engine YAMAHA TTR50 2006 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 320 of 390

5 - 10

CHASHANDLEBAR

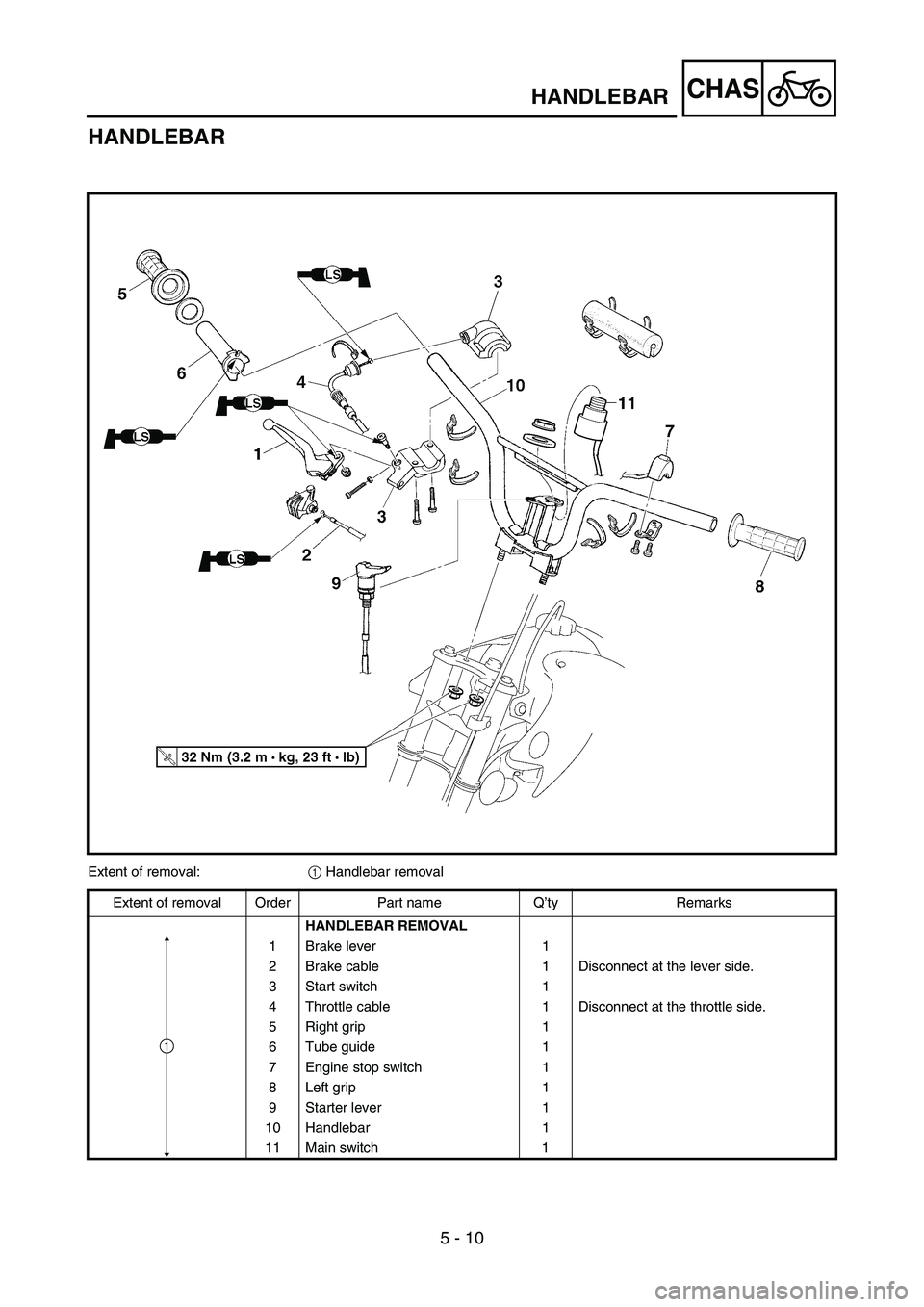

HANDLEBAR

Extent of removal: 1 Handlebar removal

Extent of removal Order Part name Q ’ty Remarks

HANDLEBAR REMOVAL

1Brake lever 1

2 Brake cable 1 Disconnect at the lever side.

3 Start switch 1

4 Throttle cable 1 Disconnect at the throttle side.

5 Right grip 1

6 Tube guide 1

7 Engine stop switch 1

8Left grip 1

9Starter lever 1

10 Handlebar 1

11 Main switch 1

1

Page 324 of 390

5 - 12

CHAS

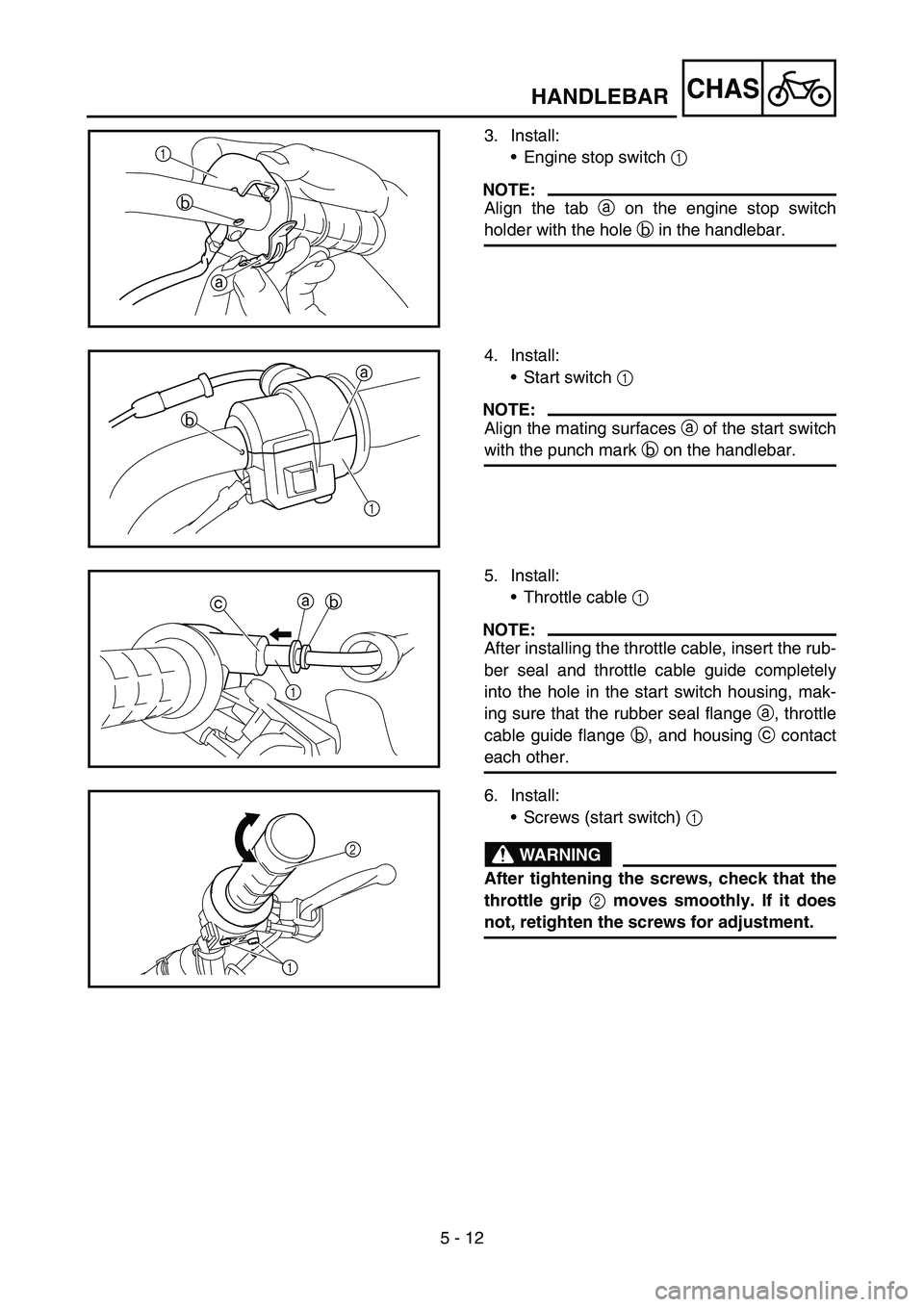

3. Install:Engine stop switch 1

NOTE:

Align the tab a on the engine stop switch

holder with the hole b in the handlebar.

a

b

1

4. Install:

Start switch 1

NOTE:

Align the mating surfaces a of the start switch

with the punch mark b on the handlebar.

1

b a

5. Install:

Throttle cable 1

NOTE:

After installing the throttle cable, insert the rub-

ber seal and throttle cable guide completely

into the hole in the start switch housing, mak-

ing sure that the rubber seal flange a, throttle

cable guide flange b, and housing c contact

each other.

a

c b

1

6. Install:

Screws (start switch) 1

WARNING

After tightening the screws, check that the

throttle grip 2 moves smoothly. If it does

not, retighten the screws for adjustment.

