YAMAHA SR400 2014 Service Manual

Manufacturer: YAMAHA, Model Year: 2014, Model line: SR400, Model: YAMAHA SR400 2014Pages: 88, PDF Size: 2.51 MB

Page 41 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

1

2

3

4

567

8

9

10

11

12

EAU59350

TIP

Air filter

This model’s air intake system is equipped with a disposable oil-coated paper element. The air filter element cannot

be cleaned with compressed air, it must be replaced.

The air filter element needs to be replaced more fr equently when riding in unusually wet or dusty areas.

Hydraulic brake service

After disassembling the brake master cylinder and caliper, always change the fluid. Regularly check the brake fluid

level and fill the reservoir as required.

Every two years replace the internal components of the brake master cylinder and caliper, and change the brake fluid. Replace the brake hose every four years and if cracked or damaged.

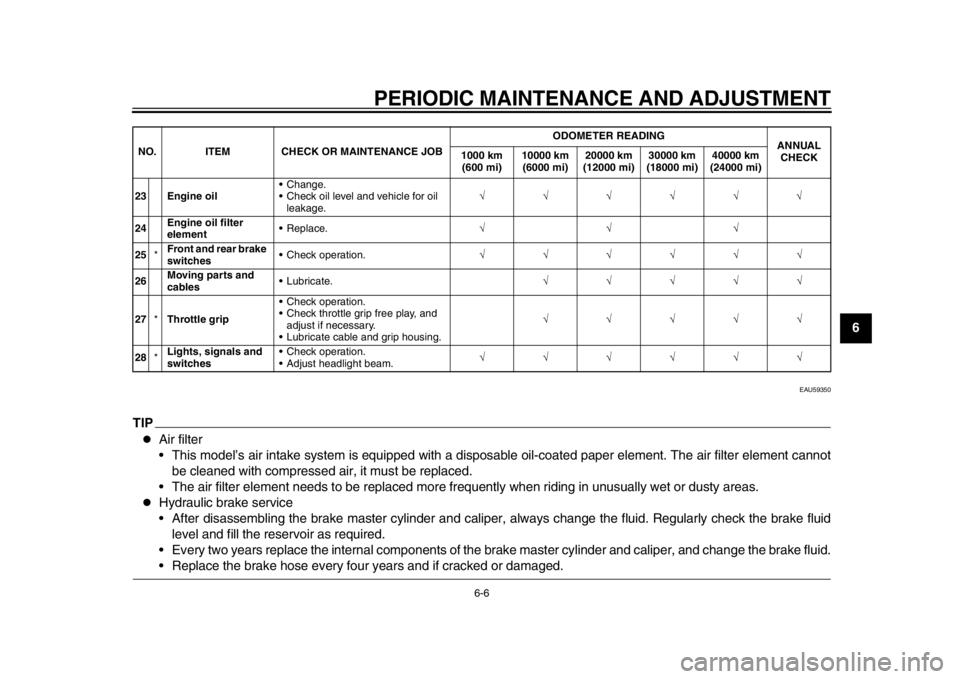

23 Engine oil Change.

Check oil level and vehicle for oil

leakage.

24 Engine oil filter

element Replace.

25 *Front and rear brake

switches Check operation.

26 Moving parts and

cables Lubricate.

27 *Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing.

