engine YAMAHA TTR90 2006 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 56 of 390

GEN

INFO

ANLASSEN UND

INBETRIEBNAHME

ACHTUNG:

Vor dem Start muss die “Routinekontrolle

vor Fahrtbeginn” ausgeführt werden.

WARNUNG

Den Motor niemals in einem geschlosse-

nen Raum anlassen oder betreiben. Motor-

abgase sind äußerst giftig und führen in

kurzer Zeit zu Bewusstlosigkeit und Tod.

Daher den Motor nur an einem gut belüfte-

ten Ort betreiben.

KALTEN MOTOR ANLASSEN

TT-R90

WARNUNG

Vor dem Anlassen sicherstellen, dass das

Getriebe in der Leerlaufstellung ist.

1. Den Kraftstoffhahn auf “ON” stellen.

2. Den Choke betätigen und den Gasdrehgriff

ganz schließen.

3. Den Motorstoppschalter “ENGINE STOP”

auf “” stellen.

4. Den Kickstarterhebel kräftig durchtreten,

um den Motor anzulassen.

5. Nach dem Anlassen den Motor einige Minu-

ten lang warm laufen lassen. Vor dem Anfah-

ren sicherstellen, dass der Chokehebel in die

Ausgangsstellung zurückgebracht wird.

TT-R90E

WARNUNG

Vor dem Anlassen sicherstellen, dass das

Getriebe in der Leerlaufstellung ist.

HINWEIS:

Das Motorrad ist mit einem Zündunterbre-

chungs- und Anlasssperrschalter-System

ausgerüstet. Der Motor kann nur dann mit

dem E-Starter angelassen werden, wenn

das Getriebe in der Leerlaufstellung ist.

Falls der Motor bei Verwendung des Elektro-

starters nicht sofort anspringt, den Starterschal-

ter freigeben und einige Sekunden bis zum

nächsten Startversuch warten. Um die Batterie

zu schonen, darf der Starterschalter jeweils nur

kurzzeitig betätigt werden. Den Motor niemals

länger als 10 Sekunden drehen. Falls der Motor

nicht mit dem Elektrostarter angelassen werden

kann, den Kickstarter benutzen.1. Den Kraftstoffhahn auf “ON” stellen.

2. Den Zündschlüssel auf “ON” stellen.

3. Das Getriebe in die Leerlaufstellung schalten.

4. Den Choke betätigen und den Gasdrehgriff

ganz schließen.

5. Den Motorstoppschalter “ENGINE STOP”

auf “” stellen.

6. Den Starterschalter drücken oder den Kick-

starterhebel durchtreten, um den Motor

anzulassen.

7. Nach dem Anlassen den Motor einige Minu-

ten lang warm laufen lassen. Vor dem Anfah-

ren sicherstellen, dass der Chokehebel in die

Ausgangsstellung zurückgebracht wird.

WARMEN MOTOR ANLASSEN

Den warmen Motor wie im Abschnitt “Kalten

Motor anlassen” beschrieben anlassen. Aller-

dings sollte der Choke nicht betätigt werden.

Den Gasdrehgriff leicht öffnen.

ACHTUNG:

Vor der ersten Inbetriebnahme unbedingt den

Abschnitt “Einfahrvorschriften” beachten.

MOTOR WARM FAHREN

Den Motor stets warm fahren, um ihm eine lange

Lebensdauer zu gewähren. Bei kaltem Motor

niemals stark beschleunigen! Der Motor ist aus-

reichend warmgefahren, wenn er bei abgeschal-

tetem Choke willig auf Gasgeben anspricht.

WARNUNG

Vor dem Losfahren sicherstellen, dass der

Seitenständer hochgeklappt bzw. abge-

nommen ist.

Ein ausgeklappter Seitenständer kann in

Kurven schwere Stürze verursachen.

EINFAHRVORSCHRIFTEN

Die Einfahrzeit ist wichtig, weil sie den vielen

Bauteilen des Motors erlaubt, sich einzupas-

sen. Außerdem kann der Fahrer sich während

dessen mit seiner Maschine vertraut machen.

Während der ersten fünf Betriebsstunden

unbedingt Vollgas vermeiden.

Nach der Probefahrt die Maschine auf lockere

Schraubverbindungen, Öllecks und andere

Probleme untersuchen.

Die Maschine gründlich kontrollieren und einstel-

len, insbesondere Seilzüge, Antriebskette und

Radspeichen.

ACHTUNG:

Am Ende der Einfahrzeit sicherstellen, dass

sämtliche Schraubverbindungen fest sind.

Bei Lockerheit nachziehen.

ANLASSEN UND INBETRIEBNAHME

1 - 13

Page 57 of 390

GEN

INFO

1 - 14

CLEANING AND STORAGE

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will

enhance its appearance, maintain good overall

performance, and extend the life of many com-

ponents.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprock-

ets, or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

CAUTION:

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been

hosed off, wash all surfaces with warm

water and a mild detergent. Use an old

toothbrush to clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel

and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery

cleaner to keep the cover pliable and

glossy.

8. Automotive wax may be applied to all

painted or chromed surfaces. Avoid combi-

nation cleaner-waxes, as they may contain

abrasives.

9. After completing the above, start the

engine and allow it to idle for several min-

utes.

