engine YAMAHA TTR90 2006 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 142 of 390

3 - 6

INSP

ADJ

ENGINE OIL LEVEL INSPECTION

1. Start the engine, warm it up for several

minutes, and then turn off the engine and

wait for five minutes.

2. Place the machine on a level place and

hold it up on upright position by placing the

suitable stand under the engine.

3. Remove:

Dipstick 1

4. Check:

Oil level

Oil level should be between maximum a

and minimum b marks.

Oil level is low → Add oil to proper level.

NOTE:

When inspecting the oil level, do not screw the

dipstick into the oil tank. Insert the gauge

lightly.

(For USA and CDN)

CAUTION:

Do not add any chemical additives.

Engine oil also lubricates the clutch and

additives could cause clutch slippage.

Do not allow foreign material to enter the

crankcase.

Recommended oil:

At –10 °C (10 °F) or higher È:

Yamalube 4 (10W-30) or SAE

10W-30 type SE/SF/SG motor

oil

At 5 °C (40 °F) or higher É:

Yamalube 4 (20W-40) or SAE

20W-40 type SE/SF/SG motor

oil010 30 50 70

90110

130

-20

-10010

20 30 40

50

È

É

˚C ˚F

ENGINE OIL LEVEL INSPECTION

Page 144 of 390

3 - 7

INSP

ADJ

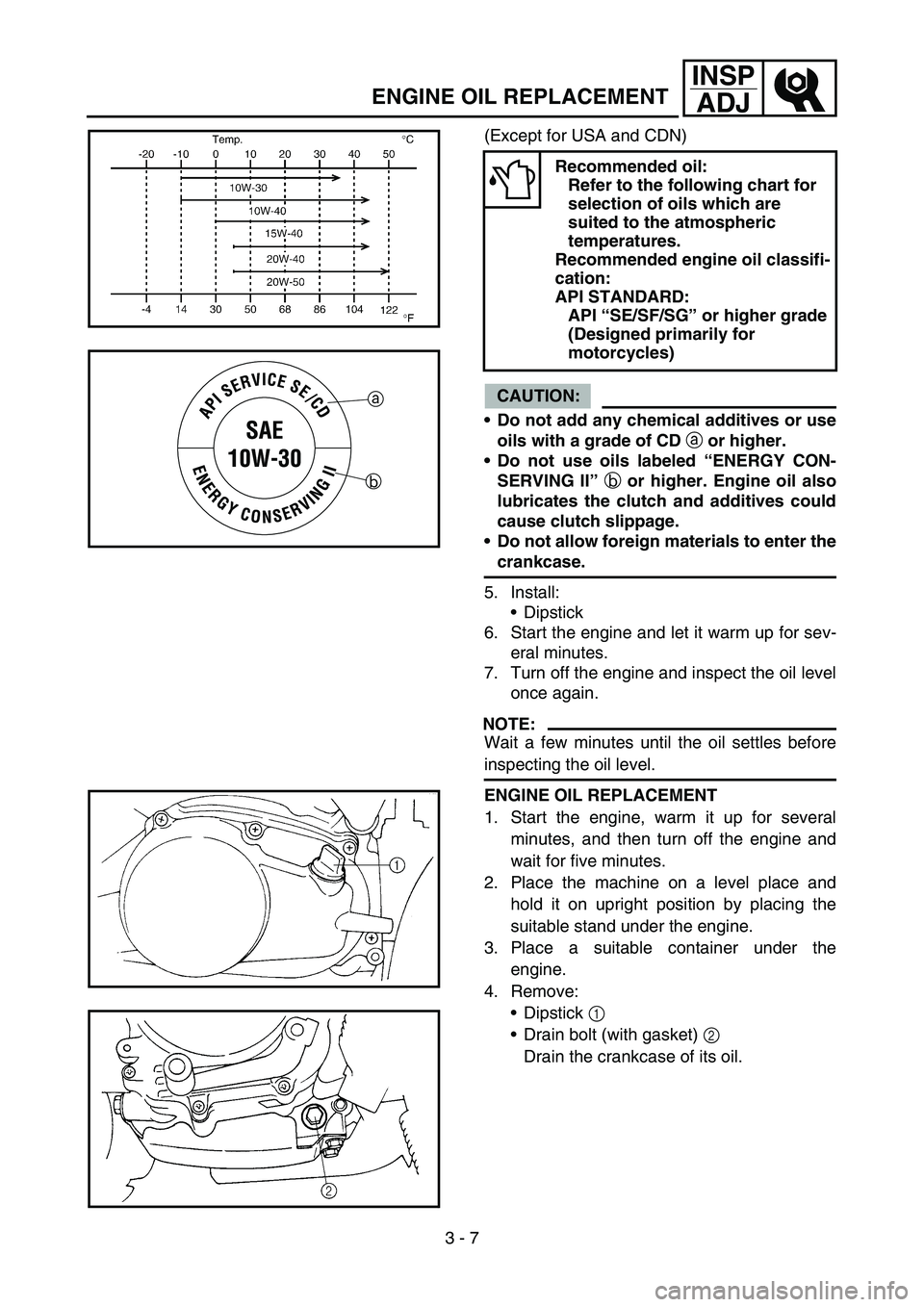

ENGINE OIL REPLACEMENT

(Except for USA and CDN)

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD

a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II”

b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

5. Install:

Dipstick

6. Start the engine and let it warm up for sev-

eral minutes.

7. Turn off the engine and inspect the oil level

once again.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

Recommended oil:

Refer to the following chart for

selection of oils which are

suited to the atmospheric

temperatures.

Recommended engine oil classifi-

cation:

API STANDARD:

API “SE/SF/SG” or higher grade

(Designed primarily for

motorcycles)

a

b

ENGINE OIL REPLACEMENT

1. Start the engine, warm it up for several

minutes, and then turn off the engine and

wait for five minutes.

2. Place the machine on a level place and

hold it on upright position by placing the

suitable stand under the engine.

3. Place a suitable container under the

engine.

