steering YAMAHA SUPERJET 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: SUPERJET, Model: YAMAHA SUPERJET 2013Pages: 78, PDF Size: 3.29 MB

Page 42 of 78

Pre-operation checks

36

Add fuel if necessary. (See page 29 for infor-

mation on filling the fuel tank.)

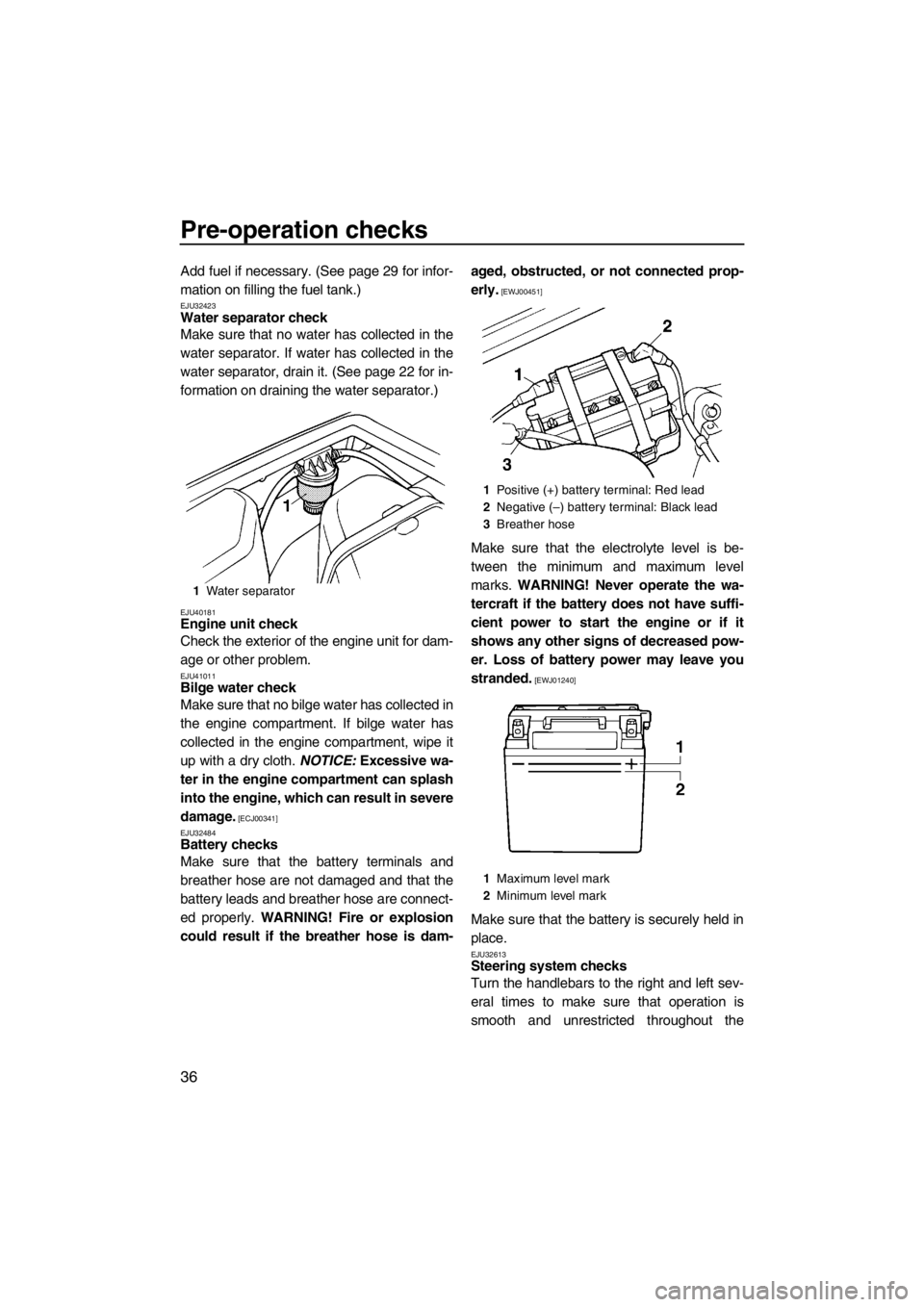

EJU32423Water separator check

Make sure that no water has collected in the

water separator. If water has collected in the

water separator, drain it. (See page 22 for in-

formation on draining the water separator.)

EJU40181Engine unit check

Check the exterior of the engine unit for dam-

age or other problem.

EJU41011Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, wipe it

up with a dry cloth. NOTICE: Excessive wa-

ter in the engine compartment can splash

into the engine, which can result in severe

damage.

[ECJ00341]

