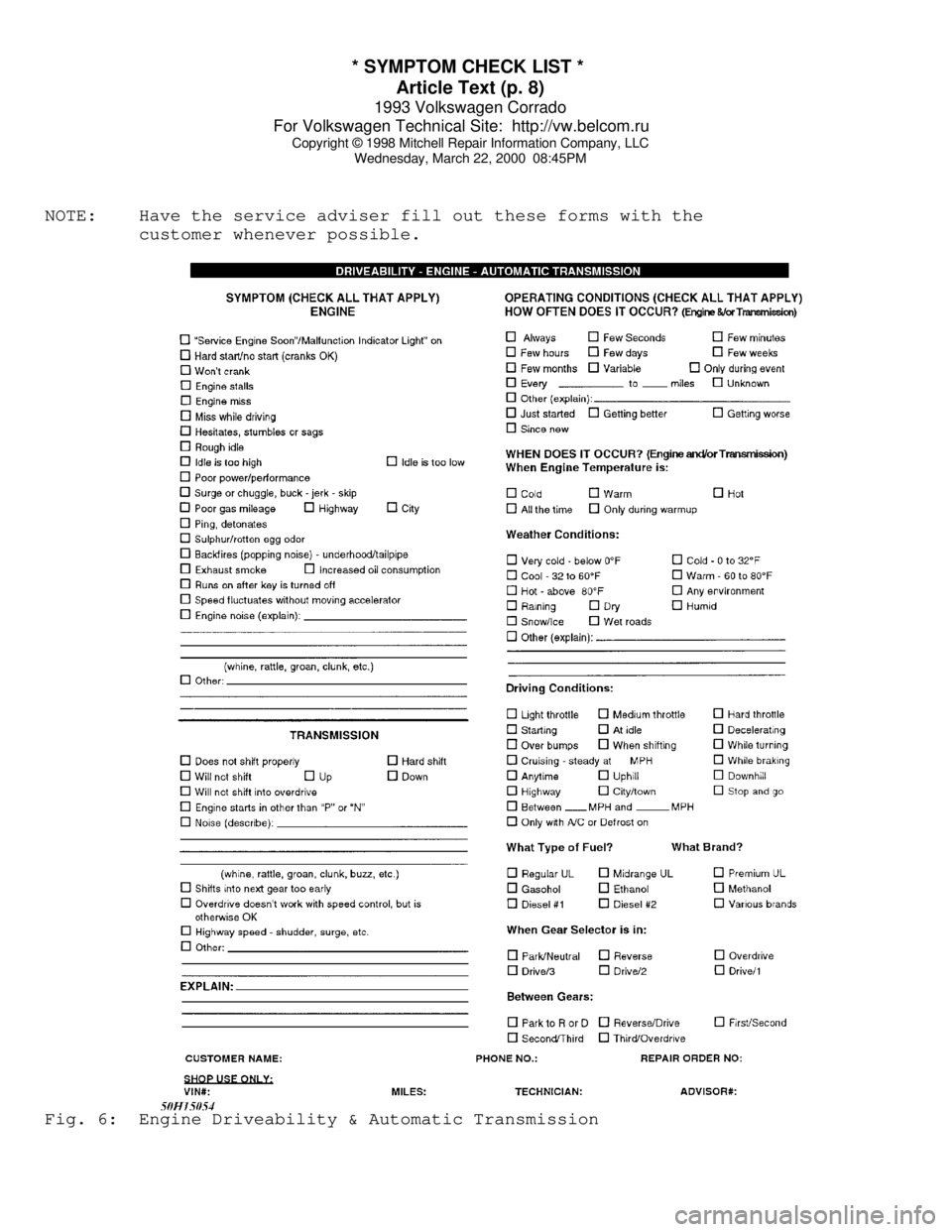

NOTE: Have the service adviser fill out these forms with the

customer whenever possible.Fig. 6: Engine Driveability & Automatic Transmission

Page 292 of 920

2.8L IN-LINE V6 (VR6)

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

ARTICLE BEGINNING

1992-93 ENGINE

Volkswagen 2.8L 6-Cylinder

1992-93 Corrado SLC, 1993 Passat

* PLEASE READ THIS FIRST *

NOTE: For engine repair procedures not covered in this article,

see ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION article

in the GENERAL INFORMATION section.

