lock VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2015, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2015Pages: 486, PDF Size: 72.17 MB

Page 223 of 486

Closing the electric pop-up roof

j'"'('n First read and observe the introductory information and safety warnings & on page 221.

• Close all of the windows in the pop-up roof can-vas.

• Remove the children's safety net.

• Lower the bed panel.

• Ensure that the roller shutter is and stays open.

• Make sure that no people or objects, such as blankets or pillows, are on the upper bed. Position the mattress correctly.

• Disconnect any connected devices from the 12-volt socket in the roof frame, and stow them in a safe place in the vehicle.

• Switch on the ignition.

• Open one of the vehicle doors to allow excess air pressure to escape.

• Switch on the central control panel.

• Select the menu option Pop-up roof in the central control panel.

• Select menu option Close (dark background).

• Press and hold the rotary/push knob for ap-proximately four seconds. An acoustic signal is giv-en and the display reads for approximately four seconds Roof bed down? Shutter open? Window open?. All control elements for the pop-up roof are blocked during this safety check.

• Press and hold the rotary/push knob again to continue closing. Make sure that the canvas is not pinched at the front or on the side between the ve-hicle and the roof or the rods.

• Press and hold the rotary/push knob until the hydraulic motor has switched off automatically and the pop-up roof has closed fully. This is shown by the .t symbol in the display. The hydraulic motor has a run-on time of approx. 5 seconds to bleed the hydraulic system.

• Close the roller shutter. Make sure that the can-vas is not pinched.

m The LED lights in the pop-up roof are switch-L!..J ed off automatically as soon as the engine is

Equipment, California I 223

Page 225 of 486

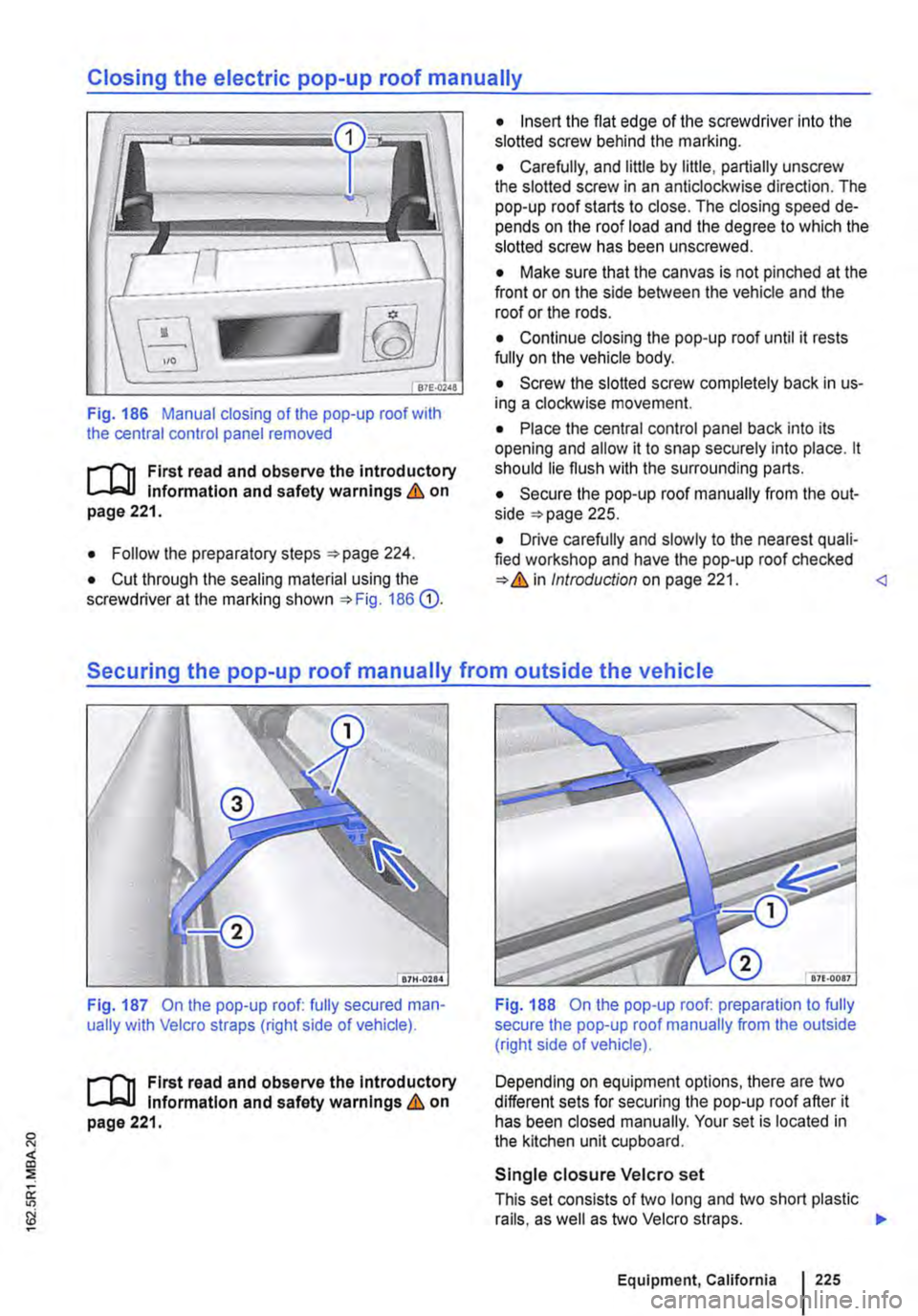

Closing the electric pop-up roof manually

Fig. 186 Manual closing of the pop-up roof with the central control panel removed

t'""('n First read and observe the introductory Information and safety warnings & on page 221.