EC182001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 60 of 390

SPEC

2 - 1

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: TT-R90V (CDN, AUS, NZ)

TT-R90 (Europe, ZA)

TT-R90EV (USA, CDN, AUS, NZ)

TT-R90E (Europe, ZA)

Model code number: TT-R90:

5HNW (Europe, AUS, NZ, ZA)

5HNX (CDN)

TT-R90E:

3P21 (USA)

3P22 (Europe, AUS, NZ, ZA)

3P23 (CDN)

Dimensions:

Overall length 1,525 mm (57.0 in)

Overall width 605 mm (23.8 in)

Overall height 865 mm (34.1 in)

Seat height 625 mm (24.6 in)

Wheelbase 1,040 mm (40.9 in)

Minimum ground clearance 160 mm (6.3 in)

Dry weight:

Without oil and fuel (TT-R90) 60.0 kg (132.3 lb)

(TT-R90E) 63.0 kg (138.9 lb)

Engine:

Engine type Air cooled 4-stroke, SOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 89 cm

3 (5.43 cu.in)

Bore × stroke 47.0 × 51.8 mm (1.85 × 2.04 in)

Compression ratio 8.5 : 1

Compression pressure (STD) 1,000 kPa (10 kg/cm

2, 145 psi) at 1,000 r/min

Starting system (TT-R90) Kick starter

(TT-R90E) Kick and electric starter

Lubrication system: Wet sump

GENERAL SPECIFICATIONS

Page 61 of 390

SPEC

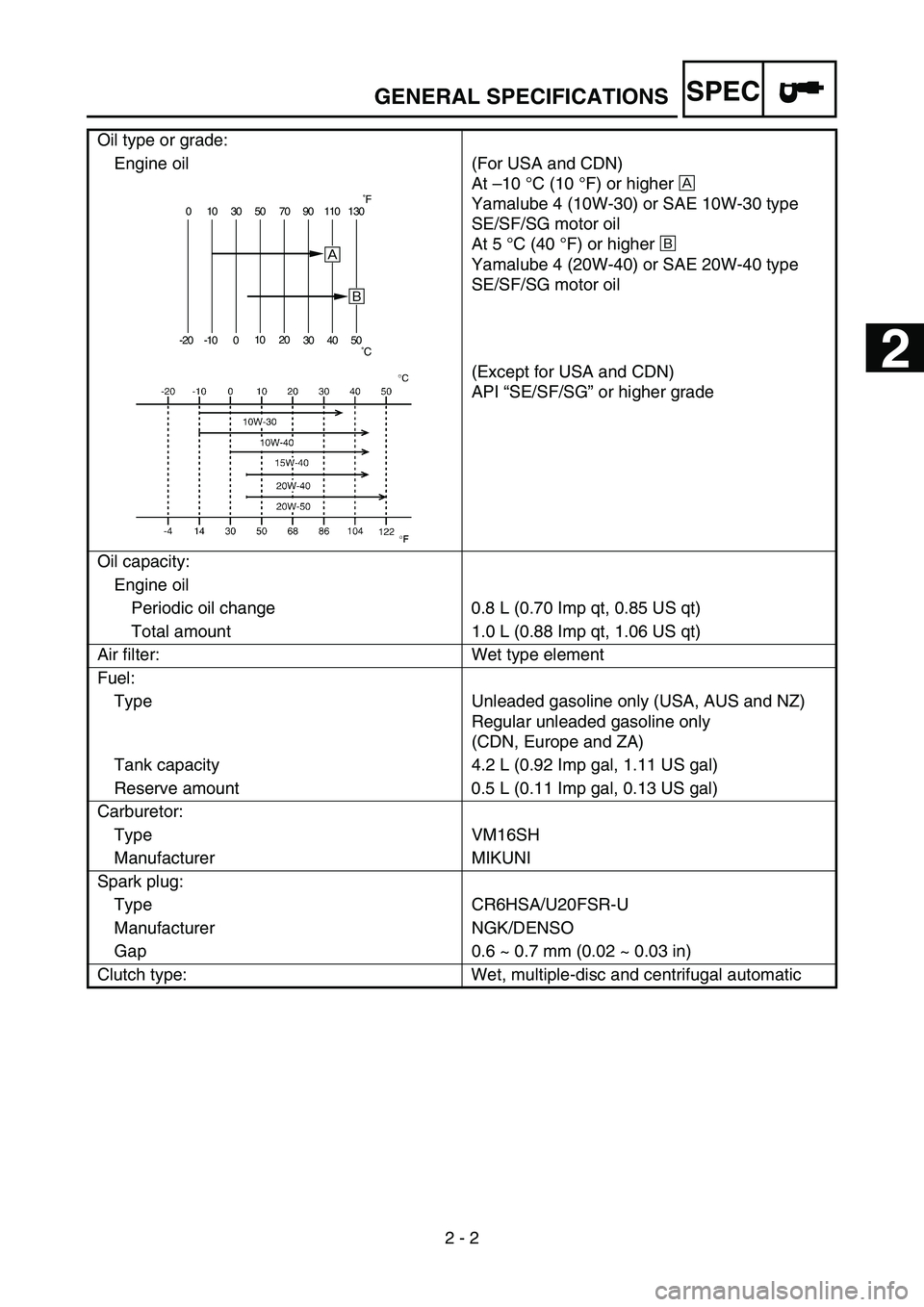

2 - 2 Oil type or grade:

Engine oil

(For USA and CDN)

At –10 °C (10 °F) or higher È

Yamalube 4 (10W-30) or SAE 10W-30 type

SE/SF/SG motor oil

At 5 °C (40 °F) or higher É

Yamalube 4 (20W-40) or SAE 20W-40 type

SE/SF/SG motor oil

(Except for USA and CDN)

API “SE/SF/SG” or higher grade

Oil capacity:

Engine oil

Periodic oil change 0.8 L (0.70 Imp qt, 0.85 US qt)