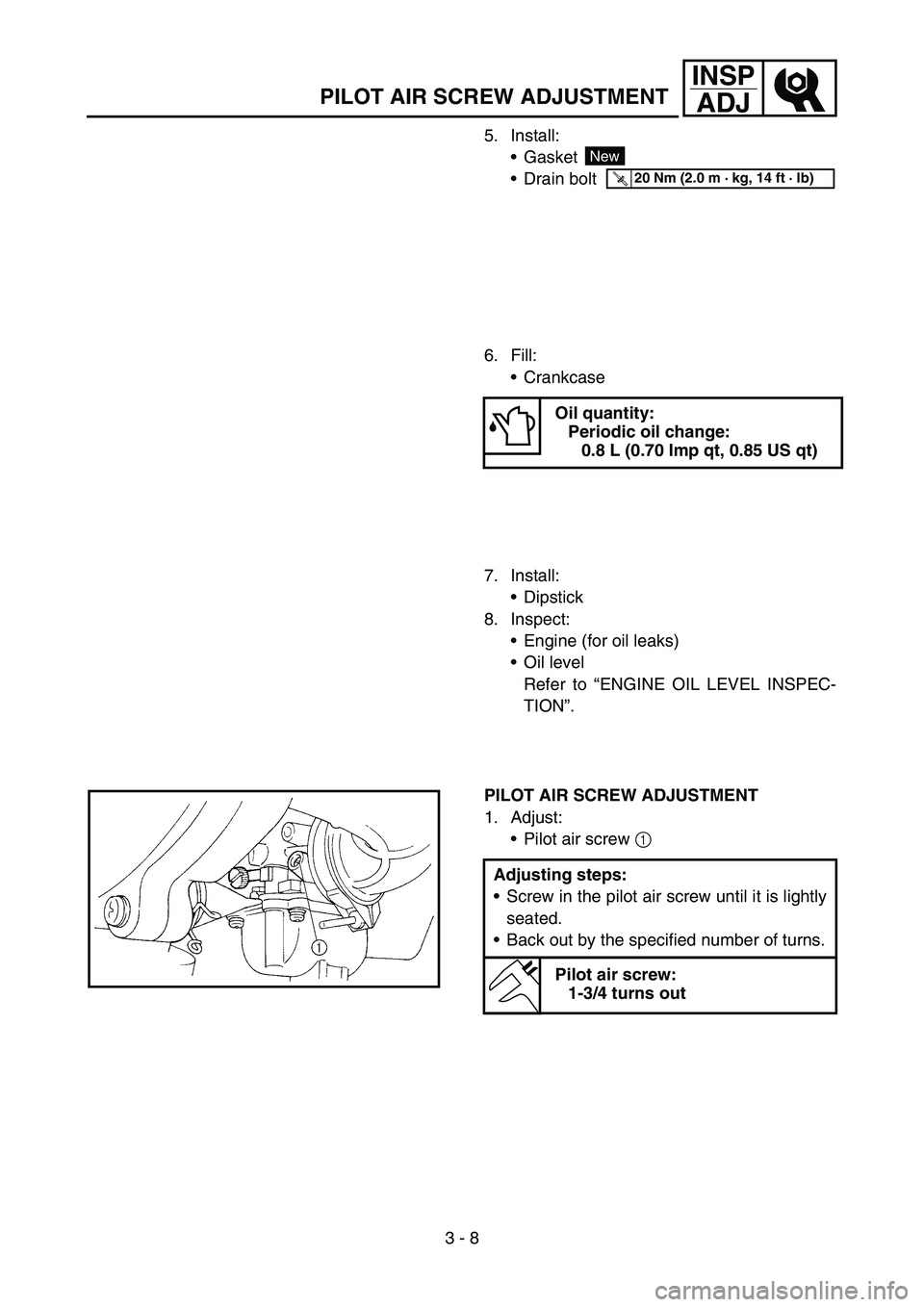

4. Remove:

Dipstick 1

Drain bolt (with gasket) 2

Drain the crankcase of its oil.

Page 146 of 390

3 - 8

INSP

ADJ

PILOT AIR SCREW ADJUSTMENT

5. Install:

Gasket

Drain bolt

New

T R..20 Nm (2.0 m · kg, 14 ft · lb)

6. Fill:

Crankcase

Oil quantity:

Periodic oil change:

0.8 L (0.70 Imp qt, 0.85 US qt)

7. Install:

Dipstick

8. Inspect:

Engine (for oil leaks)

Oil level

Refer to “ENGINE OIL LEVEL INSPEC-

TION”.

PILOT AIR SCREW ADJUSTMENT

1. Adjust:

Pilot air screw 1

Adjusting steps:

Screw in the pilot air screw until it is lightly

seated.

Back out by the specified number of turns.

Pilot air screw:

1-3/4 turns out

Page 148 of 390

3 - 9

INSP

ADJIDLE SPEED ADJUSTMENT/

VALVE CLEARANCE ADJUSTMENT

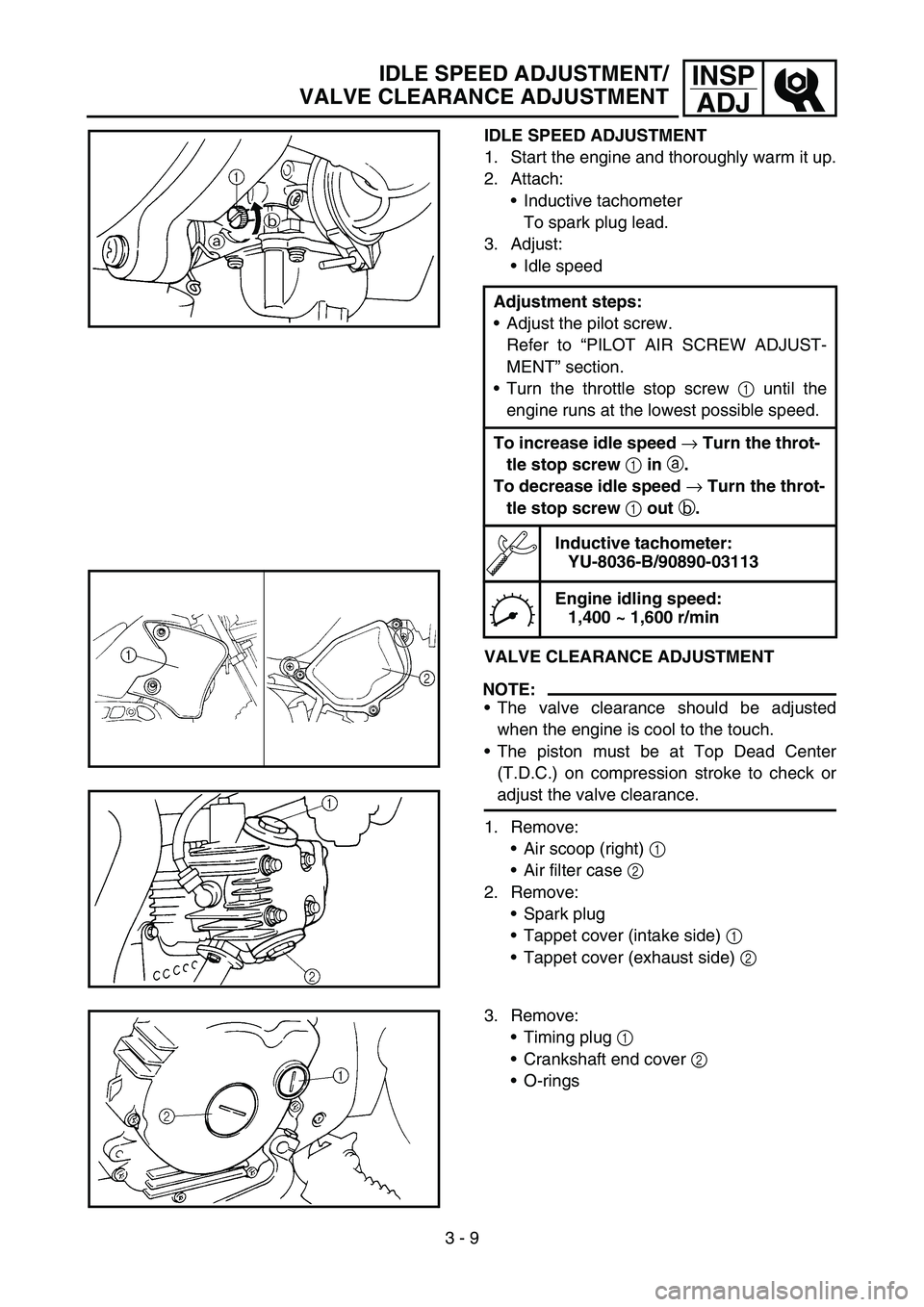

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Attach:

Inductive tachometer

To spark plug lead.

3. Adjust:

Idle speed

VALVE CLEARANCE ADJUSTMENT

NOTE:

The valve clearance should be adjusted

when the engine is cool to the touch.

The piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

Air scoop (right) 1

Air filter case 2

2. Remove:

Spark plug

Tappet cover (intake side) 1

Tappet cover (exhaust side) 2 Adjustment steps:

Adjust the pilot screw.

Refer to “PILOT AIR SCREW ADJUST-

MENT” section.

Turn the throttle stop screw 1 until the

engine runs at the lowest possible speed.

To increase idle speed

→ Turn the throt-

tle stop screw

1 in

a.

To decrease idle speed

→ Turn the throt-

tle stop screw

1 out

b.

Inductive tachometer:

YU-8036-B/90890-03113

Engine idling speed:

1,400 ~ 1,600 r/min

3. Remove:

Timing plug 1

Crankshaft end cover 2

O-rings

Page 152 of 390

3 - 11

INSP

ADJ

SPARK ARRESTER CLEANING (For USA)

6. Install:

Tappet cover (intake side) 1

O-ring 2

NOTE:

Apply the lithium soap base grease on the O-ring.

7. Install:

Tappet cover (exhaust side)

O-ring

Spark plug

Timing plug

Crankshaft end cover

NOTE:

Apply the lithium soap base grease on the O-ring.

8. Install:

Air filter case

Air scoop (right)