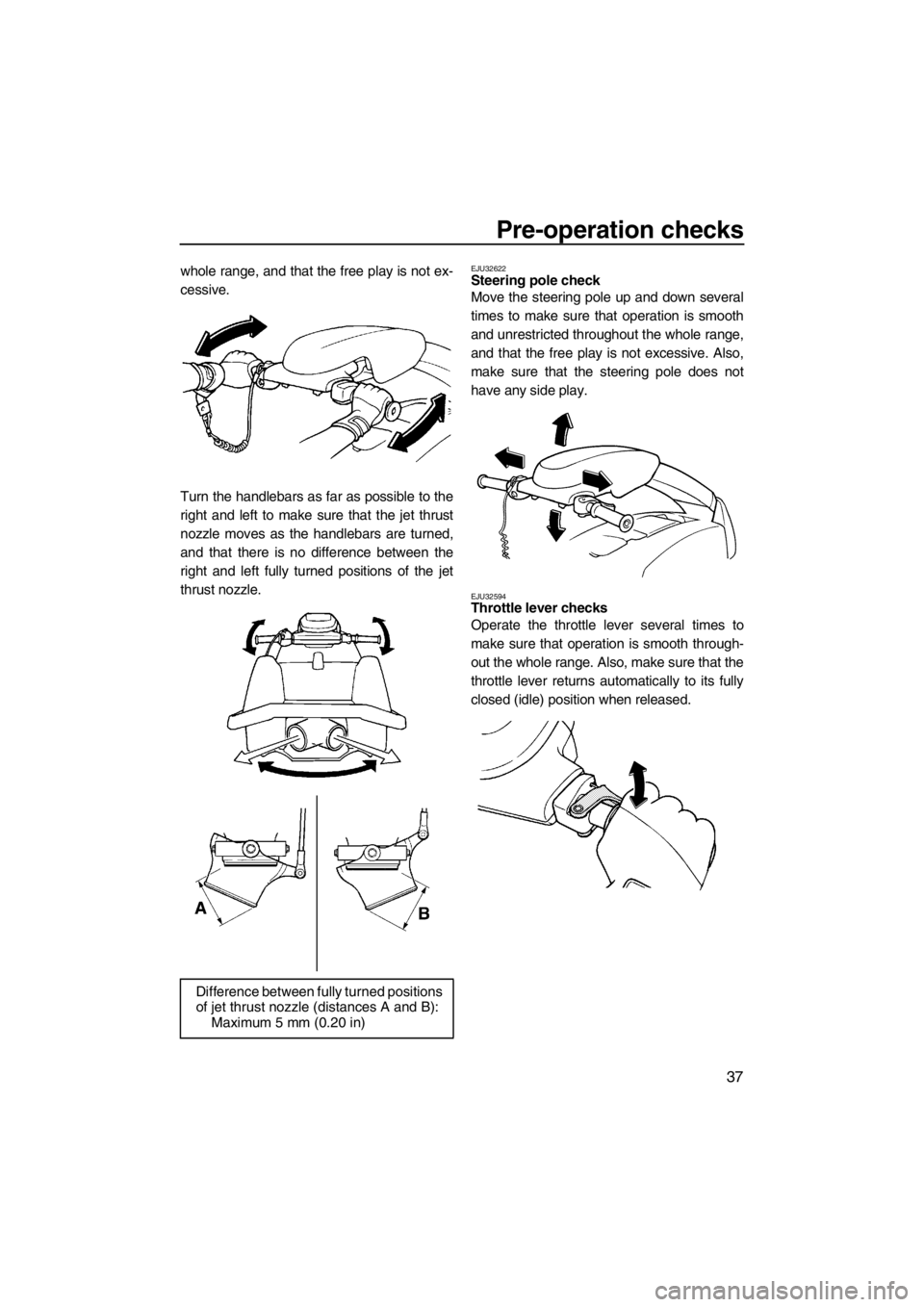

EJU32484

Battery checks

Make sure that the battery terminals and

breather hose are not damaged and that the

battery leads and breather hose are connect-

ed properly. WARNING! Fire or explosion

could result if the breather hose is dam- aged, obstructed, or not connected prop-

erly.

[EWJ00451]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks.

WARNING! Never operate the wa-

tercraft if the battery does not have suffi-

cient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01240]

Make sure that the battery is securely held in

place.