2

1

HANDLEBAR

Page 326 of 390

5 - 13

CHASSTEERING AND FRONT SUSPENSION

EC560000

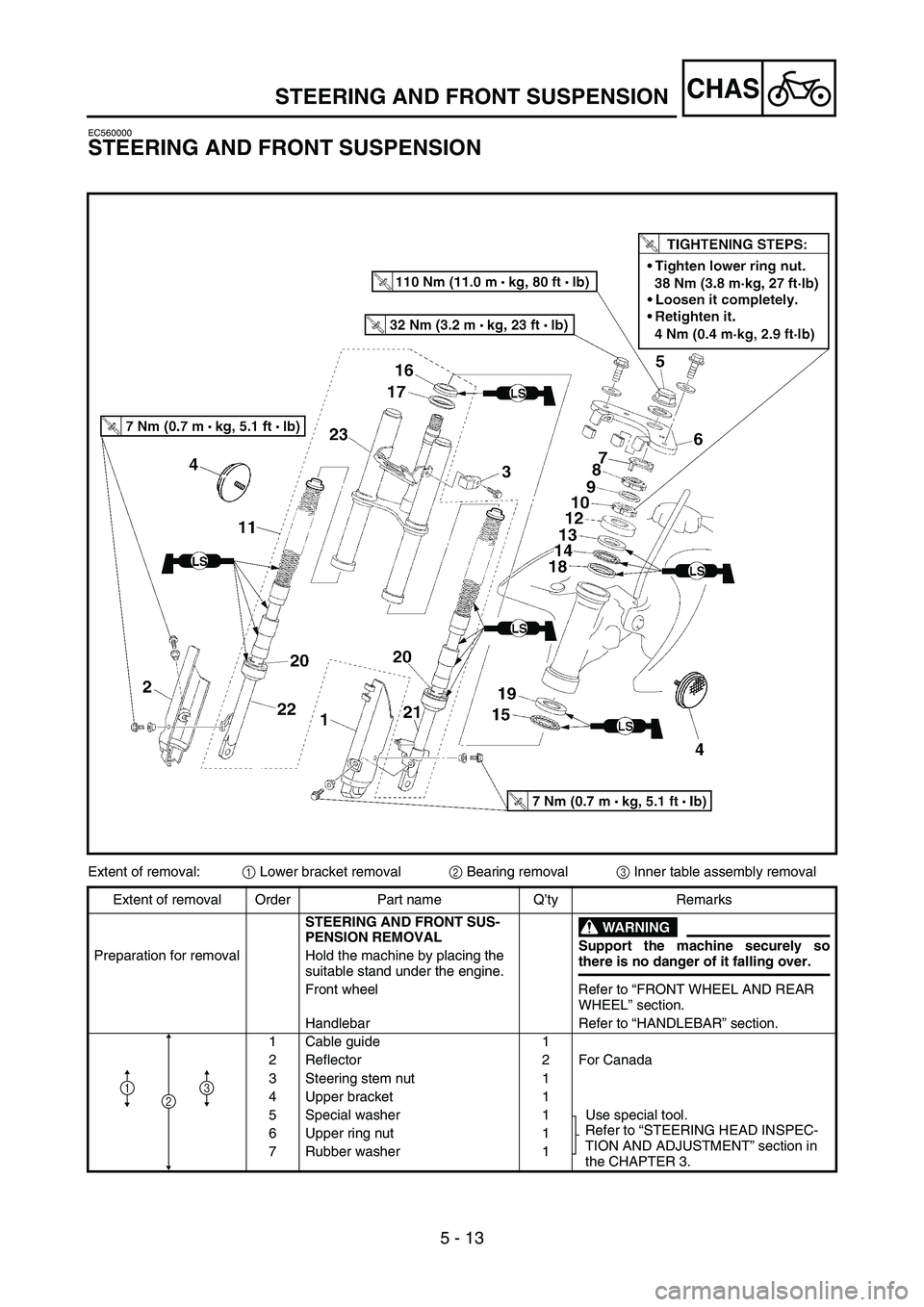

STEERING AND FRONT SUSPENSION

Extent of removal:1 Lower bracket removal

2 Bearing removal

3 Inner table assembly removal

Extent of removal Order Part name Q ’ty Remarks

STEERING AND FRONT SUS-

PENSION REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL ” section.

Handlebar Refer to “HANDLEBAR ” section.

1 Cable guide 1

2 Reflector 2 For Canada

3 Steering stem nut 1

4 Upper bracket 1

5 Special washer 1 Use special tool. Refer to “STEERING HEAD INSPEC-

TION AND ADJUSTMENT ” section in

the CHAPTER 3.