28 *Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

2RD-9-E0.book 6 ページ 2013年11月28日 木曜日 午後4時18分

Page 42 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

1

2

3

4

56

7

8

9

10

11

12

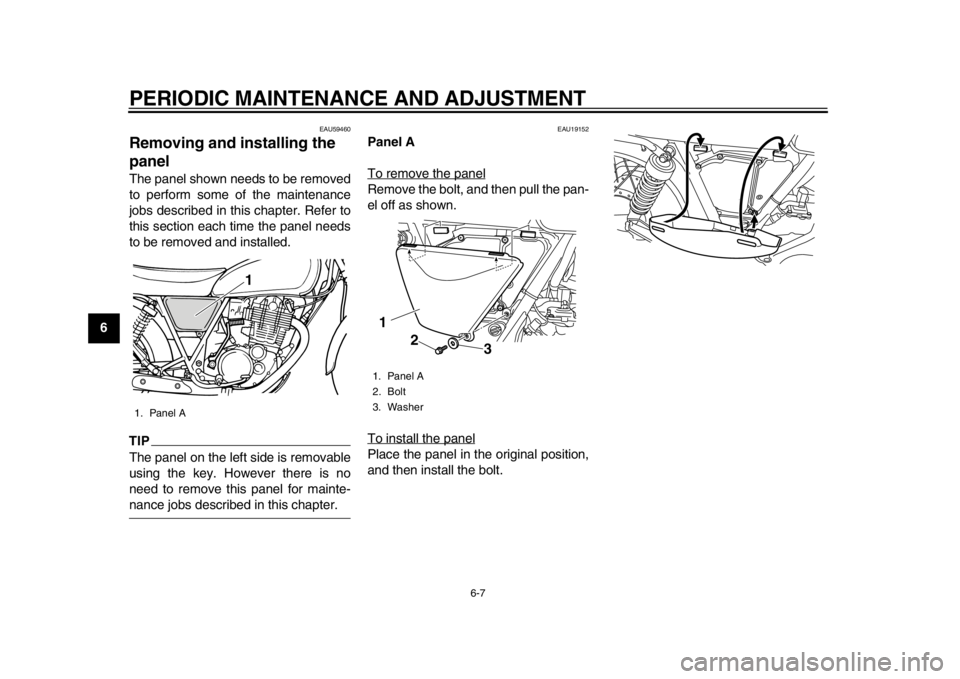

EAU59460

Removing and installing the

panelThe panel shown needs to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time the panel needs

to be removed and installed.TIPThe panel on the left side is removable

using the key. However there is no

need to remove this panel for mainte-nance jobs described in this chapter.

EAU19152

Panel A

To remove the panelRemove the bolt, and then pull the pan-

el off as shown.

To install the panelPlace the panel in the original position,

and then install the bolt.

1. Panel A

1

1. Panel A

2. Bolt

3. Washer1 2

3

2RD-9-E0.book 7 ページ 2013年11月28日 木曜日 午後4時18分

Page 43 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

1

2

3

4

567

8

9

10

11

12

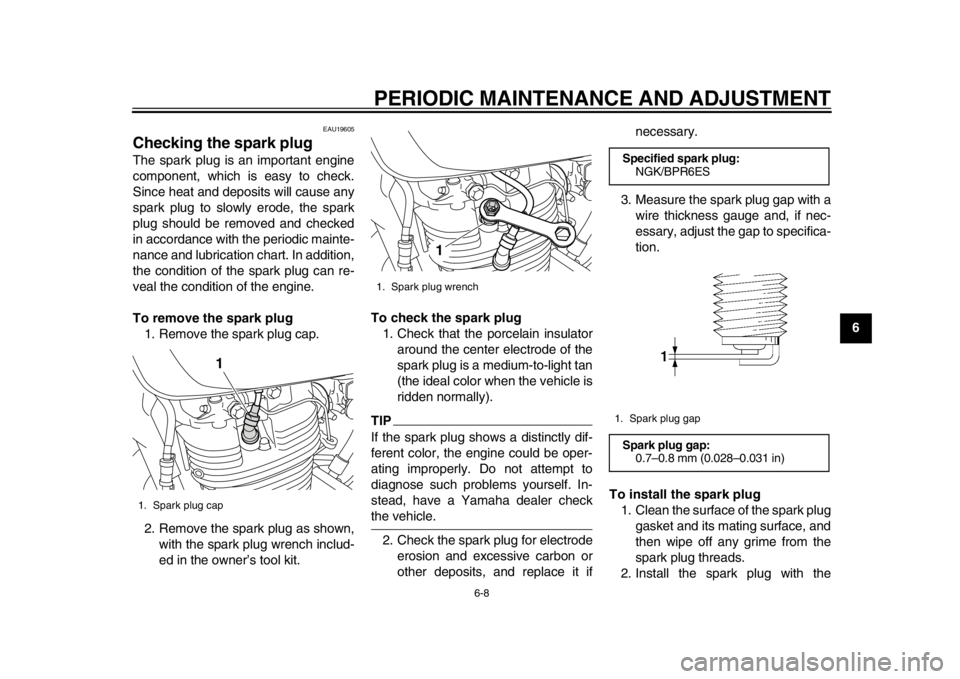

EAU19605

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plug can re-

veal the condition of the engine.