EJU32613Steering system checks

Turn the handlebars to the right and left sev-

eral times to make sure that operation is

smooth and unrestricted throughout the

1 Water separator

1Positive (+) battery terminal: Red lead

2 Negative (–) battery terminal: Black lead

3 Breather hose

1 Maximum level mark

2 Minimum level mark

UF2F75E0.book Page 36 Thursday, July 5, 2012 8:50 AM

Page 43 of 78

Pre-operation checks

37

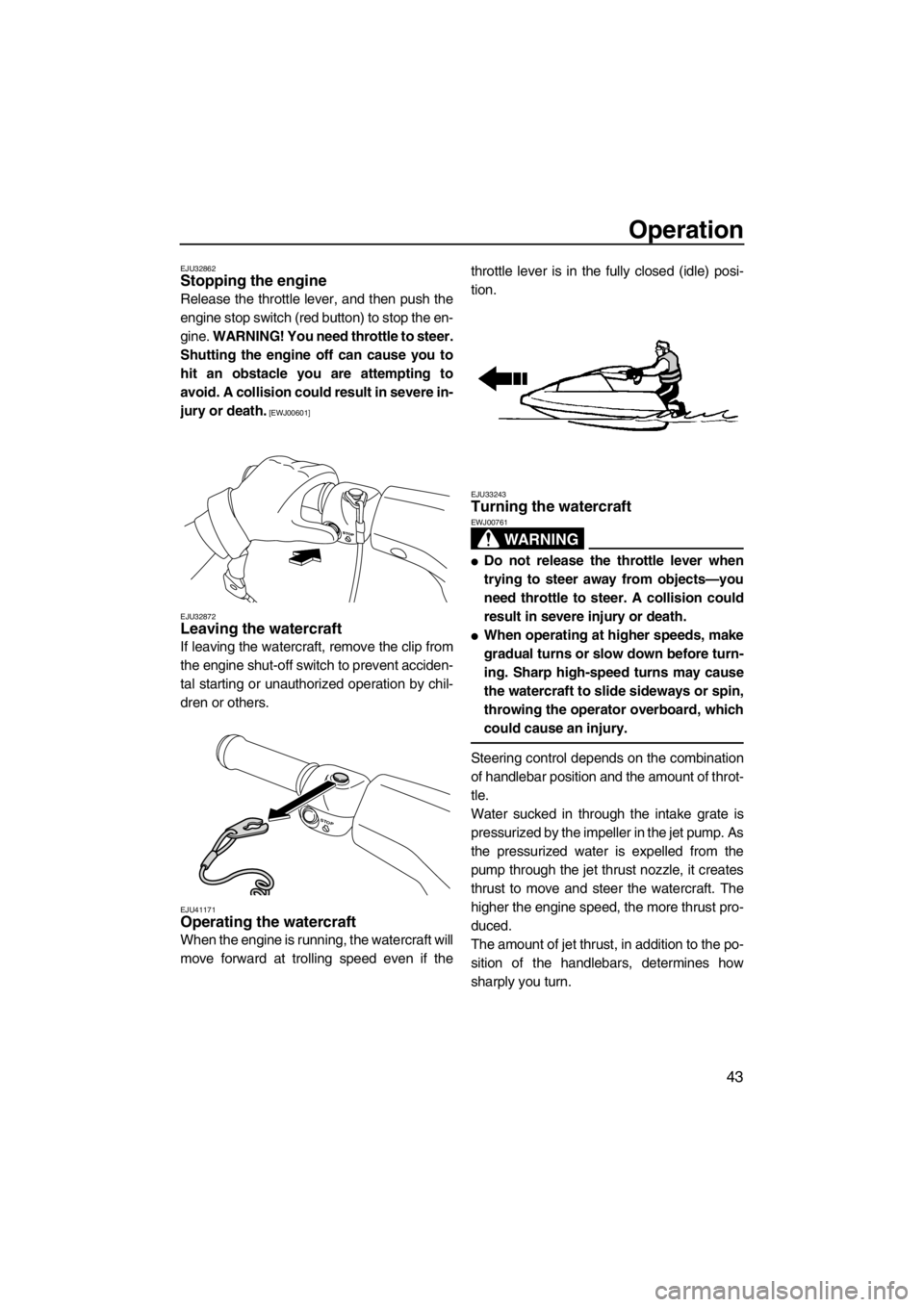

whole range, and that the free play is not ex-

cessive.

Turn the handlebars as far as possible to the

right and left to make sure that the jet thrust

nozzle moves as the handlebars are turned,

and that there is no difference between the

right and left fully turned positions of the jet

thrust nozzle.EJU32622Steering pole check

Move the steering pole up and down several

times to make sure that operation is smooth

and unrestricted throughout the whole range,

and that the free play is not excessive. Also,

make sure that the steering pole does not

have any side play.

EJU32594Throttle lever checks

Operate the throttle lever several times to

make sure that operation is smooth through-

out the whole range. Also, make sure that the

throttle lever returns automatically to its fully

closed (idle) position when released.

Difference between fully turned positions

of jet thrust nozzle (distances A and B): Maximum 5 mm (0.20 in)

UF2F75E0.book Page 37 Thursday, July 5, 2012 8:50 AM

Page 49 of 78

Operation

43

EJU32862Stopping the engine

Release the throttle lever, and then push the

engine stop switch (red button) to stop the en-

gine. WARNING! You need throttle to steer.

Shutting the engine off can cause you to

hit an obstacle you are attempting to

avoid. A collision could result in severe in-

jury or death.

[EWJ00601]

EJU32872

Leaving the watercraft

If leaving the watercraft, remove the clip from

the engine shut-off switch to prevent acciden-

tal starting or unauthorized operation by chil-

dren or others.

EJU41171Operating the watercraft

When the engine is running, the watercraft will

move forward at trolling speed even if the throttle lever is in the fully closed (idle) posi-

tion.

EJU33243Turning the watercraft

WARNING

EWJ00761

●Do not release the throttle lever when

trying to steer away from objects—you

need throttle to steer. A collision could

result in severe injury or death.

●When operating at higher speeds, make

gradual turns or slow down before turn-

ing. Sharp high-speed turns may cause

the watercraft to slide sideways or spin,

throwing the operator overboard, which

could cause an injury.

Steering control depends on the combination

of handlebar position and the amount of throt-

tle.

Water sucked in through the intake grate is

pressurized by the impeller in the jet pump. As

the pressurized water is expelled from the

pump through the jet thrust nozzle, it creates

thrust to move and steer the watercraft. The

higher the engine speed, the more thrust pro-

duced.

The amount of jet thrust, in addition to the po-

sition of the handlebars, determines how

sharply you turn.

STOP

UF2F75E0.book Page 43 Thursday, July 5, 2012 8:50 AM

Page 61 of 78

Care and storage

55

●Steering cable ball joint (handlebar end)

and steering cable inner wire (handlebar

end)

To access the steering cable ball joint (han-

dlebar end) and steering cable inner wire

(handlebar end), remove the steering pole

cover. (See step 1 in “Adjusting the jet

thrust nozzle angle” on page 57 for informa-

tion on removing the steering pole cover.)

