check engine YAMAHA GIGGLE50 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: GIGGLE50, Model: YAMAHA GIGGLE50 2007Pages: 72, PDF Size: 1.05 MB

Page 38 of 72

6-6

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIRPanel CTo remo

ve the panel

ZAUM00**

1

1. Panel C1. Open the seat. (See page 3-9.)

2. Remove the screws, and then take

the panel off.To install the panel

Place the panel in the original position,

and then install the screws.

EAUT2070

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug can

reveal the condition of the engine.

To remove the spark plug

1. Remove panel A. (See page 6-5.)

2. Remove the spark plug cap.ZAUM00**

1

1. Spark plug wrench

Spark plug, checking

3. Remove the spark plug as shown,

with a spark plug wrench available

at a Yamaha dealer.

To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light tan

(the ideal color when the vehicle is

ridden normally).

NOTE:

If the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to di-

agnose such problems yourself. In-

stead, have a Yamaha dealer check the

vehicle.2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.Specified spark plug:

CR7E (NGK)

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 6

Page 39 of 72

6-7

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)2. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

3. Install the spark plug with the spark

plug wrench, and then tighten it to

the specified torque.Tightening torque:

Spark plug:

NOTE:

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4~1/2 turn past

finger tight. However, the spark plug

should be tightened to the specified

torque as soon as possible.

4. Install the spark plug cap.

5. Install the panel.

EAUT1460

Engine oil and oil strainerThe engine oil level should be checked

before each ride. In addition, the oil must

be changed and the oil strainer cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the engine oil level

1. Place the vehicle on the

centerstand.NOTE:

Make sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Start the engine, warm it up for sev-

eral minutes, and then turn it off. Engine oil

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 7

Page 40 of 72

6-8

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIRZAUM00**

1

2

3

1. Engine oil filler cap

2. Maximum level mark

3. Minimum level mark3. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, insert it

back into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.NOTE:

The engine oil should be between the

minimum and maximum level marks.4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil and clean

the oil strainer

1. Start the engine, warm it up for sev-

eral minutes, and then turn it off.

2. Place an oil pan under the engine

to collect the used oil.

3. Remove the engine oil filler cap and

the engine oil drain bolts A and B

to drain the oil from the crankcase.

ZAUM00**

1

1. Engine oil drain bolt A

ZAUM00**

1

1. Engine oil drain bolt B

ECAT1020

cCWhen removing the engine oil drain

bolt B, the O-ring, compression

spring, and oil strainer will fall out.

Take care not to lose these parts.4. Clean the oil strainer with solvent,

and then check it for damage and

replace it if necessary.

5. Check the O-ring for damage and

replace it if necessary.

6. Install the oil strainer, compression

spring, O-ring and engine oil drain

bolt B.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 8

Page 41 of 72

6-9

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

NOTE:

Make sure that the O-ring is properly

seated.7. Install engine oil drain bolt A, and

then tighten both drain bolts to their

specified torques.Tightening torque:

Engine oil drain bolt A:

Engine oil drain bolt B:

ZAUM00**

1

1. Oil filler hole

8. Add the specified amount of the

recommended engine oil, and then

install and tighten the oil filler cap.Recommended engine oil:

See page 8-1.

Oil change quantity:

0.78 L (0.82 US qt) (0.69 Imp.qt)

ECA11670

cC● ●● ●

●

Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

● ●● ●

●

Be sure no foreign material en-

ters the crankcase.

9. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off and

check for the cause.

10. Turn the engine off, and then check

the oil level and correct it if neces-

sary.

EAUT1560

Final transmission oilThe final transmission case must be

checked for oil leakage before each ride.

If any leakage is found, have a Yamaha

dealer check and repair the scooter. In

addition, the final transmission oil must

be changed as follows at the intervals

specified in the periodic maintenance

and lubrication chart.

1. Start the engine, warm it up by

riding the scooter for several min-

utes, and then stop the engine.

2. Place the scooter on the

centerstand.

