ECU VOLKSWAGEN TIGUAN 2017 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2017, Model line: TIGUAN, Model: VOLKSWAGEN TIGUAN 2017Pages: 341, PDF Size: 9.14 MB

Page 280 of 341

With the engine at operating temperature, park the vehicle on a level surface to ensure

that the engine oil reading is correct.

Switch off the engine and wait a few minutes for the engine oil to flow back into the sump.

Open the bonnet In the engine compartment.

Identify the engine oil filler cap and oil dipstick. The engine oil filler opening bears the

symbol on the cap and the oil dipstick has a coloured handle. If you cannot find the cap

and dipstick please contact a qualified workshop.

Pull the dipstick out of the guide tube and wipe it off with a clean cloth.

Insert the oil dipstick into the guide tube again as far as it will go. If there is a marking on

the upper end of the oil dipstick, this marking must fit in the corresponding groove at the

top end of the guide tube when inserting.

After reading off the oil level, push the oil dipstick back into the guide tube as far as it will

go.

Unscrew the engine oil filler opening cap .

Only the engine oil expressly approved by Volkswagen for this engine should be gradually

refilled in small quantities (no more than 0.5 l).

In order to avoid overfilling, wait for approximately one minute after each refill step to allow

the engine oil to flow into the oil sump up to the marking on the engine oil dipstick.

Read the engine oil level from the dipstick again before refilling with a further small

quantity of engine oil. Never overfill with engine oil .

After refilling, the engine oil level should be in the middle of area Ⓒ. It should not be above

Ⓒ, in area Ⓑ, and must not reach area Ⓐ .

If too much engine oil has been added unintentionally and the engine oil level is in area Ⓐ,

do not start the engine. Inform a qualified workshop and possibly seek expert assistance.

After refilling, close the engine oil filler opening with the cap.

Insert the oil dipstick into the guide tube as far as it will go. If there is a marking on the

upper end of the oil dipstick, this marking must fit in the corresponding groove at the top

end of the guide tube when inserting.

Close the bonnet In the engine compartment.

Do not refill engine oil.

Engine oil level OK.

Engine oil level too low – refill engine oil.

Checklist

Carry out the steps in the specified order ⇒:

Pull the dipstick out again and read the engine oil level on the dipstick as follows: Ⓐ Engine

oil level too high. Follow any messages that are shown on the instrument cluster display and

go to a qualified workshop . Ⓑ Do not fill the engine oil . Continue to step 16. Ⓒ Engine oil

level OK. Engine oil can, e.g. in the case of high engine loads , be filled up to the upper limit

of this range. Continue to step 8 or 16. Ⓓ Engine oil level is too low. The engine oil must be

refilled. Continue to step 8.

The engine oil level must never be above area ⇒ Fig. 227Ⓑ. Otherwise oil can be drawn in

through the crankcase breather and escape into the atmosphere via the exhaust system.

Troubleshooting

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Engine oil can ignite if it comes into contact with hot engine components. It can cause

fires, burns and other serious injuries.

•If engine oil is spilt on cold engine parts it can heat up and ignite when the engine is

running.

•Always ensure that the engine oil filler cap is securely tightened after refilling, and that

the dipstick is properly inserted back into the guide tube. This will prevent the engine

oil from draining out on to hot engine components when the engine is running.

WARNING

•If too much engine oil has been added unintentionally and the engine oil level is in area

⇒ Fig. 227Ⓐ, do not start the engine. Inform a qualified workshop and possibly seek

expert assistance. The catalytic converter and the engine could otherwise be damaged.

•When topping up service fluids, please ensure that you pour the correct service fluids

into the correct openings. The use of incorrect service fluids could result in serious

malfunctions and engine damage.

NOTICE

Page 289 of 341

Dispose of the 12-volt vehicle battery in accordance with the regulations. 12-volt vehicle

batteries may contain toxic substances such as sulphuric acid and lead.

Electrolyte can pollute the environment. Clean up any service fluid leakages and dispose of

them properly.

Troubleshooting

First read and observe the introductoryinformation and safety warnings⇒

Introduction

12-volt vehicle battery

Fault in the alternator. Go to a qualified workshop. Have the electrical system checked. Switch

off any electrical consumers that are not required. The 12-volt vehicle battery will not be charged by

the alternator while the vehicle is in motion. The start/stop system cannot start the engine.

⇒ Start/stop system

Wheels and tyres

Tyre monitoring systems

Introduction

This chapter contains information on the followingsubjects:

⇒ Types of tyre monitoring systems

⇒ Tyre Pressure Loss Indicator

⇒ Tyre Pressure Monitoring System

⇒ Troubleshooting for the Tyre Pressure Loss Indicator

⇒ Troubleshooting for the Tyre Pressure Monitoring System

The tyre monitoring system warns the

driver when the tyre pressures get too

low.

Incorrectly securing the battery and using incorrect 12-volt vehicle batteries can cause

short circuits, fire and serious injuries.

•Always use maintenance-free and leak-proof 12-volt vehicle batteries that have the

same properties, specifications and dimensions as the factory-fitted 12-volt vehicle

battery.

•In vehicles with the 12-volt vehicle battery in the luggage compartment, ensure that the

breather hose is connected properly to the 12-volt vehicle battery. Make sure that no

open gas discharge openings are located in the area around the positive battery

terminal. If there is an open breather opening in this area, it must be closed off with a

sealing plug. The breather hose must be connected to the open breather opening in the

area of the negative terminal.

WARNING

A highly explosive mixture of gases is given off when the 12-volt vehicle battery is being

charged.

•12-volt vehicle batteries should only be charged in well-ventilated spaces.

