VOLKSWAGEN PASSAT 1995 B3, B4 / 3.G Service Workshop Manual

PASSAT 1995 B3, B4 / 3.G

VOLKSWAGEN

VOLKSWAGEN

https://www.carmanualsonline.info/img/18/7419/w960_7419-0.png

VOLKSWAGEN PASSAT 1995 B3, B4 / 3.G Service Workshop Manual

Trending: seats, wheel size, oil pressure, check engine, height, load capacity, transmission fluid

Page 131 of 369

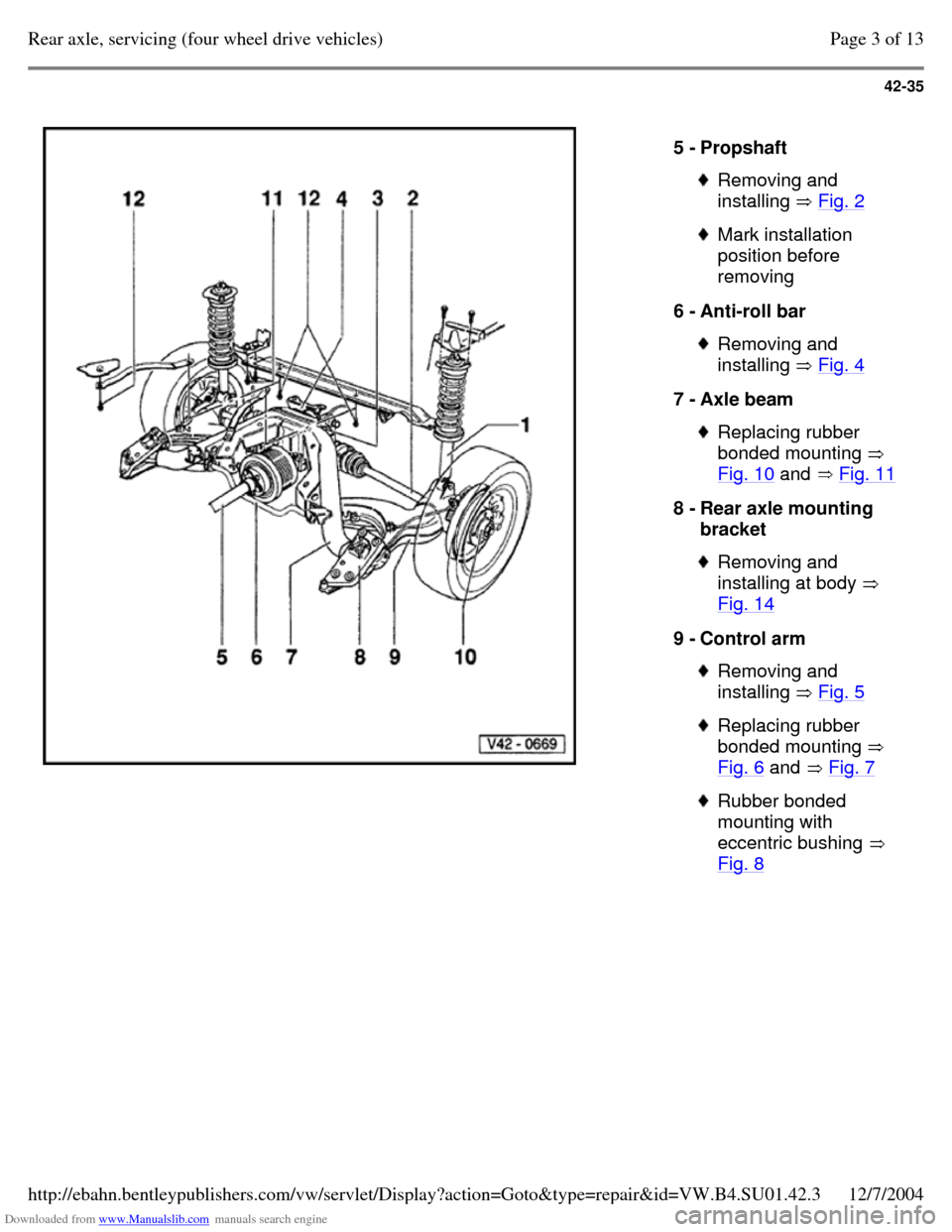

Downloaded from www.Manualslib.com manuals search engine 42-35

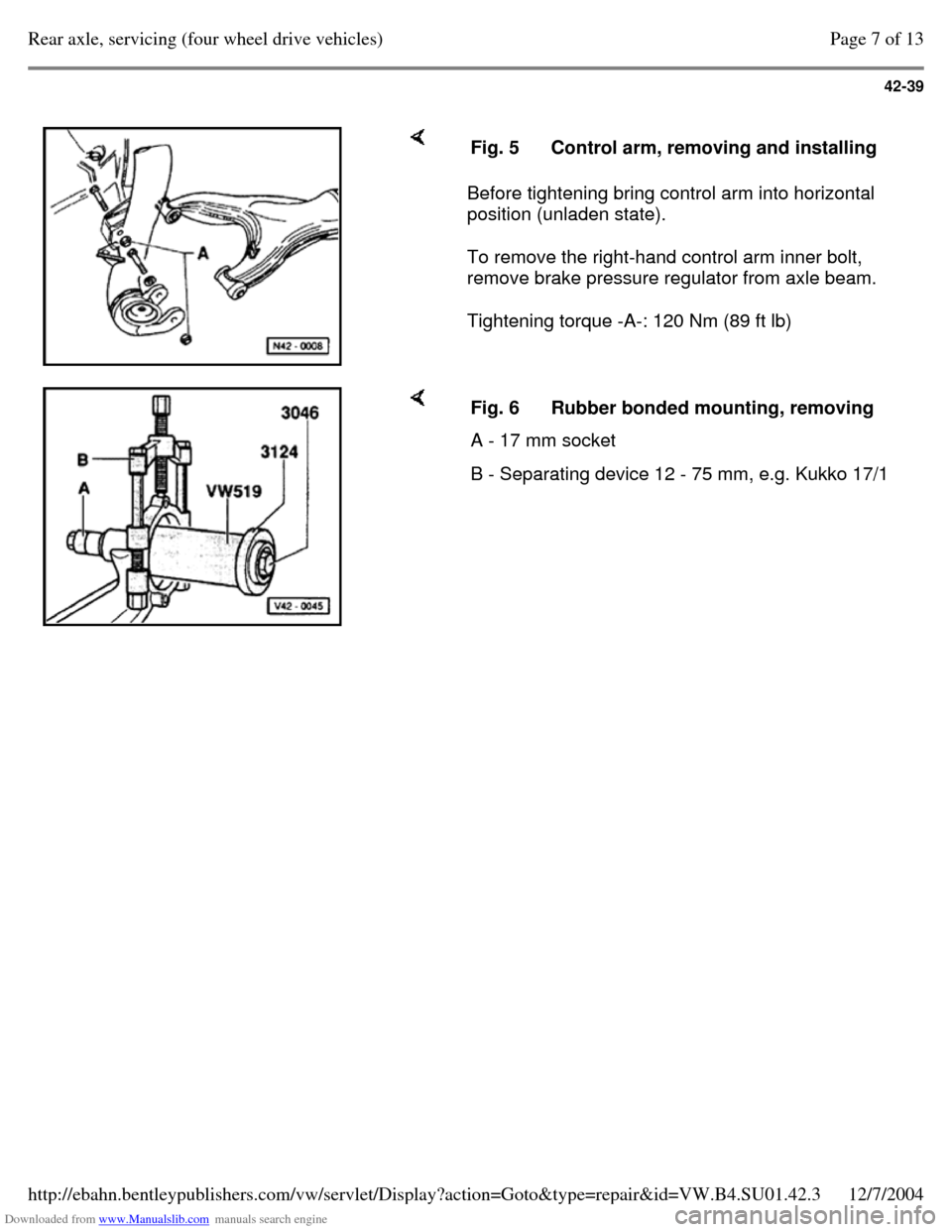

5 - Propshaft Removing and

installing Fig. 2 Mark installation