●Steering cable ball joint (jet thrust nozzle

end) and steering cable inner wire (jet thrust

nozzle end)

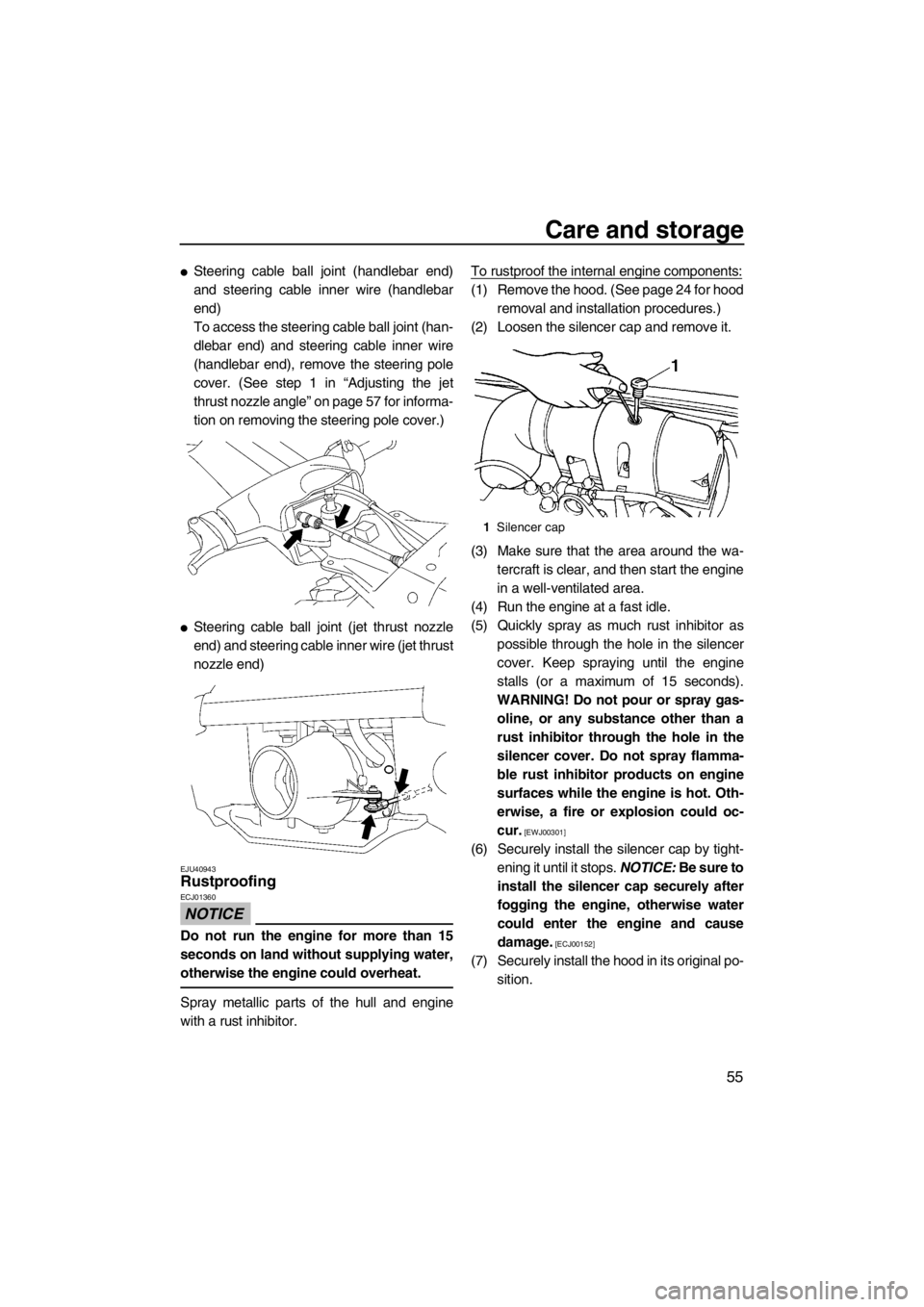

EJU40943Rustproofing

NOTICE

ECJ01360

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Spray metallic parts of the hull and engine

with a rust inhibitor.To rustproof the internal engine components:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Loosen the silencer cap and remove it.

(3) Make sure that the area around the wa- tercraft is clear, and then start the engine

in a well-ventilated area.

(4) Run the engine at a fast idle.

(5) Quickly spray as much rust inhibitor as possible through the hole in the silencer

cover. Keep spraying until the engine

stalls (or a maximum of 15 seconds).

WARNING! Do not pour or spray gas- oline, or any substance other than a

rust inhibitor through the hole in the

silencer cover. Do not spray flamma-

ble rust inhibitor products on engine

surfaces while the engine is hot. Oth-

erwise, a fire or explosion could oc-

cur.

[EWJ00301]

(6) Securely install the silencer cap by tight- ening it until it stops. NOTICE: Be sure to

install the silencer cap securely after

fogging the engine, otherwise water

could enter the engine and cause

damage.

[ECJ00152]

(7) Securely install the hood in its original po- sition.

1Silencer cap

UF2F75E0.book Page 55 Thursday, July 5, 2012 8:50 AM

Page 62 of 78

Maintenance

56

EJU33768

Maintenance

Periodic checks and lubrication will keep your

watercraft in the safest and most efficient con-

dition possible. Therefore, make sure to carry

out the periodic maintenance. Safety is an ob-

ligation of the watercraft owner. Proper main-

tenance must be carried out to keep the

exhaust emission and sound levels within the

regulated limits. The most important points of

watercraft inspection and lubrication are ex-

plained on the following pages.

See a Yamaha dealer for genuine Yamaha re-

placement parts and optional accessories de-

signed for your watercraft.

Remember, failures that are the result of the

installation of parts or accessories which are

not qualitatively equivalent to genuine

Yamaha parts are not covered by the limited warranty.

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any marine SI engine re-

pair establishment or individual. Warranty

repair, however, must be performed at an

authorized Yamaha marine dealership.