6 Upper ring nut 1

7 Rubber washer 1

213

Page 334 of 390

5 - 17

CHASSWINGARM

EC570000

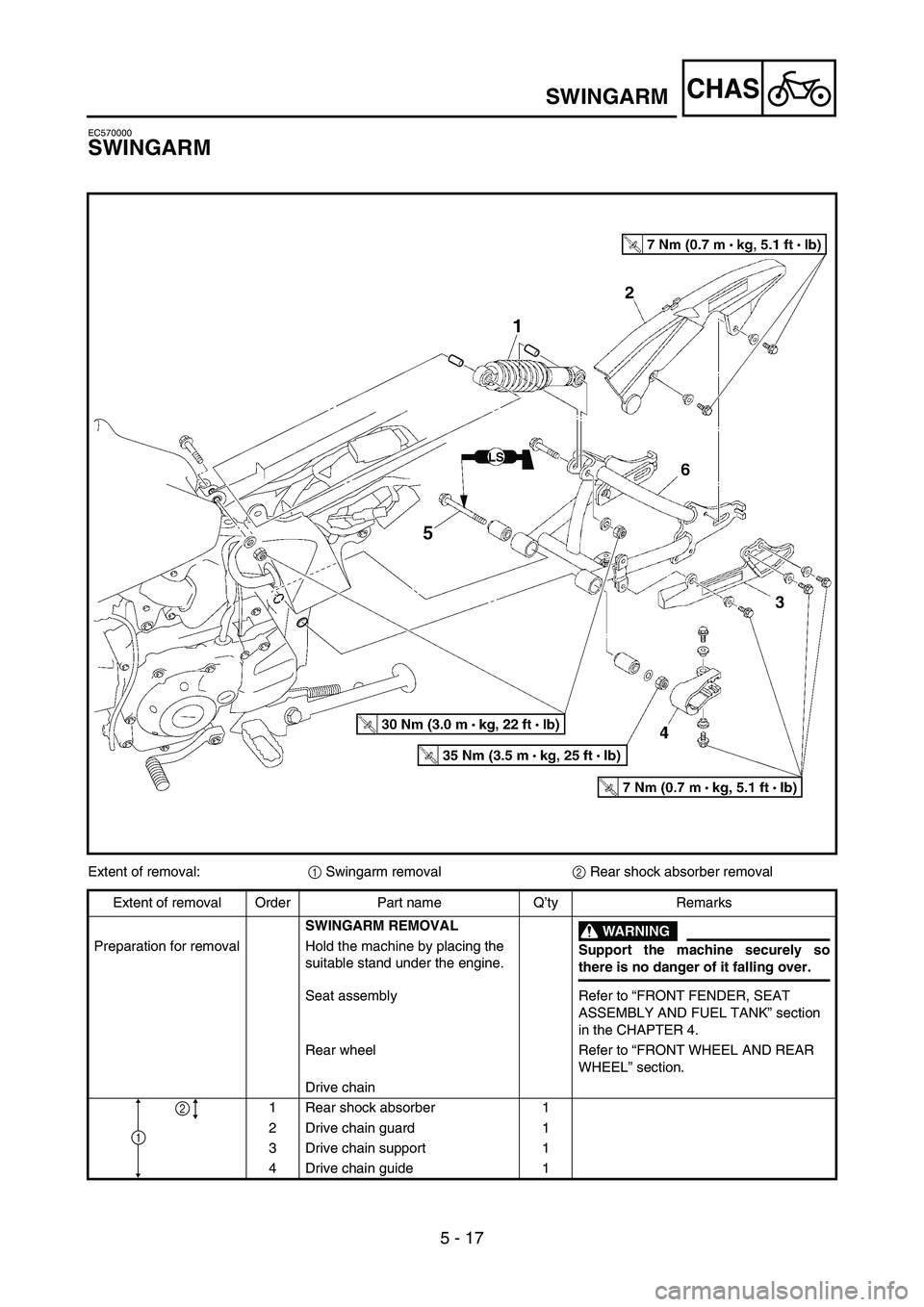

SWINGARM

Extent of removal:1 Swingarm removal

2 Rear shock absorber removal

Extent of removal Order Part name Q ’ty Remarks

SWINGARM REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Seat assembly Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section

in the CHAPTER 4.

Rear wheel Refer to “FRONT WHEEL AND REAR

WHEEL ” section.

