seat adjustment YAMAHA TRICITY 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: TRICITY, Model: YAMAHA TRICITY 2017Pages: 92, PDF Size: 3.43 MB

Page 5 of 92

Table of contents

Safety information............................1-1

Further safe-riding points ................1-6

Description........................................2-1

Left view ..........................................2-1

Right view........................................2-2

Controls and instruments ................2-3

Instrument and control functions....3-1

Main switch/steering lock ...............3-1

Keyhole shutter ...............................3-2

Indicator lights and warning

lights ............................................3-3

Multi-function meter unit .................3-5

Handlebar switches.........................3-9

Front brake lever ...........................3-10

Rear brake lever ............................3-10

ABS (for ABS models) ...................3-11

Fuel tank cap.................................3-12

Fuel................................................3-12

Fuel tank overflow hose ................3-14

Catalytic converter ........................3-14

Seat ...............................................3-15

Passenger footrest ........................3-15

Storage compartment ...................3-16

Accessory box...............................3-17

Luggage hook ...............................3-18

Sidestand ......................................3-18

Ignition circuit cut-off system........3-19

Auxiliary DC jack ..........................3-21

Auxiliary DC connector .................3-22

For your safety – pre-operation

checks...............................................4-1

Operation and important riding

points.................................................5-1

Starting the engine ..........................5-1

Starting off.......................................5-2

Acceleration and deceleration.........5-3

Braking ............................................5-3

Tips for reducing fuel

consumption ................................5-4

Engine break-in ...............................5-4

Parking ............................................5-5Periodic maintenance and

adjustment........................................ 6-1

Owner’s tool kit ............................... 6-2

Periodic maintenance chart for the

emission control system.............. 6-3

General maintenance and

lubrication chart........................... 6-4

Removing and installing the

panel ............................................ 6-7

Checking the spark plug ................. 6-8

Engine oil and oil strainer................ 6-9

Final transmission oil .................... 6-11

Coolant ......................................... 6-12

Air filter and V-belt case air filter

elements .................................... 6-14

Checking the throttle grip

free play ..................................... 6-16

Valve clearance ............................. 6-17

Tires .............................................. 6-17

Cast wheels .................................. 6-19

Checking the front brake lever

free play ..................................... 6-20

Checking the rear brake lever

free play ..................................... 6-20

Checking the front and rear

brake pads................................. 6-21

Checking the brake fluid level....... 6-22

Changing the brake fluid............... 6-23

Checking the V-belt ...................... 6-23

Checking and lubricating the

cables ........................................ 6-24

Checking and lubricating the

throttle grip and cable ............... 6-24

Lubricating the front and rear

brake levers ............................... 6-25

Checking and lubricating the

centerstand and sidestand ........ 6-25

Checking the front fork ................. 6-26

Checking the steering ................... 6-26

Checking the wheel bearings ....... 6-27

Checking the steering tie rod........ 6-27

Checking the leaning system ........ 6-28

Battery .......................................... 6-28

Replacing the fuses ...................... 6-30

Headlight....................................... 6-31

Auxiliary lights ............................... 6-32

UBR7E0E0.book Page 1 Tuesday, October 25, 2016 2:44 PM

Page 45 of 92

Periodic maintenance and adjustment

6-2

6

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and

equipped to perform these particular

services.