position before

removing

6 - Anti-roll bar Removing and

installing Fig. 4 7 - Axle beam Replacing rubber

bonded mounting

Fig. 10 and Fig. 11 8 - Rear axle mounting

bracket Removing and

installing at body

Fig. 14 9 - Control arm Removing and

installing Fig. 5 Replacing rubber

bonded mounting

Fig. 6 and Fig. 7 Rubber bonded

mounting with

eccentric bushing

Fig. 8 Page 3 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 132 of 369

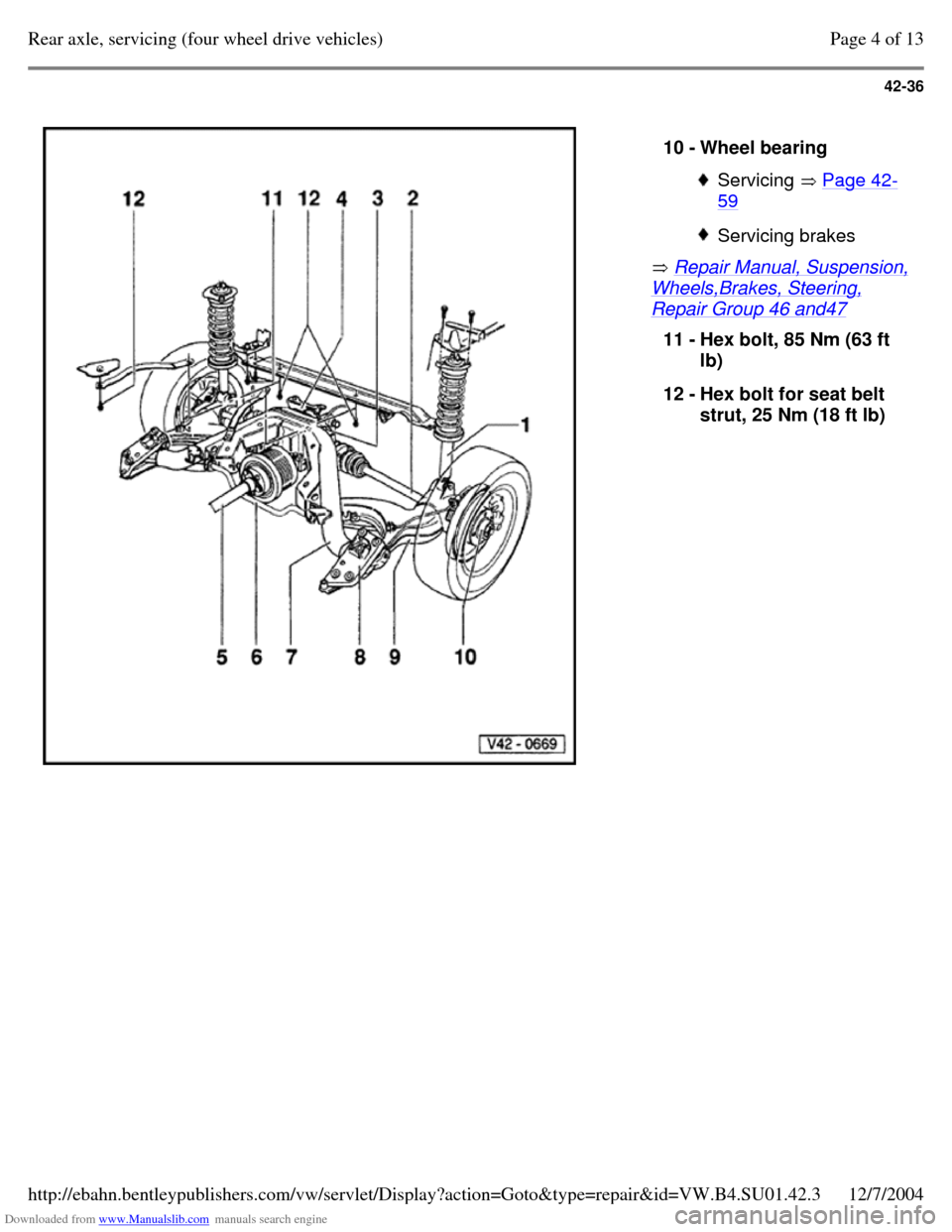

Downloaded from www.Manualslib.com manuals search engine 42-36

