engine VOLKSWAGEN CORRADO 1993 Manual Online

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 333 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 19)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Jaguar (XJS)

1) Operate engine at idle speed for 10 minutes, to return

refrigerant oil to compressor. Stop engine. Discharge refrigerant. See

SERVICING PRECAUTIONS. Clean area around compressor filler plug and

remove plug slowly.

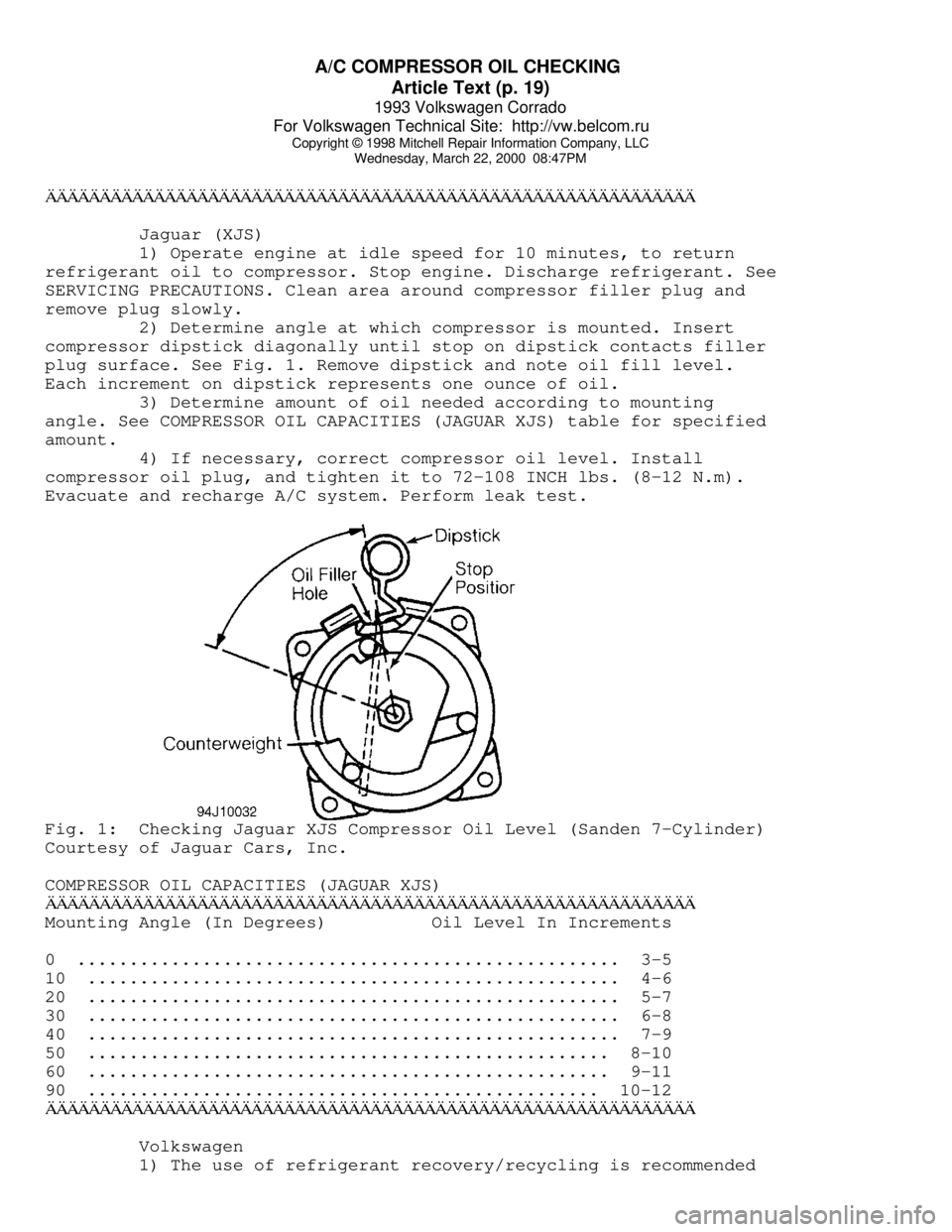

2) Determine angle at which compressor is mounted. Insert

compressor dipstick diagonally until stop on dipstick contacts filler

plug surface. See Fig. 1. Remove dipstick and note oil fill level.