•Never charge a 12-volt vehicle battery that is frozen or that has thawed. Discharged 12-

volt vehicle batteries can already freeze at temperatures of around 0°C (+32°F).

•The 12-volt vehicle battery must be replaced if it has ever been frozen.

•Incorrectly connected cables can cause a short circuit. First connect the positive cable

and then the negative cable.

WARNING

•Never connect or disconnect 12-volt vehicle batteries if the ignition is switched on or

the engine is running. Never use a 12-volt vehicle battery that does not correspond with

the vehicle's specifications. This can damage the electrical system or electronic

components, which can cause electrical faults.

•Never connect equipment that supplies electric power, such as solar panels or a

battery charger, to the 12-volt socket or to the cigarette lighter to charge the 12-volt

vehicle battery. This can damage the vehicle electrical system.

NOTICE

Page 292 of 341

There may be differences between readings on the pressure gauge when filling the tyres and the

values determined by the Tyre Pressure Monitoring System. The Tyre Pressure Monitoring System

is more precise.

Selecting target pressures for partial or full vehicle load

The driver must select the appropriate target pressure depending on the vehicle load level.

•Switch on the ignition.

•Press the button or function button, depending on version ⇒ Vehicle settings menu.

•Touch the Vehicle status function button.

•Touch the Settings function button.

•Select the Tyres menu option.

•Select the load level.

Selecting the tyre type

While the dimensions of the tyres are changed, it may be necessary to adjust the target pressure

for the new tyres. If no adjustment is necessary, the selection menu will not be available.

•Switch on the ignition.

•Press the button or function button, depending on version ⇒ Vehicle settings menu.

•Touch the Vehicle status function button.

•Touch the Settings function button.

•Select the Tyres menu option.

•Select the appropriate tyre size.

If the tyre sizes are fitted that do not correspond to the factory-specified sizes, the corresponding

target tyre pressures can be entered by a Volkswagen dealer.

Spare wheel or temporary spare wheel

The tyre pressure of the spare wheel or the temporary spare wheel in the luggage compartment is

not monitored.

Depends on the vehicle.

Troubleshooting for the Tyre Pressure Loss Indicator

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Lit up

•Do not drive on!

•Check and adjust all tyre pressures ⇒ Tyre pressure.

•The damaged tyre should be replaced.

•Re-synchronise the Tyre Pressure Loss Indicator ⇒ Tyre Pressure Loss Indicator.

•If the problem persists, seek expert assistance.

Flashes

•Do not drive on!

•Switch the ignition off and then back on again.

•Re-synchronise the Tyre Pressure Loss Indicator ⇒ Tyre Pressure Loss Indicator.

•If the problem persists, seek expert assistance.

•The pressure sensors are secured to special aluminium valves that are screwed rigidly

in place. When inflating the tyres and checking the pressure, do not bend the valves

into position.

•Missing valve caps could lead to damage to the valve and the sensors. Always make

sure that all valve caps are fully screwed on. Do not use metal valve caps.

•Do not use convenience valve caps as they do not form a proper seal. This can cause

damage to the sensors.

NOTICE

1)

Page 300 of 341

Tyre damage

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Damage to tyres and wheel rims is often hidden ⇒.

•If you suspect that a wheel is damaged, stop the vehicle as soon as it is safe to do so.

•Check the tyres and rims for damage.

•If a tyre is damaged, do not drive on. Seek expert assistance.

•If there is no visible damage, drive slowly and cautiously to the next qualified workshop in order

to have the vehicle checked.

Foreign bodies in the tyre

•Leave the foreign body in the tyre if it has entered the inner tyre. Foreign bodies that are stuck

between the tyre tread blocks can be removed.

•Replace the damaged wheel ⇒ Changing a wheel or seal the tyre with the breakdown set and

inflate it ⇒ Breakdown set. Seek professional assistance for this if necessary.

•Check and adjust the tyre pressure.

•Go to a qualified workshop. Volkswagen recommends using a Volkswagen dealership for this

purpose.

Tyre wear

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Wheel imbalance may develop when the vehicle is driven; you will notice this by nervous steering

response. Unbalanced wheels will affect the level of tyre wear. In this case the wheels should be

balanced again.

Incorrect wheel alignment causes excessive tyre wear, impairing the safety of the vehicle. The

wheel alignment should be checked by a qualified workshop if tyres show excessive wear.