To remove the spark plug 1. Remove the spark plug cap.

2. Remove the spark plug as shown, with the spark plug wrench includ-

ed in the owner’s tool kit. To check the spark plug

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light tan

(the ideal color when the vehicle is

ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer checkthe vehicle.

2. Check the spark plug for electrode erosion and excessive carbon or

other deposits, and replace it if necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifica-

tion.

To install the spark plug 1. Clean the surface of the spark plug gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

2. Install the spark plug with the

1. Spark plug cap

1

1. Spark plug wrench

1

Specified spark plug: NGK/BPR6ES1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

2RD-9-E0.book 8 ページ 2013年11月28日 木曜日 午後4時18分

Page 44 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

56

7

8

9

10

11

12 spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-fied torque as soon as possible.

3. Install the spark plug cap.

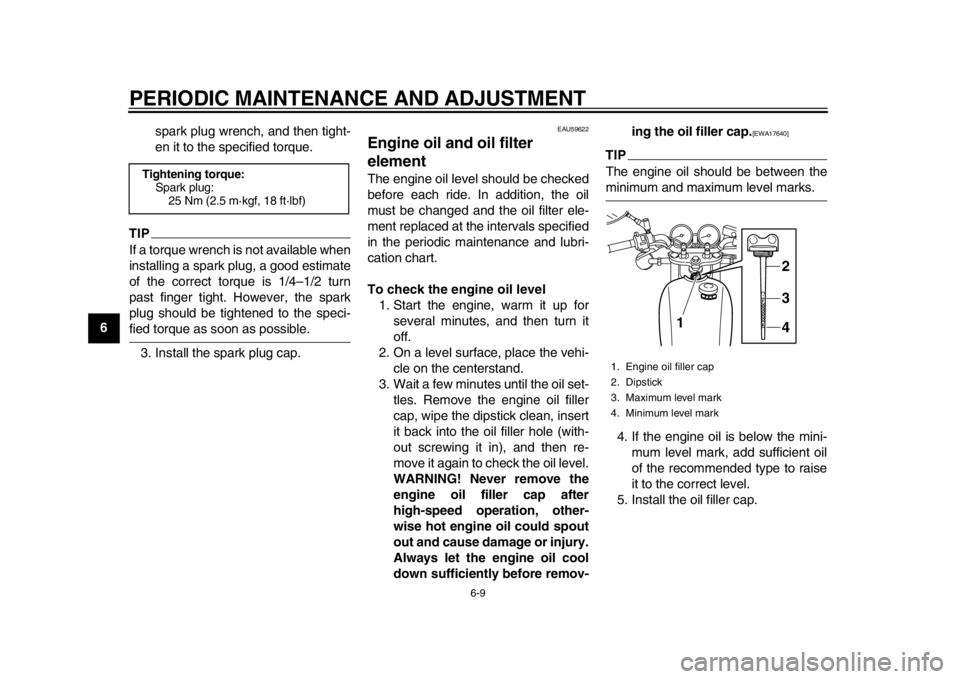

EAU59622

Engine oil and oil filter

elementThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level1. Start the engine, warm it up for several minutes, and then turn it

off.

2. On a level surface, place the vehi- cle on the centerstand.

3. Wait a few minutes until the oil set- tles. Remove the engine oil filler

cap, wipe the dipstick clean, insert

it back into the oil filler hole (with-

out screwing it in), and then re-

move it again to check the oil level.

WARNING! Never remove the

engine oil filler cap after

high-speed operation, other-

wise hot engine oil could spout

out and cause damage or injury.