Each increment on dipstick represents one ounce of oil.

3) Determine amount of oil needed according to mounting

angle. See COMPRESSOR OIL CAPACITIES (JAGUAR XJS) table for specified

amount.

4) If necessary, correct compressor oil level. Install

compressor oil plug, and tighten it to 72-108 INCH lbs. (8-12 N.m).

Evacuate and recharge A/C system. Perform leak test.Fig. 1: Checking Jaguar XJS Compressor Oil Level (Sanden 7-Cylinder)

Courtesy of Jaguar Cars, Inc.

COMPRESSOR OIL CAPACITIES (JAGUAR XJS)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMounting Angle (In Degrees) Oil Level In Increments

0 .................................................... 3-5

10 ................................................... 4-6

20 ................................................... 5-7

30 ................................................... 6-8

40 ................................................... 7-9

50 .................................................. 8-10

60 .................................................. 9-11

90 ................................................. 10-12

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Volkswagen

1) The use of refrigerant recovery/recycling is recommended

Page 334 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 20)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

by manufacturer. After refrigerant recovery process is completed, the

amount of compressor oil removed must be measured and the same amount

added to A/C system.

2) On Cabriolet, add 2/3 ounce of refrigerant oil when

replacing evaporator. When replacing condenser or receiver-drier, add

1/3 ounce of refrigerant oil per component replaced.

3) On Corrado SLC, Golf, GTI, Jetta and Passat, add 2/3 ounce

of refrigerant oil when replacing evaporator. When replacing condenser

or receiver-drier, add 1/3 ounce of refrigerant oil per component

replaced.

4) On EuroVan, add one ounce of refrigerant oil when

replacing evaporator. Add 1/2 ounce when replacing condenser (2/3

ounce on vehicles with rear A/C). When replacing receiver-drier, add

1/3 ounce (2/3 ounce on vehicles with rear A/C).

SEIKO-SEIKI

ROTARY VANE

Saab (9000)

The A/C system is filled with 6.6 ounces of compressor oil.

The compressor must be topped off with the specified amount. See

COMPONENT REFRIGERANT OIL CAPACITIES (SEIKO-SEIKI ROTARY VANE) table.

Topping off should be carried out on the high pressure side of the

compressor.

COMPONENT REFRIGERANT OIL CAPACITIES (SEIKO-SEIKI ROTARY VANE)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Compressor .......................................... (1) 2.3

Condenser ............................................... 1.3

Expansion Valve ......................................... 0.6

Evaporator .............................................. 1.3

Receiver-Drier .......................................... 1.3

Refrigerant Lines ....................................... 0.6

(1) - To avoid an excessive amount of oil in the A/C system, oil

must be drained from the compressor before it is installed.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ZEXEL

NOTE: Isuzu and Subaru compressor oil checking procedures are not

available from manufacturer.

ROTARY VANE

Nissan

1) Before checking and adjusting oil level, operate engine at

1200 RPM. Set controls at maximum cooling and high blower motor speed

for 10 minutes to return oil to compressor.

Page 335 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 21)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

2) Stop engine. Discharge refrigerant. See SERVICING

PRECAUTIONS. Measure the amount of oil drained/discharged into

refrigerant recovery/recycling equipment.

3) Remove compressor from vehicle. Drain compressor oil from

compressor drain plug and measure oil amount. Add this amount to

amount drained in step 2), to obtain total amount drained.

4) Fill compressor with total amount drained, using new oil.