Total amount 1.0 L (0.88 Imp qt, 1.06 US qt)

Air filter: Wet type element

Fuel:

Type Unleaded gasoline only (USA, AUS and NZ)

Regular unleaded gasoline only

(CDN, Europe and ZA)

Tank capacity 4.2 L (0.92 Imp gal, 1.11 US gal)

Reserve amount 0.5 L (0.11 Imp gal, 0.13 US gal)

Carburetor:

Type VM16SH

Manufacturer MIKUNI

Spark plug:

Type CR6HSA/U20FSR-U

Manufacturer NGK/DENSO

Gap 0.6 ~ 0.7 mm (0.02 ~ 0.03 in)

Clutch type: Wet, multiple-disc and centrifugal automatic

0 10 30 50 70 90 110 130

-20 -10 01020

30 40 50

È

É

˚F

˚C

GENERAL SPECIFICATIONS

1

2

Page 63 of 390

SPEC

2 - 4

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

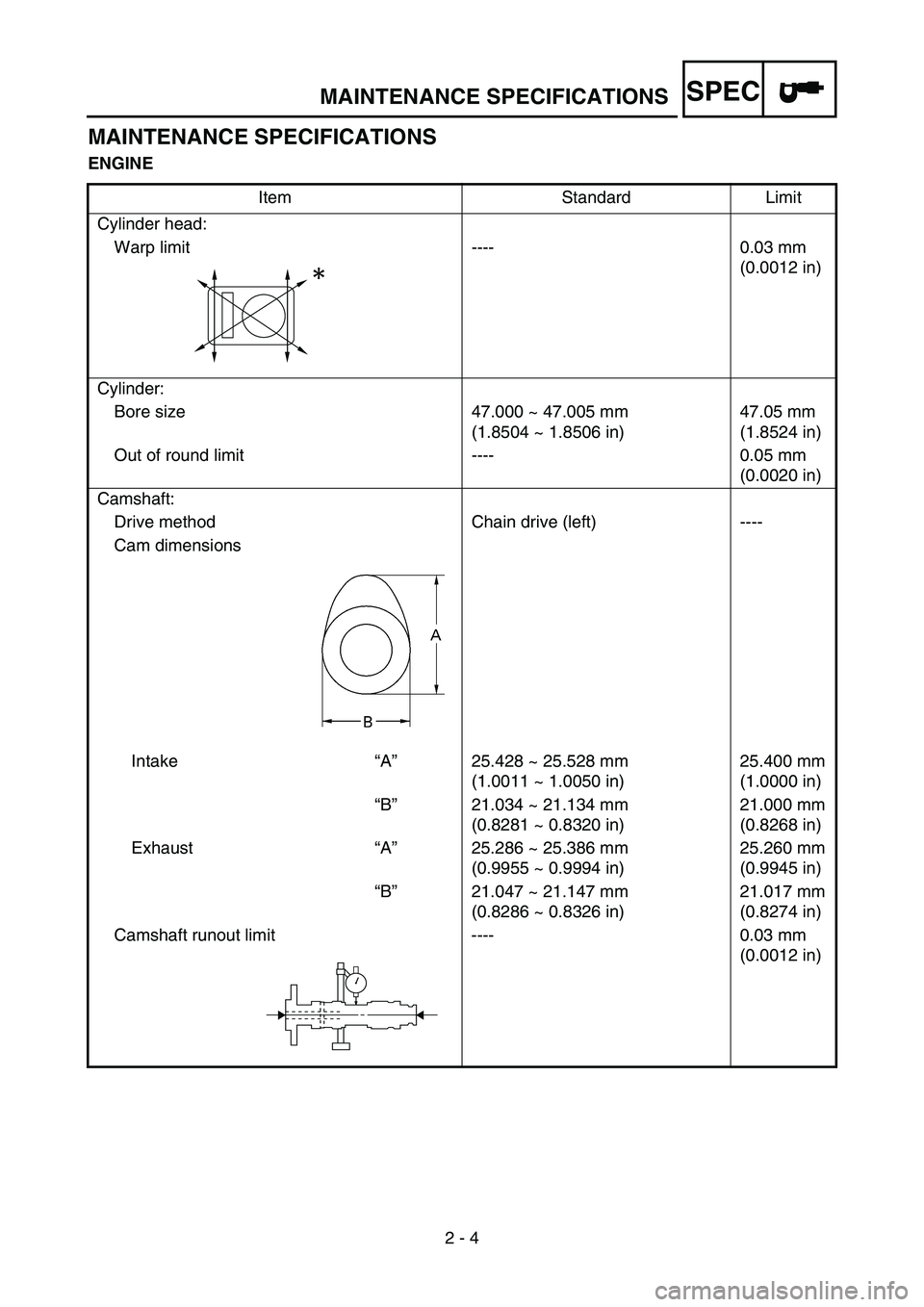

Cylinder head:

Warp limit ---- 0.03 mm

(0.0012 in)

Cylinder:

Bore size 47.000 ~ 47.005 mm

(1.8504 ~ 1.8506 in)47.05 mm

(1.8524 in)

Out of round limit ---- 0.05 mm

(0.0020 in)

Camshaft:

Drive method Chain drive (left) ----

Cam dimensions

Intake“A”25.428 ~ 25.528 mm

(1.0011 ~ 1.0050 in)25.400 mm

(1.0000 in)

“B”21.034 ~ 21.134 mm

(0.8281 ~ 0.8320 in)21.000 mm

(0.8268 in)

Exhaust“A”25.286 ~ 25.386 mm

(0.9955 ~ 0.9994 in)25.260 mm

(0.9945 in)

