maintenance YAMAHA NMAX 155 2021 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: NMAX 155, Model: YAMAHA NMAX 155 2021Pages: 114, PDF Size: 10.93 MB

Page 67 of 114

Periodic maintenance an d a djustment

9-4

9

11 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.

12 *Wheel bearin gs • Check bearing for looseness or

damage.

13 *Steerin g b earin gs • Check bearing assemblies for

looseness.

• Moderately repack with lithium- soap-based grease.

14 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened.

15 Front an

d rear

b rake lever pivot

shaft • Lubricate with silicone grease.

16 Si

destan d, center-

stan d • Check operation.

• Lubricate with lithium-soap-

based grease.

17 *Sidestan d switch • Check operation and replace if

necessary.

18 *Front fork • Check operation and for oil leak-

age.

• Replace if necessary.

19 *Shock a

bsor ber as-

sem blies • Check operation and for oil leak-

age.

• Replace if necessary.

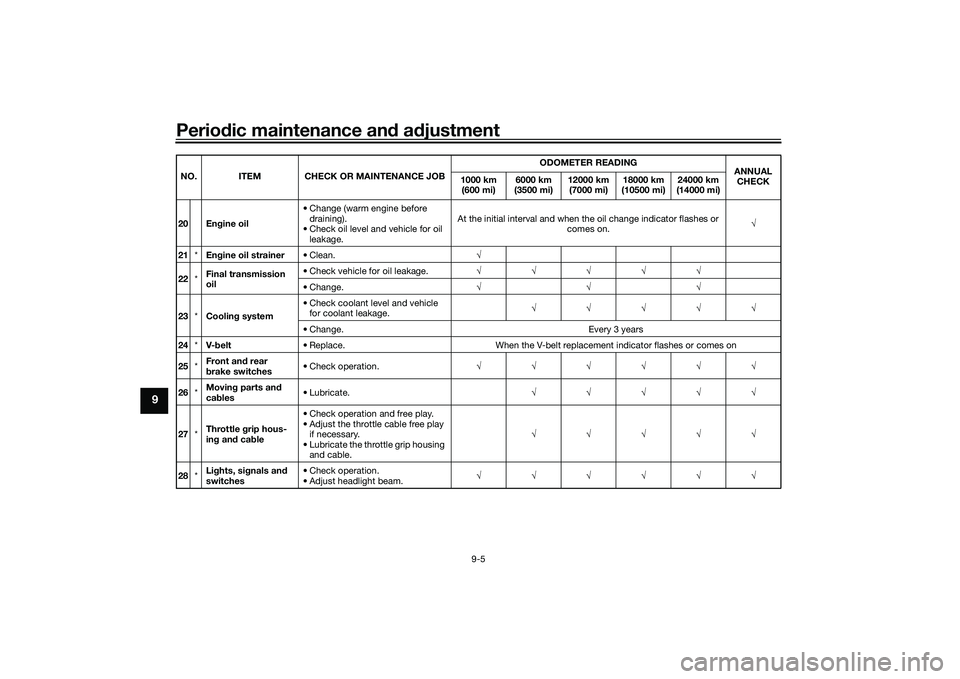

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 18000 km

(10500 mi) 2400

0 km

(14000 mi)

UBBDE0E0.book Page 4 Wednesday, June 2, 2021 2:57 PM

Page 68 of 114

Periodic maintenance an d a djustment

9-5

9

20 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. At the initial interval and when the oil change indicator flashes or

comes on.

21 *Engine oil strainer • Clean.

22 *Final transmission

oil • Check vehicle for oil leakage.

• Change.

23 *Coolin g system • Check coolant level and vehicle

for coolant leakage.

• Change. Every 3 years

24 *V-belt • Replace. When the V-belt replacement indicator flashes or comes on

25 *Front an

d rear

b rake switches • Check operation.

26 *Movin

g parts an d

cab les • Lubricate.

27 *Throttle

grip hous-

in g an d cab le • Check operation and free play.

• Adjust the throttle cable free play

if necessary.

• Lubricate the throttle grip housing and cable.

28 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 1

8000 km

(10500 mi) 24000 km

(14000 mi)

UBBDE0E0.book Page 5 Wednesday, June 2, 2021 2:57 PM

Page 69 of 114

Periodic maintenance an d a djustment

9-6

9

EAU72790

TIP Engine air filter and V-belt air filter

• This model’s engine air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with compressed air to avoid damaging it.

• The engine air filter element needs to be replaced and the V-belt air filter element needs to be serviced more fre-

quently when riding in unusually wet or dusty areas.

Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

UBBDE0E0.book Page 6 Wednesday, June 2, 2021 2:57 PM

Page 70 of 114

Periodic maintenance an d a djustment

9-7

9

EAU18773

Removin g an d installin g pan-

elsThe panels shown need to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time a panel needs to

be removed and installed.

EAUN2600

Panel A

To remove the panel1. Remove the screws. 2. Extend the right passenger foot-

rest, and then pull the panel out-

ward.

To install the panel

1. Place the panel in the original po- sition, and then install the screws. 2. Retract the right passenger foot-

rest to its original position.

Panel B

To remove the panel

1. Remove panel A.

2. Remove the quick fasteners and the bolt.

1. Panel A

2. Panel B

3. Panel C

3

1

2

1. Panel A

2. Screw

1

2

1. Panel B

2. Quick fastener

1

2

UBBDE0E0.book Page 7 Wednesday, June 2, 2021 2:57 PM

Page 71 of 114

Periodic maintenance an d a djustment

9-8

9

3. Remove the right floorboard mats

by pulling them up.

4. Remove the bolts and screw, then pull the panel outward. To install the panel

1. Place the panel in the original po-

sition, and then install the bolts

and screw.