3. Place an oil pan under the final

transmission case to collect the

used oil. Final transmission oil

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 9

Page 42 of 72

6-10

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIRZAUM00**

1

2

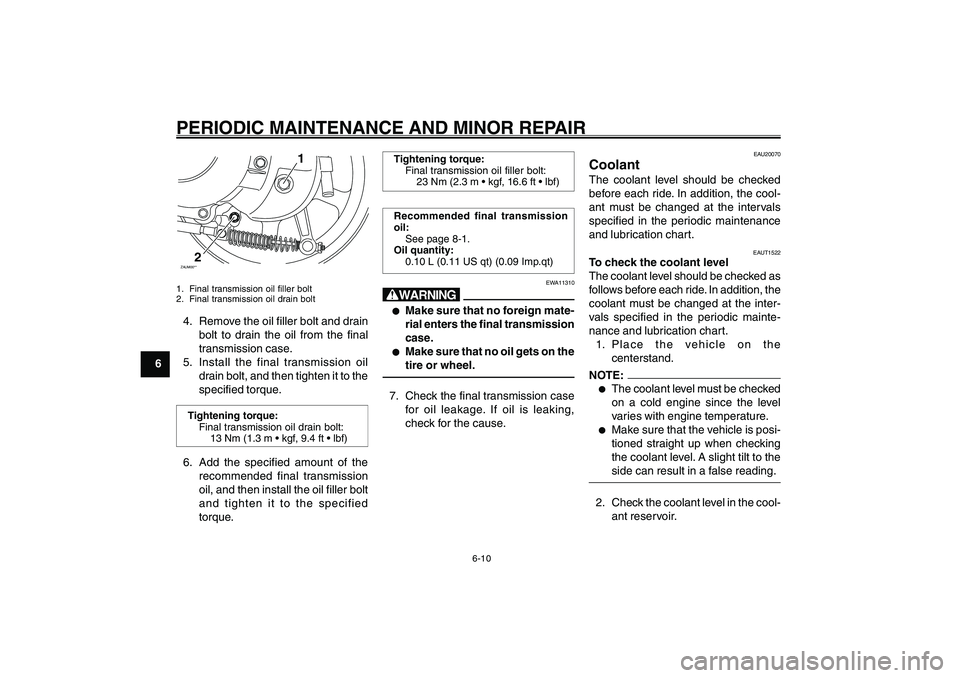

1. Final transmission oil filler bolt

2. Final transmission oil drain bolt4. Remove the oil filler bolt and drain

bolt to drain the oil from the final

transmission case.

5. Install the final transmission oil

drain bolt, and then tighten it to the

specified torque.Tightening torque:

Final transmission oil drain bolt:

6. Add the specified amount of the

recommended final transmission

oil, and then install the oil filler bolt

and tighten it to the specified

torque.

Tightening torque:

Final transmission oil filler bolt:

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.10 L (0.11 US qt) (0.09 Imp.qt)

EWA11310

w● ●● ●

●

Make sure that no foreign mate-

rial enters the final transmission

case.

● ●● ●

●

Make sure that no oil gets on the

tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20070

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart. Coolant

EAUT1522

To check the coolant level

The coolant level should be checked as

follows before each ride. In addition, the

coolant must be changed at the inter-

vals specified in the periodic mainte-

nance and lubrication chart.