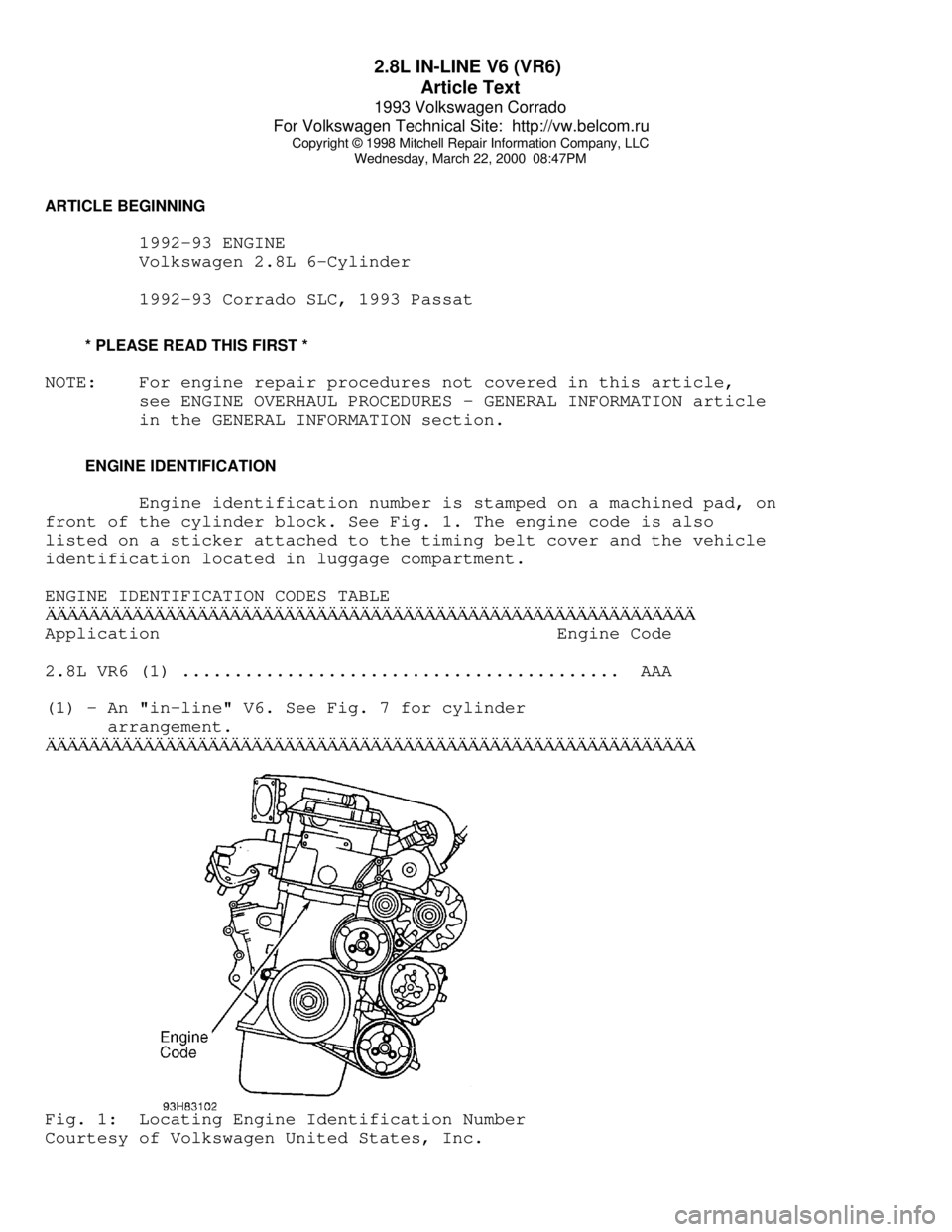

ENGINE IDENTIFICATION

Engine identification number is stamped on a machined pad, on

front of the cylinder block. See Fig. 1. The engine code is also

listed on a sticker attached to the timing belt cover and the vehicle

identification located in luggage compartment.

ENGINE IDENTIFICATION CODES TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Engine Code

2.8L VR6 (1) .......................................... AAA

(1) - An "in-line" V6. See Fig. 7 for cylinder

arrangement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 1: Locating Engine Identification Number

Courtesy of Volkswagen United States, Inc.