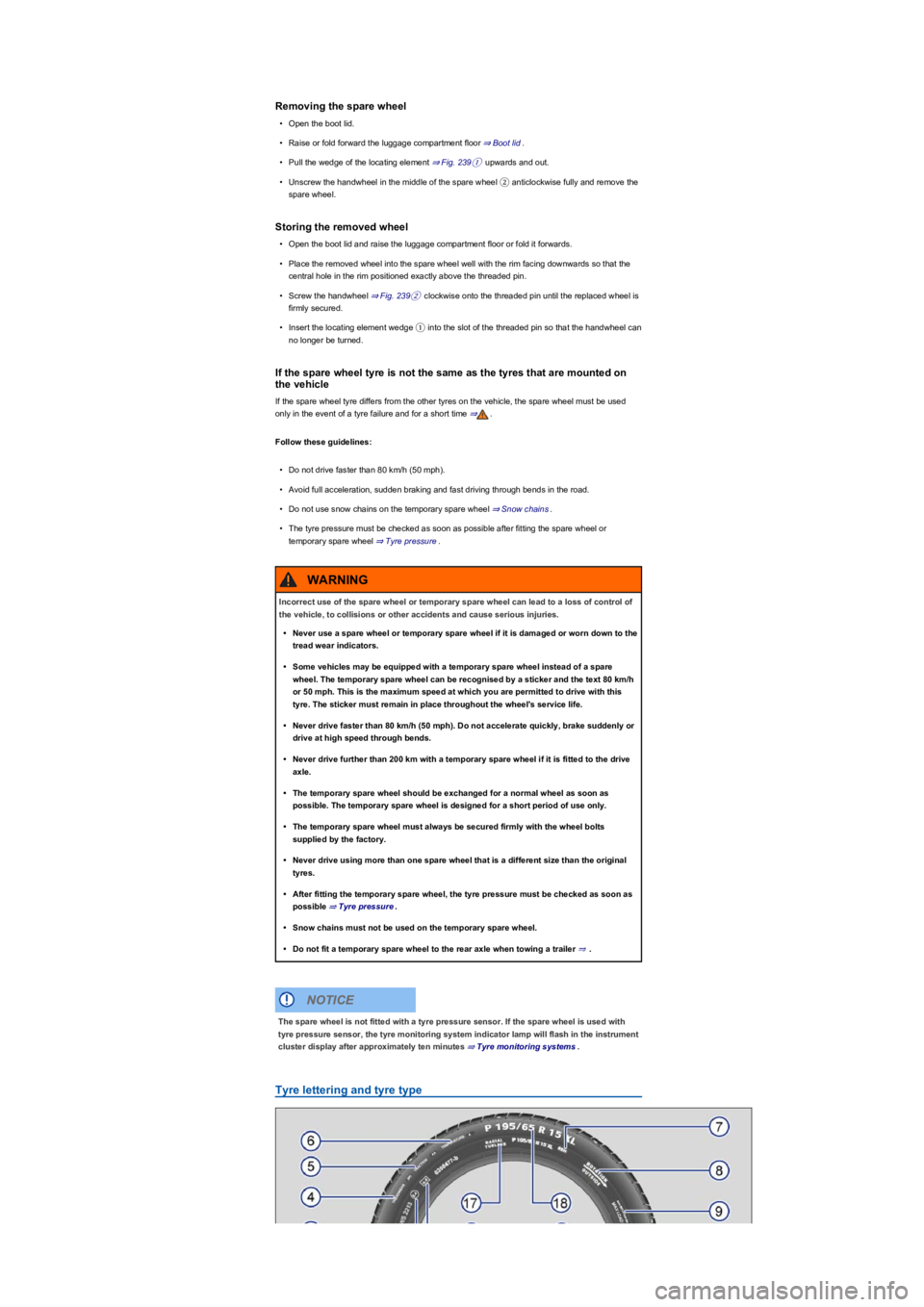

Spare wheel or temporary spare wheel

Fig. 239 In the luggage compartment: handwheel for securing the spare wheel.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Worn tyres are a safety risk and can lead to a loss of control of the vehicle and cause

serious injury.

•Tyres must be replaced at the latest when the tread is worn down to the tread wear

indicators.

•Worn tyres have considerably less grip, particularly on wet roads, which can cause the

vehicle to glide along the road surface (aquaplaning).

•Worn tyres reduce the possibility of controlling the vehicle well in normal and difficult

driving situations and increase braking distance and the risk of skidding.

WARNING

If you notice unusual vibration or the car pulling to one side while the vehicle is in motion,

this may indicate that one of the tyres is damaged.

•Reduce speed immediately and park the vehicle without obstructing traffic.

•Check the tyres and rims for damage.

•Never drive on if wheels or tyres are damaged. Seek expert assistance instead.

•If there is no visible damage, drive slowly and cautiously to the next qualified

workshop in order to have the vehicle checked.

WARNING

Page 301 of 341

Removing the spare wheel

•Open the boot lid.

•Raise or fold forward the luggage compartment floor ⇒ Boot lid.

•Pull the wedge of the locating element ⇒ Fig. 239① upwards and out.

•Unscrew the handwheel in the middle of the spare wheel ② anticlockwise fully and remove the

spare wheel.

Storing the removed wheel

•Open the boot lid and raise the luggage compartment floor or fold it forwards.

•Place the removed wheel into the spare wheel well with the rim facing downwards so that the

central hole in the rim positioned exactly above the threaded pin.

•Screw the handwheel ⇒ Fig. 239② clockwise onto the threaded pin until the replaced wheel is

firmly secured.

•Insert the locating element wedge ① into the slot of the threaded pin so that the handwheel can

no longer be turned.

If the spare wheel tyre is not the same as the tyres that are mounted on

the vehicle

If the spare wheel tyre differs from the other tyres on the vehicle, the spare wheel must be used

only in the event of a tyre failure and for a short time ⇒.

Follow these guidelines:

•Do not drive faster than 80 km/h (50 mph).

•Avoid full acceleration, sudden braking and fast driving through bends in the road.

•Do not use snow chains on the temporary spare wheel ⇒ Snow chains.

•The tyre pressure must be checked as soon as possible after fitting the spare wheel or

temporary spare wheel ⇒ Tyre pressure.

Tyre lettering and tyre type

Incorrect use of the spare wheel or temporary spare wheel can lead to a loss of control of

the vehicle, to collisions or other accidents and cause serious injuries.

•Never use a spare wheel or temporary spare wheel if it is damaged or worn down to the

tread wear indicators.

•Some vehicles may be equipped with a temporary spare wheel instead of a spare

wheel. The temporary spare wheel can be recognised by a sticker and the text 80 km/h

or 50 mph. This is the maximum speed at which you are permitted to drive with this

tyre. The sticker must remain in place throughout the wheel's service life.

•Never drive faster than 80 km/h (50 mph). Do not accelerate quickly, brake suddenly or

drive at high speed through bends.