“B”21.047 ~ 21.147 mm

(0.8286 ~ 0.8326 in)21.017 mm

(0.8274 in)

Camshaft runout limit ---- 0.03 mm

(0.0012 in)

MAINTENANCE SPECIFICATIONS

Page 67 of 390

SPEC

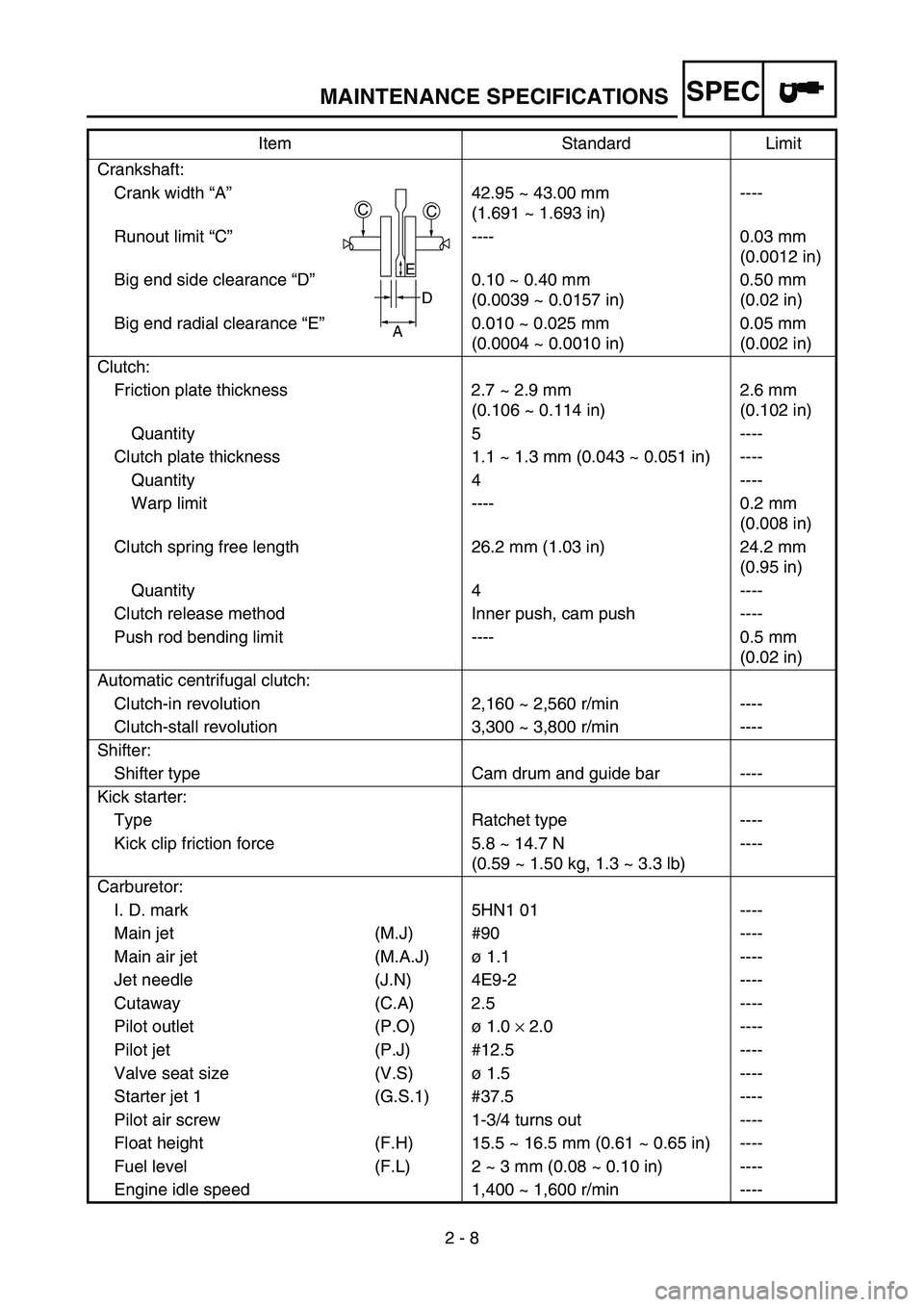

2 - 8 Crankshaft:

Crank width “A”42.95 ~ 43.00 mm

(1.691 ~ 1.693 in)----

Runout limit “C”---- 0.03 mm

(0.0012 in)

Big end side clearance “D”0.10 ~ 0.40 mm

(0.0039 ~ 0.0157 in)0.50 mm

(0.02 in)

Big end radial clearance “E”0.010 ~ 0.025 mm

(0.0004 ~ 0.0010 in)0.05 mm

(0.002 in)

Clutch:

Friction plate thickness 2.7 ~ 2.9 mm

(0.106 ~ 0.114 in)2.6 mm

(0.102 in)

Quantity 5 ----

Clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ----

Quantity 4 ----

Warp limit ---- 0.2 mm

(0.008 in)

Clutch spring free length 26.2 mm (1.03 in) 24.2 mm

(0.95 in)

Quantity 4 ----

Clutch release method Inner push, cam push ----

Push rod bending limit ---- 0.5 mm

(0.02 in)

Automatic centrifugal clutch:

Clutch-in revolution 2,160 ~ 2,560 r/min ----

Clutch-stall revolution 3,300 ~ 3,800 r/min ----

Shifter:

Shifter type Cam drum and guide bar ----

Kick starter:

Type Ratchet type ----

Kick clip friction force 5.8 ~ 14.7 N

(0.59 ~ 1.50 kg, 1.3 ~ 3.3 lb)----

Carburetor:

I. D. mark 5HN1 01 ----

Main jet (M.J) #90 ----

Main air jet (M.A.J)ø 1.1 ----

Jet needle (J.N) 4E9-2 ----

Cutaway (C.A) 2.5 ----

Pilot outlet (P.O)ø 1.0 × 2.0 ----

Pilot jet (P.J) #12.5 ----

Valve seat size (V.S)ø 1.5 ----

Starter jet 1 (G.S.1) #37.5 ----

Pilot air screw 1-3/4 turns out ----

Float height (F.H) 15.5 ~ 16.5 mm (0.61 ~ 0.65 in) ----

Fuel level (F.L) 2 ~ 3 mm (0.08 ~ 0.10 in) ----

Engine idle speed 1,400 ~ 1,600 r/min ----Item Standard Limit

CC

D

A

E

MAINTENANCE SPECIFICATIONS

Page 72 of 390

SPEC

2 - 13

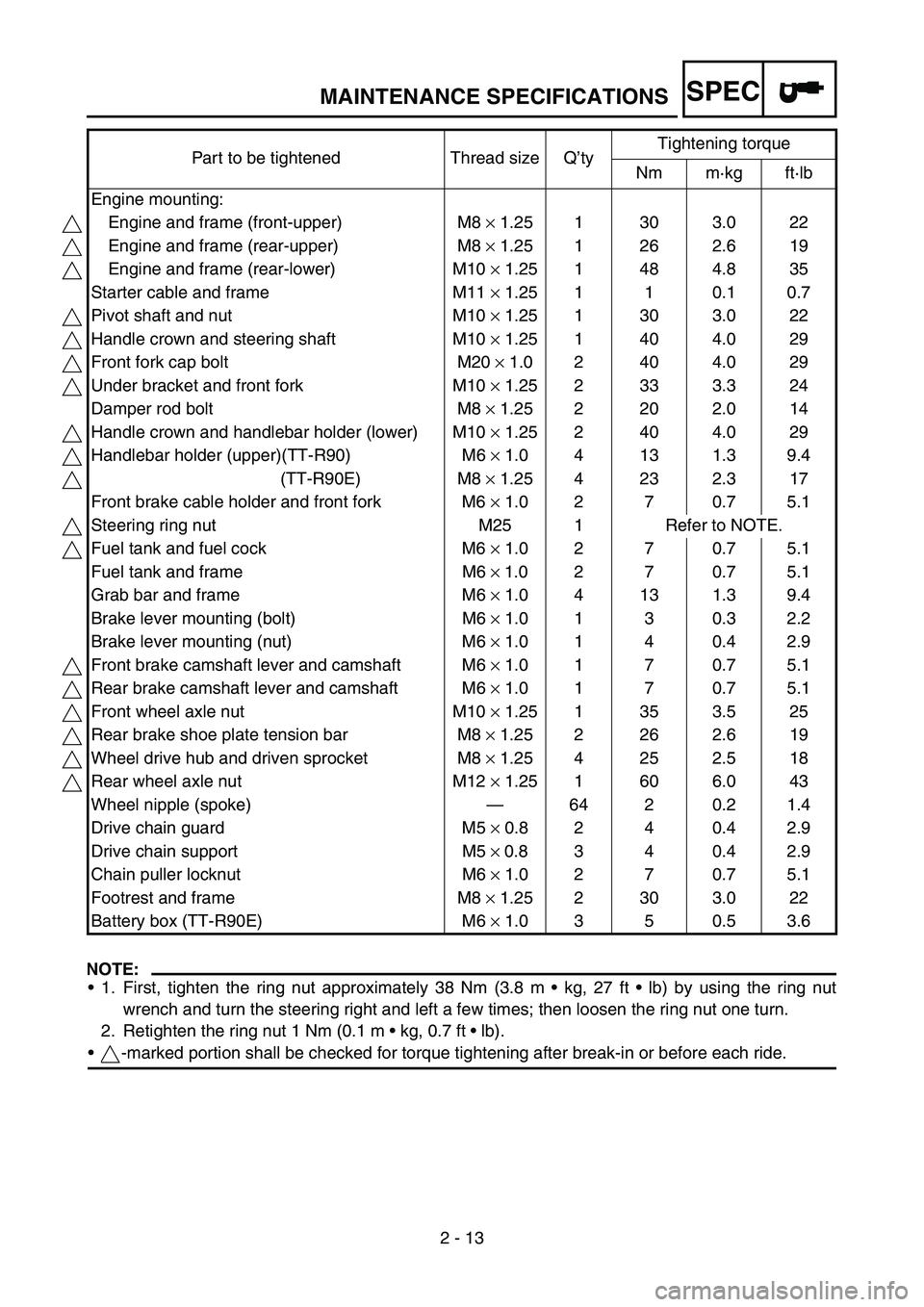

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the ring nut

wrench and turn the steering right and left a few times; then loosen the ring nut one turn.

2. Retighten the ring nut 1 Nm (0.1 m kg, 0.7 ft lb).

-marked portion shall be checked for torque tightening after break-in or before each ride.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Engine mounting:

Engine and frame (front-upper) M8 × 1.25 1 30 3.0 22

Engine and frame (rear-upper) M8 × 1.25 1 26 2.6 19

Engine and frame (rear-lower) M10 × 1.25 1 48 4.8 35

Starter cable and frame M11 × 1.25 1 1 0.1 0.7

Pivot shaft and nut M10 × 1.25 1 30 3.0 22

Handle crown and steering shaft M10 × 1.25 1 40 4.0 29

Front fork cap bolt M20 × 1.0 2 40 4.0 29

Under bracket and front fork M10 × 1.25 2 33 3.3 24

Damper rod bolt M8 × 1.25 2 20 2.0 14

Handle crown and handlebar holder (lower) M10 × 1.25 2 40 4.0 29

Handlebar holder (upper)(TT-R90) M6 × 1.0 4 13 1.3 9.4

(TT-R90E) M8 × 1.25 4 23 2.3 17

Front brake cable holder and front fork M6 × 1.0 2 7 0.7 5.1

Steering ring nut M25 1 Refer to NOTE.

