battery VOLVO XC60 2009 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2009, Model line: XC60, Model: VOLVO XC60 2009Pages: 297, PDF Size: 21.16 MB

Page 227 of 297

06 Maintenance and specifications

Maintaining your car06

}}

225

Owner maintenance

Periodic maintenance requirements and inter-

vals are described in your vehicle\fs Warranty

and Service Records Information booklet.

The following points can be carried out

between the normally scheduled maintenance

services.

Each time the car is refueled:

\b

Check the engine oil level.

\b Clean the windshield, windshield wipers,

headlights, and tail lights.

Monthly:

\bCheck cold tire pressure in all tires. Inspect

the tires for wear.

\b Check that engine coolant and other fluid

levels are between the indicated "min" and

"max" markings.

\b Clean interior glass surfaces with a glass

cleaner and soft paper towels.

\b Wipe driver information displays with a soft

cloth.

\b Visually inspect battery terminals for cor-

rosion. Corrosion may indicate a loose ter-

minal connector, or a battery near the end

of its useful service life. Consult your Volvo

retailer for additional information.

As needed:Wash the car, including the undercarriage, to

reduce wear that can be caused by a buildup

of dirt, and corrosion that can be caused by salt

residues.

Clean leaves and twigs from air intake vents at

the base of the windshield, and from other pla-

ces where they may collect.

NOTE Complete service information for qualified

technicians is available online for purchase

or subscription at www.volvotechinfo.com.

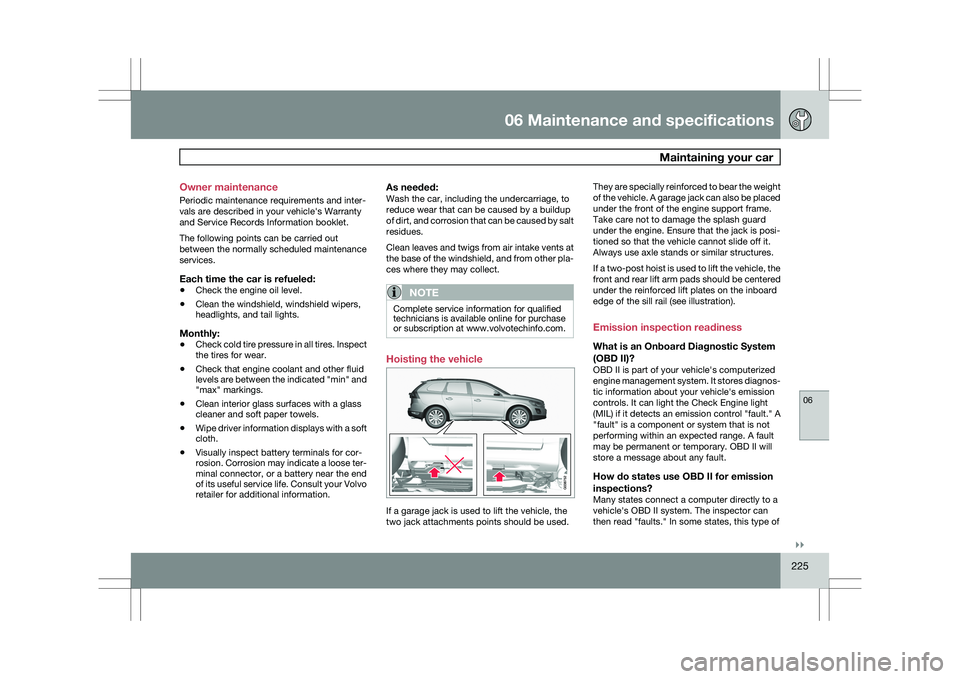

Hoisting the vehicle

If a garage jack is used to lift the vehicle, the

two jack attachments points should be used.They are specially reinforced to bear the weight

of the vehicle. A garage jack can also be placed

under the front of the engine support frame.

Take care not to damage the splash guard

under the engine. Ensure that the jack is posi-

tioned so that the vehicle cannot slide off it.

Always use axle stands or similar structures.

If a two-post hoist is used to lift the vehicle, the

front and rear lift arm pads should be centered

under the reinforced lift plates on the inboard

edge of the sill rail (see illustration).