Page 293 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

ADJUSTMENTS

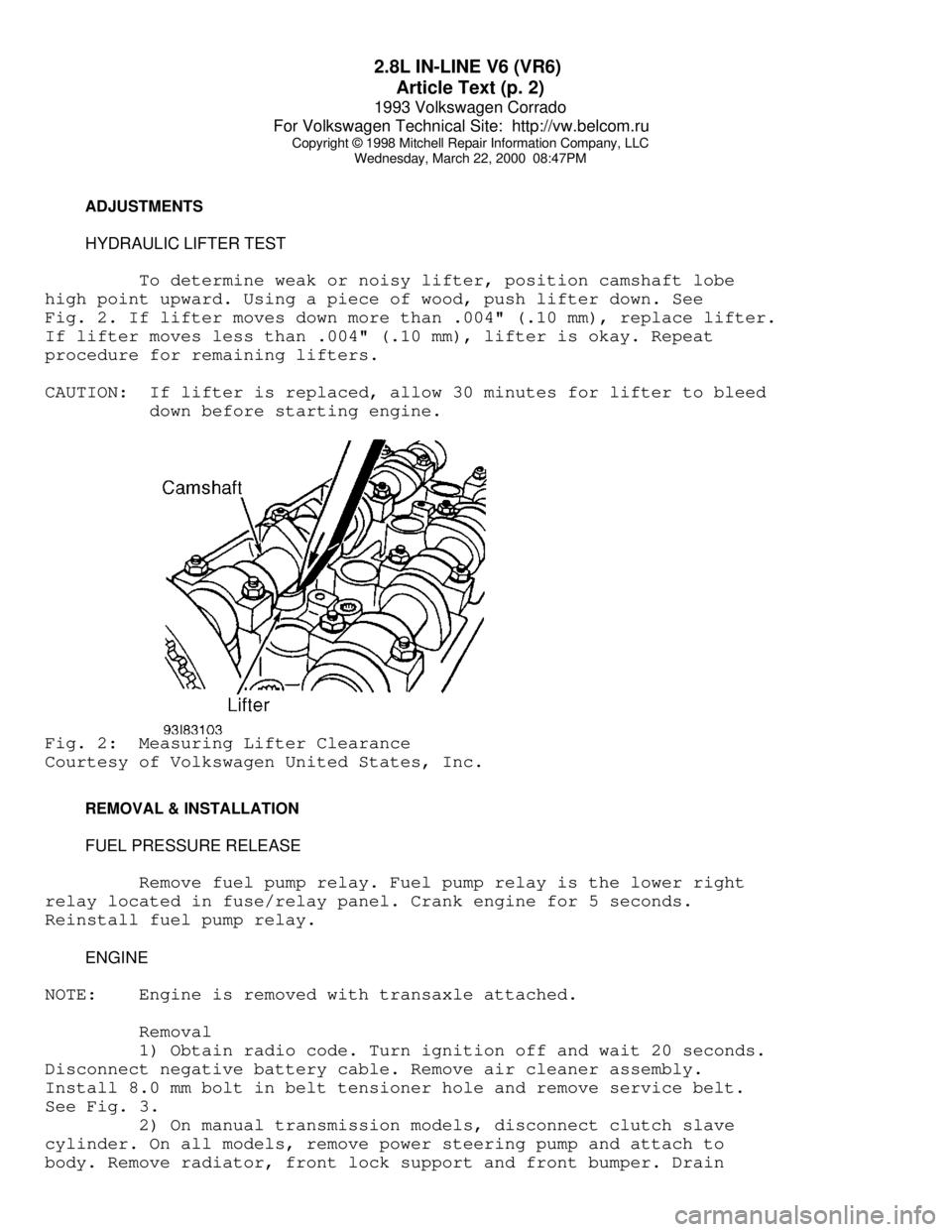

HYDRAULIC LIFTER TEST

To determine weak or noisy lifter, position camshaft lobe

high point upward. Using a piece of wood, push lifter down. See

Fig. 2. If lifter moves down more than .004" (.10 mm), replace lifter.

If lifter moves less than .004" (.10 mm), lifter is okay. Repeat

procedure for remaining lifters.

CAUTION: If lifter is replaced, allow 30 minutes for lifter to bleed

down before starting engine.Fig. 2: Measuring Lifter Clearance

Courtesy of Volkswagen United States, Inc.

REMOVAL & INSTALLATION

FUEL PRESSURE RELEASE

Remove fuel pump relay. Fuel pump relay is the lower right

relay located in fuse/relay panel. Crank engine for 5 seconds.

Reinstall fuel pump relay.

ENGINE

NOTE: Engine is removed with transaxle attached.

Removal

1) Obtain radio code. Turn ignition off and wait 20 seconds.

Disconnect negative battery cable. Remove air cleaner assembly.