Fuel tank and fuel cock M6 × 1.0 2 7 0.7 5.1

Fuel tank and frame M6 × 1.0 2 7 0.7 5.1

Grab bar and frame M6 × 1.0 4 13 1.3 9.4

Brake lever mounting (bolt) M6 × 1.0 1 3 0.3 2.2

Brake lever mounting (nut) M6 × 1.0 1 4 0.4 2.9

Front brake camshaft lever and camshaft M6 × 1.0 1 7 0.7 5.1

Rear brake camshaft lever and camshaft M6 × 1.0 1 7 0.7 5.1

Front wheel axle nut M10 × 1.25 1 35 3.5 25

Rear brake shoe plate tension bar M8 × 1.25 2 26 2.6 19

Wheel drive hub and driven sprocket M8 × 1.25 4 25 2.5 18

Rear wheel axle nut M12 × 1.25 1 60 6.0 43

Wheel nipple (spoke)—64 2 0.2 1.4

Drive chain guard M5 × 0.8 2 4 0.4 2.9

Drive chain support M5 × 0.8 3 4 0.4 2.9

Chain puller locknut M6 × 1.0 2 7 0.7 5.1

Footrest and frame M8 × 1.25 2 30 3.0 22

Battery box (TT-R90E) M6 × 1.0 3 5 0.5 3.6

MAINTENANCE SPECIFICATIONS

Page 76 of 390

SPEC

2 - 17

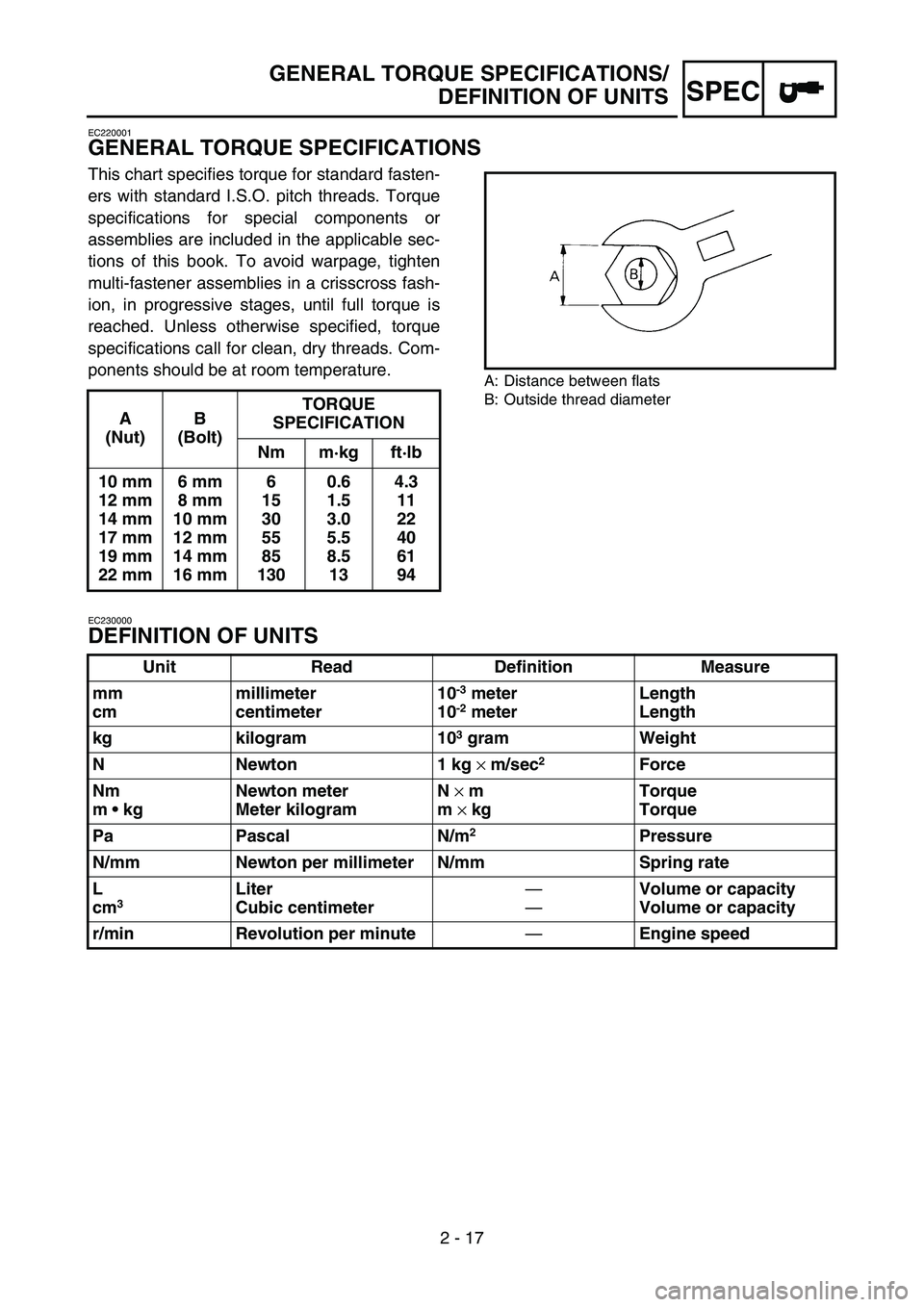

EC220001

GENERAL TORQUE SPECIFICATIONS

This chart specifies torque for standard fasten-

ers with standard I.S.O. pitch threads. Torque

specifications for special components or

assemblies are included in the applicable sec-

tions of this book. To avoid warpage, tighten

multi-fastener assemblies in a crisscross fash-

ion, in progressive stages, until full torque is

reached. Unless otherwise specified, torque

specifications call for clean, dry threads. Com-

ponents should be at room temperature.