WARNING

EWJ00311

Be sure to turn off the engine when you

perform maintenance unless otherwise

specified. If you are not familiar with ma-

chine servicing, this work should be done

by a Yamaha dealer or other qualified me-

chanic.

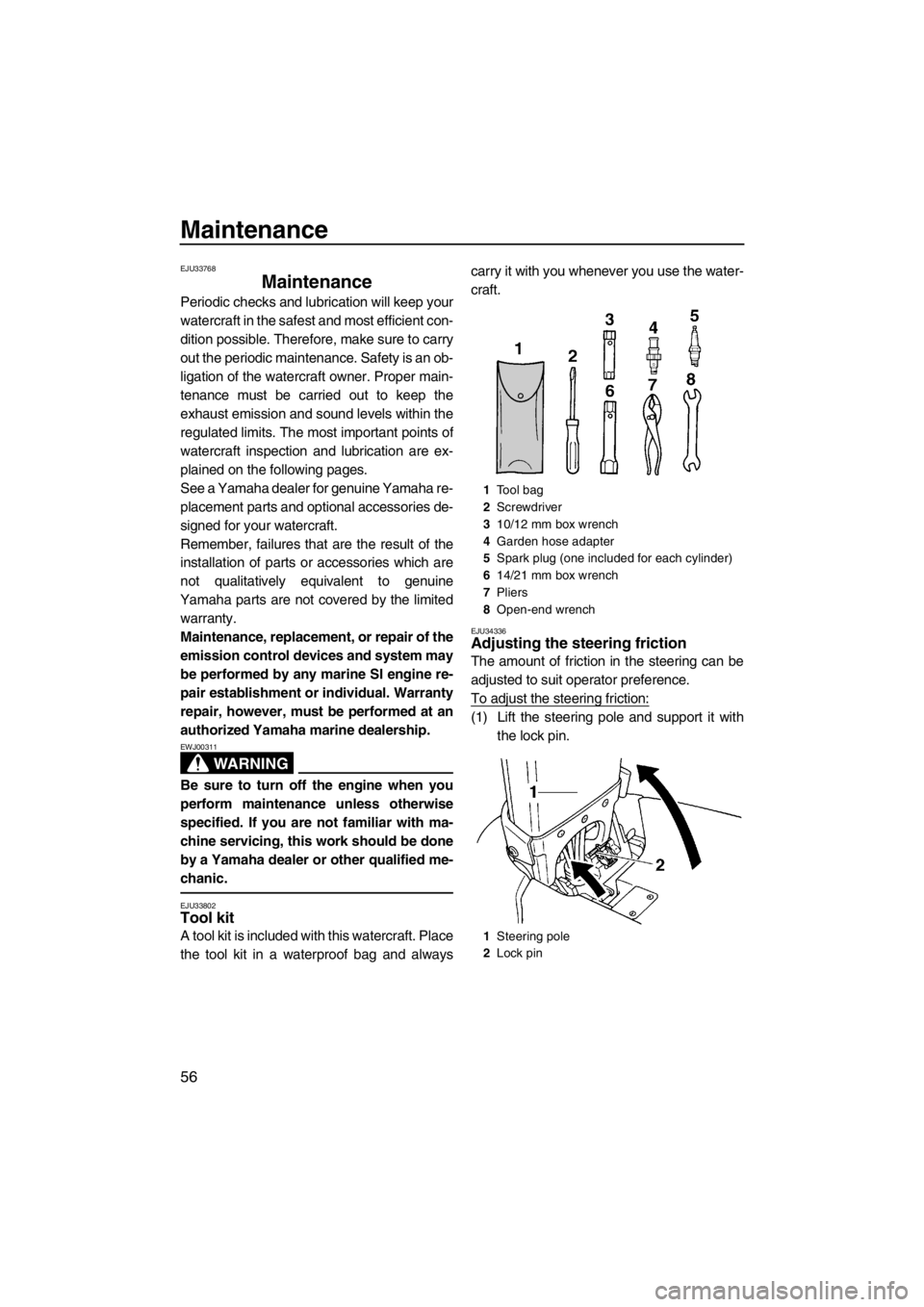

EJU33802Tool kit

A tool kit is included with this watercraft. Place

the tool kit in a waterproof bag and always carry it with you whenever you use the water-

craft.

