ESP YAMAHA DT125R 2000 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: DT125R, Model: YAMAHA DT125R 2000Pages: 91, PDF Size: 4.67 MB

Page 27 of 91

3-14

INSTRUMENT AND CONTROL FUNCTIONS

1

23

4

5

6

7

8

9

12

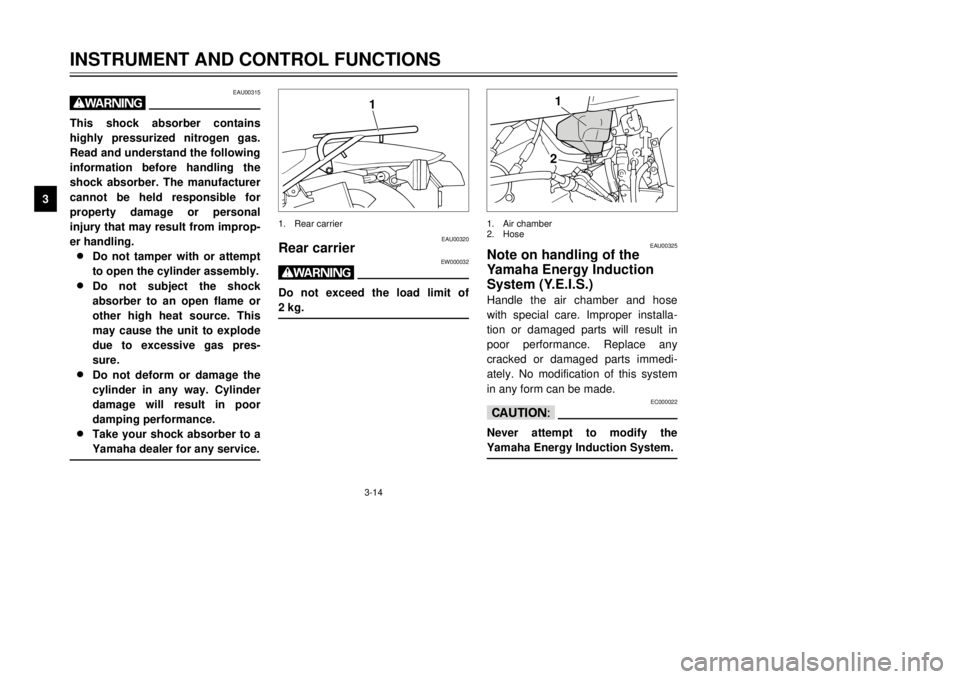

1.Air chamber

2.Hose

EAU00325

Note on handling of the

Yamaha Energy Induction

System (Y.E.I.S.)Handle the air chamber and hose

with special care. Improper installa-

tion or damaged parts will result in

poor performance. Replace any

cracked or damaged parts immedi-

ately. No modification of this system

in any form can be made.

EC000022

cCNever attempt to modify the

Yamaha Energy Induction System.

EAU00315

wThis shock absorber contains

highly pressurized nitrogen gas.

Read and understand the following

information before handling the

shock absorber. The manufacturer

cannot be held responsible for

property damage or personal

injury that may result from improp-

er handling.

8 8

Do not tamper with or attempt

to open the cylinder assembly.

8 8

Do not subject the shock

absorber to an open flame or

other high heat source. This

may cause the unit to explode

due to excessive gas pres-

sure.

8 8

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

8 8

Take your shock absorber to a

Yamaha dealer for any service.

1

EAU00320

Rear carrier

EW000032

wDo not exceed the load limit of

2 kg.1.Rear carrier

3MB-9-E7 12/27/00 2:52 PM Page 26

Page 29 of 91

EW000045

wIf improper operation is noted,

consult a Yamaha dealer immedi-

ately.

3-16

INSTRUMENT AND CONTROL FUNCTIONS

1

23

4

5

6

7

8

9

ENGINE WILL STALL.SIDESTAND SWITCH IS OK.