A: Distance between flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

A

(Nut)B

(Bolt)TORQUE

SPECIFICATION

Nm m·kg ft·lb

10 mm

12 mm

14 mm

17 mm

19 mm

22 mm6 mm

8 mm

10 mm

12 mm

14 mm

16 mm6

15

30

55

85

1300.6

1.5

3.0

5.5

8.5

134.3

11

22

40

61

94

Unit Read Definition Measure

mm

cmmillimeter

centimeter10

-3 meter

10-2 meterLength

Length

kg kilogram 10

3 gram Weight

N Newton 1 kg

× m/sec

2 Force

Nm

m kgNewton meter

Meter kilogramN

× m

m

× kgTorque

Torque

Pa Pascal N/m

2Pressure

N/mm Newton per millimeter N/mm Spring rate

L

cm

3 Liter

Cubic centimeter—

—Volume or capacity

Volume or capacity

r/min Revolution per minute

—Engine speed

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

Page 112 of 390

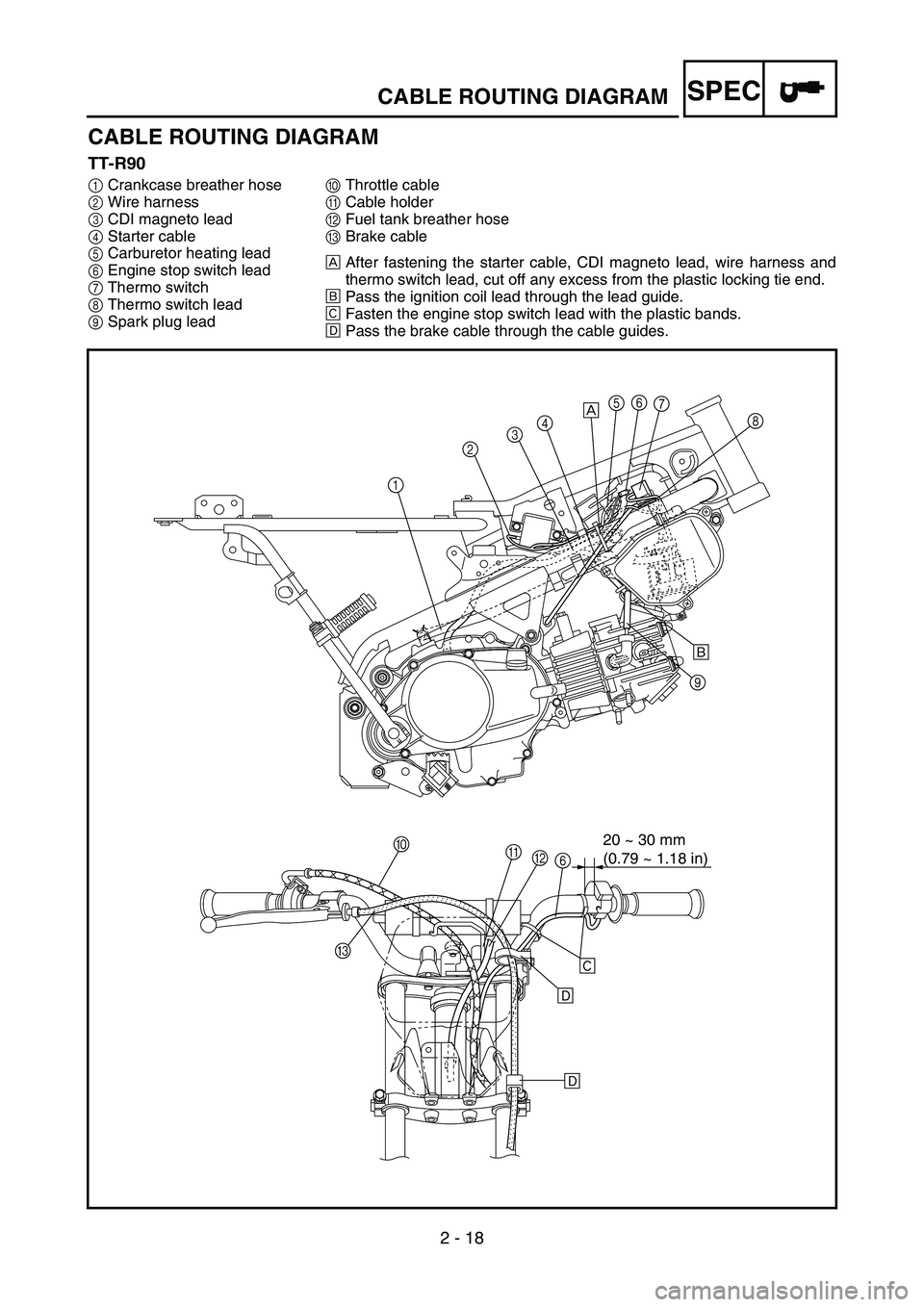

2 - 18

SPECCABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

TT-R90

1Crankcase breather hose

2Wire harness

3CDI magneto lead

4Starter cable

5Carburetor heating lead

6Engine stop switch lead

7Thermo switch

8Thermo switch lead

9Spark plug lead0Throttle cable

ACable holder

BFuel tank breather hose

CBrake cable

ÈAfter fastening the starter cable, CDI magneto lead, wire harness and

thermo switch lead, cut off any excess from the plastic locking tie end.