Emission inspection readiness

What is an Onboard Diagnostic System

(OBD II)?

OBD II is part of your vehicle\fs computerized

engine management system. It stores diagnos-

tic information about your vehicle\fs emission

controls. It can light the Check Engine light

(MIL) if it detects an emission control "fault." A

"fault" is a component or system that is not

performing within an expected range. A fault

may be permanent or temporary. OBD II will

store a message about any fault.

How do states use OBD II for emission

inspections?

Many states connect a computer directly to a

vehicle\fs OBD II system. The inspector can

then read "faults." In some states, this type of

Page 228 of 297

06 Maintenance and specificationsMaintaining your car 06

226 inspection has replaced the tailpipe emission

test.

How can my vehicle fail OBD II emission

inspection?

Your vehicle can fail OBD II emission inspec-

tion for any of the following reasons.

\b

If your Check Engine (MIL) light is lit, your

vehicle may fail inspection.

\b If your vehicle\fs Check Engine light was lit,

but went out without any action on your

part, OBD II will still have a recorded fault.

Your vehicle may pass or fail, depending

on the inspection practices in your area.

\b If you had recent service that required dis-

connecting the battery, OBD II diagnostic

information may be incomplete and "not

ready" for inspection. A vehicle that is not

ready may fail inspection.

How can I prepare for my next OBD II

emission inspection?

\bIf your Check Engine (MIL) light is lit – or

was lit but went out without service, have

your vehicle diagnosed and, if necessary,

serviced by a qualified Volvo technician.

\b If you recently had service for a lit Check

Engine light, or if you had service that

required disconnecting the battery, a

period of driving is necessary to bring the

OBD II system to "ready" for inspection. A

half-hour trip of mixed stop-and-go/high- way driving is typically needed to allow

OBD II to reach readiness. Your Volvo

retailer can provide you with more infor-

mation on planning a trip.

\b Maintain your vehicle in accordance with

your vehicle\fs maintenance schedule.

Page 229 of 297

06 Maintenance and specifications

Hood and engine compartment06

227

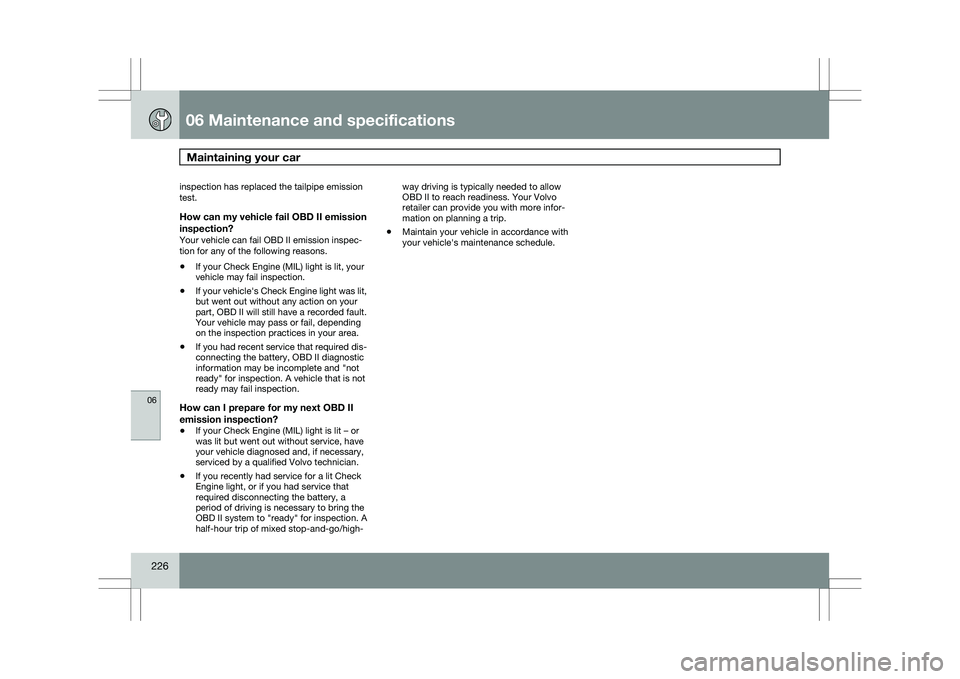

Opening and closing the hood

Pull the lever located under the left side of

the dash to release the hood lock. A sym-

bol will illuminate when the hood has been

released.