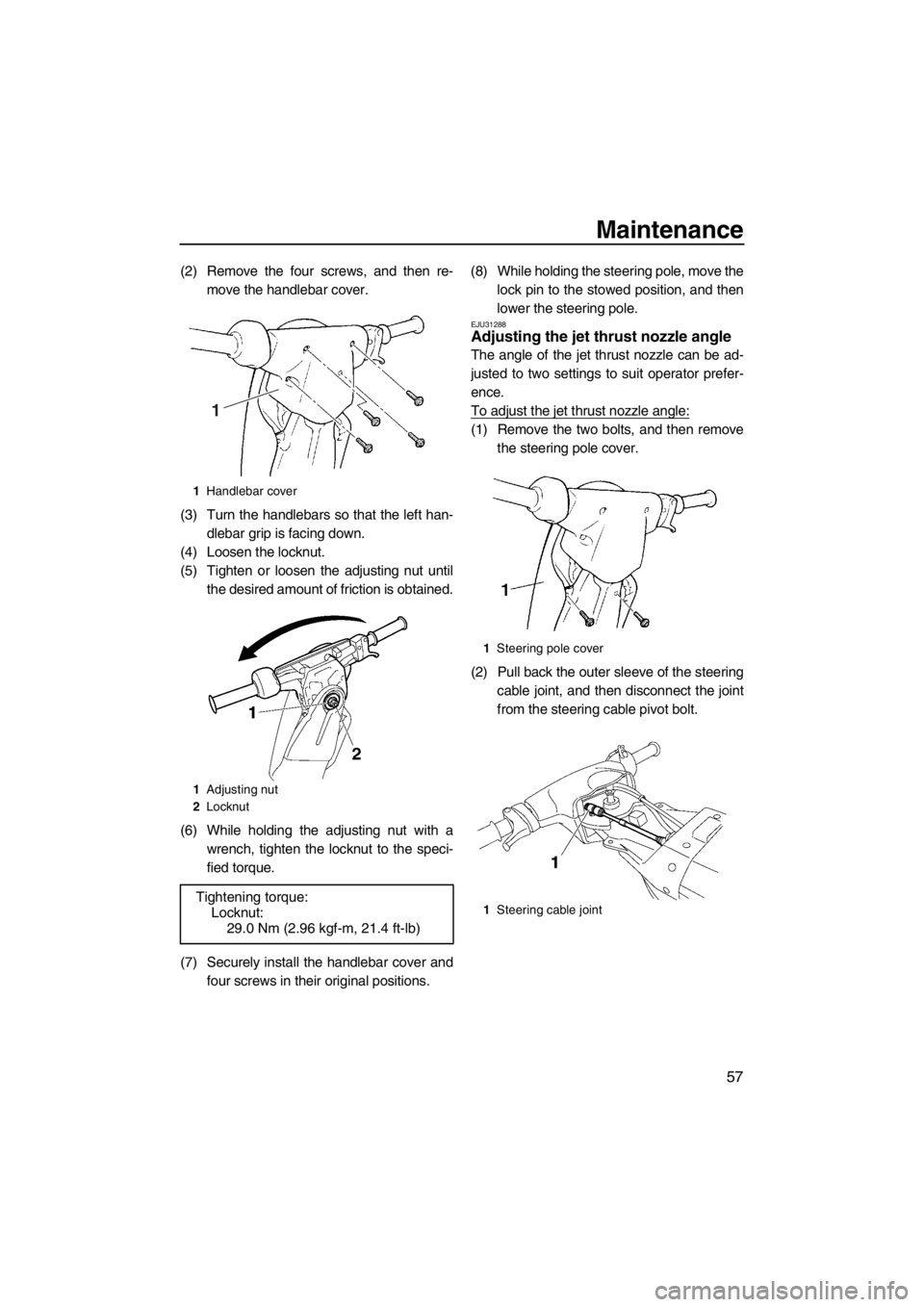

EJU34336Adjusting the steering friction

The amount of friction in the steering can be

adjusted to suit operator preference.

To adjust the steering friction:

(1) Lift the steering pole and support it with

the lock pin.

1Tool bag

2 Screwdriver

3 10/12 mm box wrench

4 Garden hose adapter

5 Spark plug (one included for each cylinder)

6 14/21 mm box wrench

7 Pliers

8 Open-end wrench

1 Steering pole

2 Lock pin

UF2F75E0.book Page 56 Thursday, July 5, 2012 8:50 AM

Page 63 of 78

Maintenance

57

(2) Remove the four screws, and then re-move the handlebar cover.

(3) Turn the handlebars so that the left han- dlebar grip is facing down.

(4) Loosen the locknut.

(5) Tighten or loosen the adjusting nut until the desired amount of friction is obtained.

(6) While holding the adjusting nut with a wrench, tighten the locknut to the speci-

fied torque.

(7) Securely install the handlebar cover and four screws in their original positions. (8) While holding the steering pole, move the

lock pin to the stowed position, and then

lower the steering pole.