• Follow the preparatory steps 224.

• Cut through the sealing material using the screwdriver at the marking shown 186 G).

• Insert the flat edge of the screwdriver into the slotted screw behind the marking.

• Carefully, and little by little, partially unscrew the slotted screw in an anticlockwise direction. The pop-up roof starts to close. The closing speed de-pends on the roof load and the degree to which the slotted screw has been unscrewed.

• Make sure that the canvas is not pinched at the front or on the side between the vehicle and the roof or the rods.

• Continue closing the pop-up roof until it rests fully on the vehicle body.

• Screw the slotted screw completely back in us-ing a clockwise movement.

• Place the central control panel back into its opening and allow it to snap securely into place. lt should lie flush with the surrounding parts.

• Secure the pop-up roof manually from the out-side 225.

• Drive carefully and slowly to the nearest quali-fied workshop and have the pop-up roof checked Introduction on page 221.

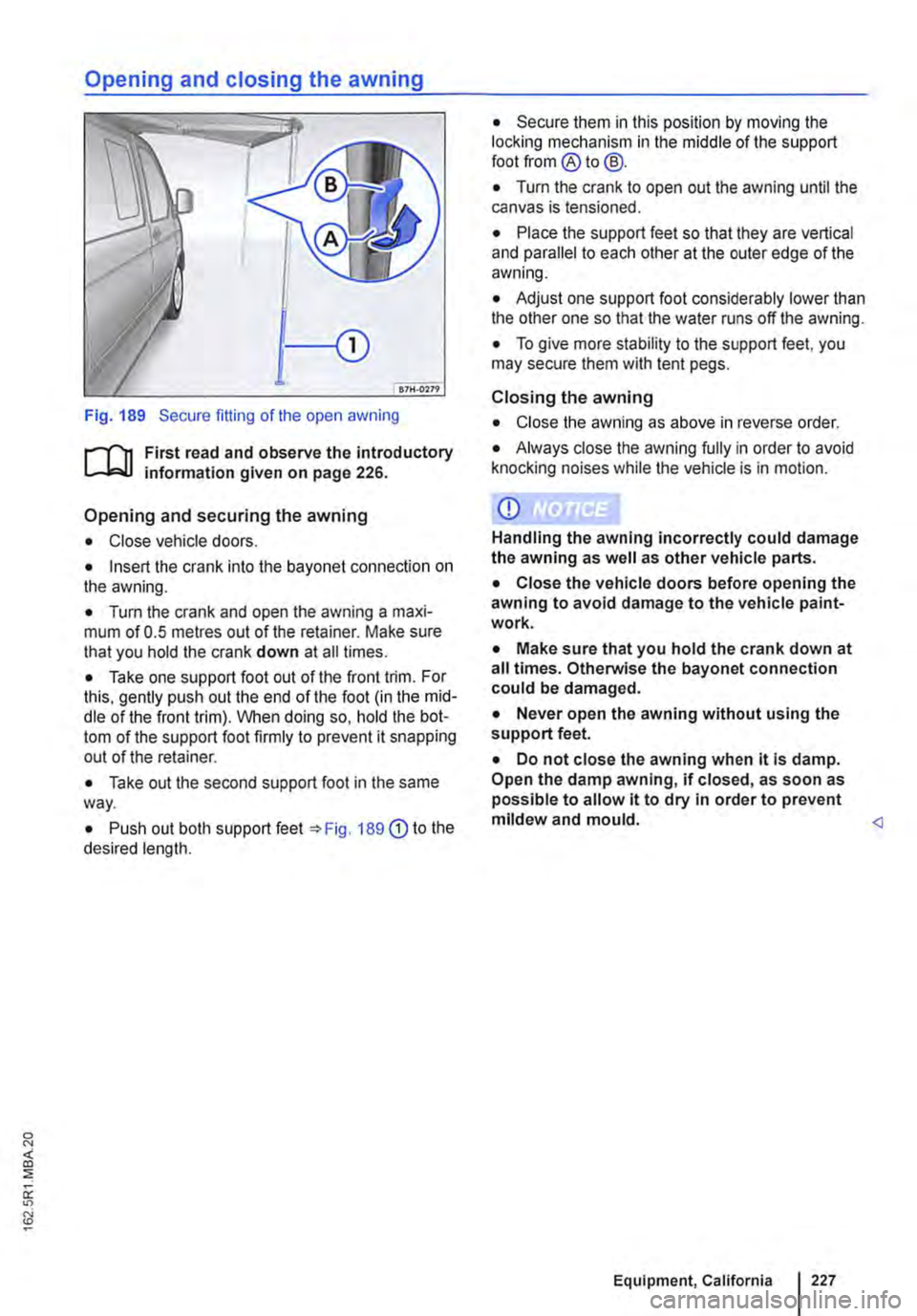

Fig. 187 On the pop-up roof: fully secured man-ually with Velcro straps (right side of vehicle).

t'""('n First read and observe the Introductory Information and safety warnings & on page 221.

Fig. 188 On the pop-up roof: preparation to fully secure the pop-up roof manually from the outside (right side of vehicle).

Depending on equipment options, there are two different sets for securing the pop-up roof after it has been closed manually. Your set is located in the kitchen unit cupboard.

Single closure Velcro set

This set consists of two long and two short plastic rails, as well as two Velcro straps. .,.