Drive chain

1 Rear shock absorber 1

2 Drive chain guard 1

3 Drive chain support 1

4 Drive chain guide 1

1

2

Page 340 of 390

6 - 1

–+ELEC

345

6

78

\b0

B\f

2

1

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1 Thermo switch

2 Main switch

3 Engine stop switch

4 Ignition coil

5 Ground lead

6 Fuse

7 Battery

8 CDI unit

9 Starter relay 0

Rectifier/regulator

A Neutral switch

B AC magneto

C Carburetor heater

D Start switch

E Spark plug

F Starter motorCOLOR CODE

B ...................... Black

Br .................... Brown

O ..................... Orange

R ..................... Red

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

EC612000

WIRING DIAGRAM

R

WR

W

BL /WSb B

RW

W

W

OO

B

B

Y /R

R

W

B

R

Y /RY /R

Y

ON

OFF

OFF ON

Y

B

BY

/RRB

SbY /RR B

W

B

B

RBrR

Br

R

/WBr

R /W

L /W

OFF

RUN

Sb

BrBr

Sb

WBY

/RW SbY

B

B

B

RR

RR

R

R

R

/W

L /W

RRRB

R /W

L

/WR

R

RR

B Br

BO

R

WB

\f

2 8

4

E

1

C

D

0

63

\b F

5 7

Br

L/W .................. Blue/White

R/W .................. Red/White

Y/R ................... Yellow/Red