Repair Manual, Suspension, Wheels,Brakes, Steering, Repair Group 46 and47 10 - Wheel bearing Servicing Page 42-59 Servicing brakes 11 - Hex bolt, 85 Nm (63 ft

lb)

12 - Hex bolt for seat belt

strut, 25 Nm (18 ft lb) Page 4 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 133 of 369

Downloaded from www.Manualslib.com manuals search engine 42-37

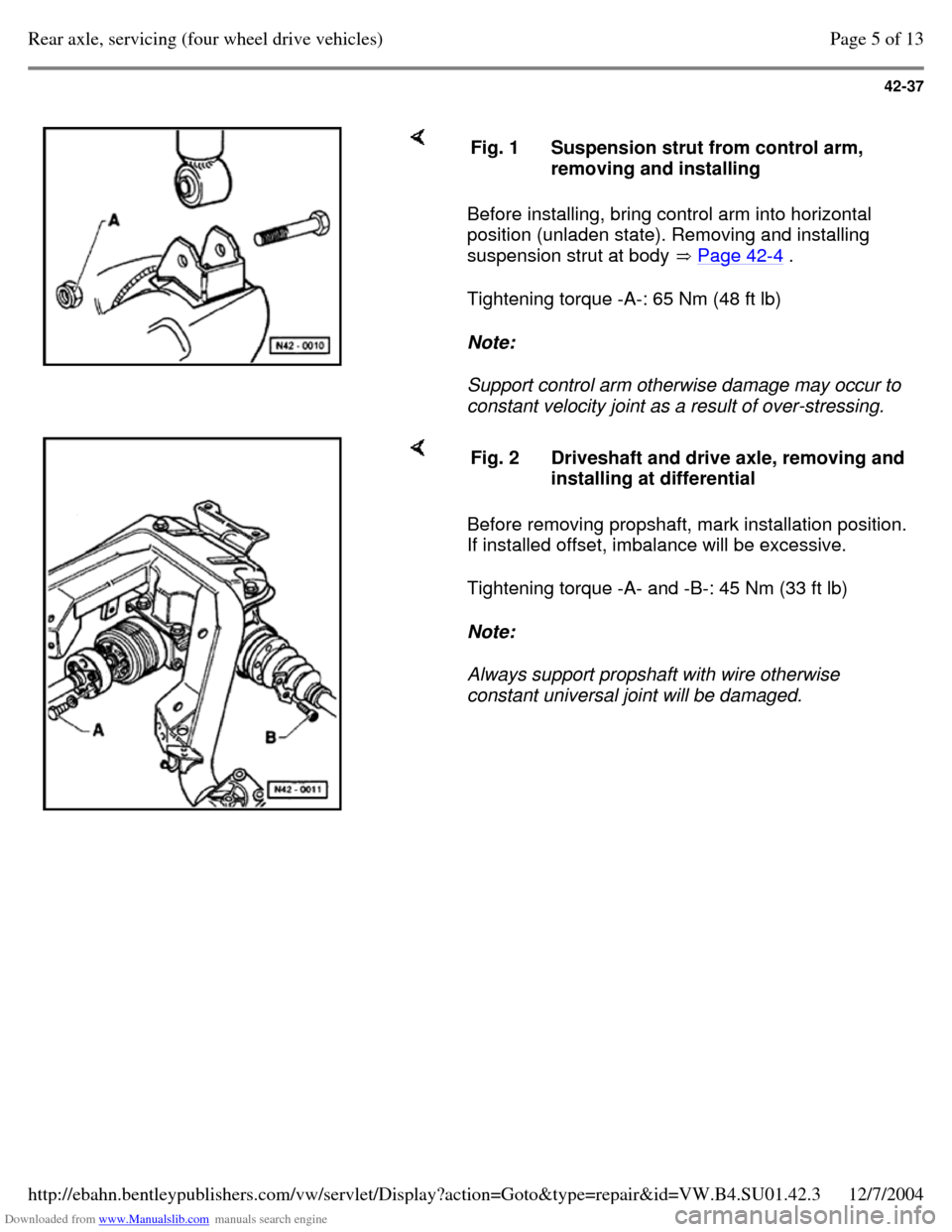

Before installing, bring control arm into horizontal

position (unladen state). Removing and installing

suspension strut at body Page 42-4 .