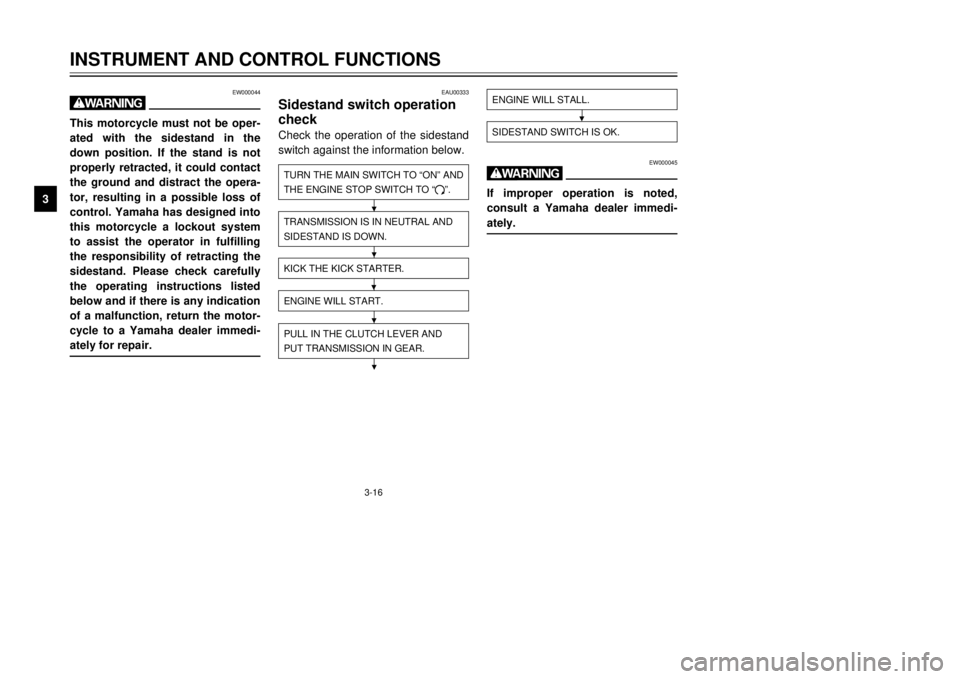

EAU00333

Sidestand switch operation

checkCheck the operation of the sidestand

switch against the information below.TURN THE MAIN SWITCH TO ÒONÓ AND

THE ENGINE STOP SWITCH TO Ò#Ó.TRANSMISSION IS IN NEUTRAL AND

SIDESTAND IS DOWN.PULL IN THE CLUTCH LEVER AND

PUT TRANSMISSION IN GEAR.ENGINE WILL START.KICK THE KICK STARTER.

EW000044

wThis motorcycle must not be oper-

ated with the sidestand in the

down position. If the stand is not

properly retracted, it could contact

the ground and distract the opera-

tor, resulting in a possible loss of

control. Yamaha has designed into

this motorcycle a lockout system

to assist the operator in fulfilling

the responsibility of retracting the

sidestand. Please check carefully

the operating instructions listed

below and if there is any indication

of a malfunction, return the motor-

cycle to a Yamaha dealer immedi-

ately for repair.

