light YAMAHA SR125 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: SR125, Model: YAMAHA SR125 2000Pages: 78, PDF Size: 8.59 MB

Page 38 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6

EAU01093*

Engine oilOil level inspection

1. Place the motorcycle on the cen-

terstand. Warm up the engine for

several minutes.NOTE:@ Be sure the motorcycle is positioned

straight up when checking the oil level.

A slight tilt toward the side can result in

false readings. @

2. With the engine stopped, check

the oil level through the level win-

dow located at the lower part of

the right side crankcase cover.NOTE:@ Wait a few minutes until the oil level

settles before checking. @3. The oil level should be between

the maximum level and minimum

level marks. If the level is low, fill

the engine with sufficient oil to

raise it to the specified level.Engine oil replacement and oil filter

element cleaning

1. Warm up the engine for a few min-

utes.

2. Stop the engine. Place an oil pan

under the engine and remove the

oil filler cap.

3. Remove the drain bolt and drain

the oil.

EC000070*

CAUTION:@ When removing the oil drain bolt,

the O-ring, compression spring, and

oil strainer will fall out. Take care not

to lose these parts. @

1. Oil level window

2. Maximum level mark

3. Minimum level mark

1. Engine oil drain bolt A

E_3mw.book Page 8 Monday, February 5, 2001 9:54 AM

Page 48 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-18

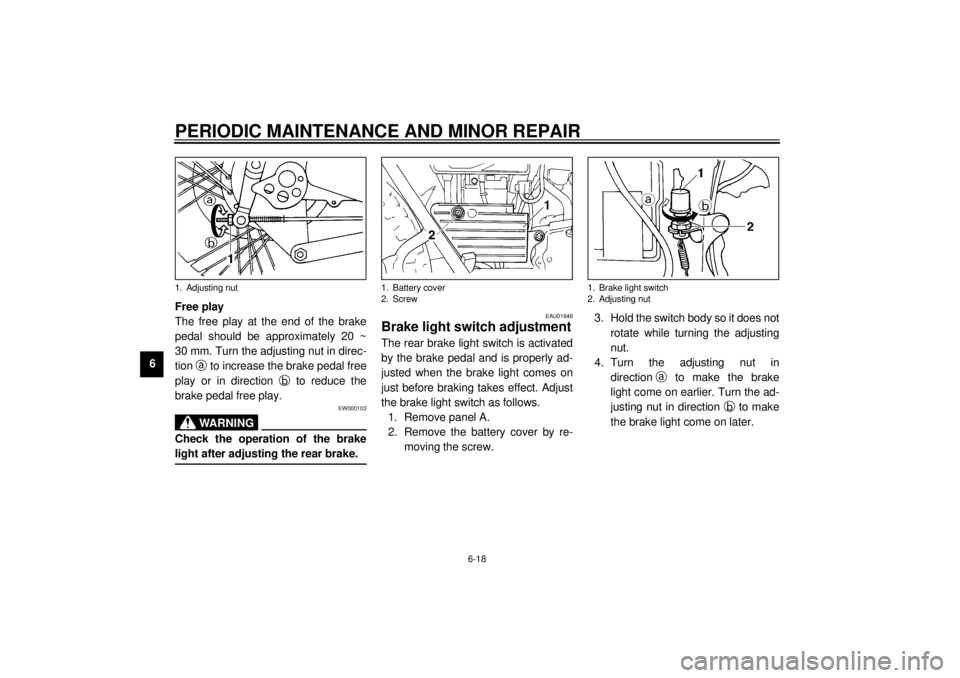

6Free play

The free play at the end of the brake

pedal should be approximately 20 ~

30 mm. Turn the adjusting nut in direc-

tion

a to increase the brake pedal free

play or in direction

b to reduce the

brake pedal free play.

EW000103

WARNING

@ Check the operation of the brake

light after adjusting the rear brake. @

EAU01646

Brake light switch adjustmentThe rear brake light switch is activated

by the brake pedal and is properly ad-

justed when the brake light comes on

just before braking takes effect. Adjust

the brake light switch as follows.

1. Remove panel A.

2. Remove the battery cover by re-

moving the screw.3. Hold the switch body so it does not

rotate while turning the adjusting

nut.

4. Turn the adjusting nut in

direction

a to make the brake

light come on earlier. Turn the ad-

justing nut in direction

b to make

the brake light come on later.

1. Adjusting nut

1. Battery cover

2. Screw

1. Brake light switch

2. Adjusting nut

E_3mw.book Page 18 Monday, February 5, 2001 9:54 AM

Page 52 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

EAU01533

Drive chain slack adjustment1. Loosen the rear brake adjusting

nut.