Tightening torque -A-: 65 Nm (48 ft lb)

Note:

Support control arm otherwise damage may occur to

constant velocity joint as a result of over-stressing. Fig. 1 Suspension strut from control arm,

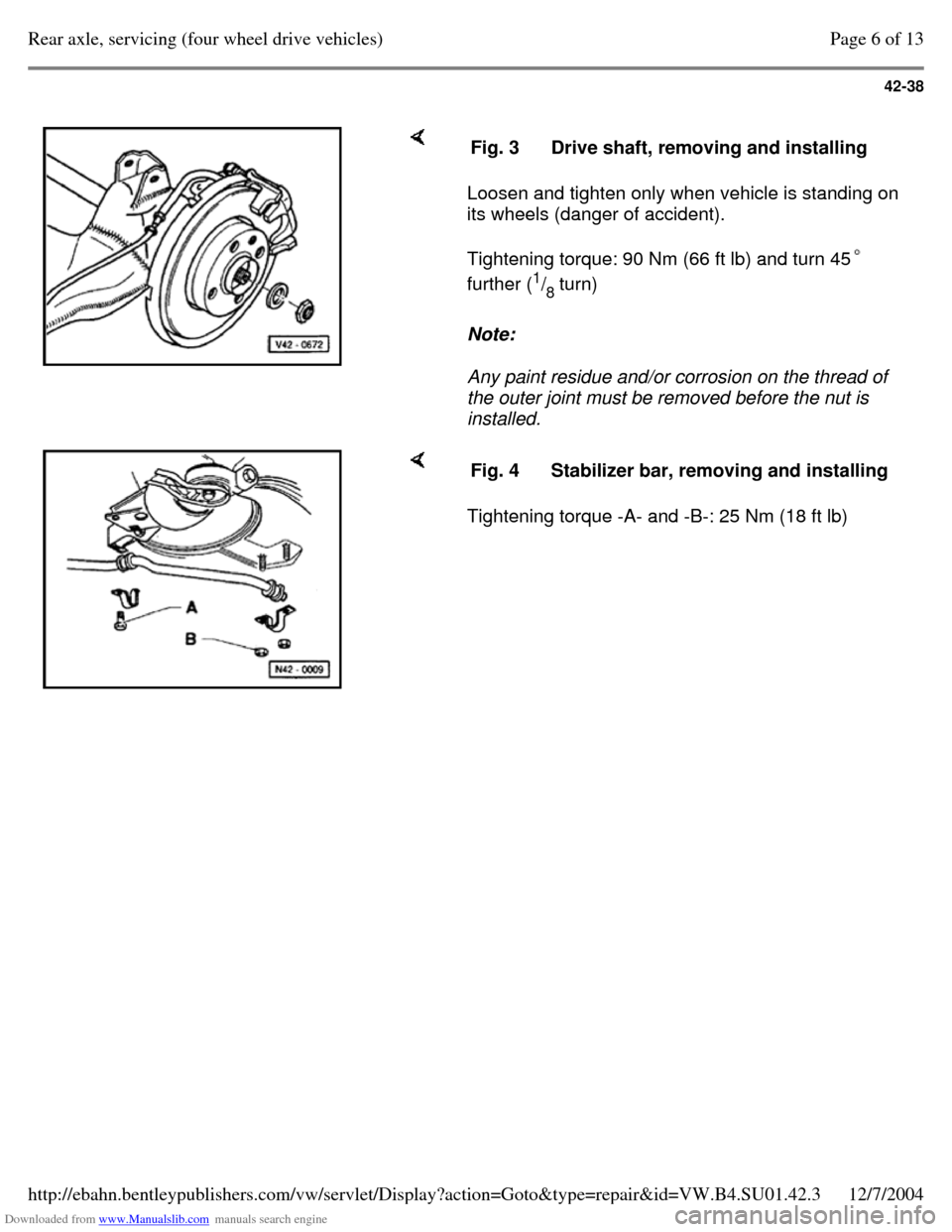

removing and installing Before removing propshaft, mark installation position.

If installed offset, imbalance will be excessive.

Tightening torque -A- and -B-: 45 Nm (33 ft lb)

Note:

Always support propshaft with wire otherwise

constant universal joint will be damaged. Fig. 2 Driveshaft and drive axle, removing and

installing at differential Page 5 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 134 of 369

Downloaded from www.Manualslib.com manuals search engine 42-38

Loosen and tighten only when vehicle is standing on

its wheels (danger of accident).