Equipment, California 225

Page 227 of 486

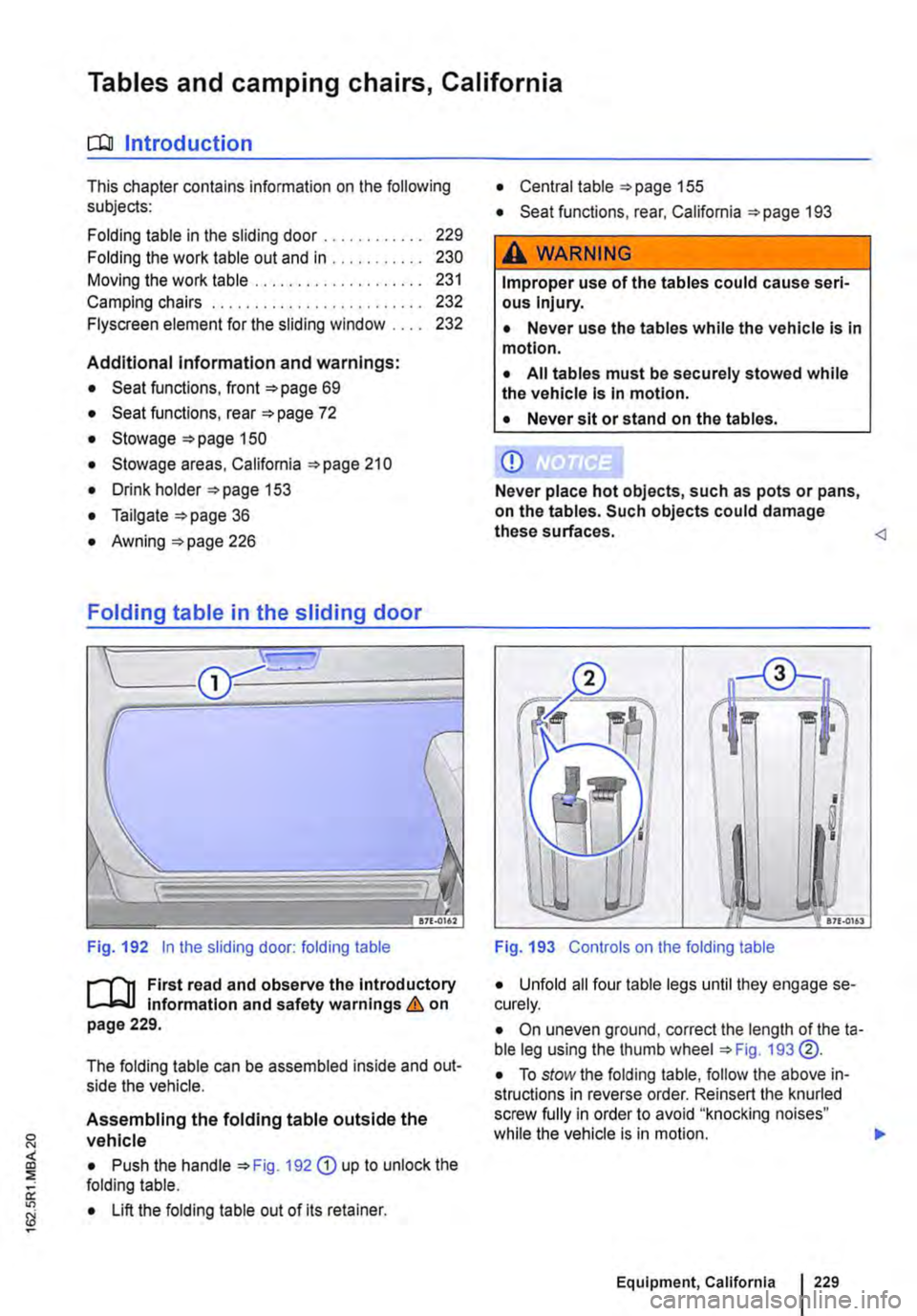

Fig. 189 Secure fitting of the open awning

r-1l1 First read and observe the introductory information given on page 226.

Opening and securing the awning

• Close vehicle doors.

• Insert the crank into the bayonet connection on the awning.

• Turn the crank and open the awning a maxi-mum of 0.5 metres out of the retainer. Make sure that you hold the crank down at all times.

• Take one support foot out of the front trim. For this, gently push out the end of the foot (in the mid-dle of the front trim). When doing so, hold the bot-tom of the support foot firmly to prevent it snapping out of the retainer.

• Take out the second support foot in the same way.

• Push out both support feet =>Fig. 189 G) to the desired length.

• Secure them in this position by moving the locking mechanism in the middle of the support foot from ®to@.

• Turn the crank to open out the awning until the canvas is tensioned.

• Place the support feet so that they are vertical and parallel to each other at the outer edge of the awning.

• Adjust one support foot considerably lower than the other one so that the water runs off the awning.

• To give more stability to the support feet, you may secure them with tent pegs.

Closing the awning

• Close the awning as above in reverse order.

• Always close the awning fully in order to avoid knocking noises while the vehicle is in motion.

CD

Handling the awning incorrectly could damage the awning as well as other vehicle parts.

• Close the vehicle doors before opening the awning to avoid damage to the vehicle paint-work.

• Make sure that you hold the crank down at all times. Otherwise the bayonet connection could be damaged.

• Never open the awning without using the support feet.

• Do not close the awning when it Is damp. Open the damp awning, if closed, as soon as possible to allow it to dry in order to prevent mildew and mould.

