sensor VOLKSWAGEN CORRADO 1993 Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 487 of 920

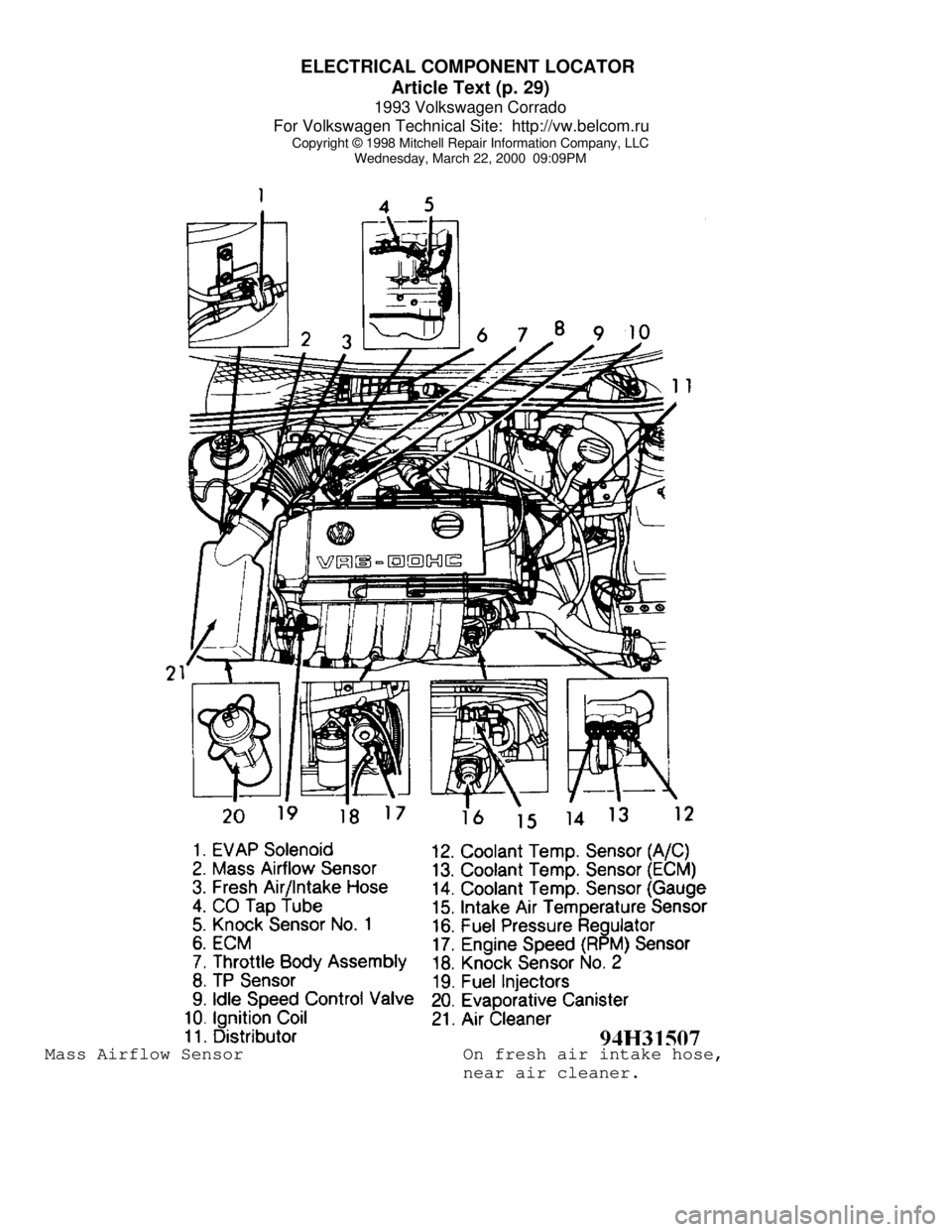

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 29)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMMass Airflow Sensor On fresh air intake hose,

near air cleaner.