Tightening torque: 90 Nm (66 ft lb) and turn 45

further (1

/

8 turn)

Note:

Any paint residue and/or corrosion on the thread of

the outer joint must be removed before the nut is

installed. Fig. 3 Drive shaft, removing and installing Tightening torque -A- and -B-: 25 Nm (18 ft lb) Fig. 4 Stabilizer bar, removing and installing Page 6 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 135 of 369

Downloaded from www.Manualslib.com manuals search engine

Page 136 of 369

Downloaded from www.Manualslib.com manuals search engine 42-40

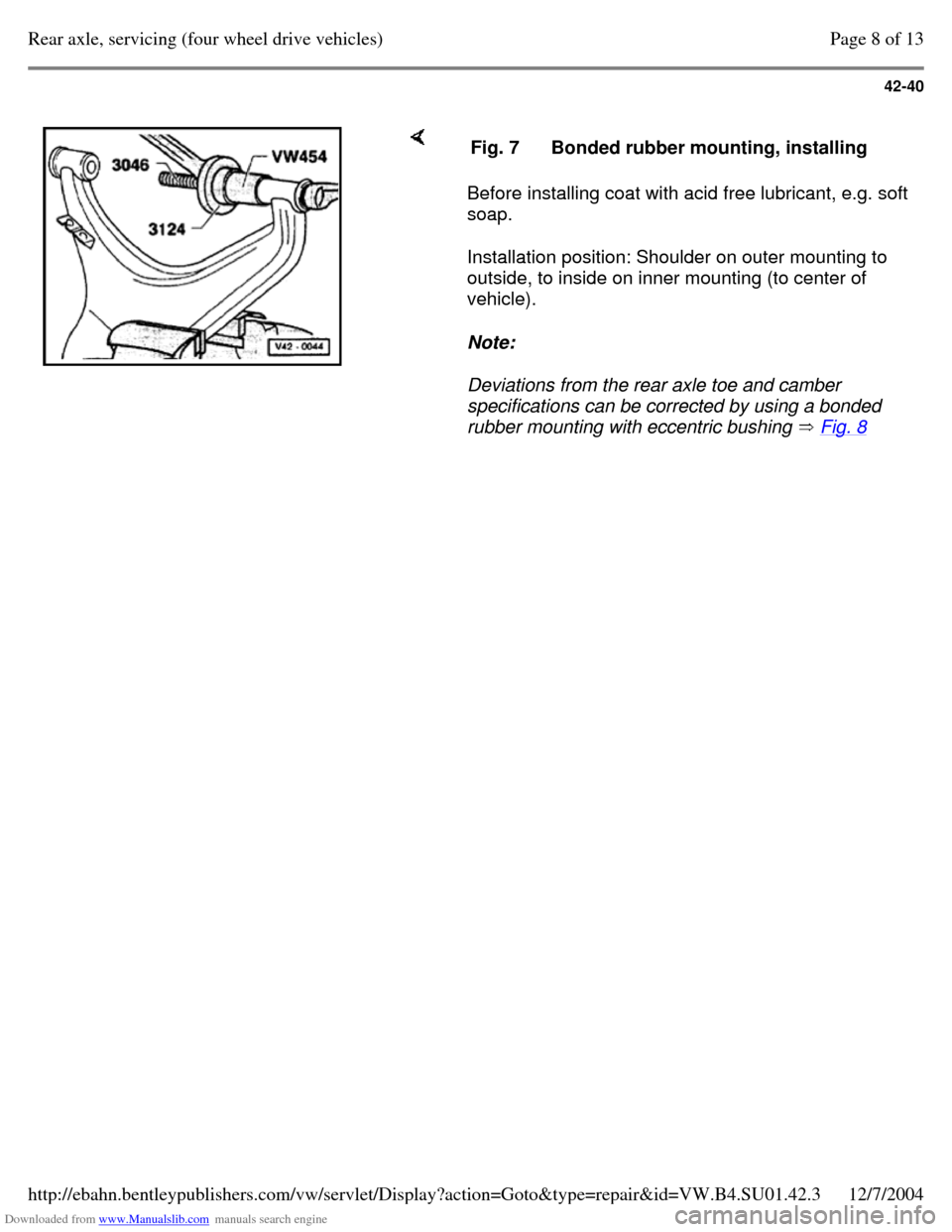

Before installing coat with acid free lubricant, e.g. soft

soap.

Installation position: Shoulder on outer mounting to

outside, to inside on inner mounting (to center of

vehicle).

Note:

Deviations from the rear axle toe and camber

specifications can be corrected by using a bonded

rubber mounting with eccentric bushing Fig. 8 Fig. 7 Bonded rubber mounting, installing Page 8 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 137 of 369