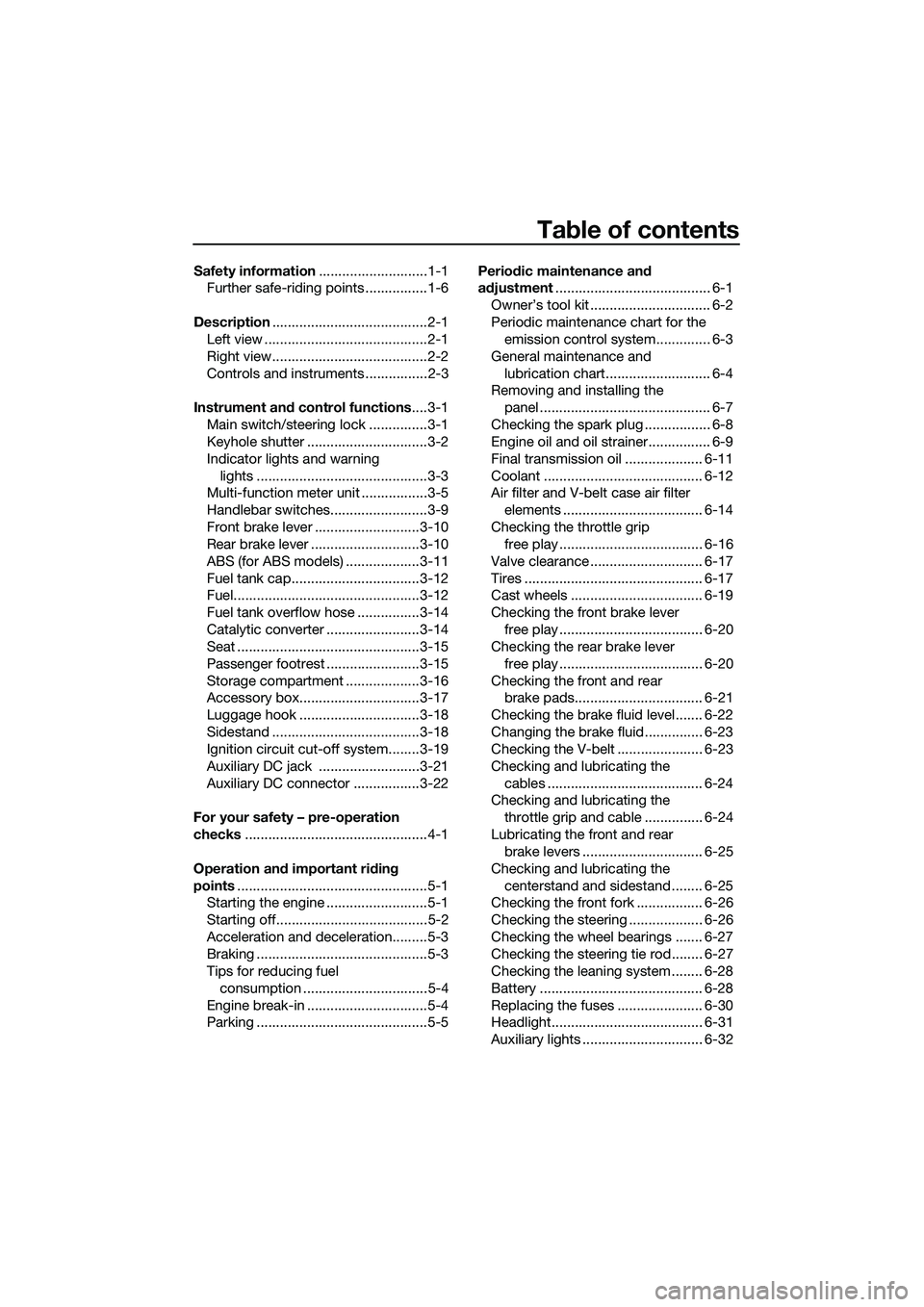

EAU39692

Owner’s tool kit

The owner’s tool kit is located on the

bottom of the seat. (See page 3-15.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

TIP

If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.

1.