Page 229 of 486

Tables and camping chairs, California

CllJ Introduction

This chapter contains information on the following subjects:

Folding table in the sliding door . . . . . . . . . . . . 229

Folding the work table out and in . . . . . . . . . . 230

Moving the work table . . . . . . . . . . . . . . . . . • . 231

Camping chairs . . . . . . . . . . . . . . . . . . . . . . . . 232 Flyscreen element for the sliding window . . . . 232

Additional Information and warnings:

• Seat functions, front 69

• Seat functions, rear =>page 72

• Stowage 150

• Stowage areas, California 210

• Drink holder 153

• Tailgate 36

• Awning 226

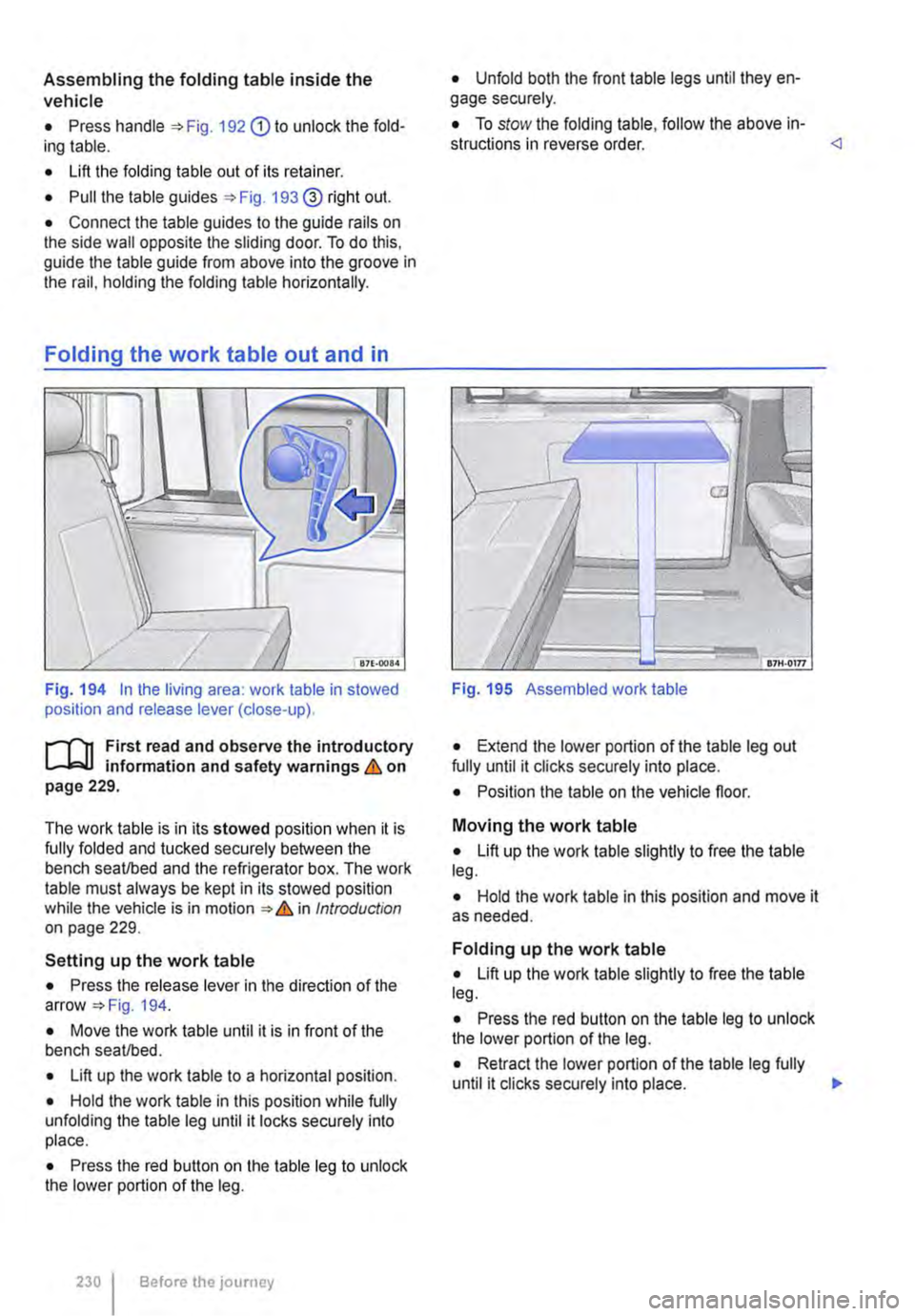

Folding table in the sliding door

Fig. 192 in the sliding door: folding table

J"'"'"('n First read and observe the introductory L-Jo:.LI information and safety warnings & on page 229.

The folding table can be assembled inside and out-side the vehicle.

Assembling the folding table outside the vehicle

• Push the handle 192 G) up to unlock the folding table.

• Lift the folding table out of its retainer.

• Central table 155

• Seat functions, rear, California 193

,A WARNING

Improper use of the tables could cause seri-ous Injury.

• Never use the tables while the vehicle is in motion.

• All tables must be securely stowed while the vehicle is in motion.

• Never sit or stand on the tables.

CD

Never place hot objects, such as pots or pans, on the tables. Such objects could damage these surfaces.

I !! I

I

I

.. -17£.0161

Fig. 193 Controls on the folding table

• Unfold all four table legs until they engage se-curely.

• On uneven ground, correct the length of theta-ble leg using the thumb wheel 193 @.

• To stow the folding table, follow the above in-structions in reverse order. Reinsert the knurled screw fully in order to avoid "knocking noises" while the vehicle is in motion. .,.

Equipment, California 229

Page 230 of 486

Assembling the folding table inside the vehicle

• Press handle 192 G) to unlock the fold-ing table.

• Lift the folding table out of its retainer.

• Pull the table guides 193@ right out.

• Connect the table guides to the guide rails on the side wall opposite the sliding door. To do this, guide the table guide from above into the groove in the rail, holding the folding table horizontally.

Fig. 194 In the living area: work table in stowed position and release lever (close-up).