Downloaded from www.Manualslib.com manuals search engine 42-41

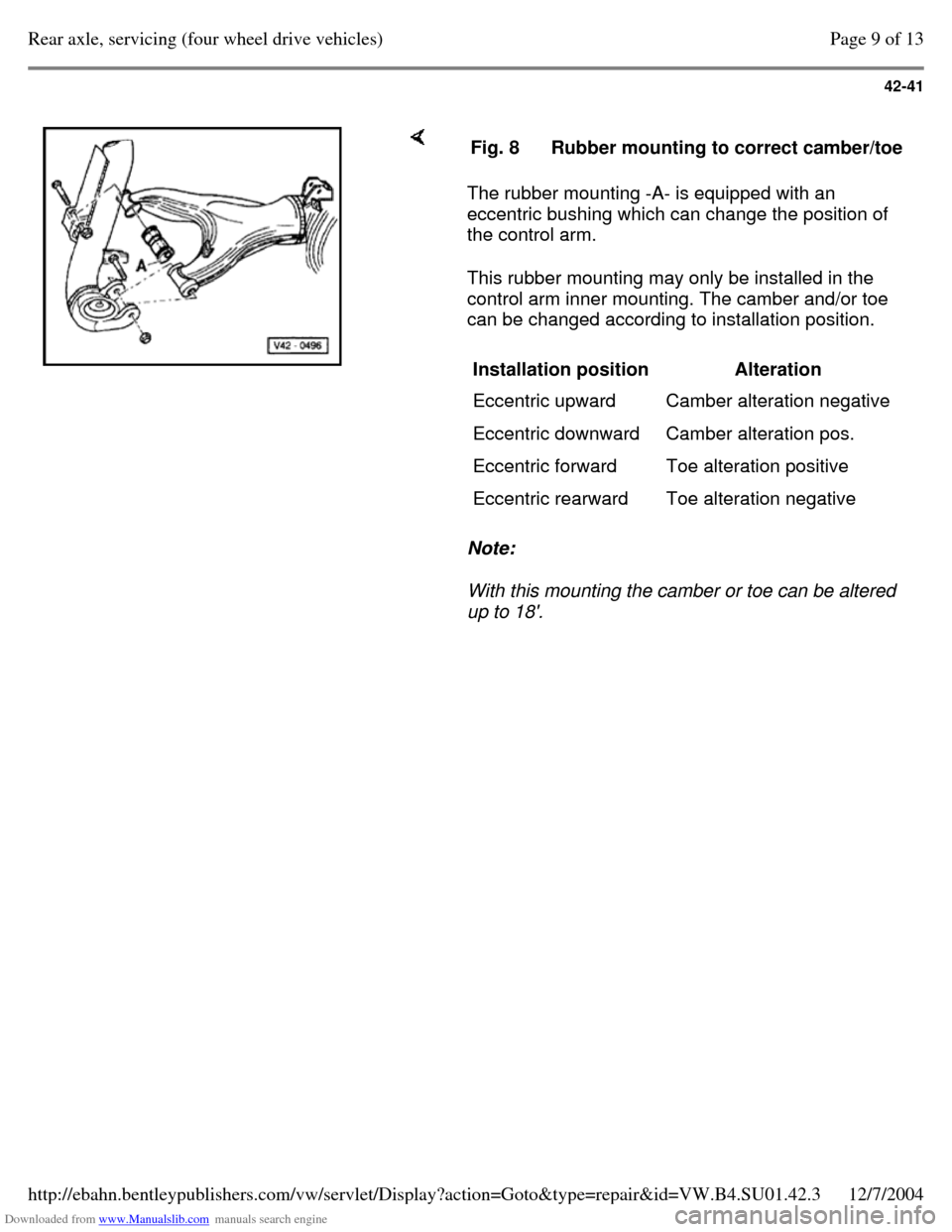

The rubber mounting -A- is equipped with an

eccentric bushing which can change the position of

the control arm.

This rubber mounting may only be installed in the

control arm inner mounting. The camber and/or toe

can be changed according to installation position.

Note:

With this mounting the camber or toe can be altered

up to 18'. Fig. 8 Rubber mounting to correct camber/toe Installation position

Alteration

Eccentric upward Camber alteration negative

Eccentric downward Camber alteration pos.

Eccentric forward Toe alteration positive

Eccentric rearward Toe alteration negative Page 9 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 138 of 369