2. Loosen the wheel axle nut.3. To tighten the chain, turn the chain

adjusting plates in direction

a.

To loosen the chain, turn the chain

adjusting plates in direction

b and

push the wheel forward. Turn each

chain adjusting plate to exactly the

same position to maintain correct

axle alignment.

EC000096

CAUTION:@ Too little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits. @

4. Tighten the wheel axle nut to the

specified torque.

5. Adjust the brake pedal free play.

EW000103

WARNING

@ Check the operation of the brake

light after adjusting the rear brake. @

1. Adjusting nut

1. Axle nut

2. Chain adjusting plate

Tightening torque:

Wheel axle nut:

65 Nm (6.5 m·kg)

E_3mw.book Page 22 Monday, February 5, 2001 9:54 AM

Page 59 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-29

6

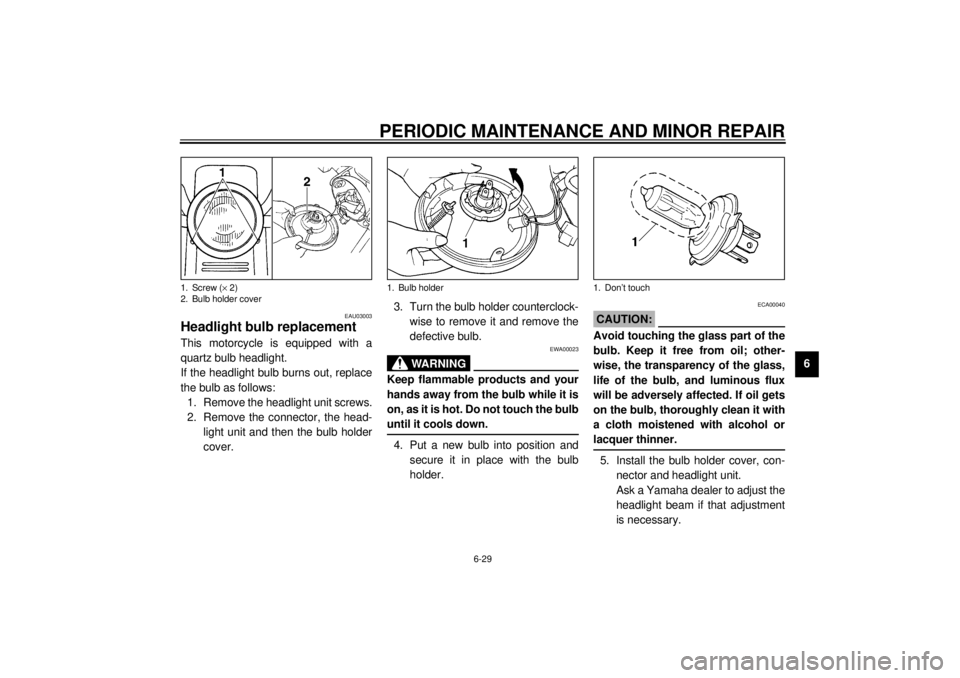

EAU03003

Headlight bulb replacementThis motorcycle is equipped with a

quartz bulb headlight.

If the headlight bulb burns out, replace

the bulb as follows:

1. Remove the headlight unit screws.

2. Remove the connector, the head-

light unit and then the bulb holder

cover.3. Turn the bulb holder counterclock-

wise to remove it and remove the

defective bulb.

EWA00023

WARNING

@ Keep flammable products and your

hands away from the bulb while it is

on, as it is hot. Do not touch the bulb

until it cools down. @4. Put a new bulb into position and

secure it in place with the bulb

holder.

ECA00040

CAUTION:@ Avoid touching the glass part of the

bulb. Keep it free from oil; other-

wise, the transparency of the glass,

life of the bulb, and luminous flux

will be adversely affected. If oil gets

on the bulb, thoroughly clean it with

a cloth moistened with alcohol or

lacquer thinner. @5. Install the bulb holder cover, con-

nector and headlight unit.

Ask a Yamaha dealer to adjust the

headlight beam if that adjustment

is necessary.