•Never drive further than 200 km with a temporary spare wheel if it is fitted to the drive

axle.

•The temporary spare wheel should be exchanged for a normal wheel as soon as

possible. The temporary spare wheel is designed for a short period of use only.

•The temporary spare wheel must always be secured firmly with the wheel bolts

supplied by the factory.

•Never drive using more than one spare wheel that is a different size than the original

tyres.

•After fitting the temporary spare wheel, the tyre pressure must be checked as soon as

possible ⇒ Tyre pressure.

•Snow chains must not be used on the temporary spare wheel.

•Do not fit a temporary spare wheel to the rear axle when towing a trailer ⇒.

WARNING

The spare wheel is not fitted with a tyre pressure sensor. If the spare wheel is used with

tyre pressure sensor, the tyre monitoring system indicator lamp will flash in the instrument

cluster display after approximately ten minutes ⇒ Tyre monitoring systems.

NOTICE

Page 306 of 341

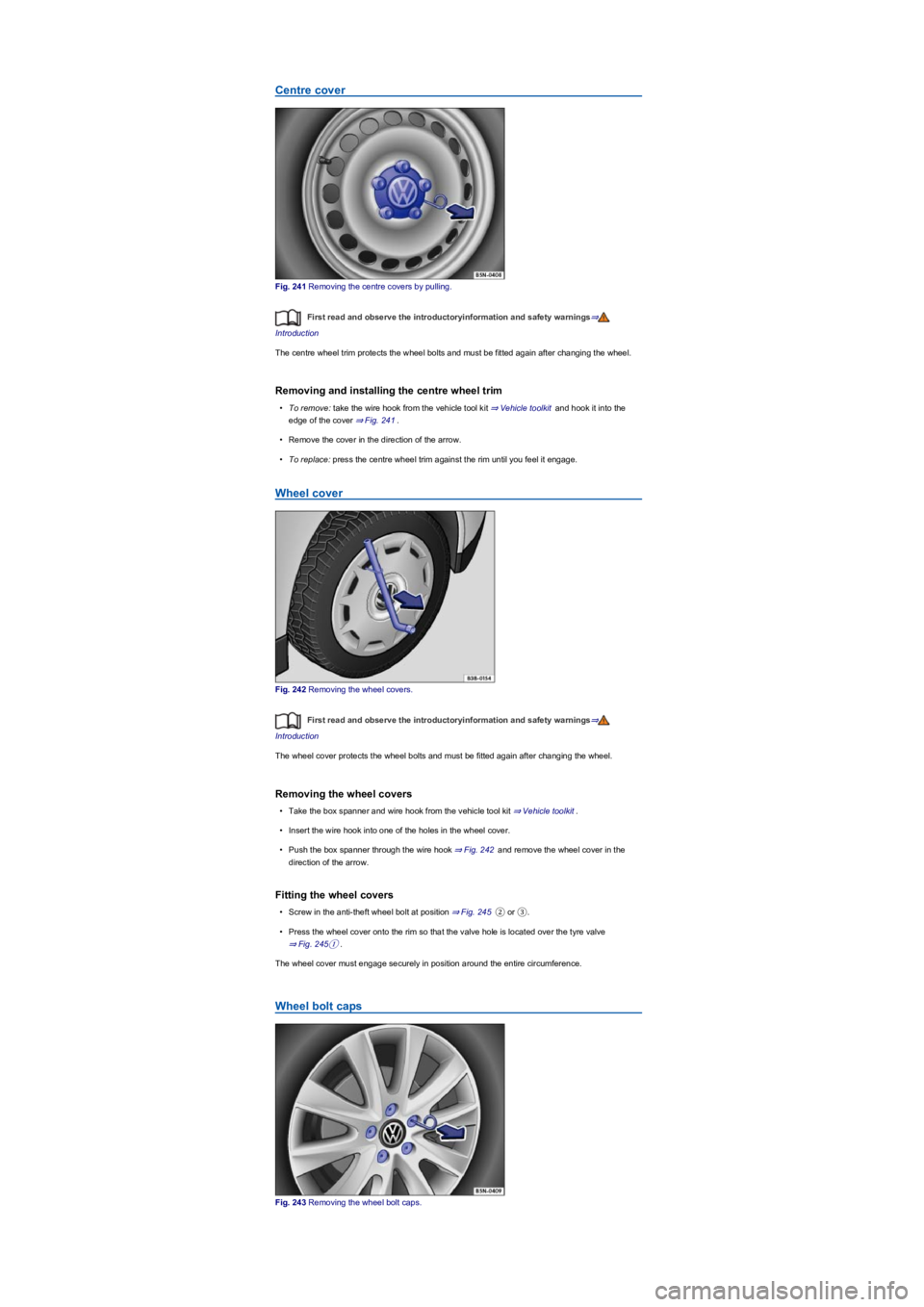

Centre cover

Fig. 241 Removing the centre covers by pulling.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The centre wheel trim protects the wheel bolts and must be fitted again after changing the wheel.

Removing and installing the centre wheel trim

•To remove: take the wire hook from the vehicle tool kit ⇒ Vehicle toolkit and hook it into the

edge of the cover ⇒ Fig. 241.

•Remove the cover in the direction of the arrow.

•To replace: press the centre wheel trim against the rim until you feel it engage.