Downloaded from www.Manualslib.com manuals search engine 42-42

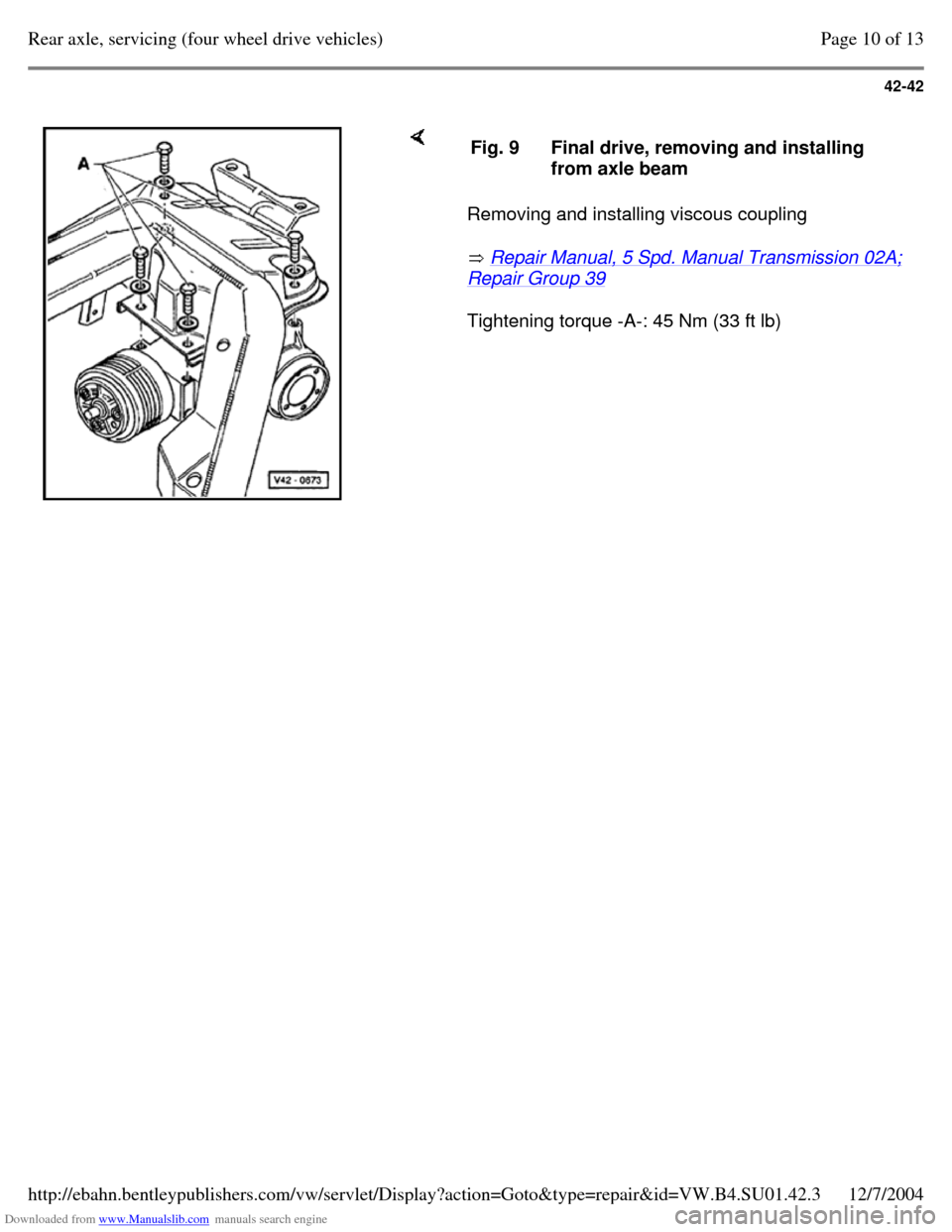

Removing and installing viscous coupling

Repair Manual, 5 Spd. Manual Transmission 02A; Repair Group 39

Tightening torque -A-: 45 Nm (33 ft lb) Fig. 9 Final drive, removing and installing

from axle beam Page 10 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 139 of 369

Downloaded from www.Manualslib.com manuals search engine 42-43

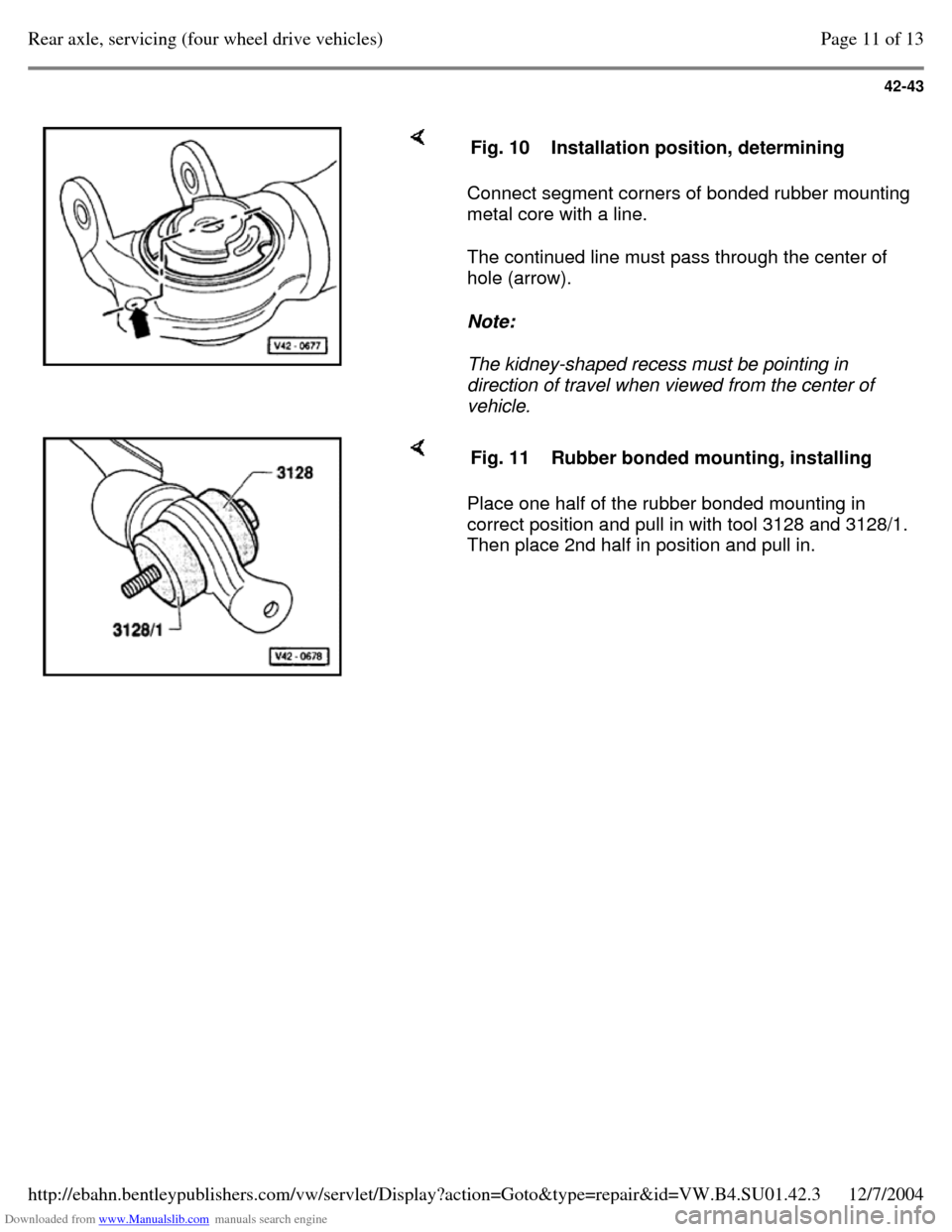

Connect segment corners of bonded rubber mounting

metal core with a line.