1

UBR7E0E0.book Page 2 Tuesday, October 25, 2016 2:44 PM

Page 50 of 92

Periodic maintenance and adjustment

6-7

6

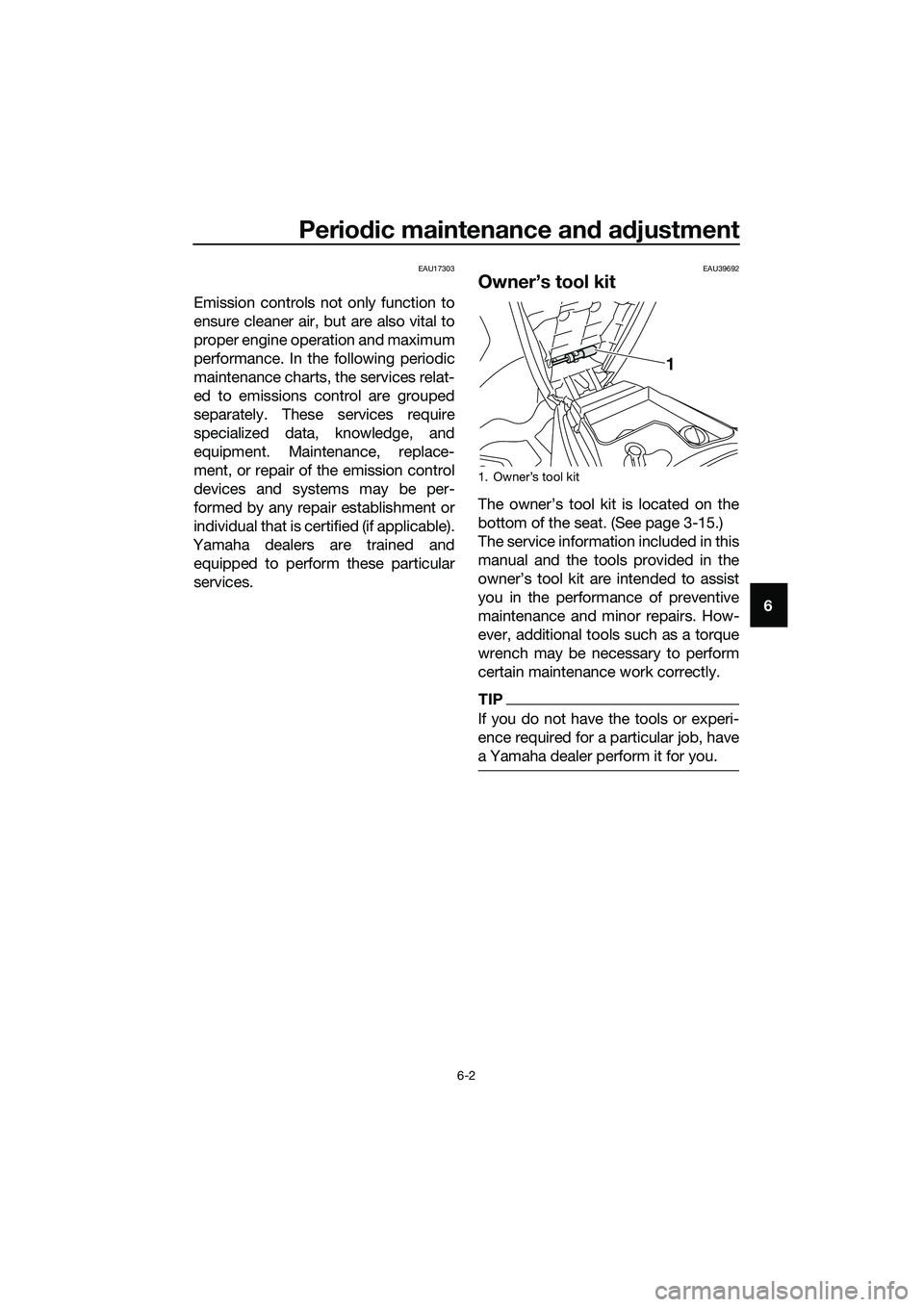

EAU18752

Removing and installing the

panel

The panel shown needs to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time the panel needs

to be removed and installed.

EAU56942Panel A

To remove the panel

1. Open the seat. (See page 3-15.)

2. Remove the screws, and pull the

panel off while closing the seat

slightly as shown.To install the panel

1. Place the panel in the original po-

sition while closing the seat slight-

ly, and then install the screws.