3MB-9-E7 12/27/00 2:52 PM Page 28

Page 30 of 91

4-1

EAU01114

PRE-OPERATION CHECKS

1

2

34

5

6

7

8

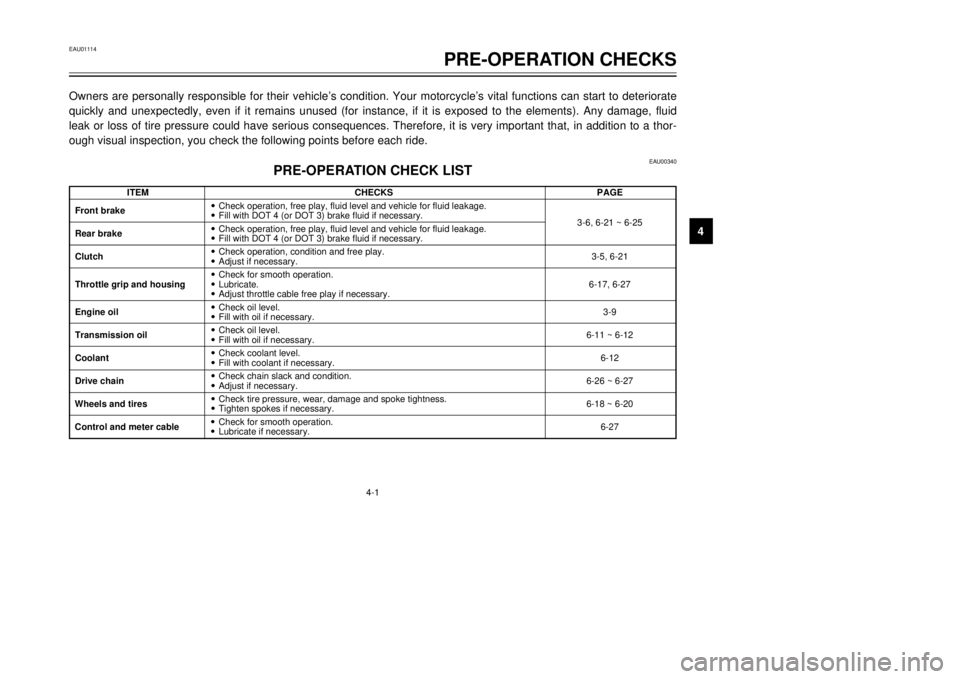

9 Owners are personally responsible for their vehicleÕs condition. Your motorcycleÕs vital functions can start to deteriorate

quickly and unexpectedly, even if it remains unused (for instance, if it is exposed to the elements). Any damage, fluid

leak or loss of tire pressure could have serious consequences. Therefore, it is very important that, in addition to a thor-

ough visual inspection, you check the following points before each ride.

EAU00340

PRE-OPERATION CHECK LIST

ITEMCHECKSPAGE

Front brake9Check operation, free play, fluid level and vehicle for fluid leakage.

9Fill with DOT 4 (or DOT 3) brake fluid if necessary.

3-6, 6-21 ~ 6-25

Rear brake9Check operation, free play, fluid level and vehicle for fluid leakage.

9Fill with DOT 4 (or DOT 3) brake fluid if necessary.

Clutch9Check operation, condition and free play.

3-5, 6-21

9Adjust if necessary.

9Check for smooth operation.

Throttle grip and housing9Lubricate.6-17, 6-27

9Adjust throttle cable free play if necessary.

Engine oil9Check oil level.

3-9

9Fill with oil if necessary.

Transmission oil9Check oil level.

6-11 ~ 6-12

9Fill with oil if necessary.

Coolant9Check coolant level.

6-12

9Fill with coolant if necessary.

Drive chain9Check chain slack and condition.

6-26 ~ 6-27

9Adjust if necessary.

Wheels and tires9Check tire pressure, wear, damage and spoke tightness.

6-18 ~ 6-20

9Tighten spokes if necessary.

Control and meter cable9Check for smooth operation.

6-27

9Lubricate if necessary.

3MB-9-E7 12/27/00 2:52 PM Page 29

Page 34 of 91

5-3

OPERATION AND IMPORTANT RIDING POINTS

1

2

3

45

6

7

8

9 1.Turn the fuel cock to ÒONÓ.

2.Turn the main switch to ÒONÓ and

the engine stop switch to Ò#Ó.

3.Shift the transmission into neu-

tral.

NOTE:

When the transmission is in neutral,

the neutral indicator light should be

on. If the light does not come on, ask

a Yamaha dealer to inspect it.4.Turn on the starter (choke) and

completely close the throttle grip.

5.Kick the kick starter to start the

engine.

6.After starting the engine, move

the starter (choke) to the halfway

position.

NOTE:

For maximum engine life, never

accelerate hard with a cold engine!7.After the engine is warm, turn off

the starter (choke) completely.NOTE:

The engine is warm when it responds

normally to the throttle with the starter

(choke) turned off.

EAU01258

Starting a warm engineThe starter (choke) is not required

when the engine is warm.

EC000046

cCSee the ÒEngine break-inÓ section

prior to operating the motorcycle

for the first time.