1. Place the vehicle on the

centerstand.NOTE:●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the cool-

ant reservoir.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 10

Page 43 of 72

6-11

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

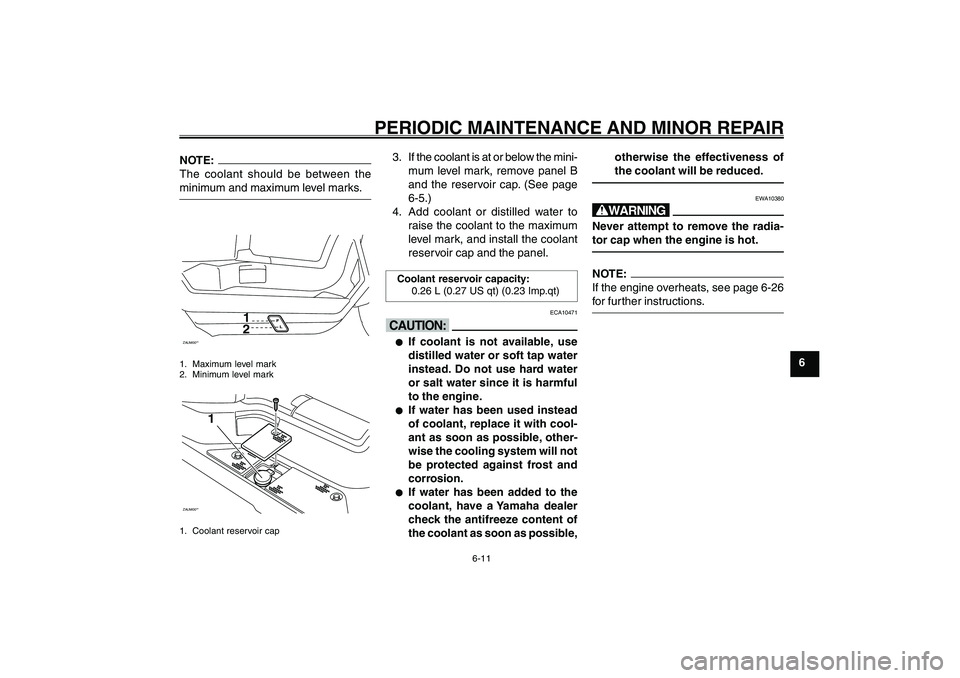

NOTE:

The coolant should be between the

minimum and maximum level marks.ZAUM00**

12

1. Maximum level mark

2. Minimum level markZAUM00**

1

1. Coolant reservoir cap

3. If the coolant is at or below the mini-

mum level mark, remove panel B

and the reservoir cap. (See page

6-5.)

4. Add coolant or distilled water to

raise the coolant to the maximum

level mark, and install the coolant

reservoir cap and the panel.Coolant reservoir capacity:

0.26 L (0.27 US qt) (0.23 Imp.qt)

ECA10471

cC● ●● ●

●

If coolant is not available, use

distilled water or soft tap water

instead. Do not use hard water

or salt water since it is harmful

to the engine.

● ●● ●

●

If water has been used instead

of coolant, replace it with cool-

ant as soon as possible, other-

wise the cooling system will not

be protected against frost and

corrosion.

● ●● ●

●

If water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possible,otherwise the effectiveness of

the coolant will be reduced.

EWA10380

wNever attempt to remove the radia-

tor cap when the engine is hot.NOTE:

If the engine overheats, see page 6-26

for further instructions.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 11

Page 44 of 72

6-12

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

EAUT1990

Replacing the air filter elementThe air filter element must be replaced

and the check hoses must be cleaned

at the intervals specified in the periodic

maintenance and lubrication char t.

Have a Yamaha dealer replace the air

filter element. Air filter element, replacing

Throttle cable free play, checking

Valve clearance

EAU21401

Valve clearanceThe valve clearance changes with use,

resulting in improper air-fuel mixture

and/or engine noise. To prevent this from

occurring, the valve clearance must be

adjusted by a Yamaha dealer at the in-

tervals specified in the periodic mainte-

nance and lubrication chart.