Page 488 of 920

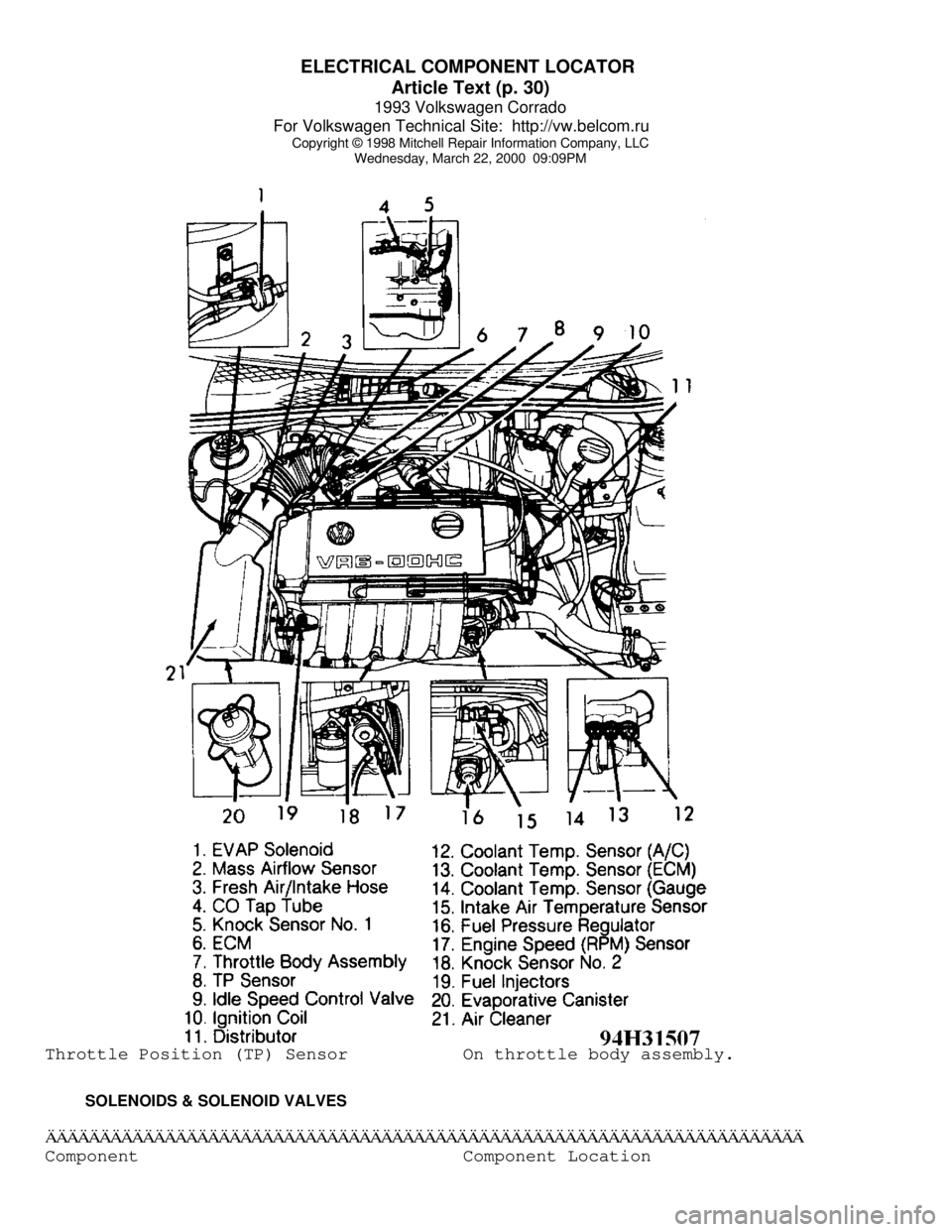

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 30)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMThrottle Position (TP) Sensor On throttle body assembly.

SOLENOIDS & SOLENOID VALVESÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Component Location