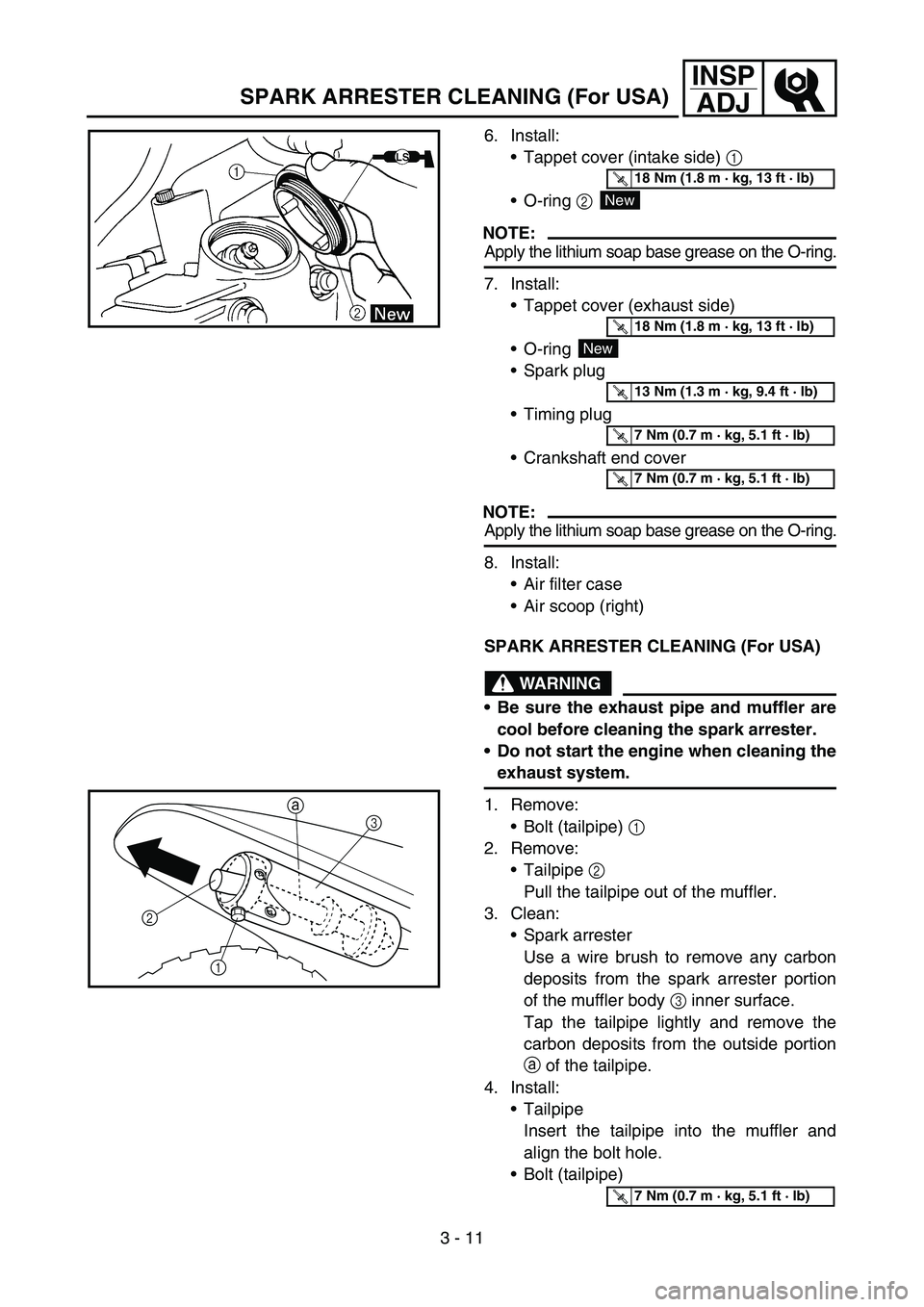

SPARK ARRESTER CLEANING (For USA)

WARNING

Be sure the exhaust pipe and muffler are

cool before cleaning the spark arrester.

Do not start the engine when cleaning the

exhaust system.

1. Remove:

Bolt (tailpipe) 1

2. Remove:

Tailpipe 2

Pull the tailpipe out of the muffler.

3. Clean:

Spark arrester

Use a wire brush to remove any carbon

deposits from the spark arrester portion

of the muffler body 3 inner surface.

Tap the tailpipe lightly and remove the

carbon deposits from the outside portion

a of the tailpipe.

4. Install:

Tailpipe

Insert the tailpipe into the muffler and

align the bolt hole.

Bolt (tailpipe)

T R..18 Nm (1.8 m · kg, 13 ft · lb)

New

T R..18 Nm (1.8 m · kg, 13 ft · lb)