Lift the hood slightly. Press the release

control (located under the right front edge

of the hood) to the left, and lift the hood

WARNING Check that the hood locks properly when

closed.

Engine compartment, overview

The appearance of the engine compartment

may vary depending on engine model.

Coolant expansion tank

Power steering fluid reservoir

Engine oil dipstick

Radiator

Filler cap for engine oil

Cover over brake fluid reservoir Battery

Relay and fuse box

Washer fluid reservoir

Air cleaner

WARNING

The cooling fan may start or continue to

operate (for up to 6 minutes) after the engine

has been switched off.

WARNING

The ignition should always be completely

switched off before performing any opera-

tions in the engine compartment.

The distributor ignition system operates at

very high voltages. Special safety precau-

tions must be followed to prevent injury.

Always turn the ignition off when:

\b

Replacing distributor ignition compo-

nents e.g. plugs, coil, etc.

\b Do not touch any part of the distributor

ignition system while the engine is run-

ning. This may result in unintended

movements and body injury. G031910 G031911

Page 244 of 297

06 Maintenance and specificationsBattery 06

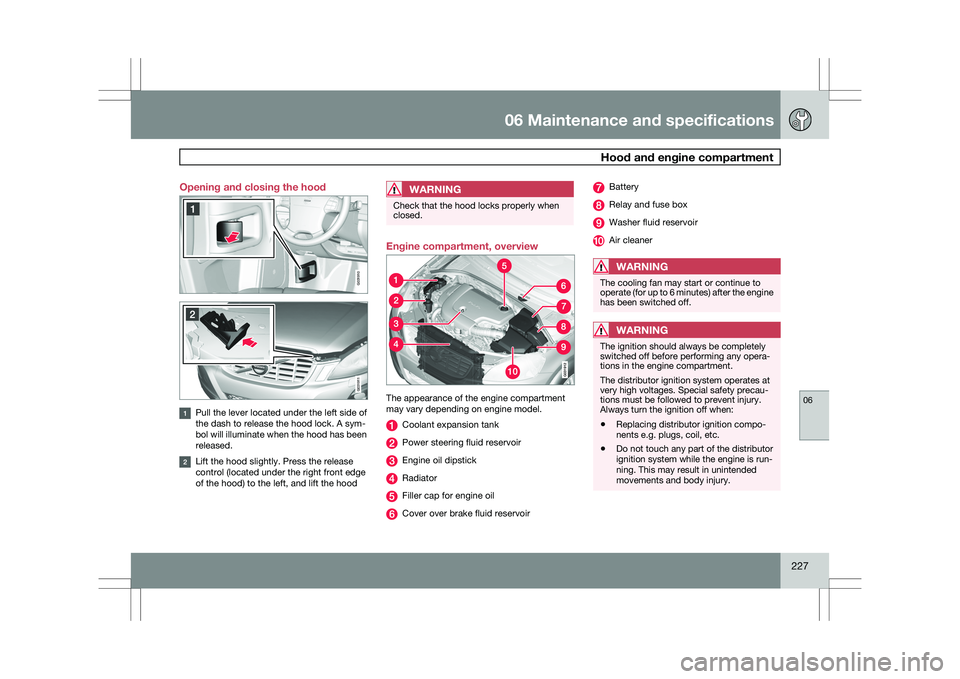

242 Warning symbols on the battery

Wear protective goggles.

Keep away from children.

Avoid smoking, open flames,

and/or sparks.

See the owner\fs manual.

Contains corrosive acid.

Risk of explosion

NOTE A used battery should be disposed of in an

environmentally responsible manner. Con-

sult your Volvo retailer or take the battery to

a recycling station.

Handling

\b

Check that the battery cables are correctly

connected and tightened.

\b Never disconnect the battery when the

engine is running (for example, when

replacing the battery).

The service life and function of the battery is

influenced by factors such as the number of

starts, discharging, driving style, driving con-

ditions, climatic conditions etc.