EAU21382

Checking the throttle cable

free playThe throttle cable free play should mea-

sure 1.5 ~ 3.5 mm (0.06 ~ 0.14 in) at

the throttle grip. Periodically check the

throttle cable free play and, if necessary,

have a Yamaha dealer adjust it.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 12

Page 51 of 72

6-19

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

ZAUM00**

EAU23290

Checking the wheel bearingsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings. Steering, checking

Wheel bearings, checking

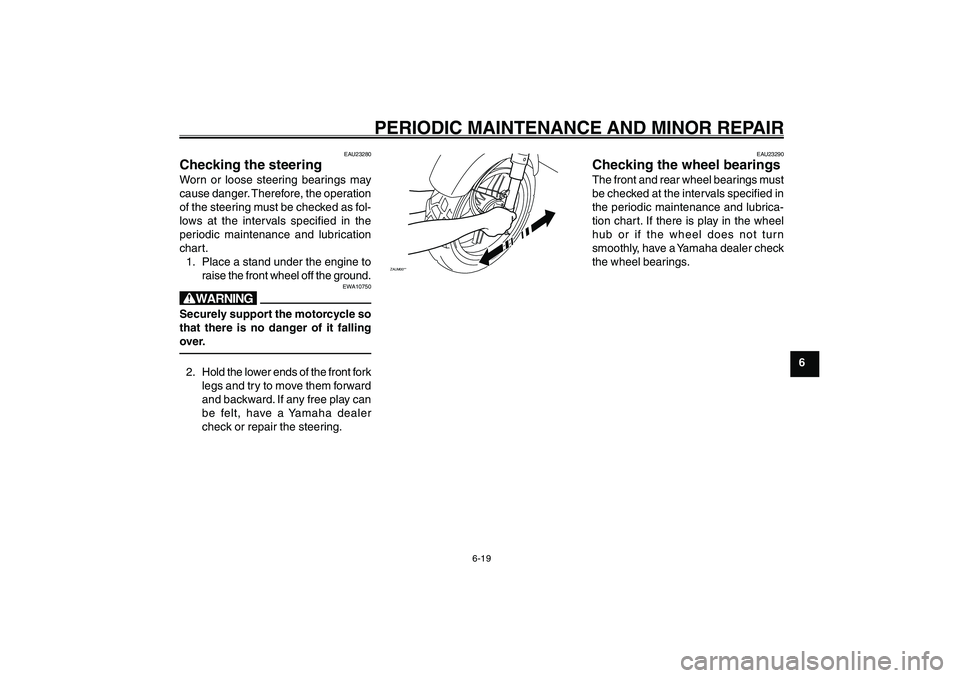

EAU23280

Checking the steeringWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

char t.

1. Place a stand under the engine to

raise the front wheel off the ground.

EWA10750

wSecurely support the motorcycle so

that there is no danger of it falling

over.2. Hold the lower ends of the front fork

legs and try to move them forward

and backward. If any free play can

be felt, have a Yamaha dealer

check or repair the steering.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 19