1""1'11 First read and observe the introductory L-J,:.,U information and safety warnings & on page 229.

The work table is in its stowed position when it is fully folded and tucked securely between the bench seat/bed and the refrigerator box. The work table must always be kept in its stowed position while the vehicle is in motion & in Introduction on page 229.

Setting up the work table

• Press the release lever in the direction of the arrow 194.

• Move the work table until it is in front of the bench seat/bed.

• Lift up the work table to a horizontal position.

• Hold the work table in this position while fully unfolding the table leg until it locks securely into place.

• Press the red button on the table leg to unlock the lower portion of the leg.

230 Before the journey

• Unfold both the front table legs until they en-gage securely.

• To stow the folding table, follow the above in-structions in reverse order.

Fig. 195 Assembled work table

• Extend the lower portion of the table leg out fully until it clicks securely into place.

• Position the table on the vehicle floor.

Moving the work table

• Lift up the work table slightly to free the table leg.

• Hold the work table in this position and move it as needed.

Folding up the work table

• Lift up the work table slightly to free the table leg.

• Press the red button on the table leg to unlock the lower portion of the leg.

• Retract the lower portion of the table leg fully until it clicks securely into place. 11>

Page 231 of 486

• Hold the work table in this position and carefully apply pressure to the table leg, folding it fully in-wards until it locks securely into place.

• Lower the work table and slide it between the refrigerator box and the bench seaUbed. Make sure that the lug on the work table runs in the re-tainer ball and engages securely on the locking lever.

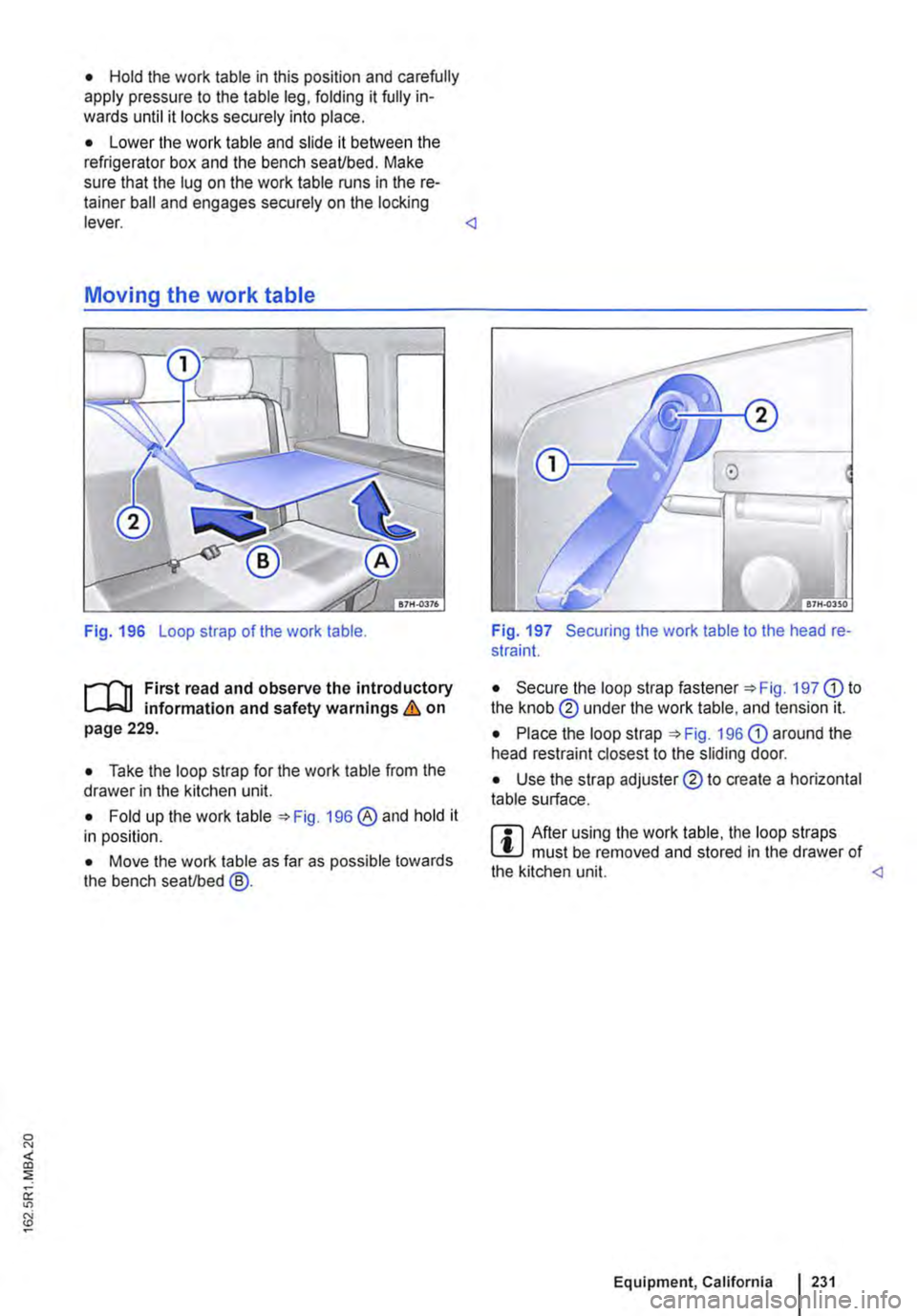

Fig. 196 Loop strap of the work table.

r--fl1 First read and observe the introductory L-J,:.JJ information and safety warnings & on page 229.

• Take the loop strap for the work table from the drawer in the kitchen unit.

• Fold up the work table 196 ®and hold it in position.