2. Close the seat.

1. Panel A

1. Panel A

2. Screw

1

1

2

2

UBR7E0E0.book Page 7 Tuesday, October 25, 2016 2:44 PM

Page 53 of 92

Periodic maintenance and adjustment

6-10

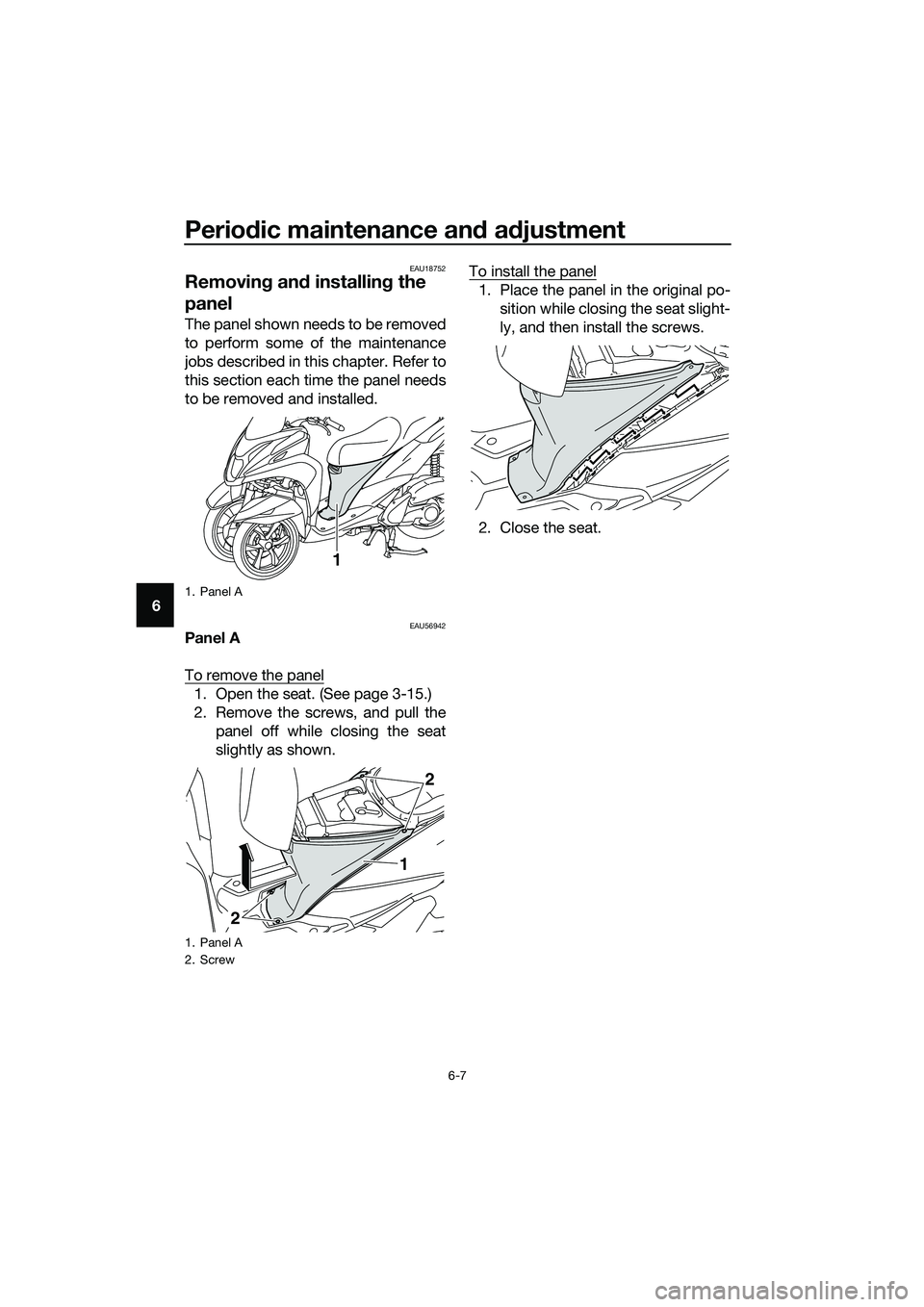

6 4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Check the O-ring for damage, and

replace it if necessary.

6. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil and clean

the oil strainer

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the engine

to collect the used oil.

3. Remove the engine oil filler cap

and engine oil drain bolts A and B

to drain the oil from the crankcase.

NOTICE: When removing the

engine oil drain bolt B, the O-

ring, compression spring, and

oil strainer will fall out. Take

care not to lose these parts.