New

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

2

1

3

a

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Page 158 of 390

3 - 14

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

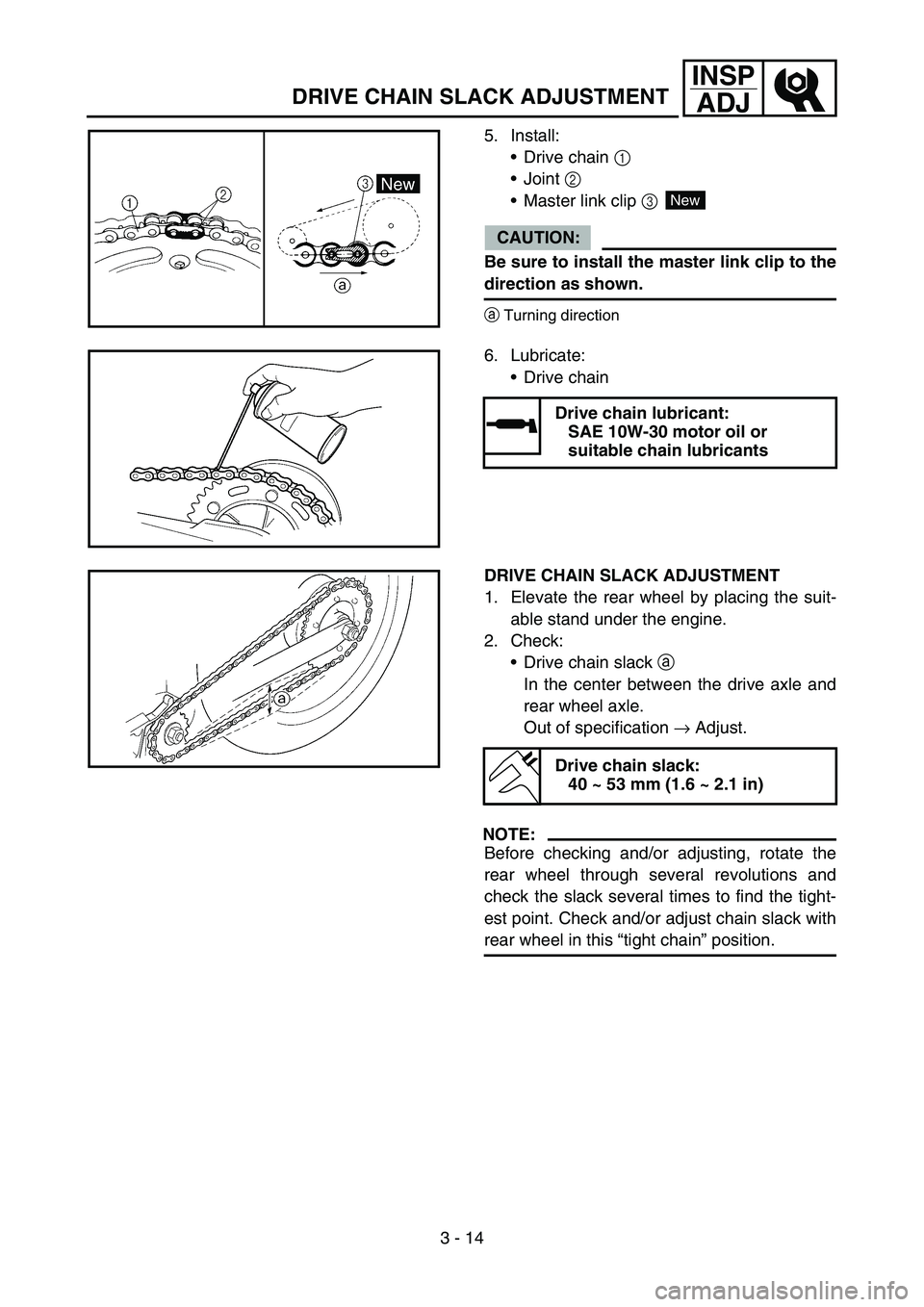

5. Install:

Drive chain 1

Joint 2

Master link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction

New

6. Lubricate:

Drive chain

Drive chain lubricant:

SAE 10W-30 motor oil or

suitable chain lubricants

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

Drive chain slack

a

In the center between the drive axle and

rear wheel axle.

Out of specification → Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

40 ~ 53 mm (1.6 ~ 2.1 in)