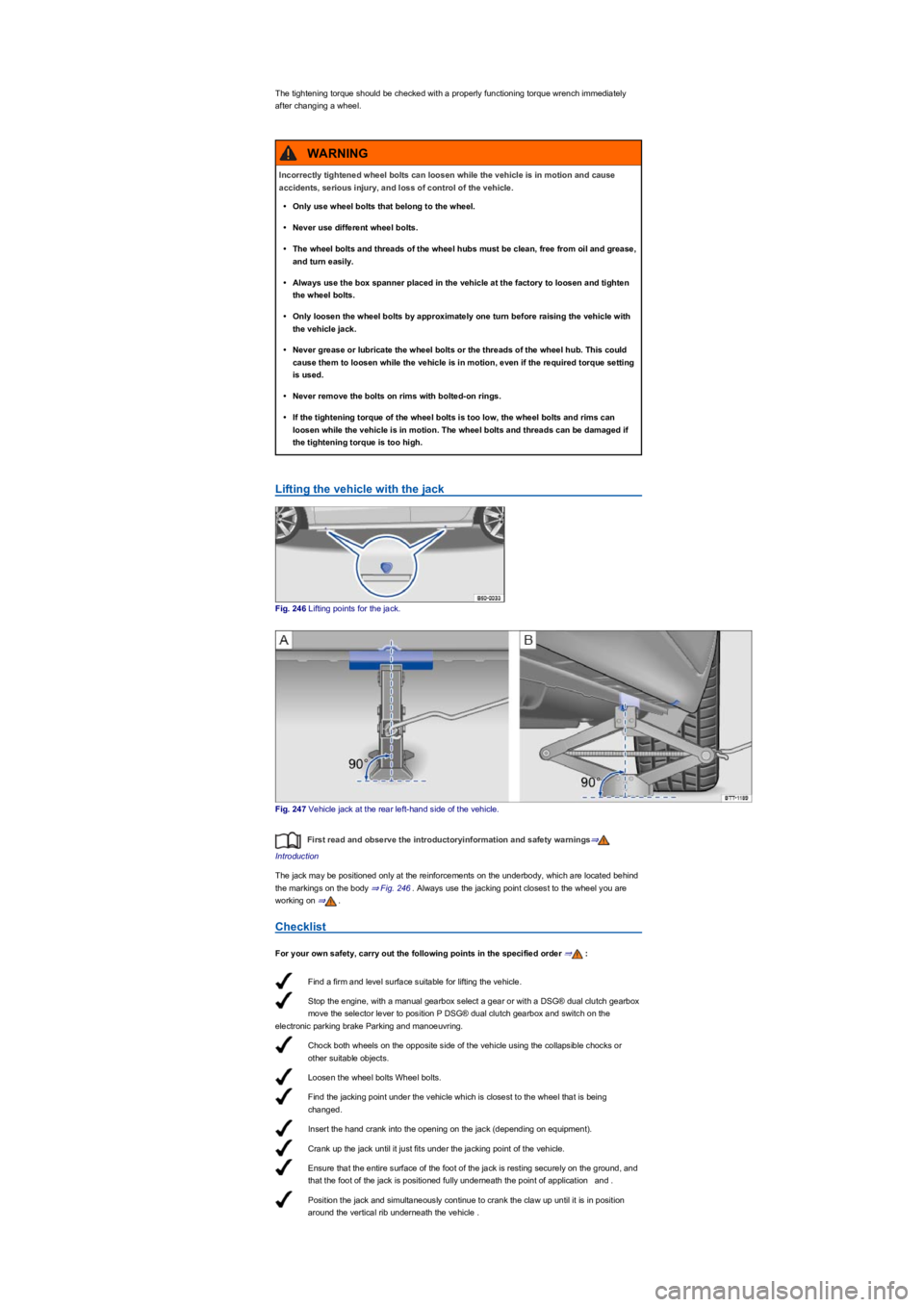

Wheel cover

Fig. 242 Removing the wheel covers.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The wheel cover protects the wheel bolts and must be fitted again after changing the wheel.

Removing the wheel covers

•Take the box spanner and wire hook from the vehicle tool kit ⇒ Vehicle toolkit.

•Insert the wire hook into one of the holes in the wheel cover.

•Push the box spanner through the wire hook ⇒ Fig. 242 and remove the wheel cover in the

direction of the arrow.

Fitting the wheel covers

•Screw in the anti-theft wheel bolt at position ⇒ Fig. 245② or ③.

•Press the wheel cover onto the rim so that the valve hole is located over the tyre valve

⇒ Fig. 245①.

The wheel cover must engage securely in position around the entire circumference.