• Move the work table as far as possible towards the bench seaUbed @.

Fig. 197 Securing the work table to the head re-straint.

• Secure the loop strap fastener 197 CD to the knob ® under the work table. and tension it.

• Place the loop strap =)Fig. 196 CD around the head restraint closest to the sliding door.

• Use the strap adjuster® to create a horizontal table surface.

m After using the work table, the loop straps l.!J must be removed and stored in the drawer of the kitchen unit.

Page 234 of 486

A WARNING (Continued)

• In addition, a leak/function check must be carried out on the gas system by a qualified workshop every time the system is repaired or the gas system connections are opened.

A WARNING

Improper use of the gas system can cause serious Injury.

• The cover on the gas bottle holder must be screwed on securely whenever the gas bottle is In the holder.

• Never connect the gas system to the town gas/gas mains.

• Close all gas shut-off valves before driv-lng and when not using the cooker for long periods.

• Never allow the vents In the floor of the gas bottle holder to become blocked by snow slush, cleaning rags, or any other object. Check the floor vents regularly to make sure they are free from obstruction.

A WARNING

There is a danger of fire any time a gas burn-er is lit.

• Never leave a lit burner unattended -es-pecially when children are nearby.

• Make sure the gas flame never extends beyond the edge of the pot or pan.

• The refrigerator box lid must always be kept closed from the moment the gas flame is lit until it is turned off again.

• The blind on the window behind the gas cooker must always be kept open from the moment the gas flame is lit until it is turned off again.

234 I Before the journey

A WARNING (Continued)

• Make sure that no inflammable Items are left close to the burners, e.g. cooking fat or oil.

• Keep towels, clothing, paper, plastic and other inflammable materials well away from the gas cooker.

• Never overheat oil or cooking fat.

A WARNING

Improper use of the gas cooker can cause se-rious injury.

• Never allow the handles of pots and pans to protrude over the edge of the gas cooker. Otherwise, they could be knocked off the gas cooker.

• Never use the gas cooker while the vehi-cle is in motion.

• Close all gas shut-off valves before driv-ing and when not using the cooker for long periods.

A WARNING

Damp or wet oven mitts or potholders can be-come very hot and cause scalding.

• Use only dry oven mitts and potholders .

CD

Never place hot objects, e.g. pots or pans, on the surface of the kitchen unit, on the refriger-ated box, or on table tops. Such objects could damage these surfaces.