E

F

D

C

Page 342 of 390

–+ELEC

6 - 2

IGNITION SYSTEM

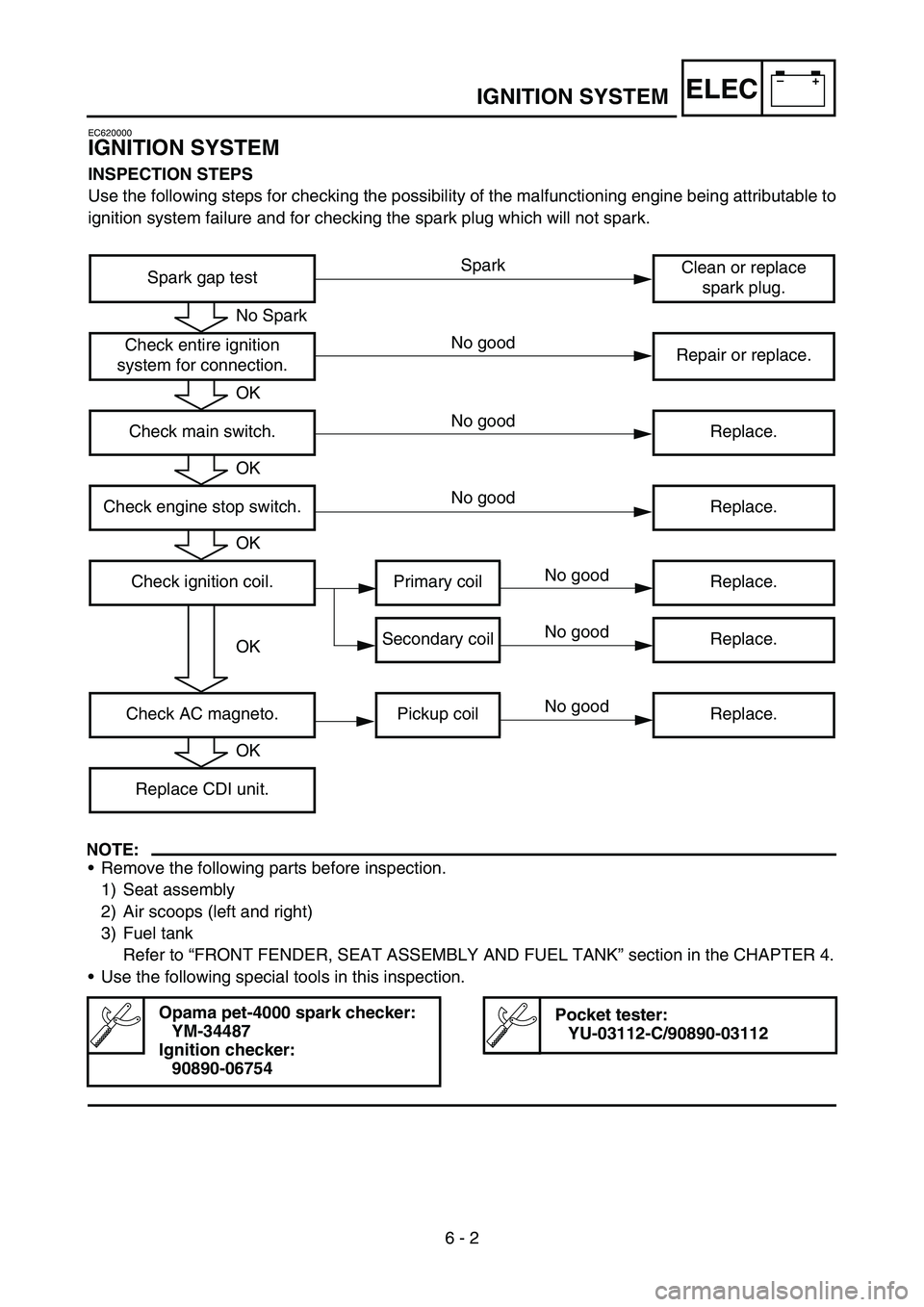

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

NOTE:

Remove the following parts before inspection.

1) Seat assembly

2) Air scoops (left and right)

3) Fuel tank

Refer to “FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK ” section in the CHAPTER 4.

Use the following special tools in this inspection.

Opama pet-4000 spark checker:

YM-34487

Ignition checker: 90890-06754Pocket tester:YU-03112-C/90890-03112

Spark gap test Clean or replace

spark plug.

Check entire ignition

system for connection. Repair or replace.

Check main switch. Replace.

Check engine stop switch. Replace.

Check ignition coil. Primary coil Replace. Secondary coil Replace.

Check AC magneto. Pickup coil Replace. Replace CDI unit.

No Spark

OK

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

Page 346 of 390

6 - 3

–+ELECIGNITION SYSTEM

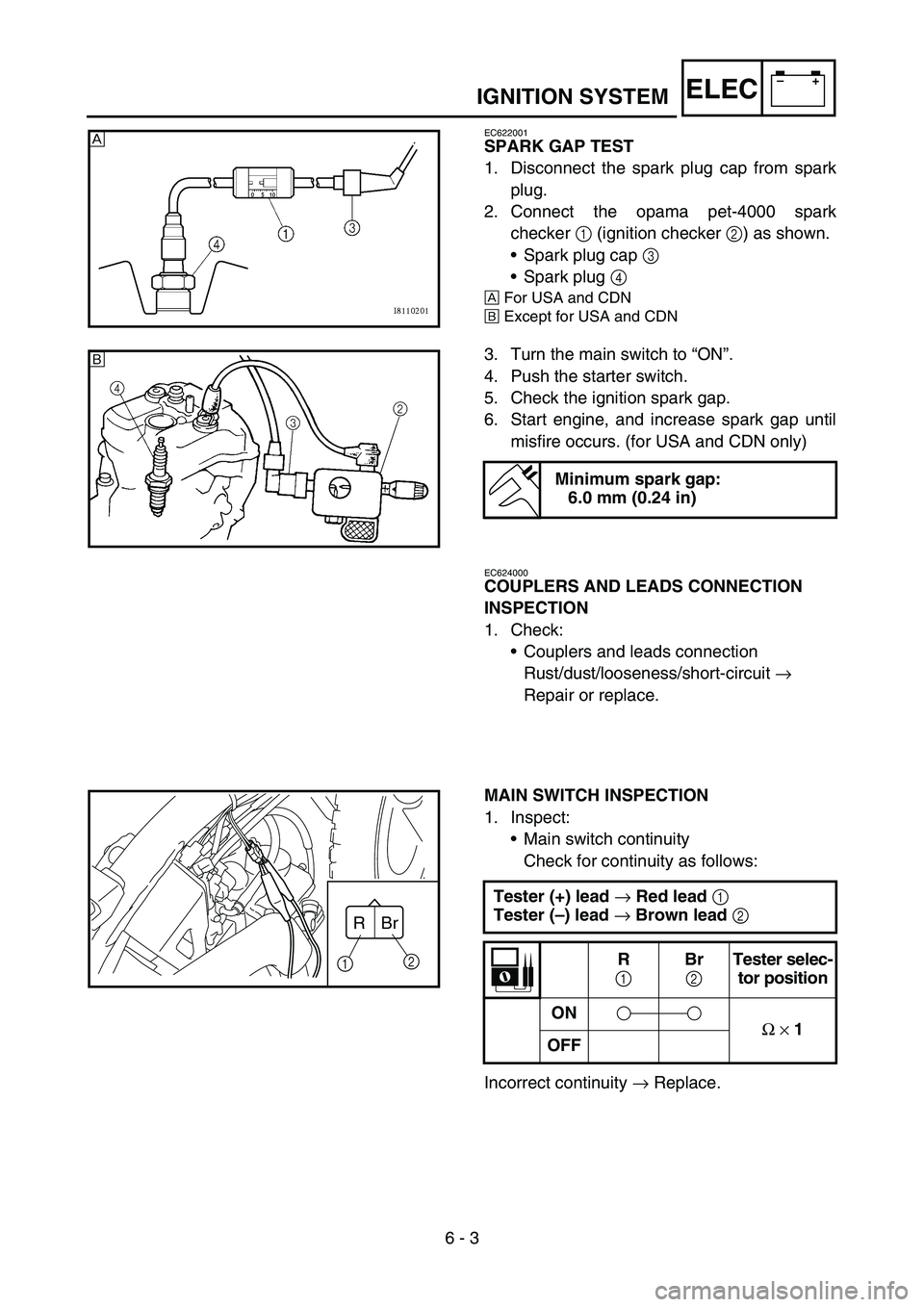

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the opama pet-4000 spark

checker 1 (ignition checker 2) as shown.