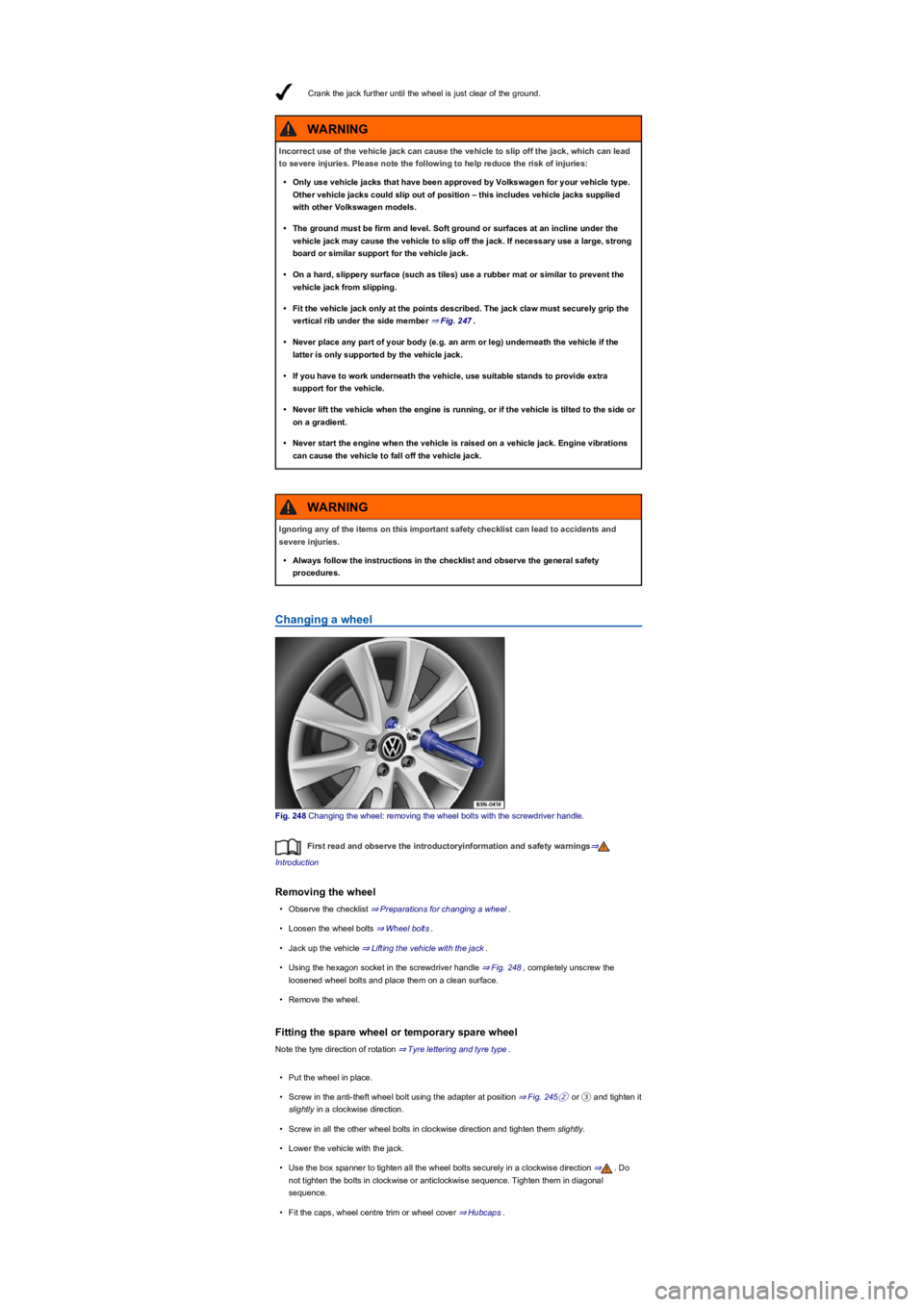

Wheel bolt caps

Fig. 243 Removing the wheel bolt caps.

Page 309 of 341

Find a firm and level surface suitable for lifting the vehicle.

Stop the engine, with a manual gearbox select a gear or with a DSG® dual clutch gearbox

move the selector lever to position P DSG® dual clutch gearbox and switch on the

electronic parking brake Parking and manoeuvring.

Chock both wheels on the opposite side of the vehicle using the collapsible chocks or

other suitable objects.

Loosen the wheel bolts Wheel bolts.

Find the jacking point under the vehicle which is closest to the wheel that is being

changed.

Insert the hand crank into the opening on the jack (depending on equipment).

Crank up the jack until it just fits under the jacking point of the vehicle.

Ensure that the entire surface of the foot of the jack is resting securely on the ground, and

that the foot of the jack is positioned fully underneath the point of application and .

Position the jack and simultaneously continue to crank the claw up until it is in position

around the vertical rib underneath the vehicle .

The tightening torque should be checked with a properly functioning torque wrench immediately

after changing a wheel.

Lifting the vehicle with the jack

Fig. 246 Lifting points for the jack.

Fig. 247 Vehicle jack at the rear left-hand side of the vehicle.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The jack may be positioned only at the reinforcements on the underbody, which are located behind

the markings on the body ⇒ Fig. 246. Always use the jacking point closest to the wheel you are

working on ⇒.

Checklist

For your own safety, carry out the following points in the specified order ⇒:

Incorrectly tightened wheel bolts can loosen while the vehicle is in motion and cause

accidents, serious injury, and loss of control of the vehicle.

•Only use wheel bolts that belong to the wheel.

•Never use different wheel bolts.

•The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease,

and turn easily.

•Always use the box spanner placed in the vehicle at the factory to loosen and tighten

the wheel bolts.

•Only loosen the wheel bolts by approximately one turn before raising the vehicle with

the vehicle jack.

•Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could

cause them to loosen while the vehicle is in motion, even if the required torque setting

is used.

•Never remove the bolts on rims with bolted-on rings.

•If the tightening torque of the wheel bolts is too low, the wheel bolts and rims can

loosen while the vehicle is in motion. The wheel bolts and threads can be damaged if

the tightening torque is too high.

WARNING

Page 310 of 341

Crank the jack further until the wheel is just clear of the ground.