Always let the engine oil cool

down sufficiently before remov- ing the oil filler cap.

[EWA17640]

TIPThe engine oil should be between theminimum and maximum level marks.

4. If the engine oil is below the mini- mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

Tightening torque: Spark plug:25 Nm (2.5 m·kgf, 18 ft·lbf)

1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Minimum level mark

3

4

12

2RD-9-E0.book 9 ページ 2013年11月28日 木曜日 午後4時18分

Page 45 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

1

2

3

4

567

8

9

10

11

12

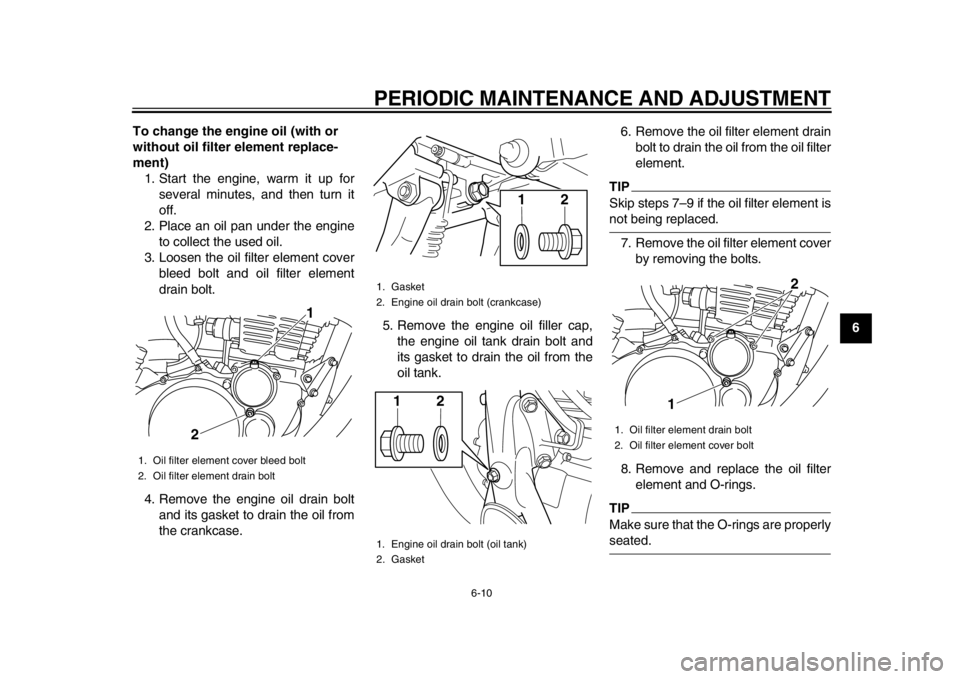

To change the engine oil (with or

without oil filter element replace-

ment)

1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place an oil pan under the engine to collect the used oil.

3. Loosen the oil filter element cover bleed bolt and oil filter element

drain bolt.

4. Remove the engine oil drain bolt and its gasket to drain the oil from

the crankcase. 5. Remove the engine oil filler cap,

the engine oil tank drain bolt and

its gasket to drain the oil from the

oil tank. 6. Remove the oil filter element drain

bolt to drain the oil from the oil filter

element.

TIPSkip steps 7–9 if the oil filter element isnot being replaced.