Spark plug cap 3

Spark plug 4

È For USA and CDN

É Except for USA and CDN

3. Turn the main switch to

“ON ”.

4. Push the starter switch.

5. Check the ignition spark gap.

6. Start engine, and increase spark gap until misfire occurs. (for USA and CDN only)

Minimum spark gap:6.0 mm (0.24 in)

È

É

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

MAIN SWITCH INSPECTION

1. Inspect: Main switch continuity

Check for continuity as follows:

Incorrect continuity → Replace.

Tester (+) lead

→ Red lead

1

Tester ( –) lead

→ Brown lead

2

R

1 Br

2 Tester selec-

tor position

ON Ω

× 1

OFF

Br

R

1 2

Page 348 of 390

6 - 4

–+ELECIGNITION SYSTEM

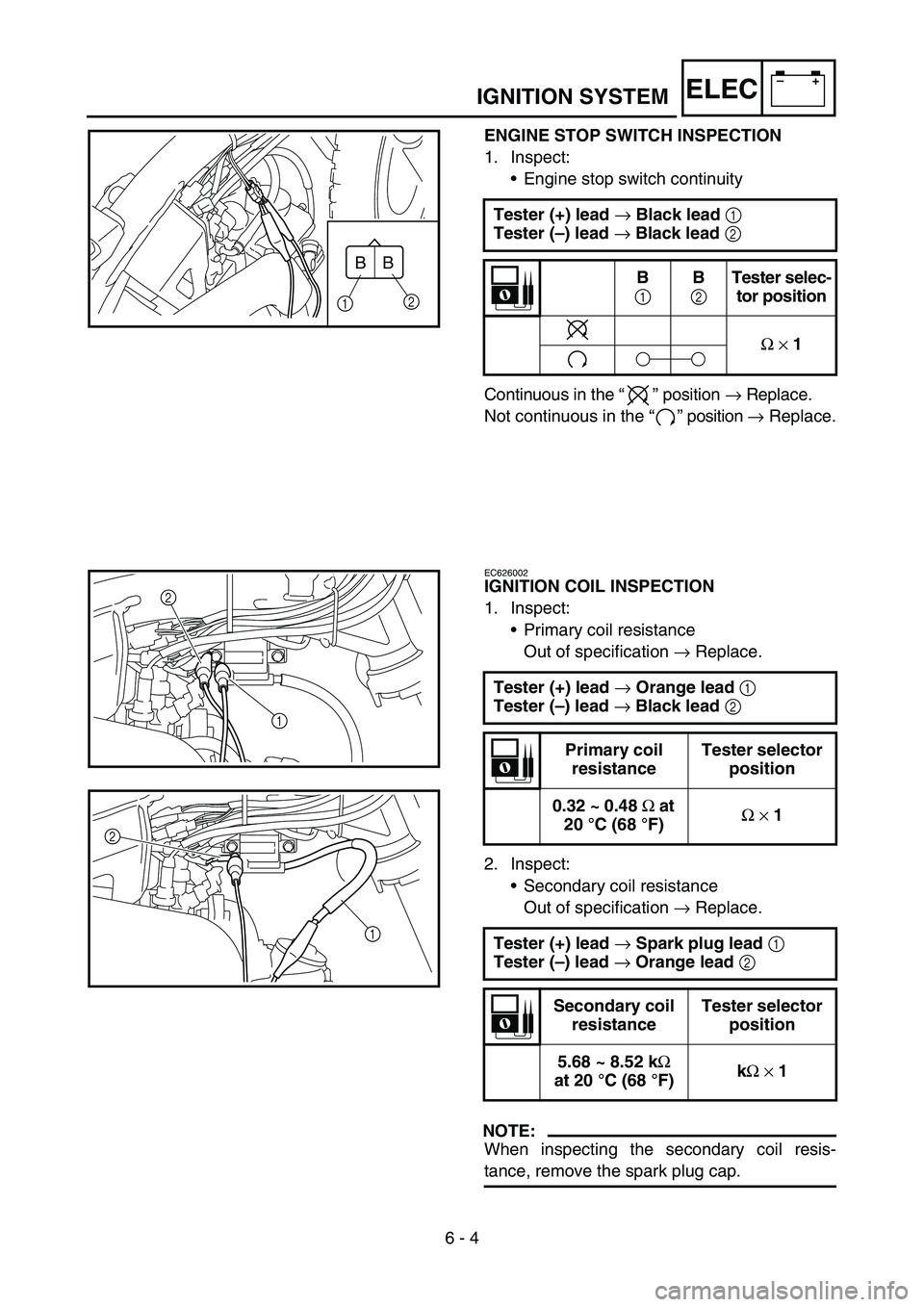

ENGINE STOP SWITCH INSPECTION

1. Inspect:

Engine stop switch continuity

Continuous in the “” position → Replace.