Never use a quick charger to charge the bat-

tery.WARNING \b

Never expose the battery to open flame

or electric spark.

\b Do not smoke near the battery.

\b Battery fluid contains sulfuric acid. Do

not allow battery fluid to contact eyes,

skin, fabrics or painted surfaces. If con-

tact occurs, flush the affected area

immediately with water. Obtain medical

help immediately if eyes are affected.

NOTE The life of the battery is shortened if it

becomes discharged repeatedly.

Maintenance

\b

Regularly check that the electrolyte level is

correct and never fill above the level mark.

\b Check all cells. Use a large screwdriver or

a coin to remove the cell caps. Each cell

has its own maximum and minimum level

mark.

\b If necessary, top up with distilled water to

the battery\fs maximum mark.

\b Tighten the cell caps thoroughly.

Page 245 of 297

06 Maintenance and specifications

Battery06

}}

243

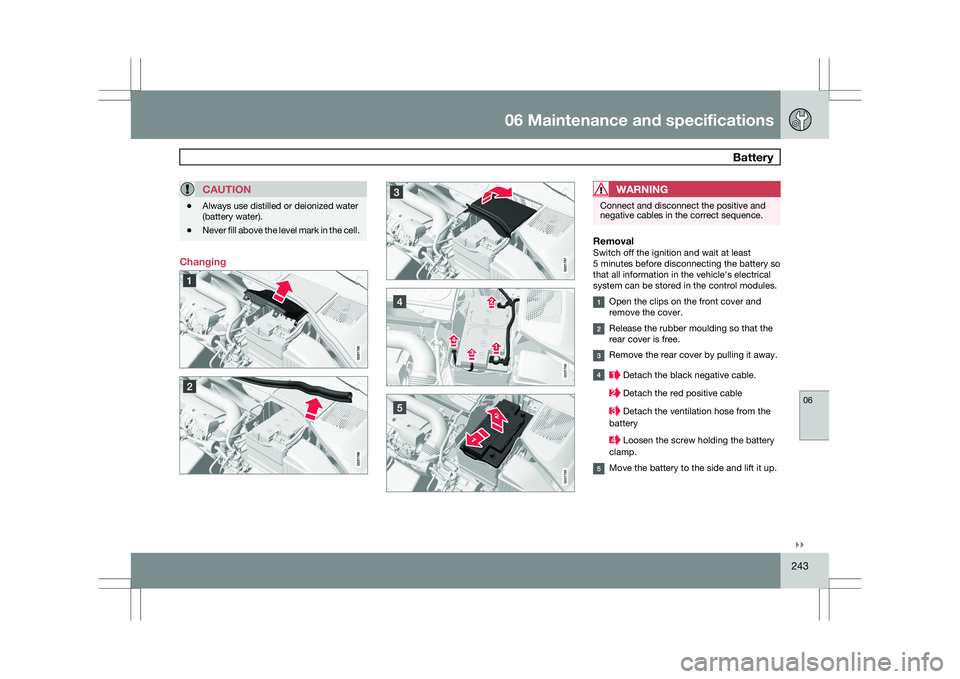

CAUTION\b

Always use distilled or deionized water

(battery water).

\b Never fill above the level mark in the cell. ChangingWARNING Connect and disconnect the positive and

negative cables in the correct sequence.

RemovalSwitch off the ignition and wait at least

5 minutes before disconnecting the battery so

that all information in the vehicle\fs electrical

system can be stored in the control modules.

Open the clips on the front cover and

remove the cover.

Release the rubber moulding so that the

rear cover is free.

Remove the rear cover by pulling it away.

Detach the black negative cable.

