YAMAHA R6 RACE 2022 Repair Manual

Manufacturer: YAMAHA, Model Year: 2022, Model line: R6 RACE, Model: YAMAHA R6 RACE 2022Pages: 112, PDF Size: 4.06 MB

Page 61 of 112

Periodic maintenance an d a djustment

7-4

7

6 *Evaporative emis-

sion control system • Check control system for dam-

age.

• Replace if necessary. √√

7 *Air in

duction sys-

tem • Check the air cut-off valve, reed

valve, and hose for damage.

• Replace any damaged parts if necessary. √√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

UBN6EBE0.book Page 4 Tuesday, October 19, 2021 8:35 AM

Page 62 of 112

Periodic maintenance an d a djustment

7-5

7

EAU71352

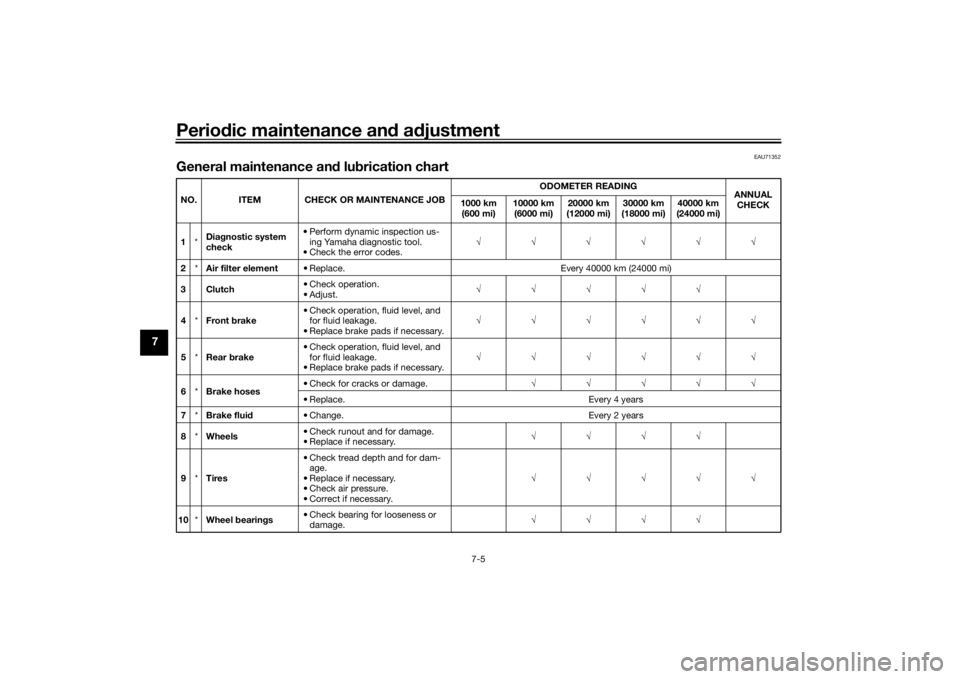

General maintenance an d lu brication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Dia

gnostic system

check • Perform dynamic inspection us-

ing Yamaha diagnostic tool.

• Check the error codes. √√√√√√

2 *Air filter element • Replace. Every 40000 km (24000 mi)

3Clutch • Check operation.

•Adjust. √√√√√

4 *Front brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

5 *Rear brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

6 *Brake hoses • Check for cracks or damage.

√√√√√

• Replace. Every 4 years

7 *Brake flui d • Change. Every 2 years

8 *Wheels • Check runout and for damage.

• Replace if necessary. √√√√

9 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary. √√√√√

10 *Wheel bearin gs • Check bearing for looseness or

damage. √√√√

UBN6EBE0.book Page 5 Tuesday, October 19, 2021 8:35 AM

Page 63 of 112

Periodic maintenance an d a djustment

7-6

7

11 *Swin

garm pivot

b earin gs • Check operation and for exces-

sive play. √√√√

• Lubricate with lithium-soap- based grease. Every 50000 km (30000 mi)

12 Drive chain • Check chain slack, alignment and

condition.

• Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 800 km (500 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

13 *Steerin g b earin gs • Check bearing assemblies for

looseness. √√ √

• Moderately repack with lithium- soap-based grease. √√

14 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened. √√√√√

15 Brake lever pivot

shaft • Lubricate with silicone grease.

√√√√√

16 Brake ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

17 Clutch lever pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Shift ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

19 Si destan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

UBN6EBE0.book Page 6 Tuesday, October 19, 2021 8:35 AM

Page 64 of 112

Periodic maintenance an d a djustment

7-7

7

20 *Sidestan d switch • Check operation and replace if

necessary. √√√√√√

21 *Front fork • Check operation and for oil leak-

age.

• Replace if necessary. √√√√

22 *Shock a

bsor ber as-

sem bly • Check operation and for oil leak-

age.

• Replace if necessary. √√√√

23 *Rear suspension re-

lay arm an

d con-

nectin g arm

pivotin g points • Check operation.