1. Screw (´ 2)

2. Bulb holder cover

1. Bulb holder

1. Don’t touch

E_3mw.book Page 29 Monday, February 5, 2001 9:54 AM

Page 60 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-30

6

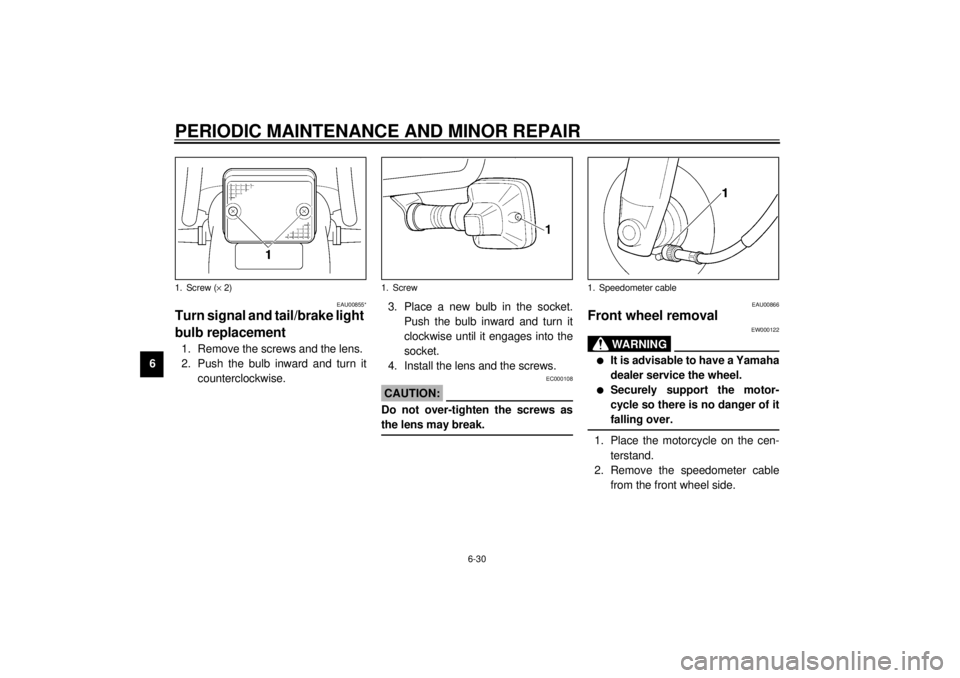

EAU00855*

Turn signal and tail/brake light

bulb replacement1. Remove the screws and the lens.

2. Push the bulb inward and turn it

counterclockwise.3. Place a new bulb in the socket.

Push the bulb inward and turn it

clockwise until it engages into the

socket.

4. Install the lens and the screws.

EC000108

CAUTION:@ Do not over-tighten the screws as

the lens may break. @

EAU00866

Front wheel removal

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so there is no danger of it

falling over.

@1. Place the motorcycle on the cen-

terstand.

2. Remove the speedometer cable

from the front wheel side.

1. Screw (´ 2)

1. Screw

1. Speedometer cable

E_3mw.book Page 30 Monday, February 5, 2001 9:54 AM

Page 63 of 78

PERIODIC MAINTENANCE AND MINOR REPAIR

6-33

6

EAU01723*

Rear wheel installation1. Install the rear wheel and the axle.

2. Install the axle nut and let the

motorcycle down.

3. Insert the brake rod into the brake

cam lever and install the brake

pedal free play adjusting nut.

4. Install the brake torque rod bolt

and tighten to the specified tight-

ening torque. Then install a new

cotter pin.

5. Adjust the drive chain free play.

(See page 6-22.)

6. Tighten the axle nut to the speci-

fied tightening torque.7. Adjust the rear brake pedal height

and free play. (See page 6-17.)

EW000103

WARNING

@ Check the operation of the brake

light after adjusting the rear brake. @

EAU01008

TroubleshootingAlthough Yamaha motorcycles receive

a rigid inspection before shipment from

the factory, trouble may occur during

operation.

Any problem in the fuel, compression,

or ignition systems can cause poor

starting and loss of power. The trouble-

shooting chart describes a quick, easy

procedure for making checks.

If your motorcycle requires any repair,

bring it to a Yamaha dealer. The skilled

technicians at a Yamaha dealership

have the tools, experience, and know-

how to properly service your motor-

cycle. Use only genuine Yamaha parts

on your motorcycle. Imitation parts may

look like Yamaha parts, but they are of-

ten inferior. Consequently, they have a

shorter service life and can lead to ex-

pensive repair bills. Specified torque:

Brake torque rod bolt:

25 Nm (2.5 m·kg)

Specified torque:

Axle nut:

65 Nm (6.5 m·kg)

E_3mw.book Page 33 Monday, February 5, 2001 9:54 AM

Page 66 of 78

MOTORCYCLE CARE AND STORAGE

7-2

7

ECA00010

CAUTION:@ l

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If you do use such

products for hard-to-remove

dirt, do not leave it on any long-

er than instructed, then thor-

oughly rinse it off with water,

immediately dry the area and

apply a corrosion protection

spray.

l

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

l

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

l

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel bearings,

swingarm bearings, forks and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

l

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure they do not

leave any marks. If the wind-

shield is scratched, use a quali-

ty plastic polishing compound

after washing.