Detach the red positive cable

Detach the ventilation hose from the

battery Loosen the screw holding the battery

clamp. Move the battery to the side and lift it up. G021768 G021769

Page 246 of 297

06 Maintenance and specificationsBattery 06

244

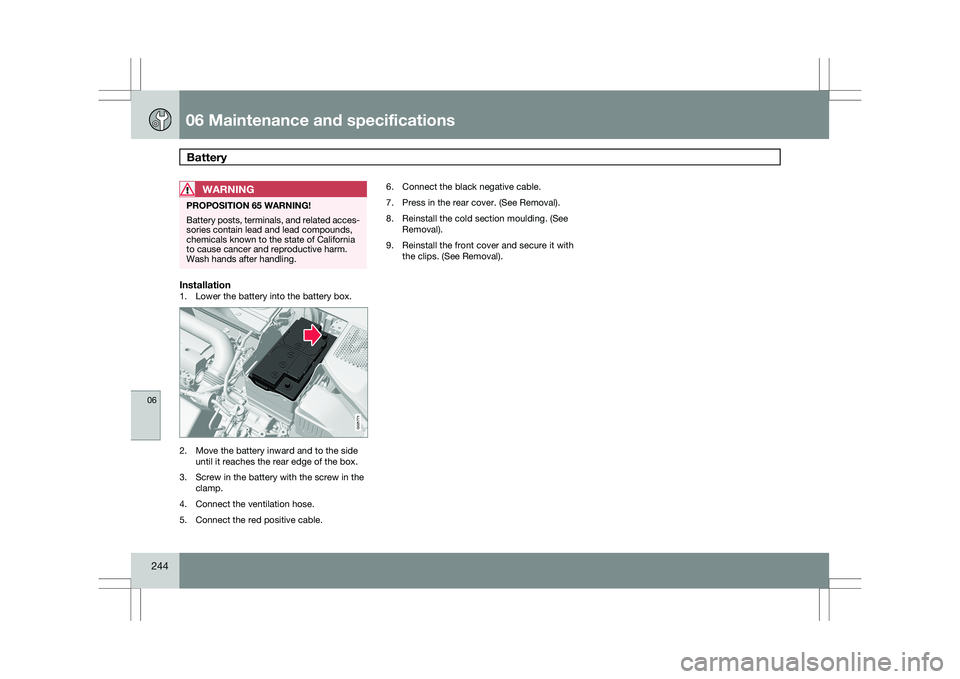

WARNING PROPOSITION 65 WARNING!

Battery posts, terminals, and related acces-

sories contain lead and lead compounds,

chemicals known to the state of California

to cause cancer and reproductive harm.

Wash hands after handling.

Installation1. Lower the battery into the battery box.

2. Move the battery inward and to the side

until it reaches the rear edge of the box.

3. Screw in the battery with the screw in the clamp.

4. Connect the ventilation hose.

5. Connect the red positive cable. 6. Connect the black negative cable.

7. Press in the rear cover. (See Removal).

8. Reinstall the cold section moulding. (See

Removal).