2. Place the right floorboard mats in their original position and push

them downward to secure them.

3. Install the bolt and the quick fas- teners.

4. Install panel A.

Panel C

To remove the panel1. Remove the windshield by remov- ing the screws. 2. Remove the panel by removing

the screws.

To install the panel

1. Place the panel in the original po- sition, and then install the screws.

1. Bolt

2. Quick fastener

1. Floorboard mat1

2

1

1. Bolt

2. Screw

12

1. Windshield

2. Screw

1. Panel C

2. Screw

1

2

1

2

2

UBBDE0E0.book Page 8 Wednesday, June 2, 2021 2:57 PM

Page 72 of 114

Periodic maintenance an d a djustment

9-9

9 2. Install the windshield by installing

the screws.

EAU67161

Checkin g the spark plu gThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plu g

1. Place the vehicle on the center- stand.

2. Remove panels A and B. (See page 9-7.)

3. Remove the spark plug cap. 4. Remove the spark plug as shown,

with the spark plug wrench includ-

ed in the owner’s tool kit.

To check the spark plu g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

1. Spark plug cap

1

1. Spark plug wrench

1

UBBDE0E0.book Page 9 Wednesday, June 2, 2021 2:57 PM

Page 73 of 114

Periodic maintenance an d a djustment

9-10

9

2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation. To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.TIPInstall the spark plug cap so that it is

positioned as shown in the illustration

and the spark plug lead does not con-

tact any surrounding parts.

4. Install the panels.

Specifie d spark plu g:

NGK/CPR8EA-91. Spark plug gapSpark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.6 lb·ft)

1. Spark plug cap

2. Spark plug lead

1

2

UBBDE0E0.book Page 10 Wednesday, June 2, 2021 2:57 PM

Page 74 of 114

Periodic maintenance an d a djustment

9-11

9

EAU36113

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

EAU66995

Engine oil an d oil strainerThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil strainer

cleaned at the intervals specified in the

periodic maintenance and lubrication

chart.

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the engine oil filler

cap, wipe the engine oil dipstick

clean, insert it back into the oil fill-

er hole (without screwing it in), and

then remove it again to check the

oil level. WARNING! The muffler

an d muffler protector become

very hot d uring use. To avoi d

possi ble burns, let the muffler

an d protector cool before re-

movin g the oil filler cap.

[EWA17810]

TIPThe engine oil should be between the

tip of the dipstick and the maximum

level mark.4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler hole, and then tighten the oil filler

cap.

1. Canister

2. Canister breather

2

1

1. Oil filler hole

2. O-ring

3. Engine oil dipstick

4. Maximum level mark

5. Tip of the engine oil dipstick

3245

1

UBBDE0E0.book Page 11 Wednesday, June 2, 2021 2:57 PM

Page 75 of 114

Periodic maintenance an d a djustment

9-12

9

To chan

ge the en gine oil an d clean

the oil strainer 1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place an oil pan under the engine to collect the used oil.

3. Remove the engine oil filler cap and engine oil drain bolts A and B

to drain the oil from the crankcase.

NOTICE: When removin g the

en gine oil drain bolt B, the O-

rin g, compression sprin g, an d

oil strainer will fall out. Take

care not to lose these parts.

[ECAT1022]

4. Clean the engine oil strainer with solvent, and then check it for

damage and replace it if neces-

sary.

5. Install the engine oil strainer, com- pression spring, new O-ring and

engine oil drain bolt B.TIPMake sure that the O-ring is properly

seated.

6. Install engine oil drain bolt A andits new gasket, and then tighten

both drain bolts to their specified

torques.

7. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA24060

Make sure that no forei gn material

enters the crankcase.

1. Engine oil drain bolt A

2. Gasket

3. Oil strainer

4. Compression spring

5. O-ring

6. Engine oil drain bolt B

2 3

4

5

6

1

Ti ghtenin g torque:

Engine oil drain bolt A: 20 N·m (2.0 kgf·m, 15 lb·ft)

Engine oil drain bolt B:

20 N·m (2.0 kgf·m, 15 lb·ft)

Recommen ded en gine oil:

See page 11-1.

Oil quantity: 0.90 L (0.95 US qt, 0.79 Imp.qt)

UBBDE0E0.book Page 12 Wednesday, June 2, 2021 2:57 PM

Page 76 of 114

Periodic maintenance an d a djustment

9-13

9 8. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

9. Turn the engine off, and then check the oil level and correct it if

necessary.

10. Reset the oil change tripmeter and oil change indicator “OIL”. (See

page 6-8 for reset procedures.)

EAU85450

Why Yamalu beYAMALUBE oil is a Genuine YAMAHA

Part born of the engineers’ passion

and belief that engine oil is an impor-

tant liquid engine component. We form

teams of specialists in the fields of me-

chanical engineering, chemistry, elec-

tronics and track testing, and have

them develop the engine together with

the oil it will use. Yamalube oils take full

advantage of the base oil’s qualities

and blend in the ideal balance of addi-

tives to make sure the final oil clears

our performance standards. Thus,

Yamalube mineral, semisynthetic and synthetic oils have their own distinct

characters and value. Yamaha’s expe-

rience gained over many years of re-

search and development into oil since

the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

EAU67822

Final transmission oilThe final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair your motorcycle. In addition, the final trans-

mission oil must be changed as follows

at the intervals specified in the periodic

maintenance and lubrication chart. 1. Start the engine and warm up the final transmission oil by riding the

motorcycle for several minutes.

2. Stop the engine and then place the motorcycle on the center-

stand.

3. Place an oil pan under the final transmission case to collect the

used oil.

4. Remove the final transmission oil filler cap and its O-ring from the fi-

nal transmission case.

UBBDE0E0.book Page 13 Wednesday, June 2, 2021 2:57 PM