[ECAT1022]

4. Clean the engine oil strainer with

solvent, and then check it for dam-

age and replace it if necessary.

5. Install the engine oil strainer, com-

pression spring, new O-ring and

engine oil drain bolt B.

TIP

Make sure that the O-ring is properly

seated.

6. Install engine oil drain bolt A and

its new gasket, and then tighten

both drain bolts to their specified

torques.

7. Refill with the specified amount of

the recommended engine oil.

1. Engine oil filler cap

2. O-ring

3. Engine oil dipstick

4. Maximum level mark

5. Tip of the engine oil dipstick

1

3

2

4

5

1. Engine oil drain bolt A

2. Gasket

3. Oil strainer

4. Compression spring

5. O-ring

6. Engine oil drain bolt B

Tightening torque:

Engine oil drain bolt A:

20 N·m (2.0 kgf·m, 14 lb·ft)

Engine oil drain bolt B:

32 N·m (3.2 kgf·m, 23 lb·ft)

Recommended engine oil:

See page 8-1.

Oil quantity:

0.90 L (0.95 US qt, 0.79 Imp.qt)

1

3

4

5

6

2

UBR7E0E0.book Page 10 Tuesday, October 25, 2016 2:44 PM

Page 57 of 92

Periodic maintenance and adjustment

6-14

6

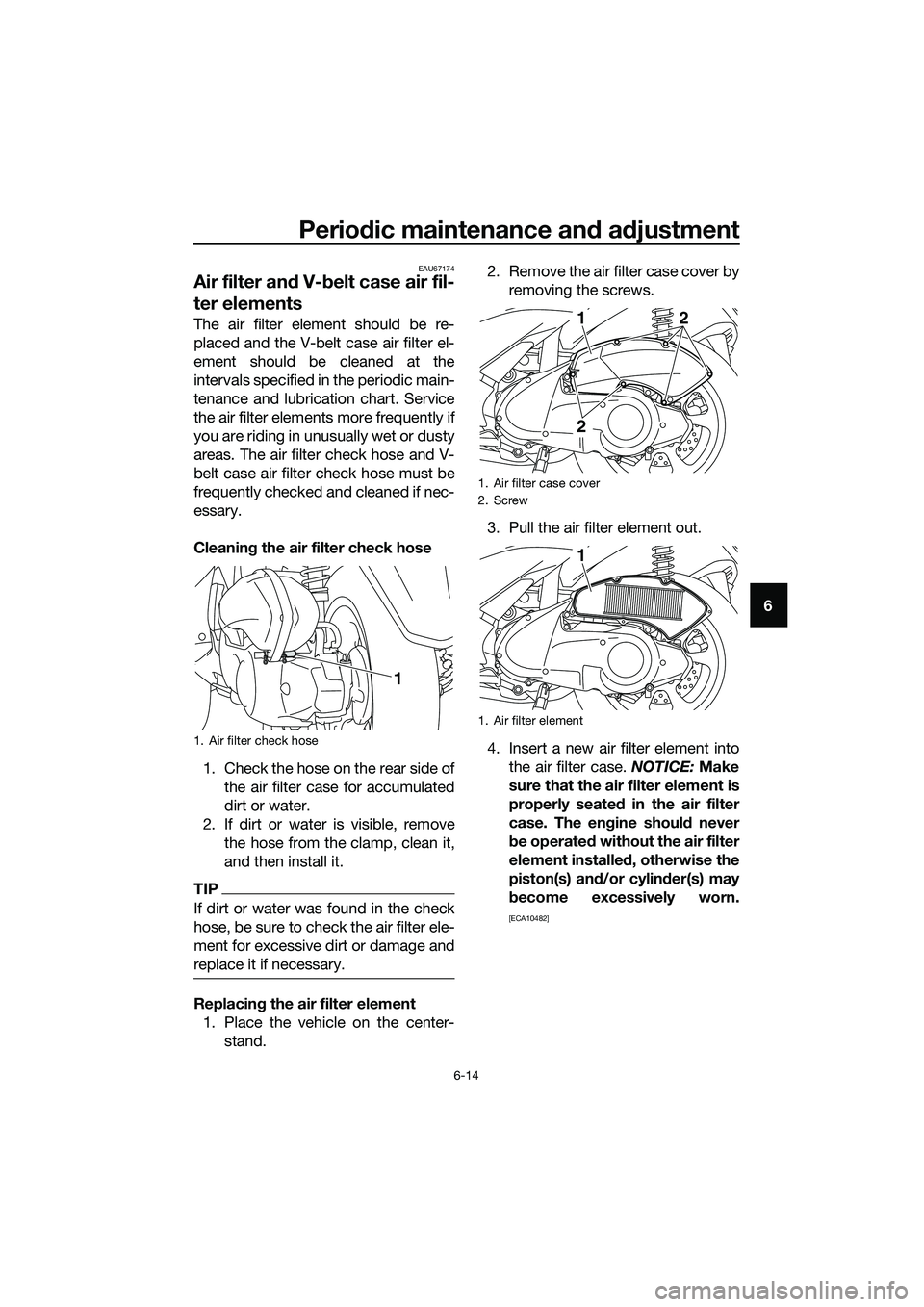

EAU67174

Air filter and V-belt case air fil-

ter elements

The air filter element should be re-

placed and the V-belt case air filter el-

ement should be cleaned at the

intervals specified in the periodic main-

tenance and lubrication chart. Service

the air filter elements more frequently if

you are riding in unusually wet or dusty

areas. The air filter check hose and V-

belt case air filter check hose must be

frequently checked and cleaned if nec-

essary.

Cleaning the air filter check hose

1. Check the hose on the rear side of

the air filter case for accumulated

dirt or water.

2. If dirt or water is visible, remove

the hose from the clamp, clean it,

and then install it.

TIP

If dirt or water was found in the check

hose, be sure to check the air filter ele-

ment for excessive dirt or damage and

replace it if necessary.

Replacing the air filter element

1. Place the vehicle on the center-

stand.2. Remove the air filter case cover by

removing the screws.

3. Pull the air filter element out.

4. Insert a new air filter element into

the air filter case. NOTICE: Make

sure that the air filter element is

properly seated in the air filter

case. The engine should never

be operated without the air filter

element installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

[ECA10482]