Page 489 of 920

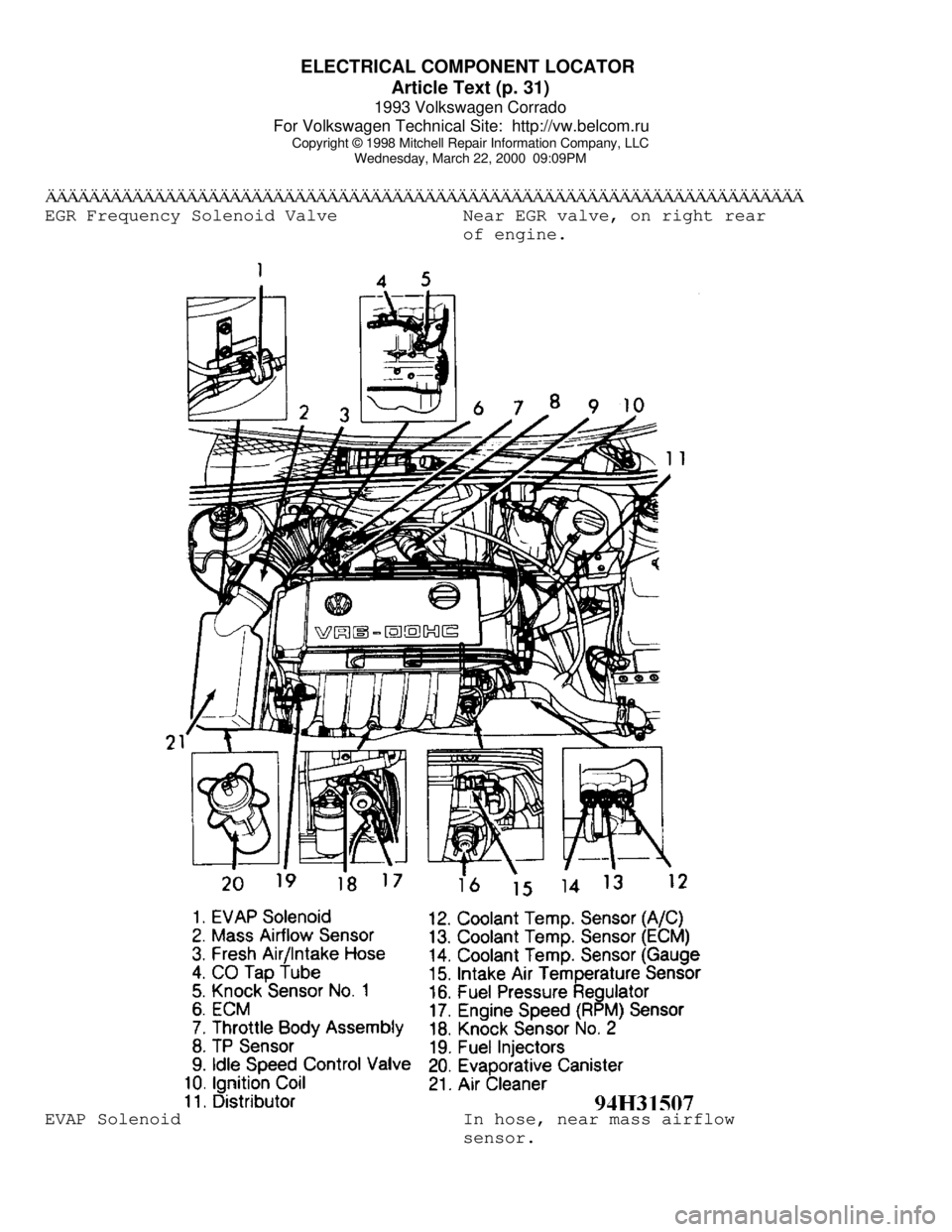

ELECTRICAL COMPONENT LOCATOR

Article Text (p. 31)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEGR Frequency Solenoid Valve Near EGR valve, on right rear

of engine.EVAP Solenoid In hose, near mass airflow

sensor.

Page 494 of 920

D - ADJUSTMENTS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:59PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

On-Vehicle Adjustments

Corrado SLC

ENGINE MECHANICAL

Before performing any on-vehicle adjustments to fuel or

ignition systems, ensure engine mechanical condition is okay.

VALVE CLEARANCE

NOTE: All models use hydraulic lifters. No adjustments are

required.

IGNITION TIMING

NOTE: See ENTERING SELF-DIAGNOSTICS in the G - TESTS W/CODES

article in this section for additional scan tester

operating instructions.

VR6 IGNITION TIMING

1) Start and warm engine to normal operating temperature.

Ensure engine oil temperature is 176øF (80øC). Ensure A/C and

electrical loads are off, including cooling fan.

2) Connect engine analyzer to engine. Connect Scan Tester

(VAG 1551) to Data Link Connectors (DLC) located in center console, in

front of shift lever. Ensure no Diagnostic Trouble Codes (DTC) are

stored.

3) Ensure throttle position sensor is properly adjusted.

Ensure idle air control valve is okay. Valve must vibrate or hum.

Connect CO tester using Adapter (VAG 1363/3) on CO tap tube. DO NOT

remove oxygen sensor. Ensure exhaust system has no leaks.

4) Start engine and let it run at closed throttle (less than

1500 RPM). Operate scan tester and observe display. Press "1" button

to select RAPID DATA TRANSFER function. Press "Q" button to enter

input. Press right arrow button.

5) Press "0" and "1" buttons to select ENGINE ELECTRONICS

function. Press "Q" button to enter input. Press right arrow button,

then "0" and "4" buttons to select BASIC SETTING function. Press "Q"

button to enter input.