9. Reinstall the front cover and secure it with the clips. (See Removal). G021771

Page 271 of 297

06 Maintenance and specifications

Wheels and tires06

}}

269

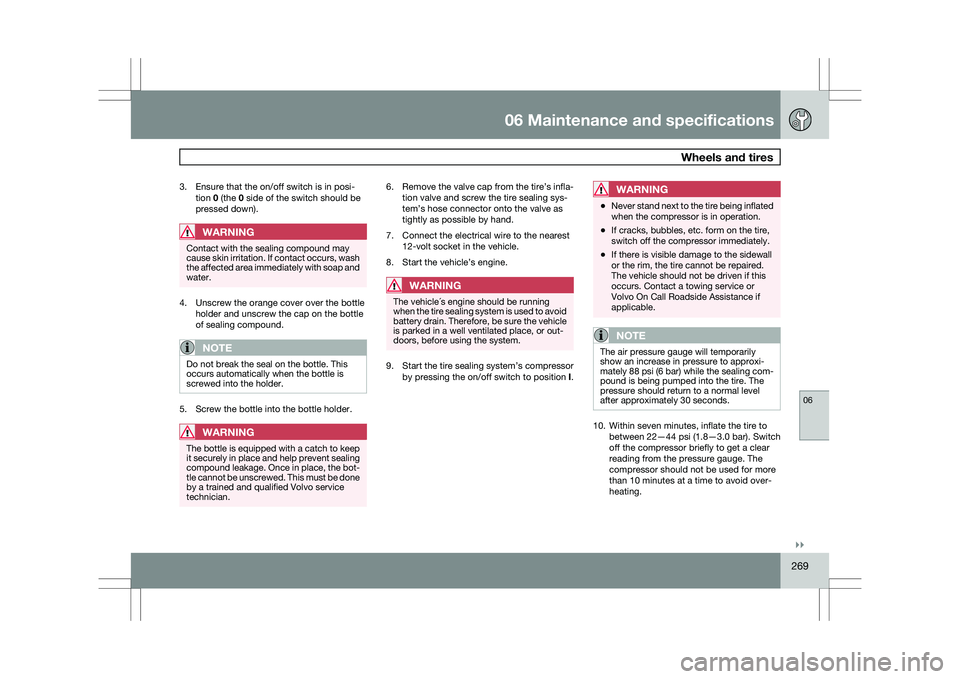

3. Ensure that the on/off switch is in posi-

tion 0 (the 0 side of the switch should be

pressed down).

WARNING Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.

4. Unscrew the orange cover over the bottle

holder and unscrew the cap on the bottle

of sealing compound.

NOTE Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

5. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bot-

tle cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician. 6.

Remove the valve cap from the tire’s infla-

tion valve and screw the tire sealing sys-

tem’s hose connector onto the valve as

tightly as possible by hand.

7. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

8. Start the vehicle’s engine.

WARNING The vehicle´s engine should be running

when the tire sealing system is used to avoid

battery drain. Therefore, be sure the vehicle

is parked in a well ventilated place, or out-

doors, before using the system.

9.

Start the tire sealing system’s compressor

by pressing the on/off switch to position I.

WARNING \b

Never stand next to the tire being inflated

when the compressor is in operation.

\b If cracks, bubbles, etc. form on the tire,

switch off the compressor immediately.

\b If there is visible damage to the sidewall

or the rim, the tire cannot be repaired.

The vehicle should not be driven if this

occurs. Contact a towing service or

Volvo On Call Roadside Assistance if

applicable.

NOTE The air pressure gauge will temporarily

show an increase in pressure to approxi-

mately 88 psi (6 bar) while the sealing com-

pound is being pumped into the tire. The

pressure should return to a normal level

after approximately 30 seconds.

10. Within seven minutes, inflate the tire to

between

22—44 psi (1.8—3.0 bar). Switch

off the compressor briefly to get a clear

reading from the pressure gauge. The

compressor should not be used for more

than 10 minutes at a time to avoid over-

heating.

Page 273 of 297

06 Maintenance and specifications

Wheels and tires06

}}

271

NOTE\b

After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

\b If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances. Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle. 6. Start the vehicle’s engine.

WARNING \b

The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem.

\b Children should never be left unattended

in the vehicle when the engine is running. 7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION The compressor should not be used for

more than 10 minutes at a time to avoid

overheating. 9. Turn off the compressor (press the on/off

switch to position 0) when the correct infla-

tion pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

11. Disconnect the electrical wire from the 12-volt socket.

Tire Pressure Monitoring System

(TPMS)–U.S models only

NOTE USA – FCC ID: KR5S122780002

This device complies with part 15 of the

FCC rules. Operation is subject to the fol-

lowing conditions: (1) This device may not

cause harmful interference, and (2) this

device must accept any interference

received, including interference that may

cause undesired operation.

The tire pressure monitoring system uses sen-

sors mounted in the tire valves to check infla-

tion pressure levels. When the vehicle is mov-

ing at a speed of approximately 20 mph

(30 km/h) or faster, these sensors transmit

inflation pressure data to a receiver located in

the vehicle.