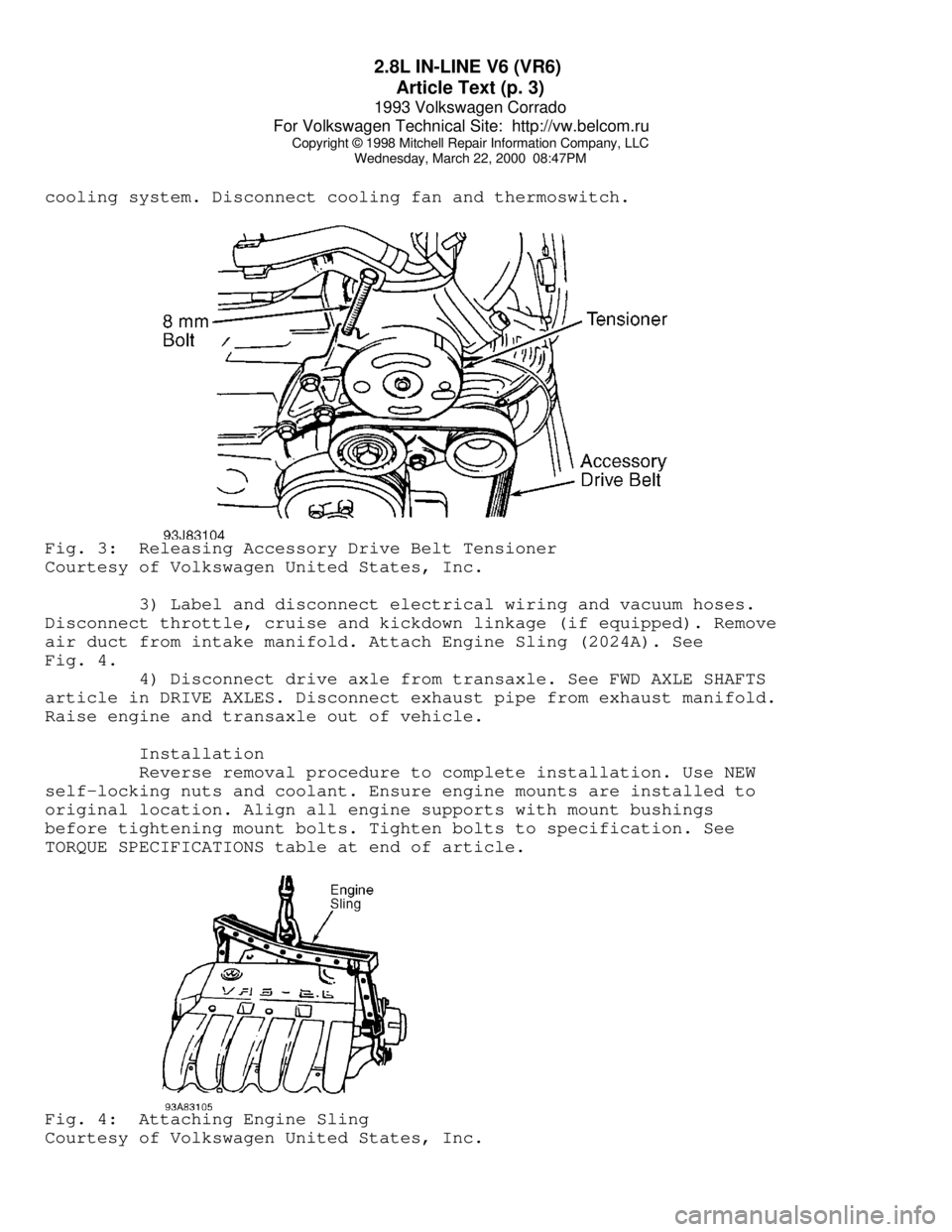

Install 8.0 mm bolt in belt tensioner hole and remove service belt.

See Fig. 3.

2) On manual transmission models, disconnect clutch slave

cylinder. On all models, remove power steering pump and attach to

body. Remove radiator, front lock support and front bumper. Drain

Page 294 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

cooling system. Disconnect cooling fan and thermoswitch.Fig. 3: Releasing Accessory Drive Belt Tensioner

Courtesy of Volkswagen United States, Inc.

3) Label and disconnect electrical wiring and vacuum hoses.

Disconnect throttle, cruise and kickdown linkage (if equipped). Remove

air duct from intake manifold. Attach Engine Sling (2024A). See

Fig. 4.

4) Disconnect drive axle from transaxle. See FWD AXLE SHAFTS

article in DRIVE AXLES. Disconnect exhaust pipe from exhaust manifold.

Raise engine and transaxle out of vehicle.

Installation

Reverse removal procedure to complete installation. Use NEW

self-locking nuts and coolant. Ensure engine mounts are installed to

original location. Align all engine supports with mount bushings

before tightening mount bolts. Tighten bolts to specification. See

TORQUE SPECIFICATIONS table at end of article.Fig. 4: Attaching Engine Sling

Courtesy of Volkswagen United States, Inc.

Page 295 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

INTAKE MANIFOLD

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of article.

EXHAUST MANIFOLD

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of article.