The continued line must pass through the center of

hole (arrow).

Note:

The kidney-shaped recess must be pointing in

direction of travel when viewed from the center of

vehicle. Fig. 10 Installation position, determining Place one half of the rubber bonded mounting in

correct position and pull in with tool 3128 and 3128/1.

Then place 2nd half in position and pull in. Fig. 11 Rubber bonded mounting, installing Page 11 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 140 of 369

Downloaded from www.Manualslib.com manuals search engine 42-44

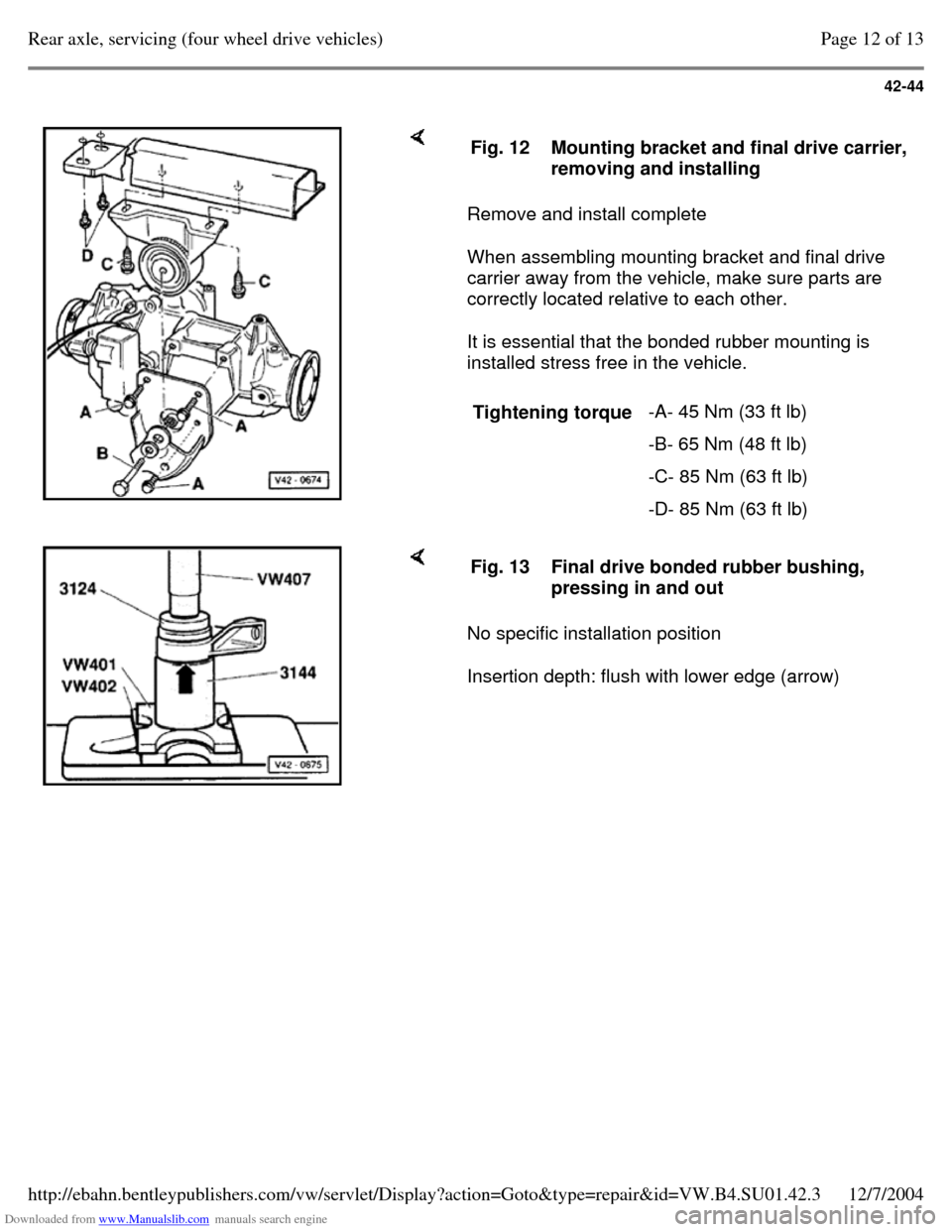

Remove and install complete

When assembling mounting bracket and final drive

carrier away from the vehicle, make sure parts are

correctly located relative to each other.

It is essential that the bonded rubber mounting is

installed stress free in the vehicle. Fig. 12 Mounting bracket and final drive carrier, removing and installing

Tightening torque -A- 45 Nm (33 ft lb)

-B- 65 Nm (48 ft lb)

-C- 85 Nm (63 ft lb)

-D- 85 Nm (63 ft lb) No specific installation position

Insertion depth: flush with lower edge (arrow) Fig. 13 Final drive bonded rubber bushing,

pressing in and out Page 12 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Trending: air suspension, ad blue, steering wheel, seat adjustment, check oil, Power steering, height