Page 288 of 297

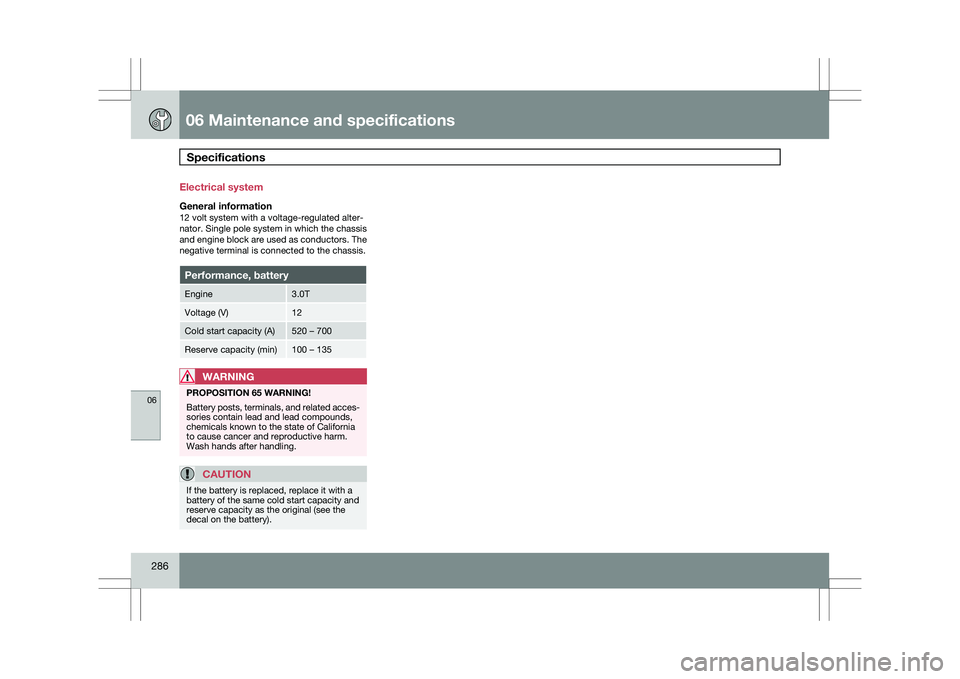

06 Maintenance and specificationsSpecifications 06

286 Electrical system

General information12 volt system with a voltage-regulated alter-

nator. Single pole system in which the chassis

and engine block are used as conductors. The

negative terminal is connected to the chassis.

Performance, battery

Engine 3.0T

Voltage (V) 12

Cold start capacity (A) 520 – 700

Reserve capacity (min) 100 – 135

WARNING

PROPOSITION 65 WARNING!

Battery posts, terminals, and related acces-

sories contain lead and lead compounds,

chemicals known to the state of California

to cause cancer and reproductive harm.

Wash hands after handling.

CAUTION

If the battery is replaced, replace it with a

battery of the same cold start capacity and

reserve capacity as the original (see the

decal on the battery).

Page 290 of 297

07 Index07

288 1, 2, 3 ...

12-volt sockets

........................................ 199

A Accessory installation warning

.................... 8

Active chassis system .............................157

Active yaw control ................................... 155

Adaptive cruise control ....172, 173, 174, 175

Airbags disconnecting the front passenger’s

side................................................. 22, 23

front.......................................... 18, 19, 20

inflatable curtain ................................... 28

side impact........................................... 26

Air conditioning ........................................ 129

Air distribution..........................................

127

Air distribution table................................. 131

Air vents................................................... 127

All Wheel Drive ......................................... 111

Anti-freeze ....................................... 204, 230

Anti-lock brake system ............................112

warning light ......................................... 74Approach lighting................................. 52, 92

Audio system

audio functions ................................... 136

CD player/changer

...................... 144, 145

Digital Audio Broadcasting (DAB) .......140

HD digital radio ................................... 139

menu control....................................... 135

overview.............................................. 133

radio functions .................................... 138

Sirius satellite radio ............141, 143, 144

sound settings .................................... 136

steering wheel keypad ........................133

USB/iPod® connector ........................134

Auto-dim rearview mirror ...........................99

Automatic locking retractor .......................34

Automatic transmission Geartronic ................................... 109, 110

general description .....................109, 110

oil ........................................................ 285

shiftlock override ................................ 110

Axle weight .............................................. 261B Battery

changing ..................................... 242, 243

maintenance ....................................... 242

remote control, replacing .....................56

specifications ...................................... 286

warning symbols.................................

242

Black box............................................. 7, 224

Blind Spot Information System

(BLIS)....................................... 193, 194, 195

Booster cushion, integrated ......................45

Booster cushions ....................................... 41

Brake lights ................................................ 88

emergency brake lights ........................88

Brake system checking fluid level ............................. 230

emergency brake assistance ..............113

fluid..................................................... 285

general information ............................. 112

Hill Descent Control ............................114

warning light ......................................... 76

Bulbs cargo area lighting .............................. 237

footwell lighting................................... 237

headlights ................................... 232, 234