CYLINDER HEAD

Removal

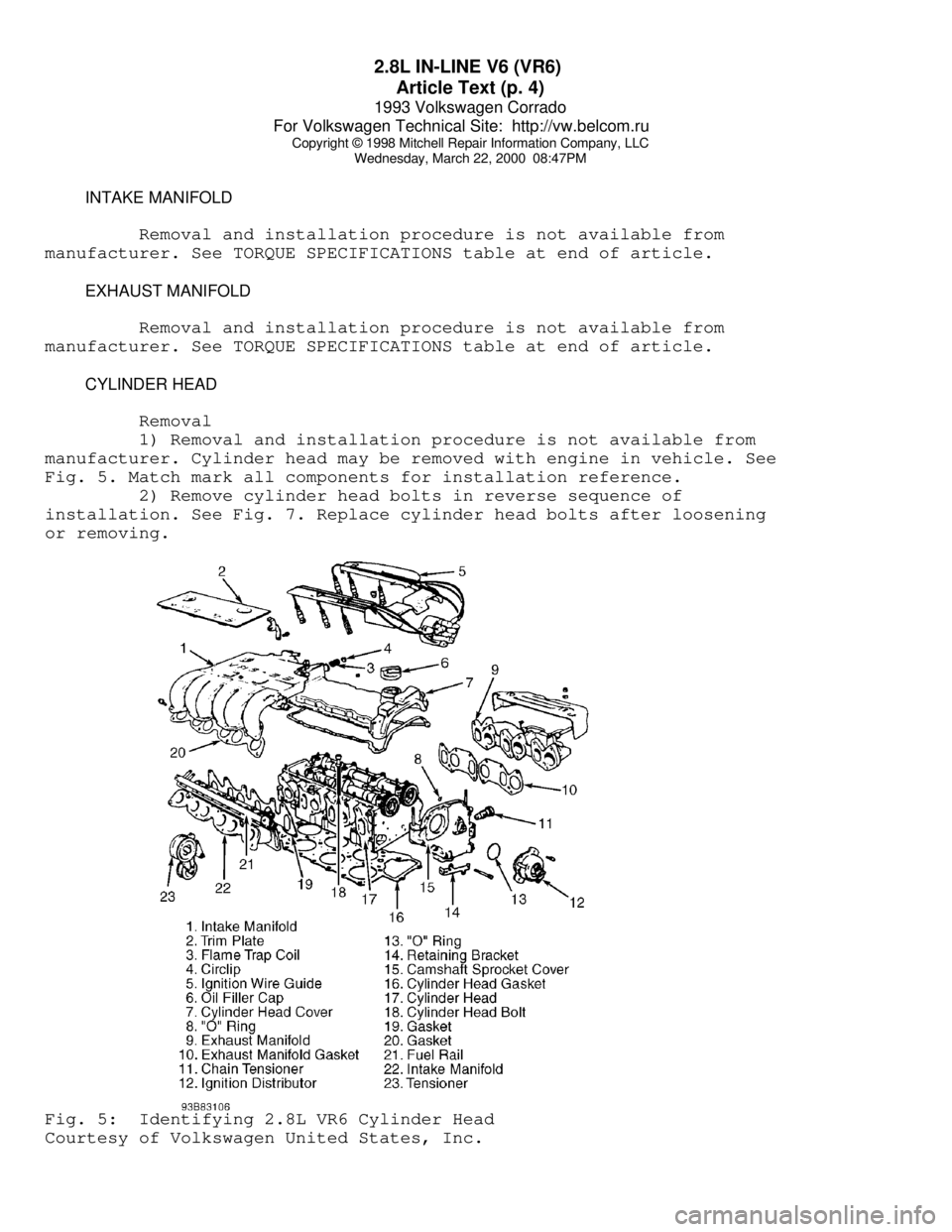

1) Removal and installation procedure is not available from

manufacturer. Cylinder head may be removed with engine in vehicle. See

Fig. 5. Match mark all components for installation reference.

2) Remove cylinder head bolts in reverse sequence of

installation. See Fig. 7. Replace cylinder head bolts after loosening

or removing.Fig. 5: Identifying 2.8L VR6 Cylinder Head

Courtesy of Volkswagen United States, Inc.

Page 300 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

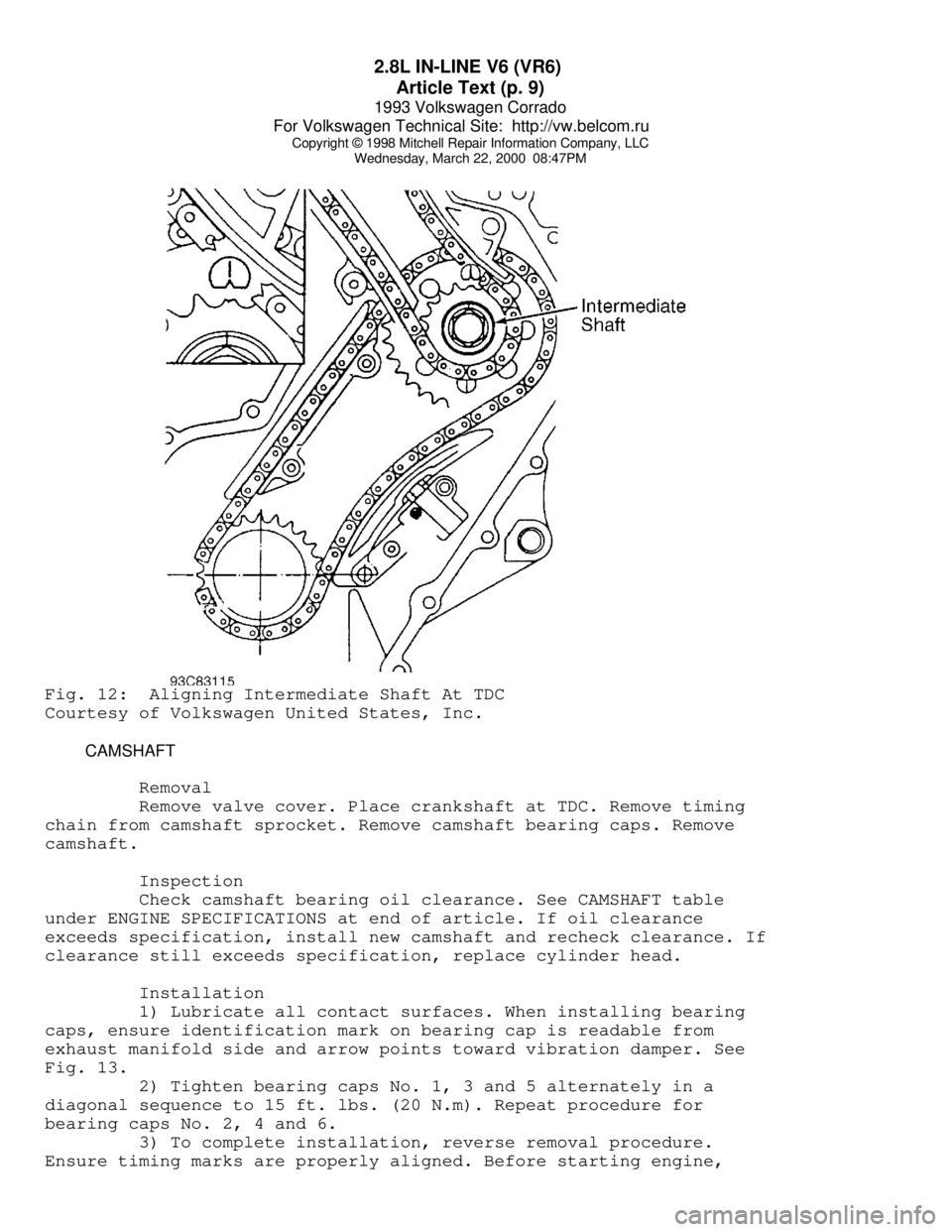

Wednesday, March 22, 2000 08:47PMFig. 12: Aligning Intermediate Shaft At TDC

Courtesy of Volkswagen United States, Inc.