3MB-9-E7 12/27/00 2:52 PM Page 33

Page 54 of 91

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

b

a

1

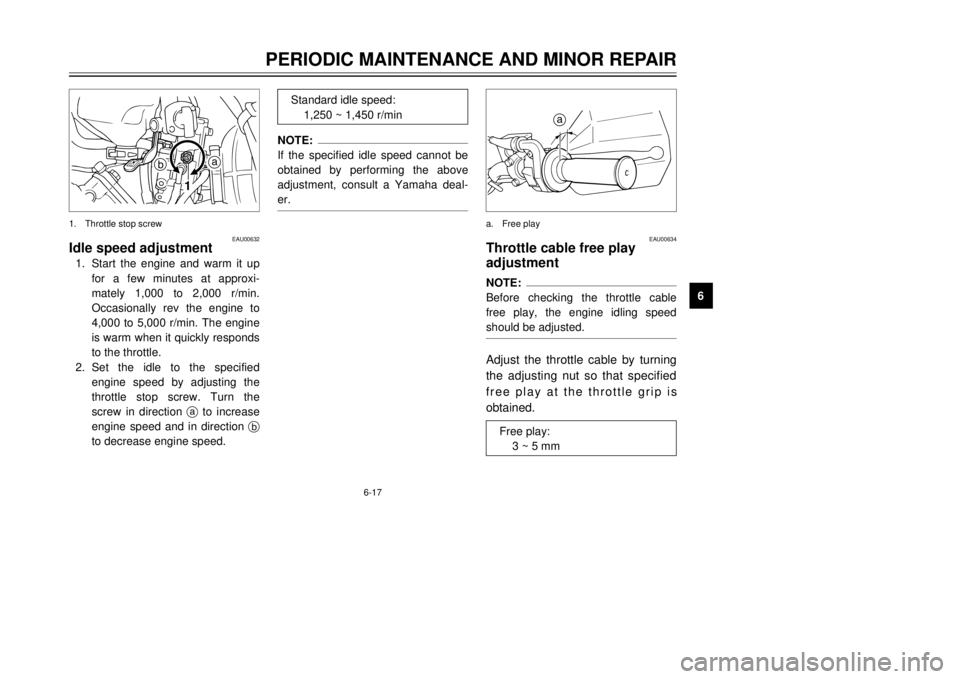

EAU00632

Idle speed adjustment1.Start the engine and warm it up

for a few minutes at approxi-

mately 1,000 to 2,000 r/min.

Occasionally rev the engine to

4,000 to 5,000 r/min. The engine

is warm when it quickly responds

to the throttle.

2.Set the idle to the specified

engine speed by adjusting the

throttle stop screw. Turn the

screw in direction ato increase

engine speed and in direction b

to decrease engine speed.1.Throttle stop screw

NOTE:

If the specified idle speed cannot be

obtained by performing the above

adjustment, consult a Yamaha deal-

er.

Standard idle speed:

1,250 ~ 1,450 r/min

a

EAU00634

Throttle cable free play

adjustmentNOTE:

Before checking the throttle cable

free play, the engine idling speed

should be adjusted.Adjust the throttle cable by turning

the adjusting nut so that specified

free play at the throttle grip is

obtained.a.Free play

Free play:

3 ~ 5 mm

3MB-9-E7 12/27/00 2:52 PM Page 53

Page 63 of 91

6-26

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

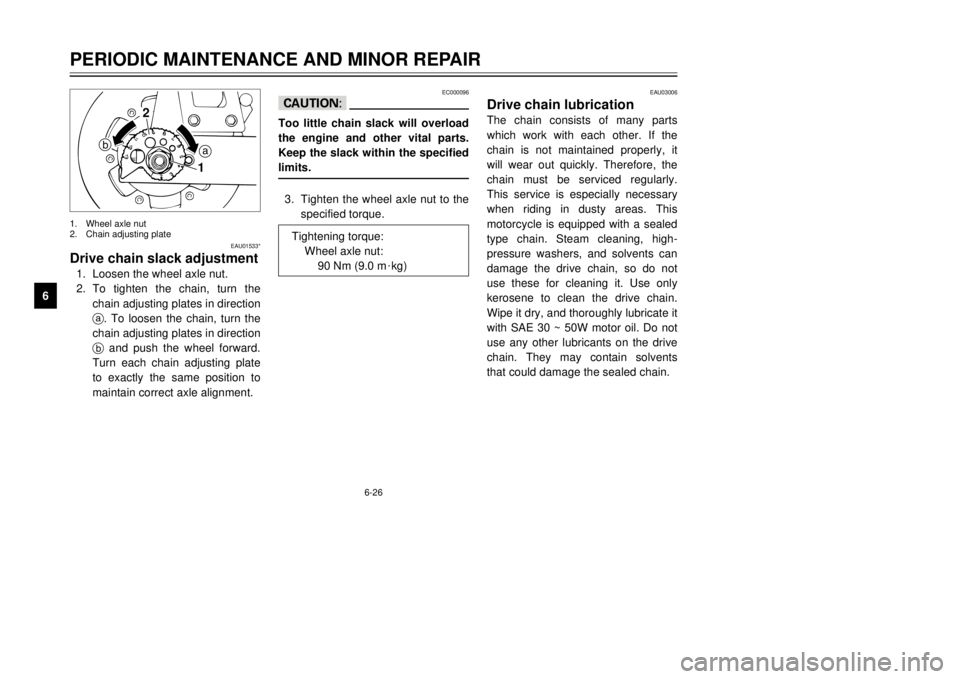

EC000096

cCToo little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits.3.Tighten the wheel axle nut to the

specified torque.