6) Press "0" and "1" buttons to select INPUT DISPLAY GROUP

NUMBER 01. Press "Q" button to enter input. Scan tester will display

SYSTEM IN BASIC ADJUSTMENT 1 through 4. Briefly increase engine speed

and then let it run for 2 minutes at closed throttle. Scan tester

displays idle speed in field one and ignition timing in field four.

Check CO level on CO tester.

7) When radiator cooling fan stops running, end basic setting

Page 495 of 920

D - ADJUSTMENTS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:59PM

function by pressing right arrow button. Press "0" and "6" for END

OUTPUT function. Press "Q" button to enter input.

8) If idle speed, CO level or ignition timing is incorrect,

turn ignition off. Check accelerator pedal and throttle cable for ease

of operation. Check dashpot adjustment. Check throttle position

sensor, idle air control valve, and EGR valve.

IDLE SPEED & MIXTURE

NOTE: Mixture adjustment is NOT a part of normal tune-up procedure

and should not be performed unless mixture control unit is

replaced or vehicle fails emissions testing.

NOTE: Ensure fuel system pressure is correct before attempting

idle speed or mixture adjustment.

VR6 IDLE SPEED & MIXTURE ADJUSTMENT

See VR6 IGNITION TIMING under IGNITION TIMING near the

beginning of this article.

THROTTLE BODY

THROTTLE BODY ADJUSTMENT

CAUTION: Throttle limiting (stop) screw is set by manufacturer and

should NOT be moved. If screw is accidentally turned,

perform throttle body adjustment.

If stop screw for basic throttle adjustment has been moved,

replace throttle body.

DASHPOT

Open and close throttle until dashpot piston contacts roller.

With throttle in this position, check gap between limiter (stop) screw

and throttle. Gap between limiter (stop) screw and throttle lever must

be 0.10-0.14" (2.5-3.5 mm).

IDLE & FULL THROTTLE SWITCHES

THROTTLE POSITION (TP) SENSOR ADJUSTMENT

1) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. Turn

ignition on. Operate scan tester and select RAPID DATA TRANSFER,

ENGINE ELECTRONICS, then READ MEASURING VALUE BLOCK functions.

2) Press "0" and "3" buttons to select INSERT DISPLAY GROUP

NUMBER 03 function. Press "Q" button to enter input. Slowly open

throttle, while observing display in channel 3, until throttle is wide

open. Numerical value must increase uniformly over entire opening

Page 496 of 920

D - ADJUSTMENTS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:59PM

range and without interruption.

3) Reading should be 5-19 at idle. Reading should be 94-100

at full throttle stop. If readings are correct, press right arrow

button. Press "0" and "6" to select ENDING OUTPUT function. Press "Q"

button to enter input. If readings are incorrect, check TP sensor

circuit or replace TP sensor as necessary.

END OF ARTICLE

Page 506 of 920

E - THEORY/OPERATION

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Theory & Operation - Motronic

Corrado SLC

INTRODUCTION

This article covers basic description and operation of engine

performance-related systems and components. Read this article before

diagnosing vehicles or systems with which you are not completely

familiar.

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL UNIT

The Motronic engine management system uses a single

Electronic Control Module (ECM) for fuel injection, idle speed

control, ignition, and emission controls. The Electronic Control

Module (ECM) continually corrects air/fuel mixture based on signals

from various signals. The ECM is located underneath center of

windshield cowl, directly behind engine compartment firewall.

NOTE: Components are grouped into 2 categories. The first category

covers INPUT DEVICES, which control or produce voltage

signals monitored by the control unit. The second category

covers OUTPUT SIGNALS, which are components controlled by

the control unit.

INPUT DEVICES

Engine Coolant Temperature (ECT) Sensor

Sensor is located on thermostat housing. As engine coolant

temperature increases, the resistance of the sensor decreases. Engine

coolant temperature sensor signals are used for control of ignition

timing, injector pulse width, and idle speed stabilization. In

addition, knock sensors, idle speed control, oxygen sensor and fuel

tank venting are activated based on coolant temperature.

Engine Speed (RPM)/Reference Sensor

Engine speed (RPM) and crankshaft position are registered by

a single sensor located on side of engine block. The sensor reads a

toothed wheel mounted on the crankshaft. The wheel has a 2-tooth gap

which is used as a reference point for crankshaft position. The engine

speed/reference signal is used to monitor engine RPM and to identify

TDC position of cylinder No. 1.