Page 57 of 72

6-25

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

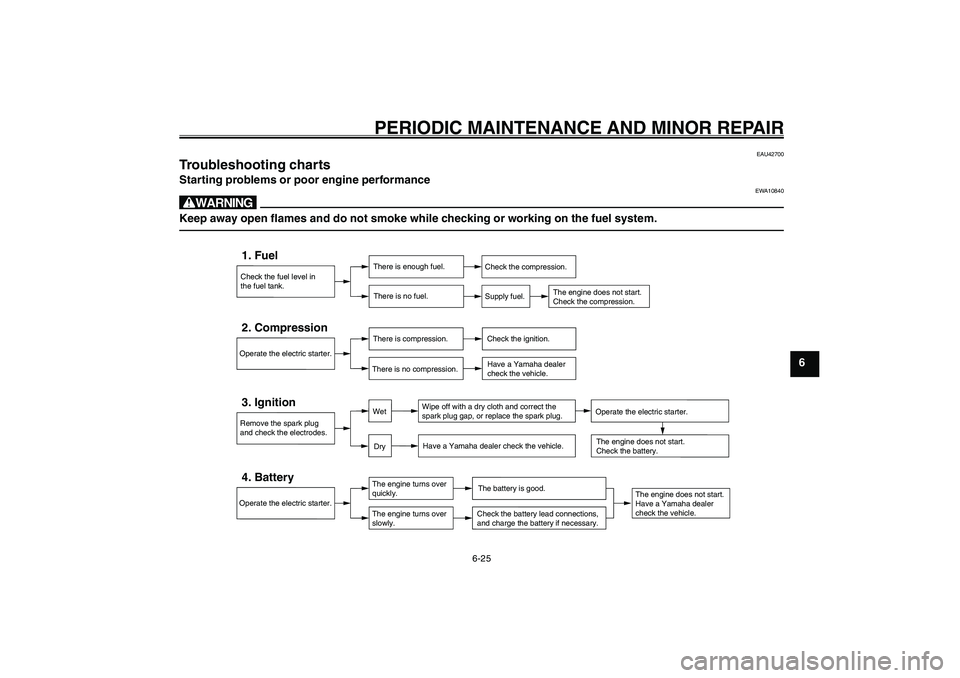

Troubleshooting charts

EAU42700

Troubleshooting chartsStarting problems or poor engine performance

EWA10840

wKeep away open flames and do not smoke while checking or working on the fuel system.

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.

There is no fuel.

Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.2. Compression

There is compression.

There is no compression.

Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer

check the vehicle.

The engine does not start.

Check the battery.

Operate the electric starter.4. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check the battery lead connections,

and charge the battery if necessary.

DryWet

Operate the electric starter.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 25

Page 58 of 72

6-26

1

2

3

4

5

6

7

8

9

EAU17226

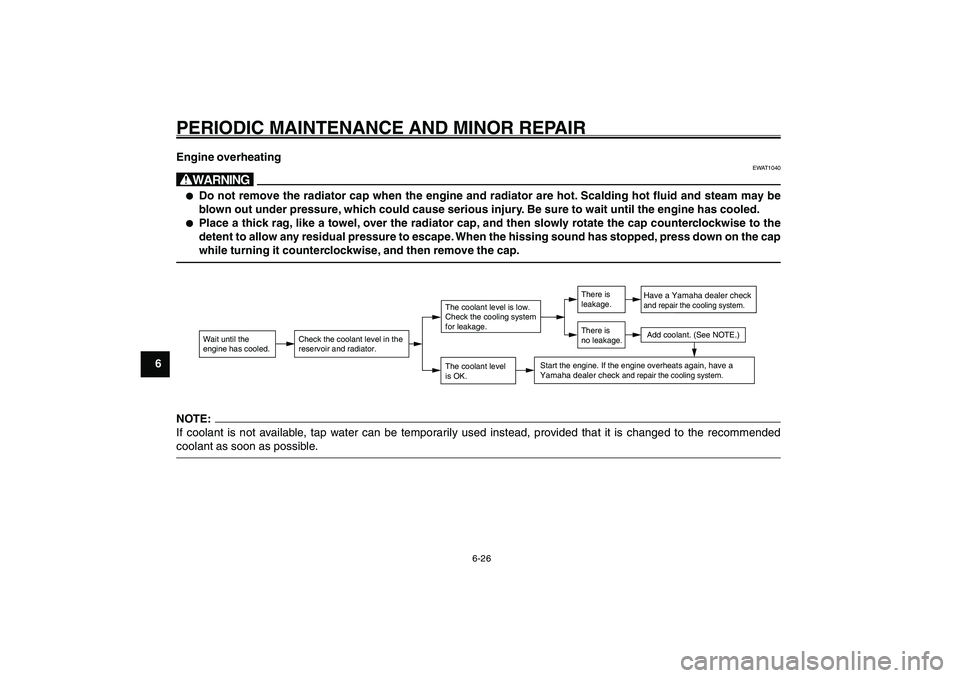

PERIODIC MAINTENANCE AND MINOR REPAIREngine overheating

EWAT1040

w● ●● ●

●

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

● ●● ●

●

Place a thick rag, like a towel, over the radiator cap, and then slowly rotate the cap counterclockwise to the

detent to allow any residual pressure to escape. When the hissing sound has stopped, press down on the cap

while turning it counterclockwise, and then remove the cap.

NOTE:

If coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended

coolant as soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See NOTE.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 26