If any major components of the system were also replaced, determine

the amount of additional oil needed. See COMPONENT REFRIGERANT OIL

CAPACITIES (ZEXEL ROTARY VANE & 6-CYLINDER) table for specified

amount.

COMPONENT REFRIGERANT OIL CAPACITIES (ZEXEL ROTARY VANE & 6-CYLINDER)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser

Altima & Maxima ............................................... 2.5

NX, Pickup, Sentra & 300ZX ................................ 1.0-1.7

Evaporator

Altima & Maxima ............................................... 2.5

NX, Pickup, Sentra & 300ZX ................................ 1.5-2.5

Receiver-Drier

Altima & Maxima ............................................... 0.2

NX, Pickup, Sentra & 300ZX ................................ 0.5-0.8

Refrigerant Lines (1) .......................................... 1.0

(1) - Add only if a refrigerant oil leak is indicated.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ 6-CYLINDER

Audi

1) The use of refrigerant recovery/recycling is recommended

by manufacturer. After refrigerant recovery process is completed, the

amount of compressor oil removed must be measured and the same amount

added to A/C system.

2) Add one ounce of refrigerant oil when replacing

accumulator. When replacing condenser, add amount drained from

condenser plus 1/3 ounce of refrigerant oil. When replacing

evaporator, add amount drained from evaporator plus 2/3 ounce of

refrigerant oil.

Nissan

1) Before checking and adjusting oil level, operate engine at

1200 RPM. Set controls at maximum cooling and high blower motor speed

for 10 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant. See SERVICING

PRECAUTIONS. Measure the amount of oil drained/discharged into

refrigerant recovery/recycling equipment.

3) Remove compressor from vehicle. Drain compressor oil from

compressor drain plug and measure oil amount. Add this amount to

Page 363 of 920

A/C SYSTEM GENERAL DIAGNOSTIC PROCEDURES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

ARTICLE BEGINNING

1993 AIR CONDITIONING & HEAT

A/C General Diagnostic Procedures

Diagnosis is an important first step in A/C system servicing.

To save time and effort, systems should be carefully checked to

identify the causes of poor performance. By using the following

diagnostic charts, defective components or system problems can be

quickly located. To identify problems that are specific to one system,

refer to the repair section of this manual. The charts in this section

apply to all systems.

PREPARATION FOR TESTING

1) Attach Low and High pressure gauges.

2) Start engine and allow to warm up.

3) Set system to COOL and blower to HIGH.

4) Open car doors and hood.

5) Run engine at fast idle for 2-3 minutes.

AIR CONDITIONING SYSTEM PERFORMANCE CHECK

AIR CONDITIONING SYSTEM PERFORMANCE CHECK TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPERFORM TESTS: SHOULD BE: IF:

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature Check Temperature Check Is:

* Switch to LOW blower.

* Close doors.

* Check outlet temperature. 35-45

ø F Too warm - Check

control lever

operation, heater

water valve, cooling

system and gauge readings.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPERFORM TESTS: SHOULD BE: IF:

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄVisual Check Visual Check Shows:

* Compressor Quiet with no leaks Noisy - Check belts,

oil level, seals,

gaskets, reed valves.

* Condenser Free of obstructions Blocked - Clean off.

Plugged - Flush or

replace.

* Receiver-Drier Dry and warm to touch Frosty - Check for

restriction, replace

desiccant.

Page 375 of 920

A/C SYSTEM GENERAL SERVICING

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

Vigor). Use High-Side Adapter (J-25498).

(3) - On low pressure line (near battery on Integra; near

right rear of engine on Legend; near compressor on

Vigor).

(4) - On high pressure (discharge) hose/line.

(5) - On low pressure (suction) hose/line.

(6) - On high pressure line, between compressor and condenser.

(7) - On suction accumulator/drier.

(8) - On low and high pressure hoses, behind compressor.

(9) - On receiver/drier and low pressure hose (near

compressor).

(1)(0) - On compressor discharge hose and accumulator.