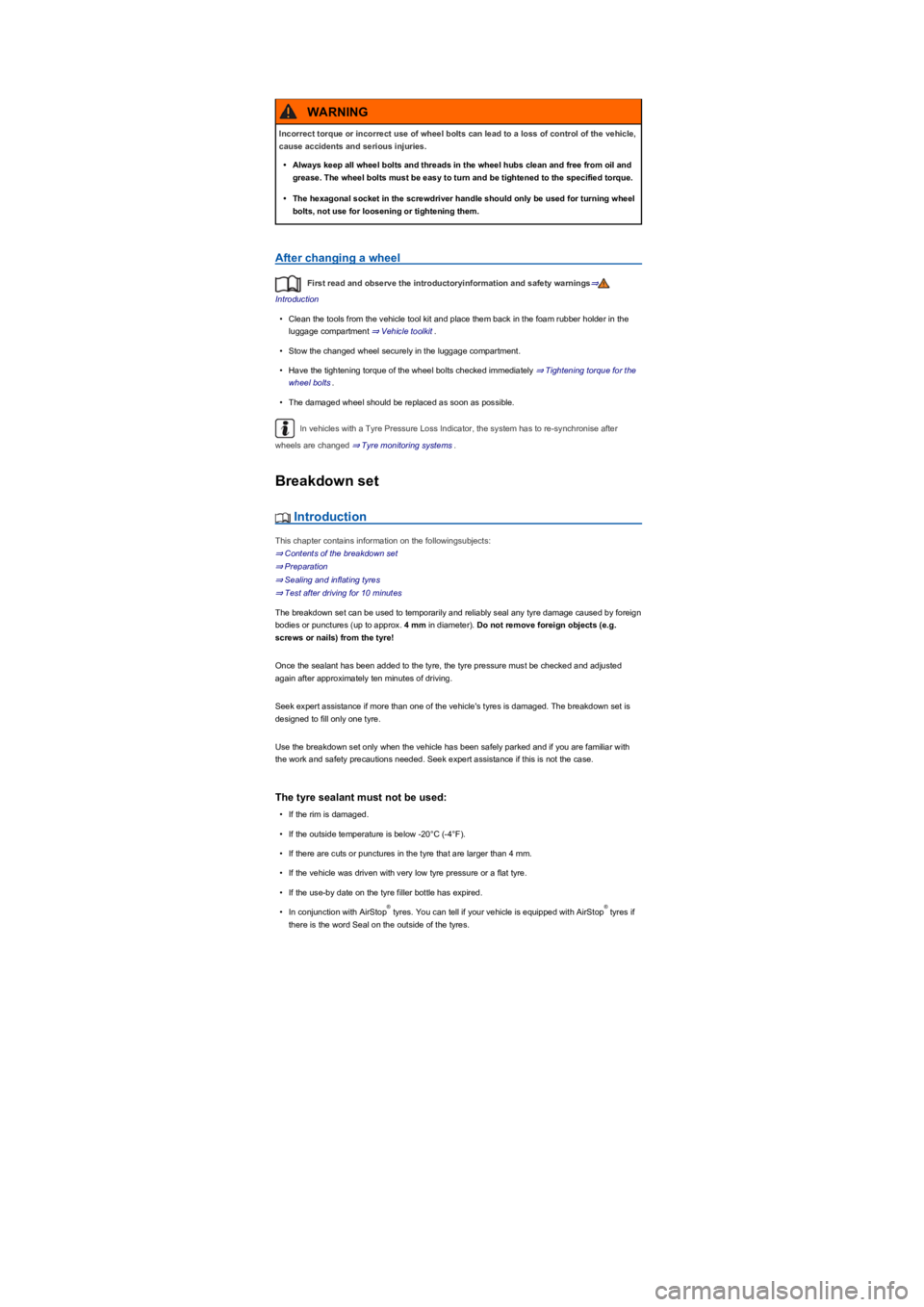

Changing a wheel

Fig. 248 Changing the wheel: removing the wheel bolts with the screwdriver handle.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Removing the wheel

•Observe the checklist ⇒ Preparations for changing a wheel.

•Loosen the wheel bolts ⇒ Wheel bolts.

•Jack up the vehicle ⇒ Lifting the vehicle with the jack.

•Using the hexagon socket in the screwdriver handle ⇒ Fig. 248, completely unscrew the

loosened wheel bolts and place them on a clean surface.

•Remove the wheel.

Fitting the spare wheel or temporary spare wheel

Note the tyre direction of rotation ⇒ Tyre lettering and tyre type.

•Put the wheel in place.

•Screw in the anti-theft wheel bolt using the adapter at position ⇒ Fig. 245② or ③ and tighten it

slightly in a clockwise direction.

•Screw in all the other wheel bolts in clockwise direction and tighten them slightly.

•Lower the vehicle with the jack.

•Use the box spanner to tighten all the wheel bolts securely in a clockwise direction ⇒. Do

not tighten the bolts in clockwise or anticlockwise sequence. Tighten them in diagonal

sequence.

•Fit the caps, wheel centre trim or wheel cover ⇒ Hubcaps.

Incorrect use of the vehicle jack can cause the vehicle to slip off the jack, which can lead

to severe injuries. Please note the following to help reduce the risk of injuries:

•Only use vehicle jacks that have been approved by Volkswagen for your vehicle type.

Other vehicle jacks could slip out of position – this includes vehicle jacks supplied

with other Volkswagen models.

•The ground must be firm and level. Soft ground or surfaces at an incline under the

vehicle jack may cause the vehicle to slip off the jack. If necessary use a large, strong

board or similar support for the vehicle jack.

•On a hard, slippery surface (such as tiles) use a rubber mat or similar to prevent the

vehicle jack from slipping.

•Fit the vehicle jack only at the points described. The jack claw must securely grip the

vertical rib under the side member ⇒ Fig. 247.

•Never place any part of your body (e.g. an arm or leg) underneath the vehicle if the

latter is only supported by the vehicle jack.

•If you have to work underneath the vehicle, use suitable stands to provide extra

support for the vehicle.

•Never lift the vehicle when the engine is running, or if the vehicle is tilted to the side or

on a gradient.

•Never start the engine when the vehicle is raised on a vehicle jack. Engine vibrations

can cause the vehicle to fall off the vehicle jack.

WARNING

Ignoring any of the items on this important safety checklist can lead to accidents and

severe injuries.

•Always follow the instructions in the checklist and observe the general safety

procedures.