EAU01533*

Drive chain slack adjustment1.Loosen the wheel axle nut.

2.To tighten the chain, turn the

chain adjusting plates in direction

a. To loosen the chain, turn the

chain adjusting plates in direction

band push the wheel forward.

Turn each chain adjusting plate

to exactly the same position to

maintain correct axle alignment.

a b

2

1

1.Wheel axle nut

2.Chain adjusting plate

Tightening torque:

Wheel axle nut:

90 Nm (9.0 m

0kg)

EAU03006

Drive chain lubricationThe chain consists of many parts

which work with each other. If the

chain is not maintained properly, it

will wear out quickly. Therefore, the

chain must be serviced regularly.

This service is especially necessary

when riding in dusty areas. This

motorcycle is equipped with a sealed

type chain. Steam cleaning, high-

pressure washers, and solvents can

damage the drive chain, so do not

use these for cleaning it. Use only

kerosene to clean the drive chain.

Wipe it dry, and thoroughly lubricate it

with SAE 30 ~ 50W motor oil. Do not

use any other lubricants on the drive

chain. They may contain solvents

that could damage the sealed chain.

3MB-9-E7 12/27/00 2:52 PM Page 62

Page 79 of 91

7-1

EAU01518

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

67

8

9

CareThe exposure of its technology

makes a motorcycle charming but

also vulnerable. Although high-quality

components are used, they are not

all rust-resistant. While a rusty

exhaust pipe may remain unnoticed

on a car, it does look unattractive on

a motorcycle. Frequent and proper

care, however, will keep your motor-

cycle looking good, extend its life and

maintain its performance. Moreover,

the warranty states that the vehicle

must be properly taken care of. For

all these reasons, it is recommended

that you observe the following clean-

ing and storing precautions.Before cleaning

1.Cover up the muffler outlet with a

plastic bag.

2.Make sure that all caps and cov-

ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly

installed.

3.Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets,

sprockets, the drive chain and

wheel axles. Always rinse the dirt

and degreaser off with water.Cleaning

After normal use

Remove dirt with warm water, a neu-

tral detergent and a soft clean

sponge, then rinse with plenty of

clean water. Use a tooth or bottle

brush for hard-to-reach parts.

Tougher dirt and insects will come off

more easily if the area is covered with

a wet cloth for a few minutes before

cleaning.

ECA00010

cC8

8

Avoid using strong acidic

wheel cleaners, especially on

spoked wheels. If you do use

such products for hard-to-

remove dirt, do not leave it on

any longer than instructed,

then thoroughly rinse it off

with water, immediately dry

the area and apply a corrosion

protection spray.

3MB-9-E7 12/27/00 2:52 PM Page 78

Page 86 of 91

8-3

1

2

3

4

5

6

78

9

SPECIFICATIONS

90 kg load ~ maximum

load*

Front150 kPa (1.50 kg/cm

2, 1.50 bar)

Rear175 kPa (1.75 kg/cm2, 1.75 bar)

Off-road riding

Front125 kPa (1.25 kg/cm2, 1.25 bar)

Rear150 kPa (1.50 kg/cm2, 1.50 bar)

* Load is total weight of cargo, rider, passenger and accessories.

Wheels

Front

TypeSpoke wheel

Size1.60 ´21

Rear

TypeSpoke wheel

Size1.85 ´18

Brakes

Front

TypeSingle disc brake

OperationRight hand operation

FluidDOT 3 or DOT 4Rear

TypeSingle disc brake

OperationRight foot operation

FluidDOT 3 or DOT 4

Suspension

FrontTelescopic fork

RearSwingarm (link suspension)

Shock absorber

FrontCoil spring/oil damper

RearCoil-gas spring/oil damper

Wheel travel

Front270 mm

Rear260 mm

Electrical

Ignition systemC.D.I.

Charging system

TypeC.D.I. magneto

3MB-9-E7 12/27/00 2:52 PM Page 85