Hall Effect Sensor

See ELECTRONIC IGNITION SYSTEM under IGNITION SYSTEM in this

Page 507 of 920

E - THEORY/OPERATION

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

article.

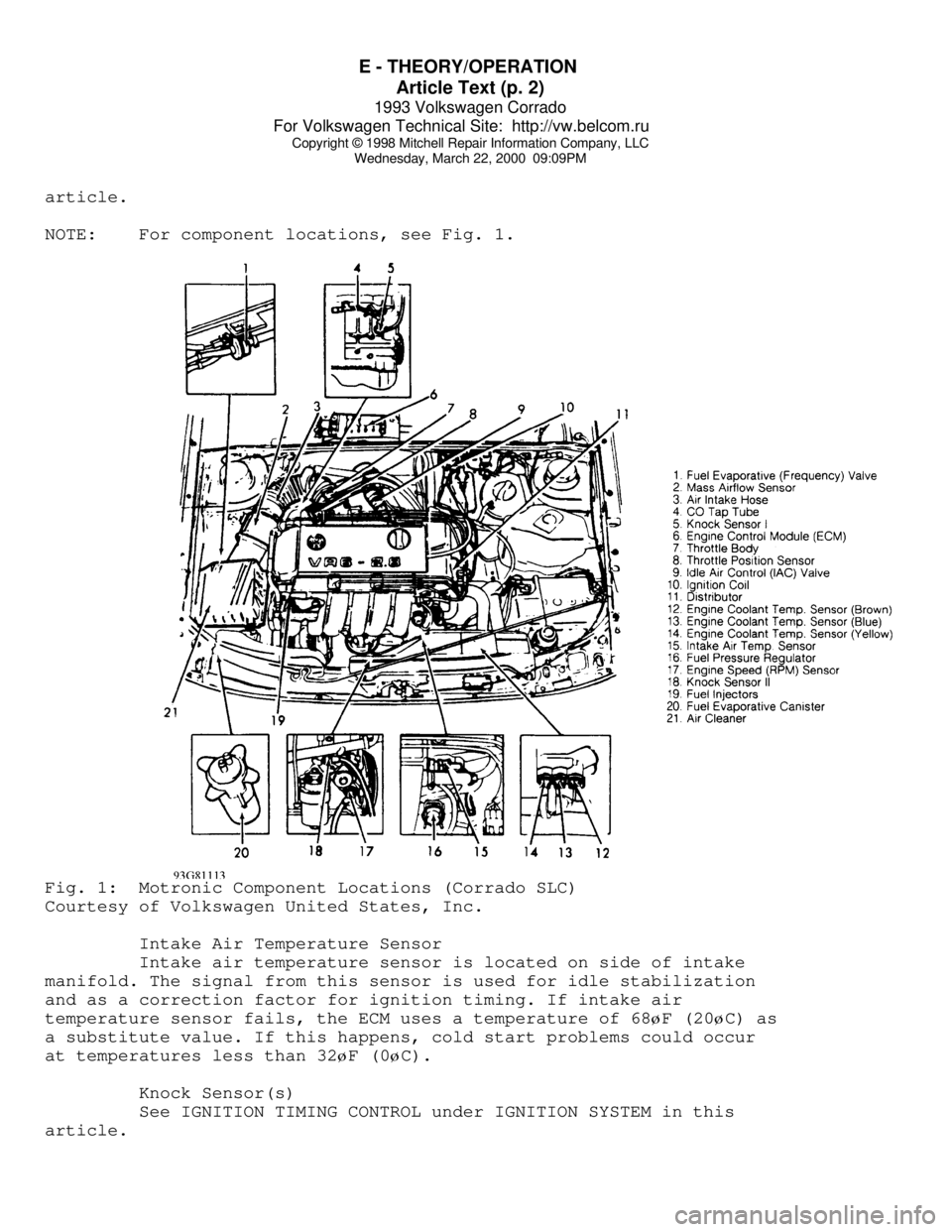

NOTE: For component locations, see Fig. 1.Fig. 1: Motronic Component Locations (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

Intake Air Temperature Sensor

Intake air temperature sensor is located on side of intake

manifold. The signal from this sensor is used for idle stabilization

and as a correction factor for ignition timing. If intake air

temperature sensor fails, the ECM uses a temperature of 68øF (20øC) as

a substitute value. If this happens, cold start problems could occur

at temperatures less than 32

øF (0øC).

Knock Sensor(s)

See IGNITION TIMING CONTROL under IGNITION SYSTEM in this

article.