1. Air filter check hose

1

1. Air filter case cover

2. Screw

1. Air filter element

2

21

1

UBR7E0E0.book Page 14 Tuesday, October 25, 2016 2:44 PM

Page 73 of 92

Periodic maintenance and adjustment

6-30

6

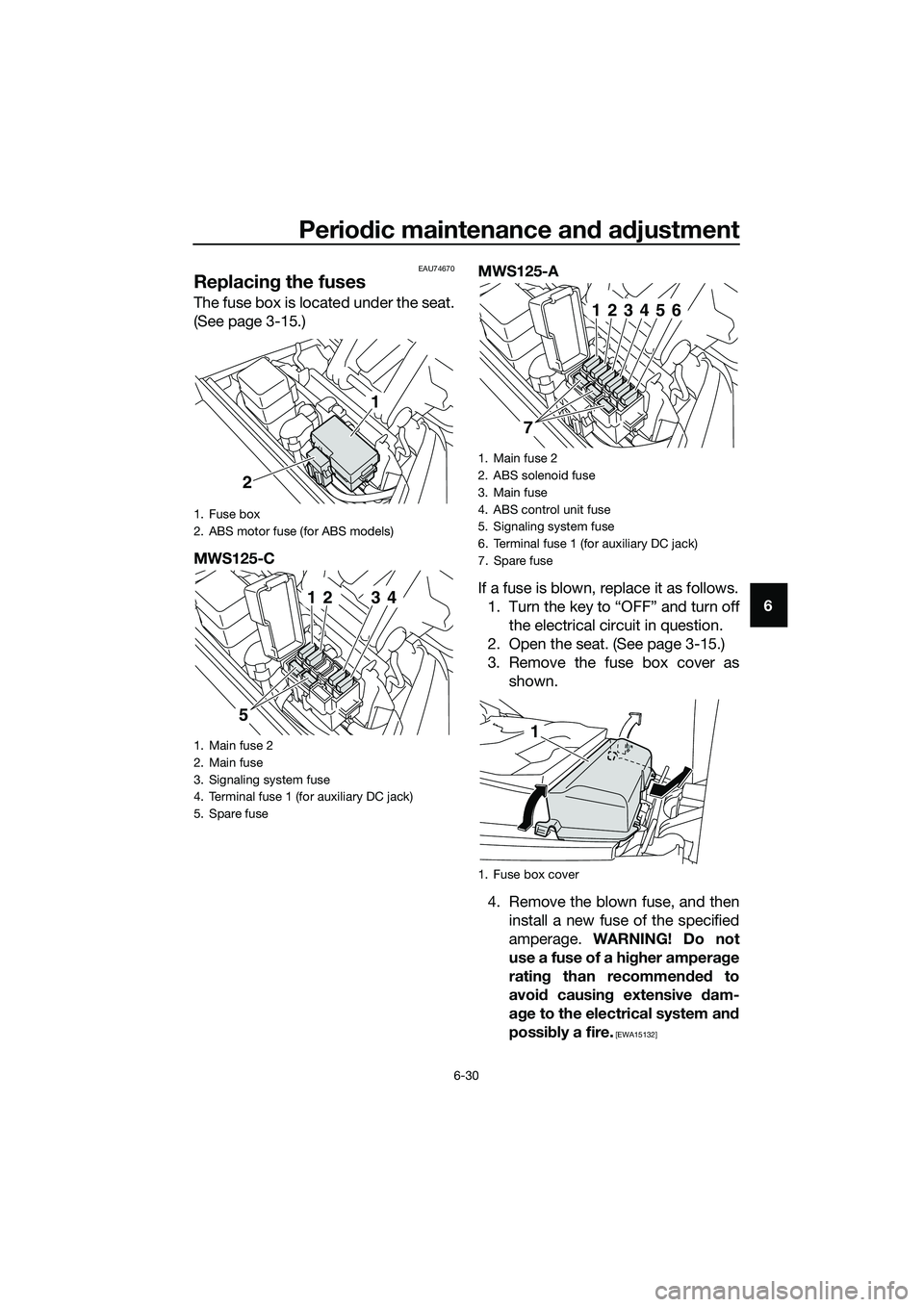

EAU74670

Replacing the fuses

The fuse box is located under the seat.

(See page 3-15.)

MWS125-CMWS125-A

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Open the seat. (See page 3-15.)

3. Remove the fuse box cover as

shown.

4. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

1. Fuse box

2. ABS motor fuse (for ABS models)

1. Main fuse 2

2. Main fuse

3. Signaling system fuse

4. Terminal fuse 1 (for auxiliary DC jack)

5. Spare fuse

2

1

51

234

1. Main fuse 2

2. ABS solenoid fuse

3. Main fuse

4. ABS control unit fuse

5. Signaling system fuse

6. Terminal fuse 1 (for auxiliary DC jack)

7. Spare fuse

1. Fuse box cover

71

23456

1

UBR7E0E0.book Page 30 Tuesday, October 25, 2016 2:44 PM

Page 74 of 92

Periodic maintenance and adjustment

6-31

65. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

6. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

7. Install the fuse box cover, and

then close the seat.

EAU62850

Headlight

This model is equipped with an LED-

type headlight.

If a headlight does not come on, have

a Yamaha dealer check its electrical

circuit.

NOTICE

ECA16581

Do not affix any type of tinted film or

stickers to the headlight lens.

Specified fuses:

Main fuse:

15.0 A

Main fuse 2:

7.5 A

Te r m i n a l f u s e 1 :

2.0 A

Signaling system fuse:

7.5 A

ABS motor fuse:

30.0 A (MWS125-A)

ABS solenoid fuse:

30.0 A (MWS125-A)

ABS control unit fuse:

7.5 A (MWS125-A)

UBR7E0E0.book Page 31 Tuesday, October 25, 2016 2:44 PM