7. Remove the oil filter element cover by removing the bolts.

8. Remove and replace the oil filter element and O-rings.TIPMake sure that the O-rings are properlyseated.

1. Oil filter element cover bleed bolt

2. Oil filter element drain bolt

1

2

1. Gasket

2. Engine oil drain bolt (crankcase)

1. Engine oil drain bolt (oil tank)

2. Gasket

21

21

1. Oil filter element drain bolt

2. Oil filter element cover bolt

2

1

2RD-9-E0.book 10 ページ 2013年11月28日 木曜日 午後4時18分

Page 46 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

56

7

8

9

10

11

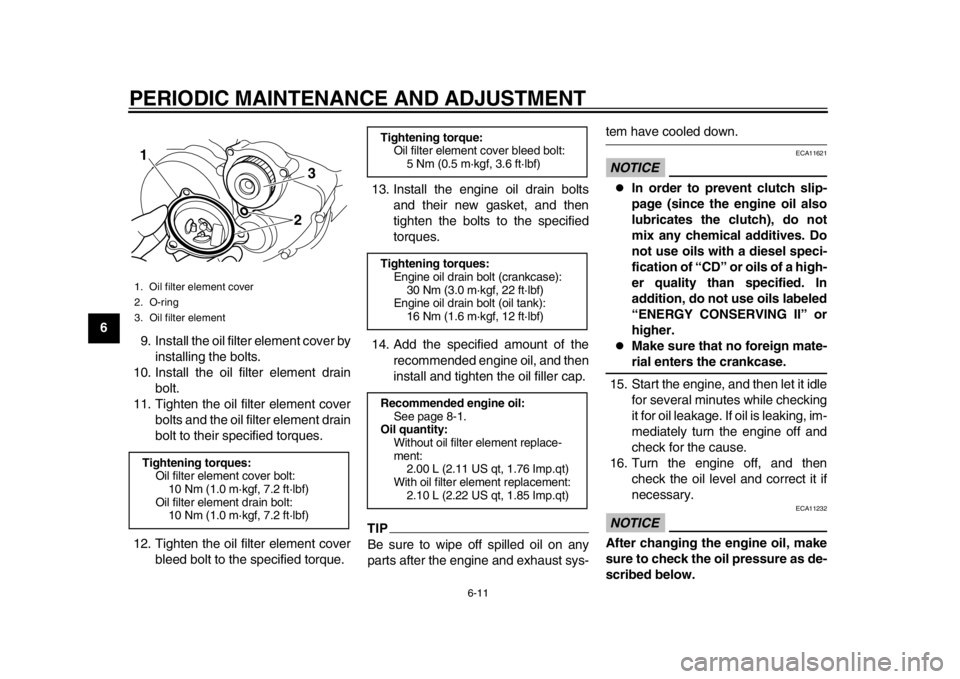

12 9. Install the oil filter element cover by

installing the bolts.

10. Install the oil filter element drain bolt.

11. Tighten the oil filter element cover bolts and the oil filter element drain

bolt to their specified torques.

12. Tighten the oil filter element cover bleed bolt to the specified torque. 13. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques.

14. Add the specified amount of the recommended engine oil, and then

install and tighten the oil filler cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase.

15. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

16. Turn the engine off, and then check the oil level and correct it if

necessary.

NOTICE

ECA11232

After changing the engine oil, make

sure to check the oil pressure as de-

scribed below.

1. Oil filter element cover

2. O-ring

3. Oil filter elementTightening torques:Oil filter element cover bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element drain bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

2

1

3

Tightening torque:Oil filter element cover bleed bolt:5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Tightening torques: Engine oil drain bolt (crankcase):30 Nm (3.0 m·kgf, 22 ft·lbf)

Engine oil drain bolt (oil tank):

16 Nm (1.6 m·kgf, 12 ft·lbf)

Recommended engine oil: See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:2.00 L (2.11 US qt, 1.76 Imp.qt)

With oil filter element replacement: 2.10 L (2.22 US qt, 1.85 Imp.qt)

2RD-9-E0.book 11 ページ 2013年11月28日 木曜日 午後4時18分

Page 47 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

1

2

3

4

567

8

9

10

11

12

Loosen the bleed bolt.

Start the engine and keep it

idling until oil flows out. If no oil

comes out after one minute,

turn the engine off immediately

so it will not seize. If this occurs,

have a Yamaha dealer repair the

vehicle.

After checking the oil pressure,

tighten the bleed bolt to thespecified torque.

EAU52031

Replacing the air filter elementThe air filter element should be re-

placed at the intervals specified in the

periodic maintenance and lubrication

chart. Replace the air filter element

more frequently if you are riding in un-

usually wet or dusty areas.

To replace the air filter element 1. Remove panel A. (See page 6-7.)