CAMSHAFT

Removal

Remove valve cover. Place crankshaft at TDC. Remove timing

chain from camshaft sprocket. Remove camshaft bearing caps. Remove

camshaft.

Inspection

Check camshaft bearing oil clearance. See CAMSHAFT table

under ENGINE SPECIFICATIONS at end of article. If oil clearance

exceeds specification, install new camshaft and recheck clearance. If

clearance still exceeds specification, replace cylinder head.

Installation

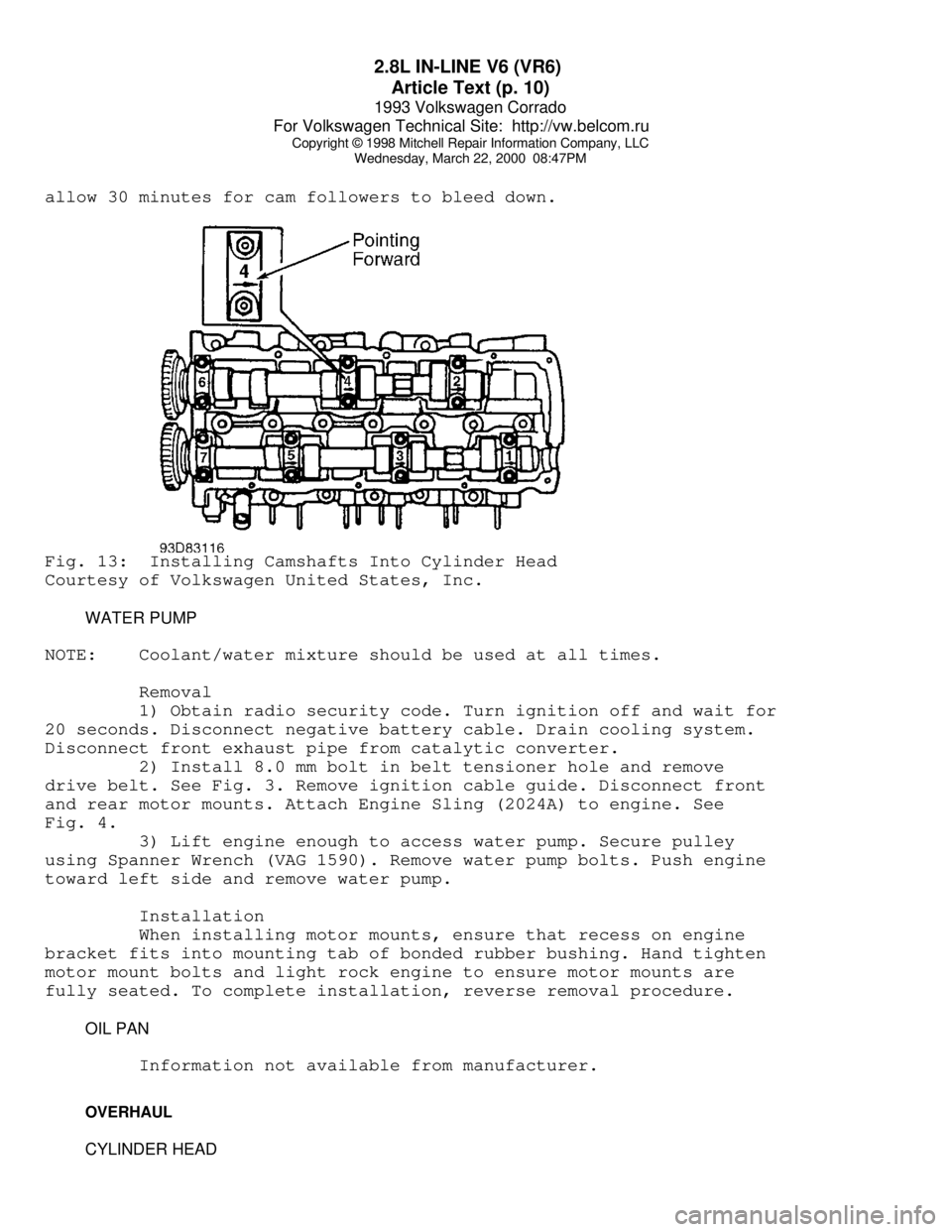

1) Lubricate all contact surfaces. When installing bearing

caps, ensure identification mark on bearing cap is readable from

exhaust manifold side and arrow points toward vibration damper. See

Fig. 13.

2) Tighten bearing caps No. 1, 3 and 5 alternately in a

diagonal sequence to 15 ft. lbs. (20 N.m). Repeat procedure for

bearing caps No. 2, 4 and 6.

3) To complete installation, reverse removal procedure.

Ensure timing marks are properly aligned. Before starting engine,

Page 301 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 10)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

allow 30 minutes for cam followers to bleed down.Fig. 13: Installing Camshafts Into Cylinder Head

Courtesy of Volkswagen United States, Inc.

WATER PUMP

NOTE: Coolant/water mixture should be used at all times.

Removal

1) Obtain radio security code. Turn ignition off and wait for

20 seconds. Disconnect negative battery cable. Drain cooling system.

Disconnect front exhaust pipe from catalytic converter.

2) Install 8.0 mm bolt in belt tensioner hole and remove

drive belt. See Fig. 3. Remove ignition cable guide. Disconnect front

and rear motor mounts. Attach Engine Sling (2024A) to engine. See

Fig. 4.