(1)(1) - On compressor discharge and suction ports.

(1)(2) - Front of condenser on right side.

(1)(3) - Towards rear of compressor.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ REFRIGERANT RECOVERY/RECYCLING

Refrigerant recovery/recycling equipment is used to remove

refrigerant from vehicle's A/C system without polluting atmosphere. To

remove and recycle refrigerant, connect the recovery/recycling system

and follow instructions provided with the system.

The removed refrigerant is filtered, dried and stored in a

tank within the recovery/recycling system until it is ready to be

pumped back into the vehicle's A/C system. With refrigerant stored in

the recovery/recycling system, A/C system can be opened without

polluting atmosphere.

NOTE: Separate sets of hoses, gauges and refrigerant

recovery/recycling equipment MUST be used for R-12 and

R-134a based systems. DO NOT mix R-12 and R-134a

refrigerants, as their refrigerant oils and desiccants are

not compatible. On systems with R-134a refrigerant, use

Polyalkylene Glycol (PAG) wax-free refrigerant oil.

END OF ARTICLE

Page 379 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

too low. This protects compressor if not enough refrigerant is in

system. Low-pressure cut-out switch shuts compressor off at about 29

psi (2.0 kg/cmý).

THERMOSWITCH

Thermoswitch shuts compressor off if coolant temperature is

greater than 248

øF (120øC).

ADJUSTMENTS

AIR DISTRIBUTION CONTROL

1) Move air distribution control knob to defrost position.

Connect 3-foot long control cable to footwell/defrost flap lever. Push

flap lever toward cable and secure cable sheath with retainer clip.

2) Move air distribution control knob to panel (vent)

position. Connect 2-foot long control cable to center flap lever. Push

flap lever away from cable and secure cable sheath with retainer clip.

TEMPERATURE CONTROL

Move temperature knob to full cool position. Connect

temperature control cable (Blue sheath) to temperature flap lever.

Push flap lever away from cable and secure cable sheath with retainer

clip.

TROUBLE SHOOTING

NO COOLING

1) Ensure blower fan motor operates in all 4 speeds. Ensure

air duct closes off outside air and heater water valve is closed.

Clean condenser.

2) Inspect receiver-drier pressure seal. If seal is good, go

to step 3). If seal is broken, replace seal. Evacuate and recharge

system. If system cools properly, testing is complete. If system does

not cool, connect pressure gauges.

3) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

connect pressure gauges. Operate system for 10 minutes.

4) If fan does not operate, replace pressure switch. Ensure

system is okay. If fan does come on, turn engine off, and check for

condenser obstructions and blocked airflow.

5) Turn air conditioner on and off with temperature control.

Ensure compressor clutch engages. Push lever to extreme right position

and back again. A click should be heard from compressor clutch. If a

click is not heard, check for voltage at clutch coil wire with switch

on. If voltage is present, replace clutch coil. If voltage is not

present, check wiring or replace thermostatic switch.

6) If compressor clutch operates, check gauge readings. If

Page 380 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

both gauges read too low, locate leak and recharge system. If both

gauges read too high, replace expansion valve. If low side is too high

and high side is too low, replace compressor.

INSUFFICIENT COOLING

1) Ensure blower fan motor operates at all 4 speeds. Ensure

air duct closes off outside air intake and heater water valve is

closed. Clean condenser.

2) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

connect pressure gauges. Operate system for 10 minutes.

3) If both gauges read too high, replace expansion valve. If

both gauges read low, locate leak and recharge system. If both gauge

readings are normal, go to next step. If high side is too high and

suction side is normal, go to step 5). If high side is too low and

suction side is too high, go to step 6). If high side is normal and

suction side is too low, go to step 7).

4) Turn compressor off and observe gauges. If readings

equalize in 30 seconds, replace compressor. If readings take longer to

equalize, ensure capillary tube installed length is 13" (330 mm).