ÉPass the ignition coil lead through the lead guide.

ÊFasten the engine stop switch lead with the plastic bands.

ËPass the brake cable through the cable guides.

12345

9

0

B A

6

CÈ

É

Ê

Ë

Ë

67

8

20 ~ 30 mm

(0.79 ~ 1.18 in)

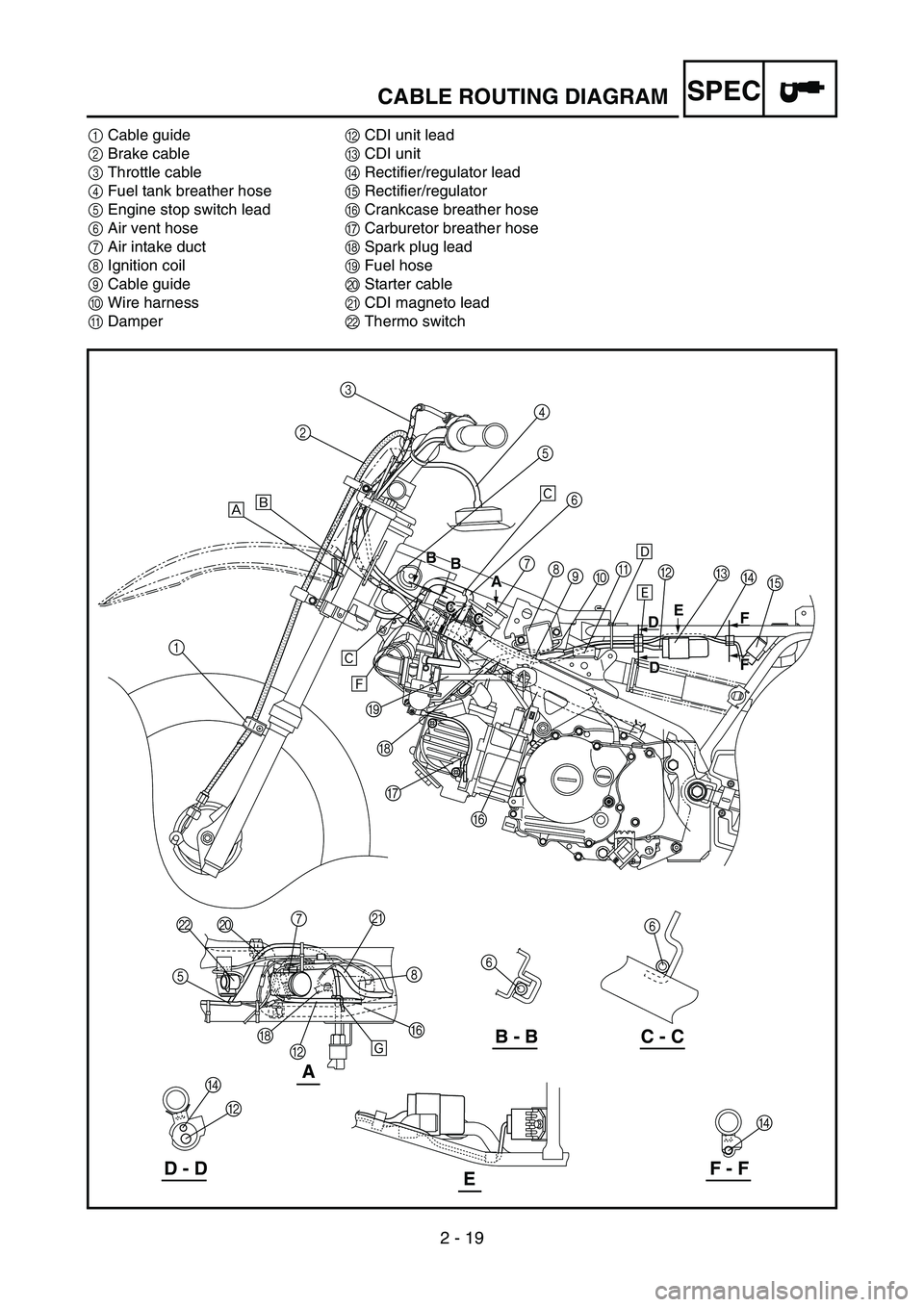

Page 114 of 390

2 - 19

SPECCABLE ROUTING DIAGRAM

1Cable guide

2Brake cable

3Throttle cable

4Fuel tank breather hose

5Engine stop switch lead

6Air vent hose

7Air intake duct

8Ignition coil

9Cable guide

0Wire harness

ADamperBCDI unit lead

CCDI unit

DRectifier/regulator lead

ERectifier/regulator

FCrankcase breather hose

GCarburetor breather hose

HSpark plug lead

IFuel hose

JStarter cable

KCDI magneto lead

LThermo switch

A

123

4

5

6

7

8

9

0A

C

E B

F G H I

6

6 J L

5

H

B8

F K

7 ÈÊ

Ì

Ê

Í

ÎB - B C - C

D - DF - FE

É

Ë

D

D

B

D

A A B

B B

B

C

C C

CE

B D

B

D

F F F F