3) Lift engine enough to access water pump. Secure pulley

using Spanner Wrench (VAG 1590). Remove water pump bolts. Push engine

toward left side and remove water pump.

Installation

When installing motor mounts, ensure that recess on engine

bracket fits into mounting tab of bonded rubber bushing. Hand tighten

motor mount bolts and light rock engine to ensure motor mounts are

fully seated. To complete installation, reverse removal procedure.

OIL PAN

Information not available from manufacturer.

OVERHAUL

CYLINDER HEAD

Page 302 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 11)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

Cylinder Head

Clean all gasket mating surfaces. Check cylinder head for

warpage. Ensure warpage does not exceed .004" (0.1 mm).

Valve Stem Oil Seals

With valve springs removed, remove oil seals using Valve Seal

Remover (3047A). To install new oil seal, slide plastic sleeve over

valve stem. Lubricate new oil seal. Using Valve Seal Installer (3129),

push oil seal on valve guide.

Valve Guides

1) Check valve-to-guide clearance specification. See

CYLINDER HEAD table under ENGINE SPECIFICATIONS at end of article. If

valve guide have previously been replaced, replace cylinder head.

2) To replace valve guide, press guide out from camshaft

side. Lubricate guide and press in cold cylinder head (from camshaft

side) until shoulder makes contact. DO NOT exceed one ton pressure.

Ream guides to proper valve-to-guide clearance. See CYLINDER HEAD

table under ENGINE SPECIFICATIONS at end of article.

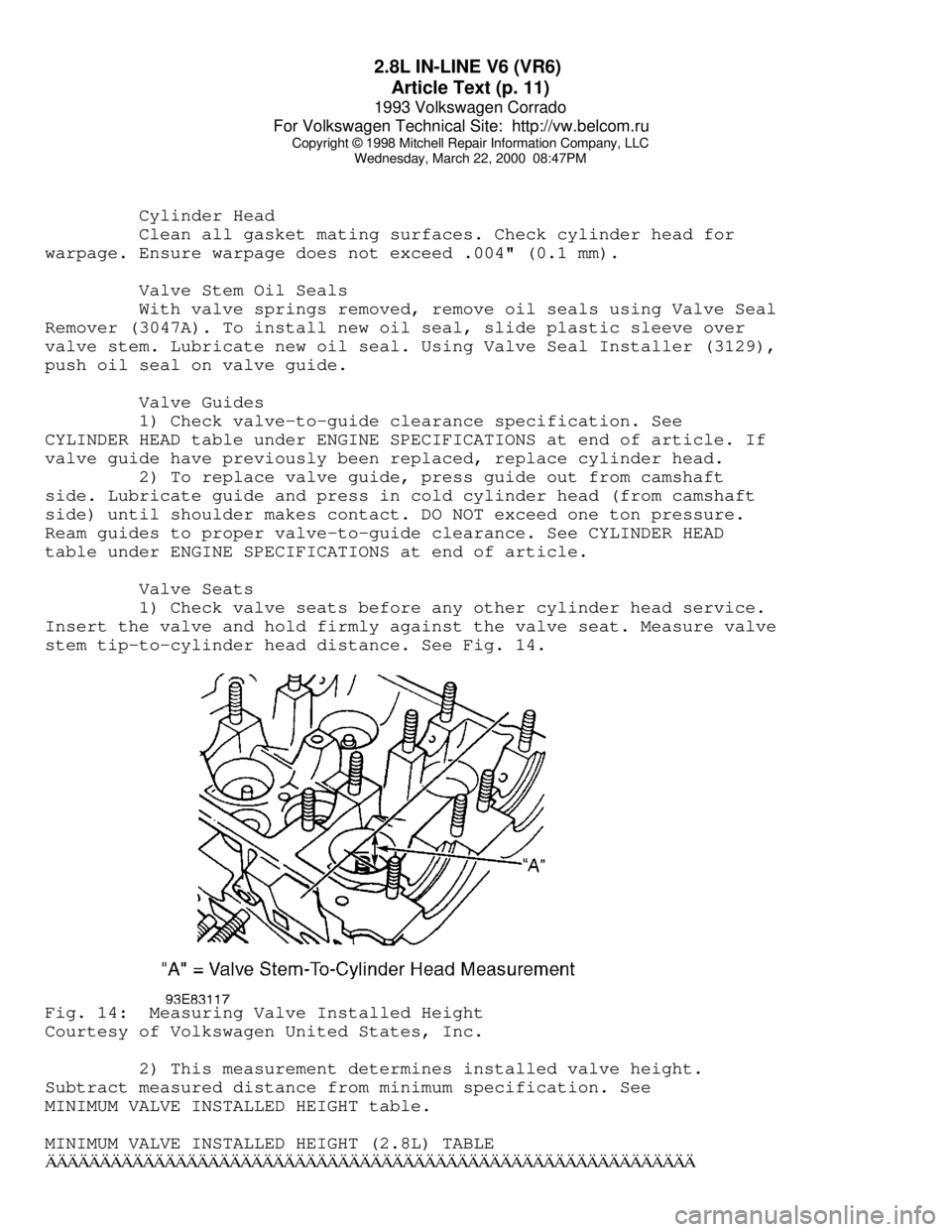

Valve Seats

1) Check valve seats before any other cylinder head service.