2. Remove the air filter case cover by removing the screws.

3. Pull the air filter element out. 4. Insert a new air filter element into

the air filter case. NOTICE: Make

sure that the air filter element is

properly seated in the air filter

case. The engine should never

be operated without the air filter

element installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

[ECA10482]

5. Install the air filter case cover by in- stalling the screws.

6. Install the panel.

1. Bleed boltTightening torque: Bleed bolt: 18 Nm (1.8 m·kgf, 13 ft·lbf)

1

1. Screw

2. Air filter case cover

1

2

1

1. Air filter element

1

2RD-9-E0.book 12 ページ 2013年11月28日 木曜日 午後4時18分

Page 48 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

1

2

3

4

56

7

8

9

10

11

12

EAU44735

Checking the engine idling

speedCheck the engine idling speed and, if

necessary, have it corrected by a

Yamaha dealer.

EAU21385

Checking the thrott le grip free

playThe throttle grip free play should mea-

sure 3.0–5.0 mm (0.12–0.20 in) at the

inner edge of the throttle grip. Periodi-

cally check the throttle grip free play

and, if necessary, have a Yamaha

dealer adjust it.

EAU21402

Valve clearanceThe valve clearance changes with use,

resulting in improper air-fuel mixture

and/or engine noise. To prevent this

from occurring, the valve clearance

must be adjusted by a Yamaha dealer

at the intervals specified in the periodic

maintenance and lubrication chart.

Engine idling speed: 1200–1400 r/min

1. Throttle grip free play

1

2RD-9-E0.book 13 ページ 2013年11月28日 木曜日 午後4時18分

Page 49 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

1

2

3

4

567

8

9

10

11

12

EAU59632

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be checked

and, if necessary, adjusted before each

ride.

WARNING

EWA10504

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control.

The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the temperature

of the tires equals the ambient

temperature).

The tire air pressure must be ad-

justed in accordance with the

riding speed and with the total weight of rider, passenger, car-

go, and accessories approved

for this model.WARNING

EWA10512

Never overload your vehicle. Opera-

tion of an overloaded vehicle couldcause an accident.

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail or

glass fragments in it, or if the sidewall is

cracked, have a Yamaha dealer re-

place the tire immediately.

TIPThe tire tread depth limits may differ

from country to country. Always complywith the local regulations.

Tire air pressure (measured on cold

tires):

Up to 90 kg (198 lbs) load:Front: 175 kPa (1.75 kgf/cm

2, 25 psi)

Rear: 200 kPa (2.00 kgf/cm2, 29 psi)

90 kg (198 lbs) to maximum load:

Front: 200 kPa (2.00 kgf/cm2, 29 psi)

Rear:

225 kPa (2.25 kgf/cm2, 33 psi)

Maximum load*: 150 kg (331 lb)

* Total weight of rider, passenger, car- go and accessories

1. Tire sidewall

2. Tire tread depthMinimum tire tread depth (front and

rear): 1.6 mm (0.06 in)

2RD-9-E0.book 14 ページ 2013年11月28日 木曜日 午後4時18分

Page 50 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

1

2

3

4

56

7

8

9

10

11

12 Tire information

This motorcycle is equipped with tube

tires.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10462

The front and rear tires should be of

the same make and design, other-

wise the handling characteristics of

the vehicle may be different, whichcould lead to an accident.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

WARNING

EWA10572

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the mo-

torcycle with excessively worn

tires decreases riding stability

and can lead to loss of control.

The replacement of all wheel-

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the

necessary professional knowl-

edge and experience.

It is not recommended to patch

a punctured tube. If unavoid-

able, however, patch the tube

very carefully and replace it as

soon as possible with a high-quality product.

Ride at moderate speeds after

changing a tire since the tire

surface must first be “broken

in” for it to develop its optimalcharacteristics.

Front tire:

Size:90/100-18M/C 54S

Manufacturer/model:

METZELER/ME77 Front

Rear tire: Size:

110/90-18M/C 61S

Manufacturer/model: METZELER/ME77

2RD-9-E0.book 15 ページ 2013年11月28日 木曜日 午後4時18分