Not continuous in the “” position → Replace.

Tester (+) lead

→ Black lead

1

Tester ( –) lead

→ Black lead

2

B

1 B

2 Tester selec-

tor position

Ω

× 1B

B

1 2

EC626002

IGNITION COIL INSPECTION

1. Inspect:

Primary coil resistance

Out of specification → Replace.

2. Inspect: Secondary coil resistance

Out of specification → Replace.

NOTE:

When inspecting the secondary coil resis-

tance, remove the spark plug cap.Tester (+) lead

→ Orange lead

1

Tester ( –) lead

→ Black lead

2

Primary coil

resistance Tester selector

position

0.32 ~ 0.48 Ω at

20 °C (68 °F) Ω

× 1

Tester (+) lead → Spark plug lead

1

Tester ( –) lead

→ Orange lead

2

Secondary coil

resistance Tester selector

position

5.68 ~ 8.52 k Ω

at 20 °C (68 °F) k

Ω

× 1

1

2

1

2

Page 352 of 390

–+ELEC

6 - 6

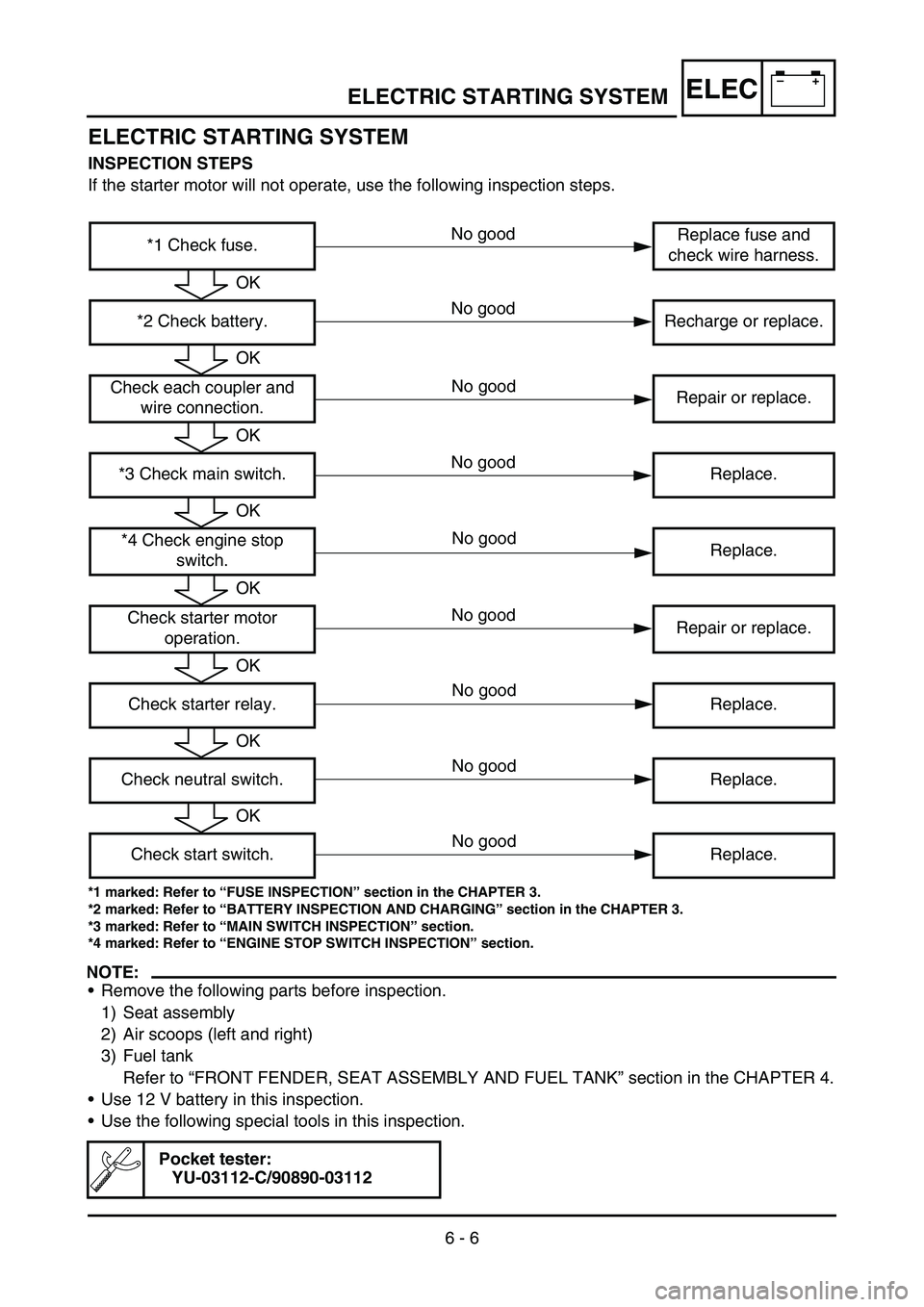

ELECTRIC STARTING SYSTEM

INSPECTION STEPS

If the starter motor will not operate, use the following inspection steps.

*1 marked: Refer to “FUSE INSPECTION ” section in the CHAPTER 3.

*2 marked: Refer to “BATTERY INSPECTION AND CHARGING ” section in the CHAPTER 3.

*3 marked: Refer to “MAIN SWITCH INSPECTION ” section.

*4 marked: Refer to “ENGINE STOP SWITCH INSPECTION ” section.