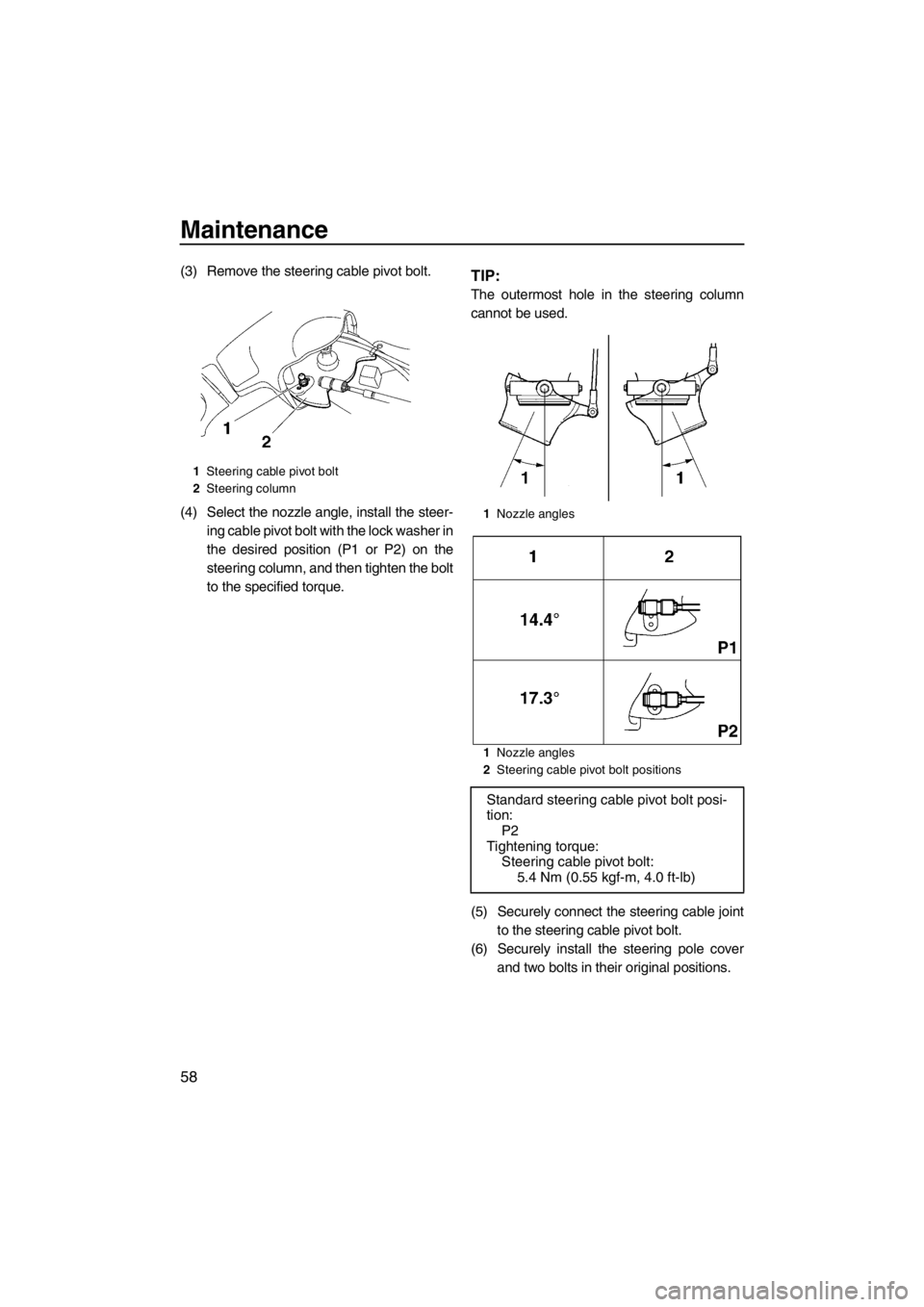

EJU31288Adjusting the jet thrust nozzle angle

The angle of the jet thrust nozzle can be ad-

justed to two settings to suit operator prefer-

ence.

To adjust the jet thrust nozzle angle:

(1) Remove the two bolts, and then removethe steering pole cover.

(2) Pull back the outer sleeve of the steering cable joint, and then disconnect the joint

from the steering cable pivot bolt.

1Handlebar cover

1 Adjusting nut

2 Locknut

Tightening torque:

Locknut:29.0 Nm (2.96 kgf-m, 21.4 ft-lb)

1

1Steering pole cover

1 Steering cable joint

UF2F75E0.book Page 57 Thursday, July 5, 2012 8:50 AM

Page 64 of 78

Maintenance

58

(3) Remove the steering cable pivot bolt.

(4) Select the nozzle angle, install the steer-ing cable pivot bolt with the lock washer in

the desired position (P1 or P2) on the

steering column, and then tighten the bolt

to the specified torque.TIP:

The outermost hole in the steering column

cannot be used.

(5) Securely connect the steering cable jointto the steering cable pivot bolt.

(6) Securely install the steering pole cover and two bolts in their original positions.

1Steering cable pivot bolt

2 Steering column

1Nozzle angles

1 Nozzle angles

2 Steering cable pivot bolt positions

Standard steering cable pivot bolt posi-

tion:

P2

Tightening torque: Steering cable pivot bolt: 5.4 Nm (0.55 kgf-m, 4.0 ft-lb)