Insert the valve and hold firmly against the valve seat. Measure valve

stem tip-to-cylinder head distance. See Fig. 14.Fig. 14: Measuring Valve Installed Height

Courtesy of Volkswagen United States, Inc.

2) This measurement determines installed valve height.

Subtract measured distance from minimum specification. See

MINIMUM VALVE INSTALLED HEIGHT table.

MINIMUM VALVE INSTALLED HEIGHT (2.8L) TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 303 of 920

2.8L IN-LINE V6 (VR6)

Article Text (p. 12)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

Application In. (mm)

Intake Valve ................................. 1.33 (33.9)

Exhaust Valve ................................ 1.34 (34.1)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ 3) The difference is maximum refacing allowable for valve and

seat. If valve installed height is too low or too high, lifters will

not work correctly. Replace cylinder head assembly.

Valves

Measure valve length, stem diameter and valve margin. If not

within specification, replace valves. Lap valves by hand or replace as

necessary. See VALVES SPECIFICATIONS table under ENGINE SPECIFICATIONS

at end of article.

CYLINDER BLOCK ASSEMBLY

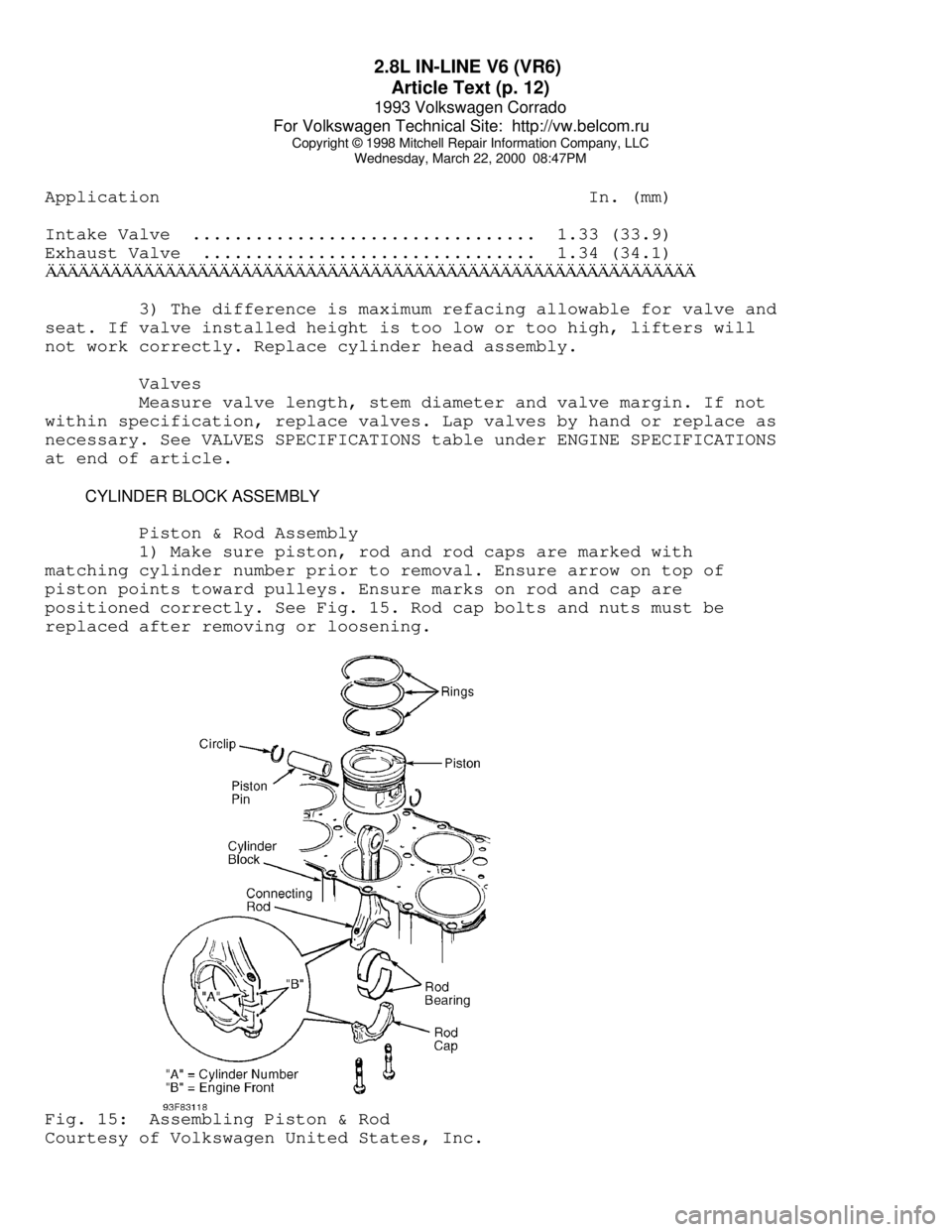

Piston & Rod Assembly

1) Make sure piston, rod and rod caps are marked with

matching cylinder number prior to removal. Ensure arrow on top of

piston points toward pulleys. Ensure marks on rod and cap are

positioned correctly. See Fig. 15. Rod cap bolts and nuts must be

replaced after removing or loosening.Fig. 15: Assembling Piston & Rod

Courtesy of Volkswagen United States, Inc.