5) If capillary tube installation is correct, run system at

maximum cooling for 15 minutes. If thermometer indicates temperature

is less than 36øF (2øC) when compressor is turned off, or temperature

is greater than 48

øF (9øC) with compressor on, replace thermostatic

switch.

6) Check condenser fins and clean or straighten. If operation

is still not correct, discharge system until bubbles appear in sight

glass. Recharge system until bubbles disappear, and recheck pressures.

If operation is still incorrect, locate leaks and tighten fittings.

Discharge A/C system using approved refrigerant recovery/recycling

equipment. Evacuate system to remove all air and recharge system.

7) Check for bubbles at sight glass. If bubbles are present,

repair leaks and recharge system. If no bubbles are present, check

condenser-to-expansion valve line for kinks and repair if necessary.

Check line (from condenser to expansion valve) for restrictions by

feeling line for cold spots. If there are no cold spots, replace

expansion valve.

8) If cold spot is felt, remove and flush out lines and

condenser. Check for bubbles at sight glass. If there are no bubbles

present, replace compressor. If bubbles are present, check for leaks.

Repair and recharge system.

INTERMITTENT COOLING

1) Ensure blower fan motor operates in all 4 speeds. Ensure

air duct closes off outside air and heater water valve is closed.

Clean condenser.

2) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

Page 381 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

connect pressure gauges. Operate system for 10 minutes.

3) Check for cool air from left duct. Low pressure gauge

should read more than 16 psi (1.1 kg/cmý). If low pressure gauge

reading is incorrect, place hands around expansion valve to warm

valve. If pressure rises, moisture is present in system. Discharge A/C

system using approved refrigerant recovery/recycling equipment.

Evacuate and recharge system. If pressure does not rise, go to next

step.

4) Check temperature on thermometer when thermostatic switch

turns compressor off. If temperature is 39

øF (4øC), system is okay. If

temperature is lower than 39

øF (4øC), ensure capillary tube installed

length is 13" (330 mm). If capillary tube installation is correct,

replace thermostatic switch.

TESTING

A/C SYSTEM PERFORMANCE

1) Park vehicle out of direct sunlight. Start engine and

operate engine at 2500 RPM. Set A/C controls to outside air, panel

(vent) mode, full cold, and A/C button on.

2) Set blower/fan on high speed and open windows. Operate

system for 6-7 minutes to allow system to stabilize. Insert

thermometer in center vent, and measure temperature. Temperature at

center vent must be 19-40

øF (-7 to 4øC) at center vent, with high side

and low side pressures within specification. See SPECIFICATIONS table

at beginning of article.

AMBIENT TEMPERATURE SWITCH

1) Remove air intake grille from right side cowl. Remove

switch from panel on right side of tray area. Place switch in freezer.

2) Using a DVOM, check switch resistance. Switch resistance

must be infinite (no continuity) below 30

øF (-1øC). Allow switch to

warm above 45

øF (7øC). Switch resistance must be zero ohms

(continuity). Replace switch if necessary.

COMPRESSOR CLUTCH COIL

Disconnect compressor clutch harness connector. Check

resistance between clutch connector terminals. Resistance reading

should be 3.6 ohms. If resistance reading is not as specified, replace

clutch coil.

DUAL-PRESSURE SWITCH

High-Pressure Cut-Out Switch

Locate dual-pressure switch on refrigerant line (right strut

tower). Switch is identified by its 4 wires. Ensure switch opens at

464 psi (32 kg/cm

ý). Ensure switch closes at 348 psi (24 kg/cmý).

NOTE: Dual-pressure switch may be removed without discharging

Page 387 of 920

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

ARTICLE BEGINNING

ENGINE PERFORMANCE

How To Use This Section

INTRODUCTION

NOTE: Because there are so many possible combinations of

articles for the different manufacturers and models,

the new hyper-text capabilities built into this product

DO NOT apply to this article.