Page 508 of 920

E - THEORY/OPERATION

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

Mass Airflow Sensor

A hot-wire air mass sensor is used to measure airflow into

the engine. The sensor is attached to air filter housing. The hot-wire

in sensor is kept at 356øF (180øC) above air temperature.

As airflow increases, the wire is cooled and the resistance

of the sensor changes. The resulting current change is converted to a

voltage signal and is used by the ECM to calculate the volume of air

taken in.

If a fault develops with mass airflow sensor signal, the

signal from throttle valve potentiometer is used as a substitute in

order for the car to be driveable.

Throttle Valve Potentiometer

Throttle valve potentiometer (throttle position sensor) is

connected to throttle valve shaft. It informs the ECM about the power

requested by the driver (throttle opening). Idle and full throttle

switches are NOT used in potentiometer. Idle speed and full throttle

applications are recognized by the ECM from the voltage output of the

potentiometer.

Throttle valve potentiometer signals are used for idle speed

stabilization, idle air volume control, fuel after-run shut-off, and

full throttle enrichment. The ECM uses mass airflow sensor signal and

engine RPM signals as substitute values if the potentiometer fails.

NOTE: On automatic transmission equipped vehicles, the throttle

valve potentiometer is combined in the housing with the

potentiometer for transmission control.

Oxygen (O2) Sensor

The heated oxygen sensor is made from zirconium dioxide,

while the inner and outer surfaces are coated with platinum. If fuel

mixture is lean (excess oxygen), the oxygen sensor will send a low

voltage signal (about 100 millivolts) to the ECM. If fuel mixture is

rich (lack of oxygen), the oxygen sensor will send a high voltage

signal (about 900 millivolts) to the ECM.

OUTPUT SIGNALS

NOTE: Vehicles are equipped with different combinations of

computer-controlled components. Not all components listed

below are used on every vehicle. For theory and operation on

each output component, refer to the system indicated after

component.

EGR Frequency Valve

See EXHAUST GAS RECIRCULATION (EGR) SYSTEM under EMISSION

SYSTEMS in this article.

Fuel Evaporative (Frequency) Valve

See FUEL EVAPORATIVE EMISSIONS SYSTEM under EMISSION SYSTEMS

in this article.

Page 510 of 920

E - THEORY/OPERATION

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:09PM

NOTE: Corrado SLC models are equipped with a Distributorless

Ignition System (DIS).

ELECTRONIC IGNITION SYSTEM

The electronic ignition system consists of ECM, power output

stage, ignition coil, distributor, mass airflow sensor, throttle valve

potentiometer, engine coolant temperature sensor, and Hall Effect

sensor.

Ignition system uses engine speed, engine load, and throttle

valve potentiometer signals to calculate ignition timing. Engine

coolant temperature signal is used to correct ignition timing when

engine is cold and to activate knock sensor circuit. See KNOCK

SENSOR(S) under IGNITION TIMING CONTROL in this article.

Hall Effect Sensor

On Corrado SLC, this sensor is mounted on end of camshaft

(near ignition coil). Sensor consists of a magnetic enclosure and

integrated semi-conductor circuit. A voltage signal is generated when

trigger wheel, turning at camshaft speed, interrupts magnetic field

created by the semi-conductor. Hall Effect sensor and engine

speed/reference signals are used to identify TDC position of cylinder

No. 1 for sequential fuel injection and spark knock regulation.

DISTRIBUTORLESS IGNITION SYSTEM (DIS)

Hall Effect Sensor

See HALL EFFECT SENSOR under ELECTRONIC IGNITION SYSTEM in

this article.

Ignition Coil & Output Stage

The distributorless (direct) ignition system consists of ECM,

power output stage, 3 double-ended ignition coils and secondary

ignition wires. The ECM operates each ignition coil through the power

output stage. The power output stage and heat sink are located behind

ignition coils. The ignition coils are located on left side of

cylinder head. When the power output stage fires an ignition coil, a

spark is supplied to 2 spark plugs at one time. One spark plug fires

during the compression stroke, and the other spark plug fires during

the exhaust stroke (waste spark).

IGNITION TIMING CONTROL

Knock Sensor(s)

The knock sensor(s) work(s) like a microphone to "listen" for

spark knock (detonation). When detonation occurs, ignition timing is

retarded until the knock is eliminated.

On Corrado SLC, 2 knock sensors are mounted on side of engine

block. Knock sensor I monitors cylinders No. 1, 3 and 5. Knock sensor

II monitors cylinders No. 2, 4 and 6.