UF2F75E0.book Page 58 Thursday, July 5, 2012 8:50 AM

Page 65 of 78

Maintenance

59

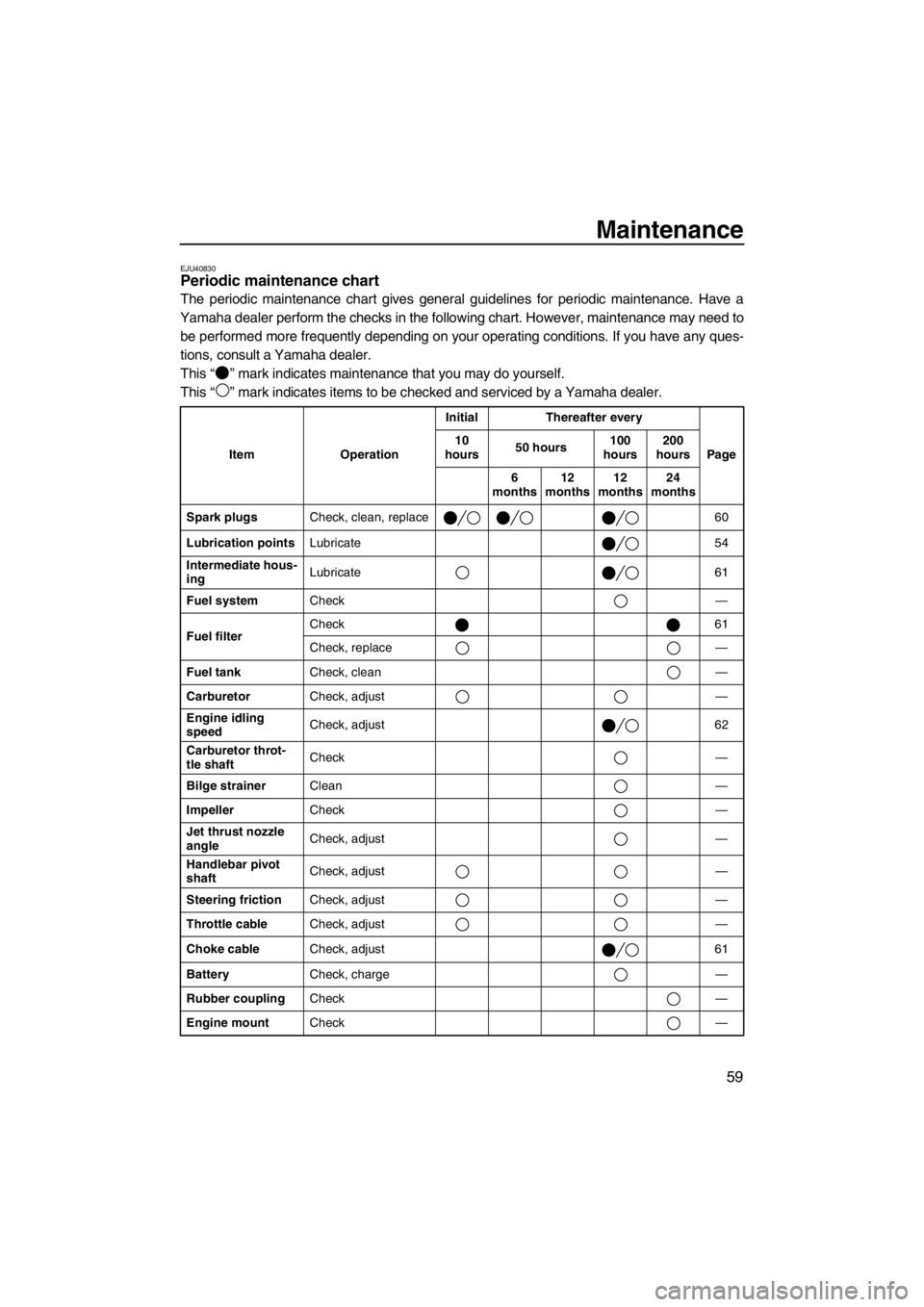

EJU40830Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need to be performed more frequently depending on your operating conditions. If you have any ques-

tions, consult a Yamaha dealer.

This “ ” mark indicates maintenance that you may do yourself.

This “ ” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial

Thereafter every

Page

10

hours 50 hours

100

hours 200

hours

6

months 12

months 12

months 24

months

Spark plugs Check, clean, replace 60

Lubrication points Lubricate 54

Intermediate hous-

ing Lubricate

61

Fuel system Check —

Fuel filter Check

61

Check, replace —

Fuel tank Check, clean —

Carburetor Check, adjust —

Engine idling

speed Check, adjust

62

Carburetor throt-

tle shaft Check

—

Bilge strainer Clean —

Impeller Check —

Jet thrust nozzle

angle Check, adjust

—

Handlebar pivot

shaft Check, adjust

—

Steering friction Check, adjust —

Throttle cable Check, adjust —

Choke cable Check, adjust 61

Battery Check, charge —

Rubber coupling Check —

Engine mount Check —

UF2F75E0.book Page 59 Thursday, July 5, 2012 8:50 AM

Page 75 of 78

Trouble recovery

69

compartment. Then, have a Yamaha dealer

service the watercraft as soon as possible.

(1) Remove the watercraft from the water,and then remove the hood.

(2) Turn the fuel cock knob to “OFF”.

(3) Turn the watercraft over far enough to drain the bilge water from the engine

compartment. NOTICE: Turning the wa-

tercraft on its side with the hood re-

moved could cause damage to the

steering pole. Use two people to pro-

vide enough support to make sure

that the steering pole is not damaged.

[ECJ00701]

(4) Turn the watercraft upright again.

(5) Have the watercraft serviced by a Yamaha dealer as soon as possible.

NOTICE: Be sure to have a Yamaha

dealer inspect the watercraft. Other-

wise, serious engine damage could re-

sult.

[ECJ00791]

UF2F75E0.book Page 69 Thursday, July 5, 2012 8:50 AM

Page 77 of 78

Index

Operation requirements ........................... 10

P

Periodic maintenance chart...................... 59

Post-launch checks .................................. 39

Post-operation care .................................. 50

Pre-launch checks.................................... 35

Pre-operation check points ...................... 35

Pre-operation checklist............................. 33

Primary Identification (PRI-ID) number ...... 1

R

Recommended equipment ....................... 12

Rustproofing ............................................. 55

S

Safe boating rules .................................... 14

Safety equipment check ........................... 39

Spark plugs, checking .............................. 60

Start switch............................................... 19

Starting off ................................................ 45

Starting the engine on water .................... 41

Steering friction, adjusting ........................ 56

Steering pole ............................................ 20

Steering pole check.................................. 37

Steering system ....................................... 20

Steering system checks ........................... 36

Stern rope hole......................................... 25

Stopping the engine ................................. 43

Stopping the watercraft ............................ 45

Storage pouch .......................................... 25

Storage pouch checks.............................. 38

Submerged watercraft .............................. 68

Switch checks .......................................... 38

T

Throttle lever ............................................ 20

Throttle lever checks ................................ 37

Tool kit...................................................... 56

Towing the watercraft ............................... 68

Transporting ............................................. 31

Troubleshooting ....................................... 64

Troubleshooting chart .............................. 64

Turning the watercraft .............................. 43

W

Water separator ....................................... 22

Water separator check ............................. 36

Watercraft characteristics......................... 13

Watercraft control functions ..................... 19

UF2F75E0.book Page 2 Thursday, July 5, 2012 8:50 AM