It is the purpose of this repair information system to help

professional automotive technicians maintain top vehicle performance

and correct driveability problems related to today's high tech

vehicles.

Because of the limited amount of space allowable for the this

product, our titles have been condensed to fit into the menus. An

alphabetical designation has been added to the front of each title to

allow the titles to be displayed in a way that reflects their

respective order of use. References to the titles in some of the

diagnostic flow charts sometimes will not correlate with the titles in

the this product menu. If not, refer to the MENU CROSS-REFERENCE table

below.

MENU CROSS-REFERENCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTitle Associate Print (Book) Title:

A - ENGINE/VIN I D .................................... Introduction

B - EMISSION APPLICATION ..................... Emission Applications

C - TUNE-UP SPECS .............. Service & Adjustment Specifications

C - SPECIFICATIONS ............. Service & Adjustment Specifications

D - ADJUSTMENTS ............................. On-Vehicle Adjustments

E - THEORY/OPERATION ............................ Theory & Operation

F - BASIC TESTING ...................... Basic Diagnostic Procedures

G - TESTS W/ CODES ................................ Self-Diagnostics

H - TESTS W/O CODES .................... Trouble Shooting - No Codes

I - SYS/COMP TESTS ..................... Systems & Component Testing

J - PIN VOLTAGE CHARTS .......................... Pin Voltage Charts

K - SENSOR RANGE CHARTS .............. Sensor Operating Range Charts

L - WIRING DIAGRAMS ................................ Wiring Diagrams

M - VACUUM DIAGRAMS ................................ Vacuum Diagrams

N - REMOVE/INSTALL/OHAUL .......... Removal, Overhaul & Installation

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Because of this we recommend that you read the rest of these

INTRODUCTION paragraphs to better understand why the information is

presented in this new format.

The A - ENGINE/VIN I D article will help you identify the

vehicle and its systems. It will also explain the VIN code and in many

cases, show its location.

Page 388 of 920

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

If you want "TUNE-UP" type information, see D - ADJUSTMENTS

for the adjustment procedures. If you are familiar with the

procedures, but need a quick way to find the specification, go to C -

TUNE-UP SPECS or C - SPECIFICATIONS for the specifications pertaining

to the vehicle.

When diagnosing driveability problems, first go to F - BASIC

TESTING. This article is here to help eliminate wasted diagnostic

time. If the basic systems are working properly, go to G - TESTS W/

CODES.

If the vehicle still is having a driveability problem or if

the vehicle has no self-diagnostic system, go to H - TESTS W/O CODES.

This article will help you diagnose the problem by symptom, locate the

symptom exhibited by the vehicle, and inspect or test the items which

may be causing the problem.

After finding which specific system or component requires

testing, use the I - SYS/COMP TESTS article to tests the systems and

components. We have also included (when available) pin voltage charts

and sensor range charts. These can be found in J - PIN VOLTAGE CHARTS

and K - SENSOR RANGE CHARTS.

Also included in this section are wiring diagrams and vacuum

diagrams. These can be found in L - WIRING DIAGRAMS and M - VACUUM

DIAGRAMS.

When all diagnostic tests have been performed and the problem

has been discovered, it may be necessary to replace or overhaul the

defective part. This information can be found in

N - REMOVE/INSTALL/OHAUL.

The content of each of these articles is outlined below. As a

summary of the driveability diagnosis, see ROUTINE OUTLINE in this

article.

A - ENGINE/VIN ID

This article shows how to identify the model and engine by

its Vehicle Identification Number (VIN). A model coverage chart shows

each model and engine, the fuel system, ignition system and engine

code. The engine serial number locations are also included in this

article.

B - EMISSION APPLICATION

These charts identify the emission systems and sub-systems

applicable to each model and engine combination.

C - TUNE-UP SPECS

This is a collection of quick-reference type specifications.

This article is helpful when you are familiar with proper adjustment

procedures and only need specifications. Included in this section are:

* Battery specifications.

* Fluid capacities.