WARNING

Page 311 of 341

After changing a wheel

First read and observe the introductoryinformation and safety warnings⇒

Introduction

•Clean the tools from the vehicle tool kit and place them back in the foam rubber holder in the

luggage compartment ⇒ Vehicle toolkit.

•Stow the changed wheel securely in the luggage compartment.

•Have the tightening torque of the wheel bolts checked immediately ⇒ Tightening torque for the

wheel bolts.

•The damaged wheel should be replaced as soon as possible.

In vehicles with a Tyre Pressure Loss Indicator, the system has to re-synchronise after

wheels are changed ⇒ Tyre monitoring systems.

Breakdown set

Introduction

This chapter contains information on the followingsubjects:

⇒ Contents of the breakdown set

⇒ Preparation

⇒ Sealing and inflating tyres

⇒ Test after driving for 10 minutes

The breakdown set can be used to temporarily and reliably seal any tyre damage caused by foreign

bodies or punctures (up to approx. 4 mm in diameter). Do not remove foreign objects (e.g.

screws or nails) from the tyre!

Once the sealant has been added to the tyre, the tyre pressure must be checked and adjusted

again after approximately ten minutes of driving.

Seek expert assistance if more than one of the vehicle's tyres is damaged. The breakdown set is

designed to fill only one tyre.

Use the breakdown set only when the vehicle has been safely parked and if you are familiar with

the work and safety precautions needed. Seek expert assistance if this is not the case.

The tyre sealant must not be used:

•If the rim is damaged.

•If the outside temperature is below -20°C (-4°F).

•If there are cuts or punctures in the tyre that are larger than 4 mm.

•If the vehicle was driven with very low tyre pressure or a flat tyre.

•If the use-by date on the tyre filler bottle has expired.

•In conjunction with AirStop tyres. You can tell if your vehicle is equipped with AirStop tyres if

there is the word Seal on the outside of the tyres.

Incorrect torque or incorrect use of wheel bolts can lead to a loss of control of the vehicle,

cause accidents and serious injuries.

•Always keep all wheel bolts and threads in the wheel hubs clean and free from oil and

grease. The wheel bolts must be easy to turn and be tightened to the specified torque.

•The hexagonal socket in the screwdriver handle should only be used for turning wheel

bolts, not use for loosening or tightening them.

WARNING

®®

Page 324 of 341

authorization symbol). These devices include cruise control systems or an electronically controlled

suspension.

Any additional electrical components fitted that do not serve to control the vehicle itself must

bear the mark (manufacturer conformity declaration in the European Union). Such devices

include refrigerator boxes, laptops and ventilator fans.

Repairs and technical modifications

Repairs and technical modifications must always be carried out according to Volkswagen

specifications⇒.

Unauthorised modifications to the electronic components or software in the vehicle may cause

malfunctions. As the electronic components are linked together in networks, these faults may

indirectly affect the working of other systems. This can seriously impair safety, lead to excessive

wear of components, and also invalidate the type approval for the vehicle.

The Volkswagen dealership cannot be held liable for any damage caused by technical

modifications and/or work performed incorrectly.

The Volkswagen dealership is not responsible for damage caused by technical modifications and/or

work performed incorrectly. Such damage is not covered by the Volkswagen guarantee.

Volkswagen recommends that all repairs and technical modifications be performed by an

authorised Volkswagen workshop using Volkswagen Genuine Parts.

Volkswagen repair information

Volkswagen Service information and official Volkswagen repair information can be purchased for a

fee.

Customers in Europe, Asia, Australia, Africa, Central and South America: please contact a

Volkswagen dealership or qualified workshop or register on the online portal erWin (electronic

repair and workshop information):

https://erwin.volkswagen.de

erWin is available in numerous languages.

Vehicles with special auxiliary equipment or body parts

The manufacturer of these components must ensure that these parts (fittings) adhere to the

stipulated environmental laws and regulations, particularly the EU directive 2000/53/EC concerning

end-of-life vehicles and EU directive 2003/11/EC concerning the restriction on the marketing and

use of certain dangerous substances and preparations.

The vehicle owner should keep all assembly documentation for these auxiliary fittings, and pass it

on to any scrapping company later engaged. This is to facilitate environmentally responsible

disposal for all vehicles, including refitted vehicles.

Windscreen repairs

To function properly, some items of equipment require an electrical or electronic module, which is

located on the inside of the windscreen near the interior mirror. If the windscreen has been

damaged in the viewing field of the electrical or electronic module, e.g. by stone impact, the

windscreen must be replaced. Repairing the crack can lead to malfunctions or functional faults in

the equipment.

After changing the windscreen, the camera and sensors must be set up and calibrated by a

qualified workshop.

Impairment or damage to sensors and cameras

Incorrect repairs, retrofit structural modifications to the vehicle, e.g. lowering the body, add-on parts

on the vehicle or trailer ⇒ Trailer towing, or changes to the trim may lead to the sensors or

cameras being disrupted or damaged. This can also be caused by collisions, e.g. when parking.

Failure to observe this may impair important functions (driver assist systems) and damage the

vehicle.

The area in front of and around the sensors and cameras must not be covered by stickers,

additional headlights, trim frames for number plates or similar.

Incorrectly performed repairs or modifications to your vehicle can impair the effectiveness

of the airbags, cause malfunctions, accidents and fatal injury.

•Never secure or mount objects such as drink holders or telephone holders either on or

next to the airbag covers or within the deployment zones of the airbag modules.

•Objects either on or next to the airbag module covers or are in the deployment zone of

the airbags can cause serious or even fatal injuries should the airbags be activated.

WARNING

®