√√√√

24 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. √√√√√√

25 En

gine oil filter car-

tri dge • Replace.

√√√

26 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change. Every 3 years

27 *EXUP system • Check operation, cable free play

and pulley position. √√√

28 *Front an

d rear

b rake switches • Check operation.

√√√√√√

29 *Movin

g parts an d

cab les • Lubricate.

√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 k

m

(600 m

i) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

UBN6EBE0.book Page 7 Tuesday, October 19, 2021 8:35 AM

Page 65 of 112

Periodic maintenance an d a djustment

7-8

7

EAU80531

TIPAir filter

This model’s air filter uses a disposable oil-coated paper element. This element cannot be cleaned with compressed

air, doing so will only damage it.

The air filter element needs to be replaced more frequently when riding in unusually wet or dusty areas.

Hydraulic brake service Regularly check the front and rear brake fluid levels. Replenish if necessary.

Every two years replace the rear brake master cylinder, the internal components of the front brake master cylinder, the

brake calipers, and change the brake fluid.

Replace the brake hoses every four years or sooner if cracked or damaged.30 *Throttle g

rip hous-

in g an d ca ble • Check operation and free play.

• Adjust the throttle cable free play

if necessary.

• Lubricate the throttle grip housing and cable. √√√√√

31 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

UBN6EBE0.book Page 8 Tuesday, October 19, 2021 8:35 AM

Page 66 of 112

Periodic maintenance an d a djustment

7-9

7

EAU18713

Removin g an d installin g cowl-

in gs an d panelsThe cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU79983

Cowlin g A

To remove the cowling1. Remove panel A. (See page 7-13.)

2. Remove the bolts, quick fasten- ers, and quick fastener screw.

1. Cowling A

2. Cowling B

1

2

1. Cowling C

2. Cowling a

1. Panel A

2. Panel B

1

2

1

2

1. Cowling A

2. Bolt

3. Quick fastener screw

1

3

2

2

UBN6EBE0.book Page 9 Tuesday, October 19, 2021 8:35 AM

Page 67 of 112

Periodic maintenance an d a djustment

7-10

7

3. Slide the cowling as shown. 4. Remove the upper projections

from the slots, and then slide the

cowling forward.

To install the cowling

1. Slide the cowling rearward, and then fit the upper projections into

the slots. 2. Slide the cowling as shown.

3. Install the bolts, quick fasteners,

and quick fastener screw.

1. Bolt

1. Quick fastener

1

1

1. Cowling A

1. Cowling A

1

1

1. Cowling A

1. Cowling A

1

1

UBN6EBE0.book Page 10 Tuesday, October 19, 2021 8:35 AM

Page 68 of 112

Periodic maintenance an d a djustment

7-11

7

TIPInstall the bolts loosely, then install the

quick fasteners and quick fastener

screw, and then tighten the bolts.4. Install the panel.

Cowlin g B

To remove the cowling1. Remove panel A and cowling A. (See page 7-13.)

2. Remove cowling B by removing the bolts. To install the cowling

1. Place cowling B in its original po-

sition, and then install the bolts.

2. Install cowling A and panel A.

Cowlin g C

To remove the cowling1. Remove panel B. (See page 7-13.)

2. Remove the bolts, quick fastener, and quick fastener screw.

3. Slide the cowling as shown.

1. Cowling B

2. Bolt

12 2

1. Cowling C

2. Bolt

3. Quick fastener screw

1

2

2

3

1. Bolt

1. Quick fastener

1

1

UBN6EBE0.book Page 11 Tuesday, October 19, 2021 8:35 AM

Page 69 of 112

Periodic maintenance an d a djustment

7-12

7

4. Remove the cowling by removing

the upper projections from the

slots.

To install the cowling

1. Fit the upper projections into the slots. 2. Slide the cowling as shown.

3. Install the bolts, quick fastener,

and quick fastener screw.

TIPInstall the bolts loosely, then install the

quick fastener and quick fastener

screw, and then tighten the bolts.4. Install the panel.

Cowlin g D

To remove the cowling1. Remove panel B and cowling C. (See page 7-13.)

2. Remove cowling D by removing the bolts.

1. Cowling C

1. Cowling C

11

1. Cowling C

1. Cowling C

11

1. Cowling a

2. Bolt

2

12

UBN6EBE0.book Page 12 Tuesday, October 19, 2021 8:35 AM

Page 70 of 112

Periodic maintenance an d a djustment

7-13

7 To install the cowling

1. Place cowling D in its original po-

sition, and then install the bolts.

2. Install cowling C and panel B.

EAU79970

Panels A an d B

To remove a panelRemove the quick fasteners, and then

pull the panel off as shown.

To install a panelPlace the panel in the original position,

and then install the quick fasteners.

EAU19653

Checkin g the spark plu gsThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

1. Panel A

2. Quick fastener

2

1

UBN6EBE0.book Page 13 Tuesday, October 19, 2021 8:35 AM