Page 235 of 486

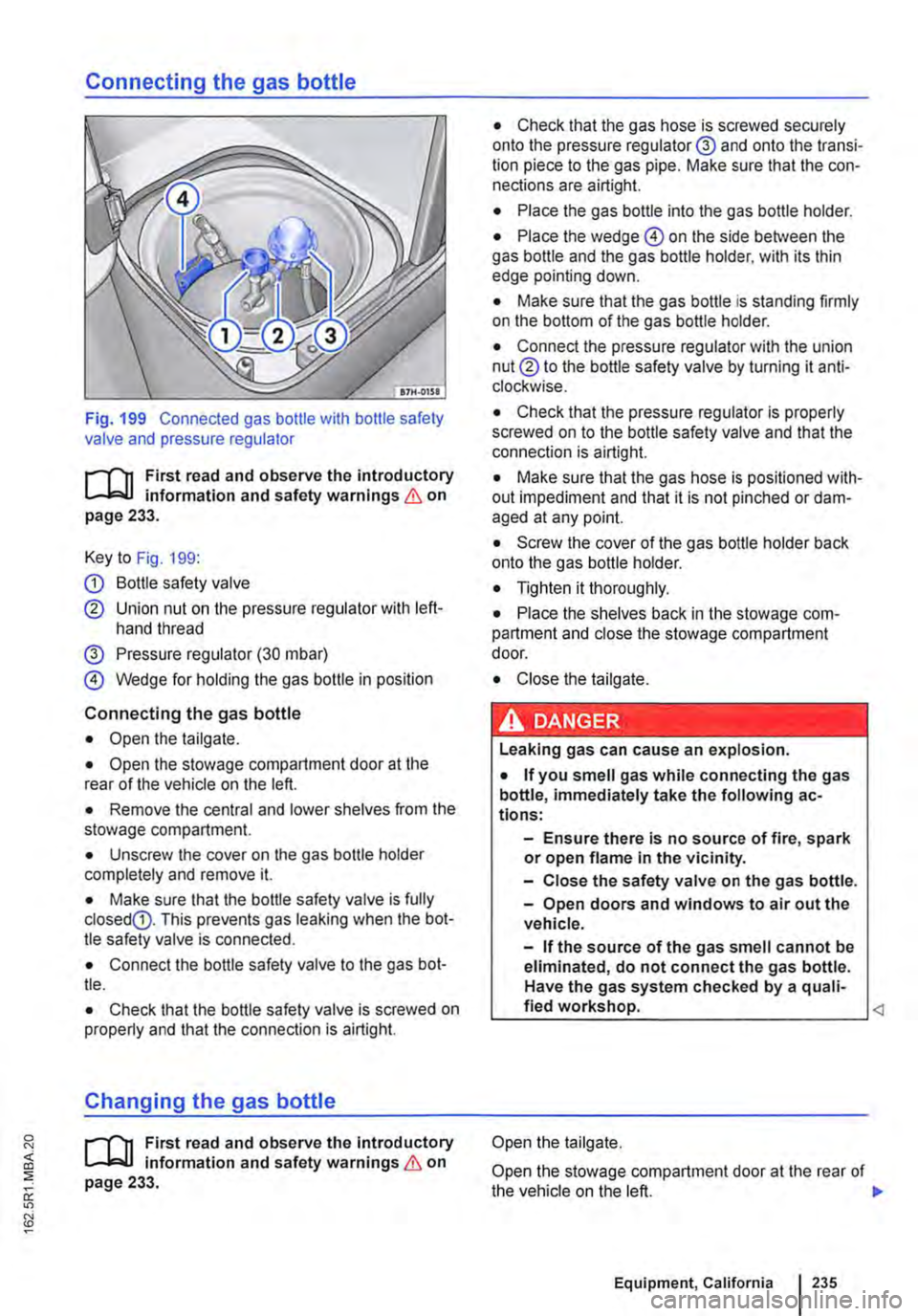

Connecting the gas bottle

Fig. 199 Connected gas bottle with bottle safety valve and pressure regulator

r-l'n First read and observe the introductory L-J.:.IJ information and safety warnings & on page 233.

Key to Fig. 199:

G) Bottle safety valve

® Union nut on the pressure regulator with left-hand thread

@ Pressure regulator (30 mbar)

@ Wedge for holding the gas bottle in position

Connecting the gas bottle

• Open the tailgate.

• Open the stowage compartment door at the rear of the vehicle on the left.

• Remove the central and lower shelves from the stowage compartment.

• Unscrew the cover on the gas bottle holder completely and remove it.

• Make sure that the bottle safety valve is fully closedG). This prevents gas leaking when the bot-tle safety valve is connected.

• Connect the bottle safety valve to the gas bot-tle.

• Check that the bottle safety valve is screwed on properly and that the connection is airtight.

Changing the gas bottle

r-l'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 233.

• Check that the gas hose is screwed securely onto the pressure regulator@ and onto the transi-tion piece to the gas pipe. Make sure that the con-nections are airtight.

• Place the gas bottle into the gas bottle holder.

• Place the wedge @ on the side between the gas bottle and the gas bottle holder. with its thin edge pointing down.

• Make sure that the gas bottle is standing firmly on the bottom of the gas bottle holder.

• Connect the pressure regulator with the union nut® to the bottle safety valve by turning it anti-clockwise.

• Check that the pressure regulator is properly screwed on to the bottle safety valve and that the connection is airtight.

• Make sure that the gas hose is positioned with-out impediment and that it is not pinched or dam-aged at any point.

• Screw the cover of the gas bottle holder back onto the gas bottle holder.

• Tighten it thoroughly.

• Place the shelves back in the stowage com-partment and close the stowage compartment door.

• Close the tailgate.

· &' DANGER .. --' • ,.,_.._.. '·-• I Leaking gas can cause an explosion.

• If you smell gas while connecting the gas bottle, immediately take the following ac-tions:

-Ensure there is no source of fire, spark or open flame in the vicinity.

-Close the safety valve on the gas bottle.

-Open doors and windows to air out the vehicle.

-If the source of the gas smell cannot be eliminated, do not connect the gas bottle. Have the gas system checked by a quali-fied workshop.

Open the stowage compartment door at the rear of the vehicle on the left. 11>

Equipment, California I 235

Page 236 of 486

Remove the central and lower shelves from the stowage compartment.

Unscrew the cover on the gas bottle holder com-pletely and remove it.

Make sure that the bottle safety valve 199 G) is completely closed. This prevents gas from leaking when the union nut® is slack-ened.

Completely unscrew the union nut of the pressure regulator from the bottle safety valve by turning it clockwise.

Lift out the gas bottle together with the wedge.