@

E_3mw.book Page 2 Monday, February 5, 2001 9:54 AM

Page 72 of 78

SPECIFICATIONS

8-3

8

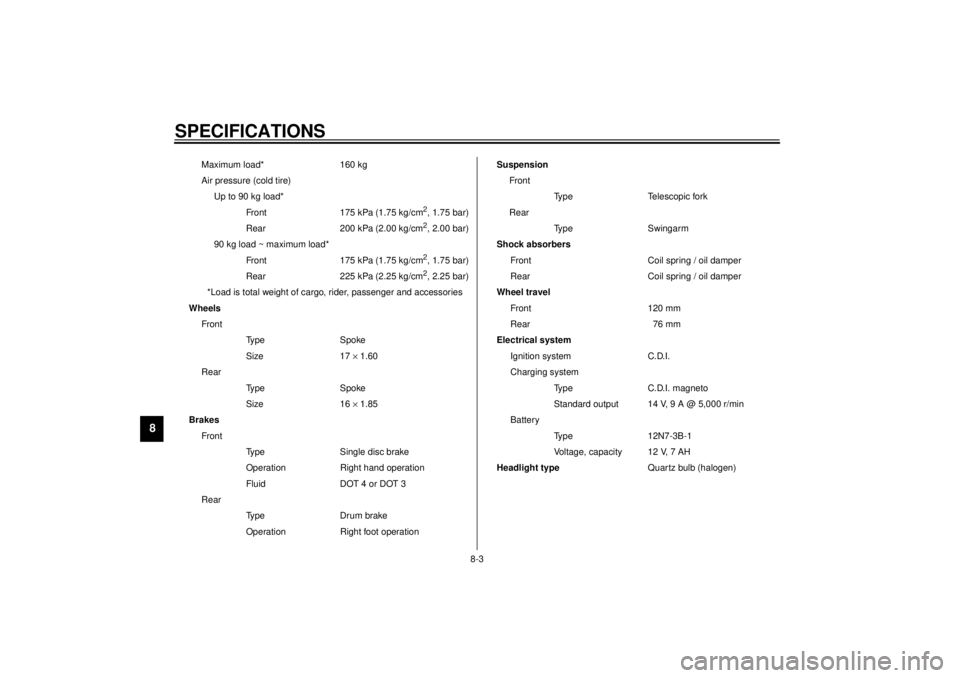

Maximum load* 160 kg

Air pressure (cold tire)

Up to 90 kg load*

Front 175 kPa (1.75 kg/cm

2, 1.75 bar)

Rear 200 kPa (2.00 kg/cm2, 2.00 bar)

90 kg load ~ maximum load*

Front 175 kPa (1.75 kg/cm2, 1.75 bar)

Rear 225 kPa (2.25 kg/cm2, 2.25 bar)

*Load is total weight of cargo, rider, passenger and accessories

Wheels

Front

Type Spoke

Size 17 ´ 1.60

Rear

Type Spoke

Size 16 ´ 1.85

Brakes

Front

Type Single disc brake

Operation Right hand operation

Fluid DOT 4 or DOT 3

Rear

Type Drum brake

Operation Right foot operationSuspension

Front

Ty p e Te l e s c o p i c f o r k

Rear

Type Swingarm

Shock absorbers

Front Coil spring / oil damper

Rear Coil spring / oil damper

Wheel travel

Front 120 mm

Rear 76 mm

Electrical system

Ignition system C.D.I.

Charging system

Type C.D.I. magneto

Standard output 14 V, 9 A @ 5,000 r/min

Battery

Type 12N7-3B-1

Voltage, capacity 12 V, 7 AH

Headlight typeQuartz bulb (halogen)

E_3mw.book Page 3 Monday, February 5, 2001 9:54 AM

Page 73 of 78

SPECIFICATIONS

8-4

8

Bulb voltage, wattage ´ quantity

Headlight 12 V, 60/55 W ´ 1

Auxiliary light 12 V, 4 W ´ 1

Tail/brake light 12 V, 5/21 W ´ 1

Turn signal light 12 V, 21 W ´ 4

Meter light 14 V, 3 W ´ 1

Neutral indicator light 12 V, 1.7 W ´ 1

High beam indicator light 12 V, 1.7 W ´ 1

Turn indicator light 12 V, 1.7 W ´ 1

Fuse20 A

E_3mw.book Page 4 Monday, February 5, 2001 9:54 AM