NOTE:

Remove the following parts before inspection.

1) Seat assembly

2) Air scoops (left and right)

3) Fuel tank

Refer to “FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK ” section in the CHAPTER 4.

Use 12 V battery in this inspection.

Use the following special tools in this inspection.

Pocket tester:

YU-03112-C/90890-03112

*1 Check fuse. Replace fuse and

check wire harness.

*2 Check battery. Recharge or replace.

Check each coupler and wire connection. Repair or replace.

*3 Check main switch. Replace. *4 Check engine stop switch. Replace.

Check starter motor operation. Repair or replace.

Check starter relay. Replace.

Check neutral switch. Replace. Check start switch. Replace.

OK

OK

OK

OK

OK

OK

OK

OK

No good

No good

No good

No good

No good

No good

ELECTRIC STARTING SYSTEM

No good

No good

No good

Page 362 of 390

6 - 10

–+ELEC

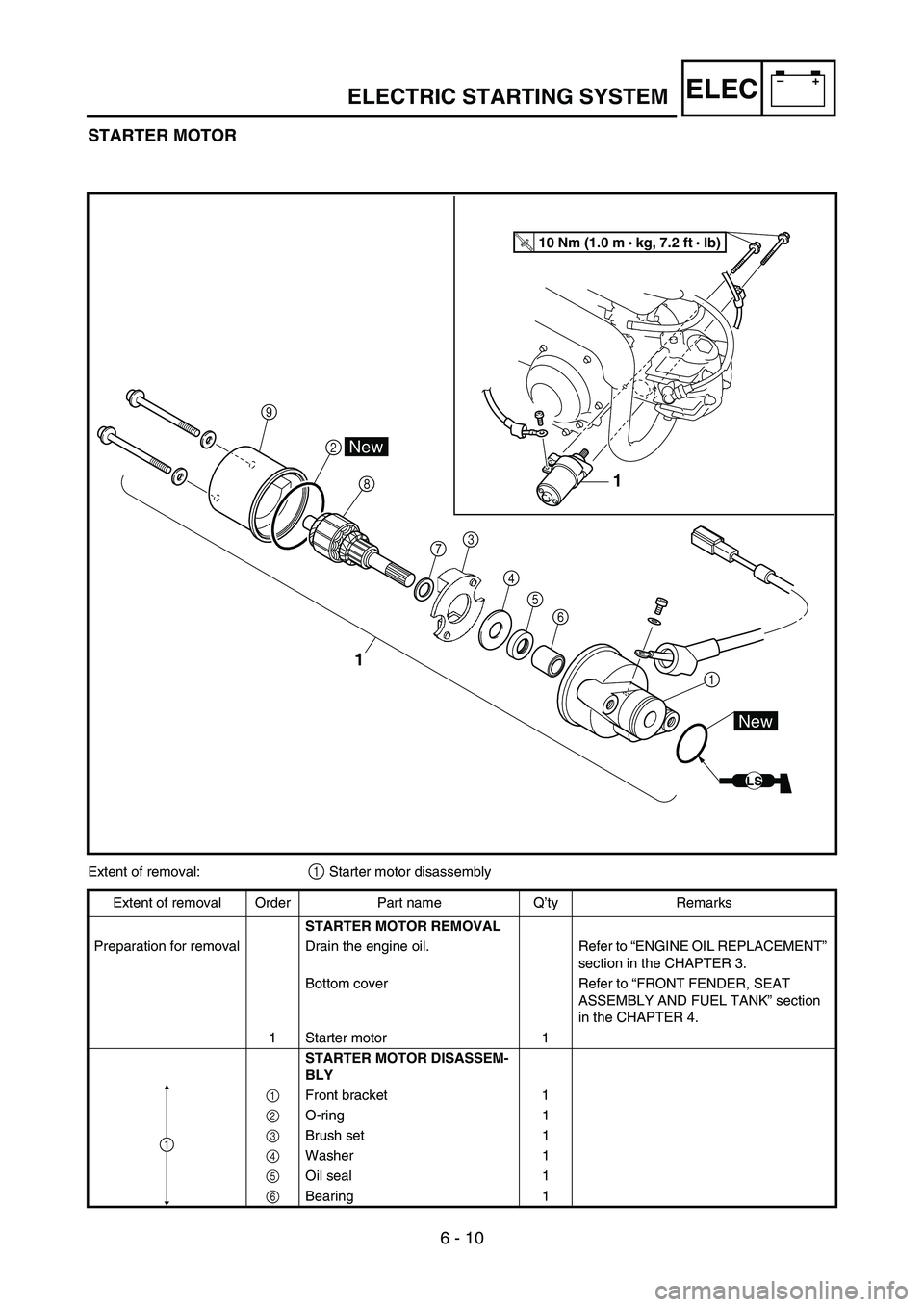

STARTER MOTOR

1

3

45 6

8

2

\b

1

1

LS

New

New

T R..10 Nm (1.0 m •

kg, 7.2 ft • Ib)

7

Extent of removal:1 Starter motor disassembly

Extent of removal Order Part name Q ’ty Remarks

STARTER MOTOR REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT ”

section in the CHAPTER 3.

Bottom cover Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section

in the CHAPTER 4.

1 Starter motor 1 STARTER MOTOR DISASSEM-

BLY

1 Front bracket 1

2 O-ring 1

3 Brush set 1

4 Washer 1

5 Oil seal 1

6 Bearing 1

1

ELECTRIC STARTING SYSTEM