Connecting a new gas bottle 235

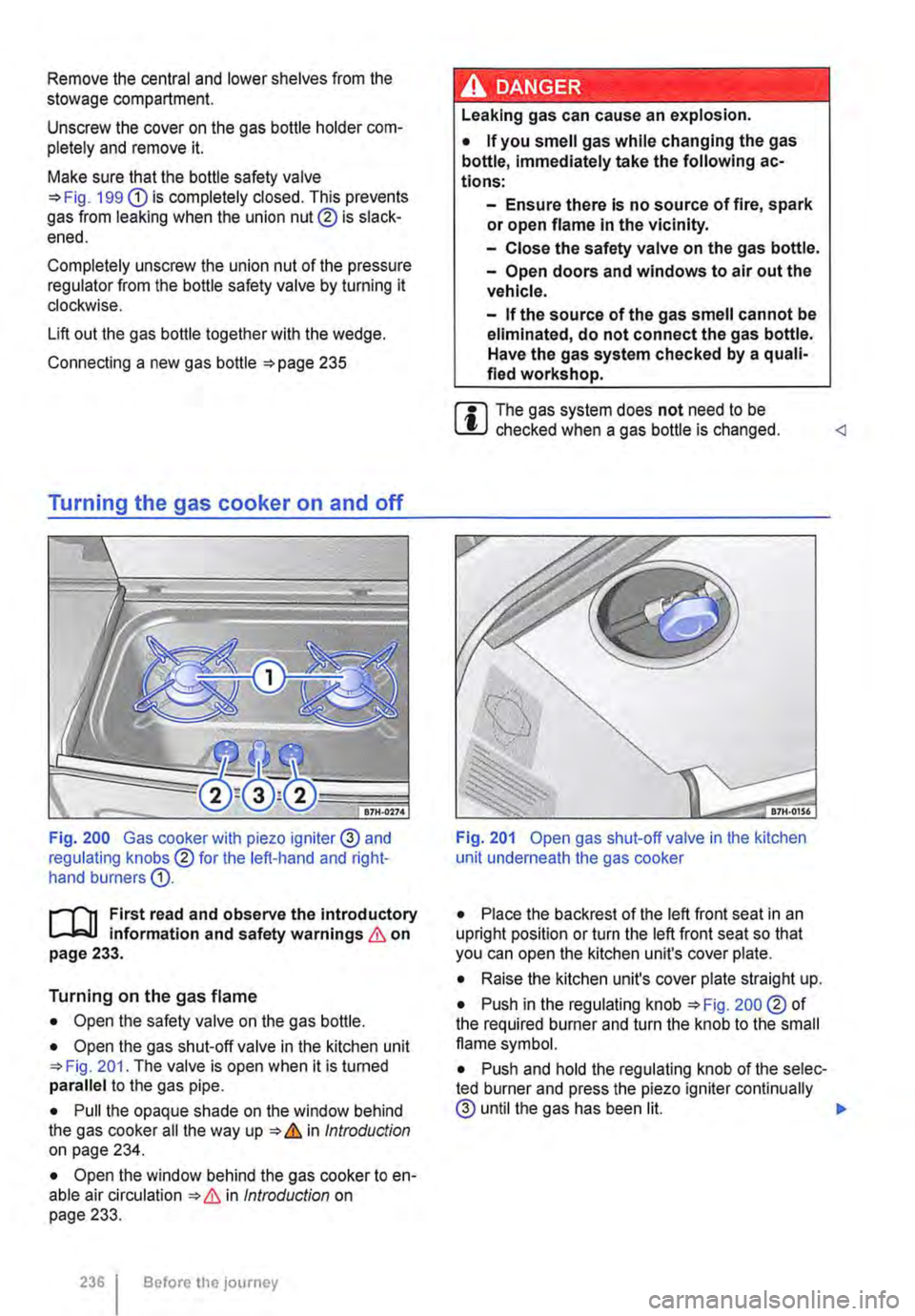

Turning the gas cooker on and off

B7H·0274

Fig. 200 Gas cooker with piezo igniter 0 and regulating knobs® for the left-hand and right-hand burners G).

i""""('n First read and observe the introductory information and safety warnings & on page 233.

Turning on the gas flame

• Open the safety valve on the gas bottle.

• Open the gas shut-off valve in the kitchen unit 201. The valve is open when it is turned parallel to the gas pipe.

• Pull the opaque shade on the window behind the gas cooker all the way up & in Introduction on page 234.

• Open the window behind the gas cooker to en-able air circulation & in Introduction on page 233.

236 Before the journey

Leaking gas can cause an explosion.

• If you smell gas while changing the gas bottle, immediately take the following ac-tions:

-Ensure there is no source of fire, spark or open flame In the vicinity.

-Close the safety valve on the gas bottle.

-Open doors and windows to air out the vehicle.

-If the source of the gas smell cannot be eliminated, do not connect the gas bottle. Have the gas system checked by a quali-fied workshop.

m The gas system does not need to be L!J checked when a gas bottle is changed.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can open the kitchen unit's cover plate.

• Raise the kitchen unit's cover plate straight up.

• Push in the regulating knob 200 ®of the required burner and turn the knob to the small flame symbol.

• Push and hold the regulating knob of the selec-ted burner and press the piezo igniter continually 0 until the gas has been lit. .,.

Page 237 of 486

• Keep the knob pressed in for approx. 15 sec-onds to temporarily bridge the igniter safety device. If you let go of the knob too quickly, the gas flame goes out. If this occurs, re-light the burner as de-scribed above.

• Release the regulating knob and adjust the gas flame as required.

Turning off the gas flame

• Turn the appropriate knob@ fully clockwise to turn off the gas flame.

• Close the gas shut-off valve in the kitchen unit.

• Close the safety valve on the gas bottle.

• Remove all objects from the gas cooker and al-low the cooker to cool fully.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can close the kitchen unit's cover plate.

• Lower the kitchen unit cover plate and latch it securely. <1

Water supply and disposal, California

n::n Introduction

This chapter contains information on the following subjects:

Fresh water system . . . . . . . . . . . . . . . . . . . . . . 238

Sterilising agent . . . . . . . . . . . . . . . . • . . . . . . . . 239

Cleaning the fresh water tank . . . . . . . . . . . . . 239 Waste water tank . . . . . . . . . . . . . . . . . . . . . . . . 240

Turning the water on and off . . . . . . . . . . . . . . 240

Cleaning the drain . . . . . . . . . . . . . . . . . . . . . . . 241

Additional information:

• Central control panel 204

• Rectifying faults on the camping equipment 254

• Fuses for the camping equipment 249

• Winter conditions 253

• Filling the tank 340

A WARNING

Improper use of the fresh water system can lead to poisoning and illness.

• The fresh water tank should only be filled with drinking water from the public water supply.

• Never fill the fresh water tank from springs or streams. Such water could be con-taminated or contain debris.

• Never use commercially available house-hold cleaners to clean the fresh water tank.

• Never leave water in the fresh water tank for long periods without replacing it with fresh water.

,A WARNING (Continued)

• Drain the fresh water system completely when it will not be used for a long time.

A WARNING

Both the fresh water tank and the waste water tank drain out underneath the vehicle. In very cold conditions this poses a danger from the formation of ice.

• Be especially careful when fresh or waste water are drained during freezing or very cold weather.

CD

In very cold weather the fresh and waste water systems should be emptied to prevent them from becoming damaged if the vehicle is not to be kept heated continuously or Is only to be used for short periods.

CD

Do not allow the water pump to run dry as this will damage the pump.

• Only switch on the water pump when there Is water in the fresh water tank.

m if you do not use the sink for a long period' it L.:!J should be kept dry and free of salt.

m Never confuse the fresh water tank filler neck L.:!J with the fuel tank filler neck. <1

Equipment, California 237