Page 160 of 390

3 - 15

INSP

ADJ

FRONT FORK INSPECTION

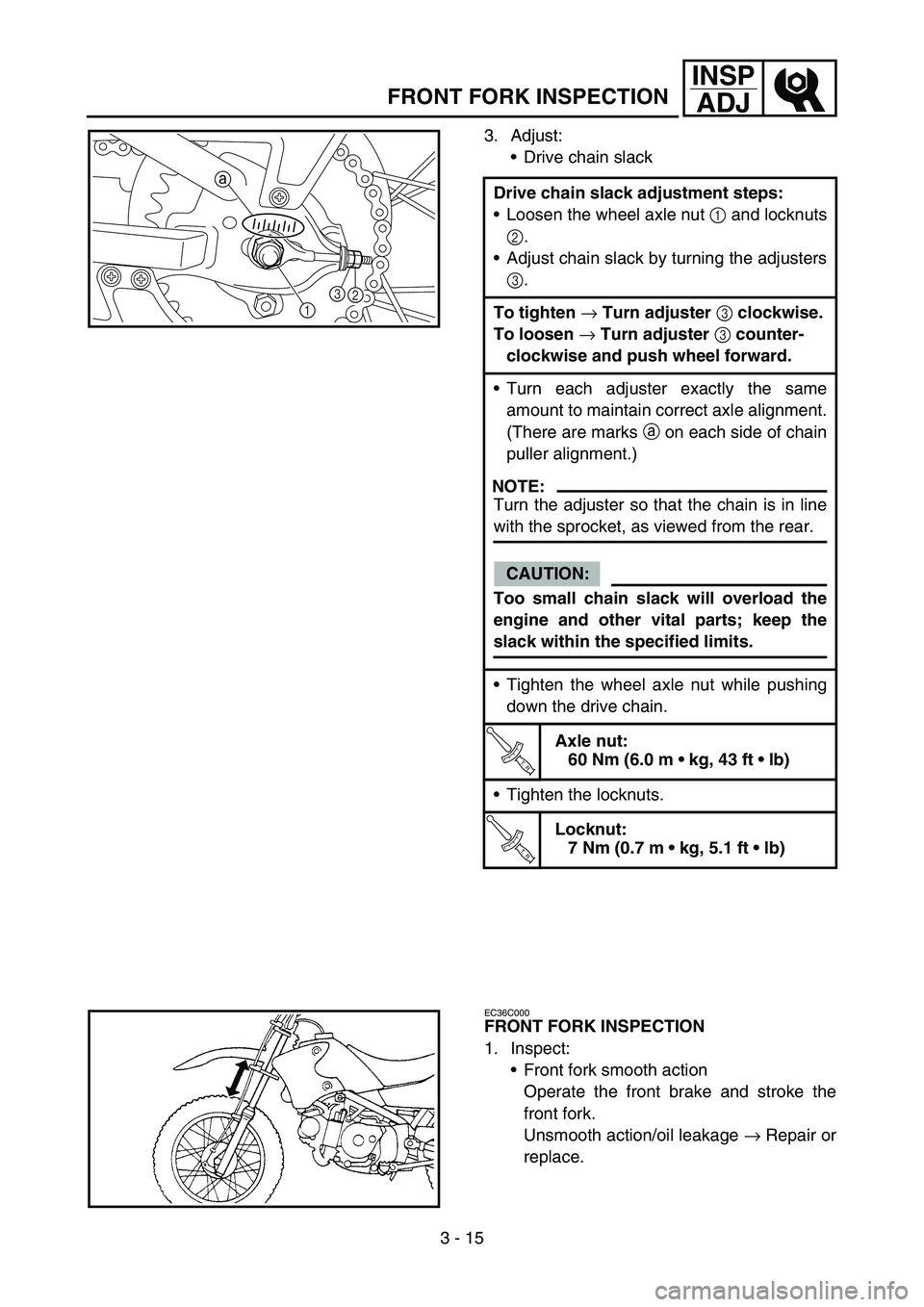

3. Adjust:

Drive chain slack

Drive chain slack adjustment steps:

Loosen the wheel axle nut 1 and locknuts

2.

Adjust chain slack by turning the adjusters

3.

To tighten

→ Turn adjuster

3 clockwise.

To loosen

→ Turn adjuster

3 counter-

clockwise and push wheel forward.

Turn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

Tighten the wheel axle nut while pushing

down the drive chain.

T R..

Axle nut:

60 Nm (6.0 m kg, 43 ft lb)

Tighten the locknuts.

T R..

Locknut:

7 Nm (0.7 m kg, 5.1 ft lb)

13 a2

EC36C000

FRONT FORK INSPECTION

1. Inspect:

Front fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage → Repair or

replace.

Page 162 of 390

3 - 16

INSP

ADJREAR SHOCK ABSORBER INSPECTION/

REAR SHOCK ABSORBER SPRING PRELOAD ADJUSTMENT

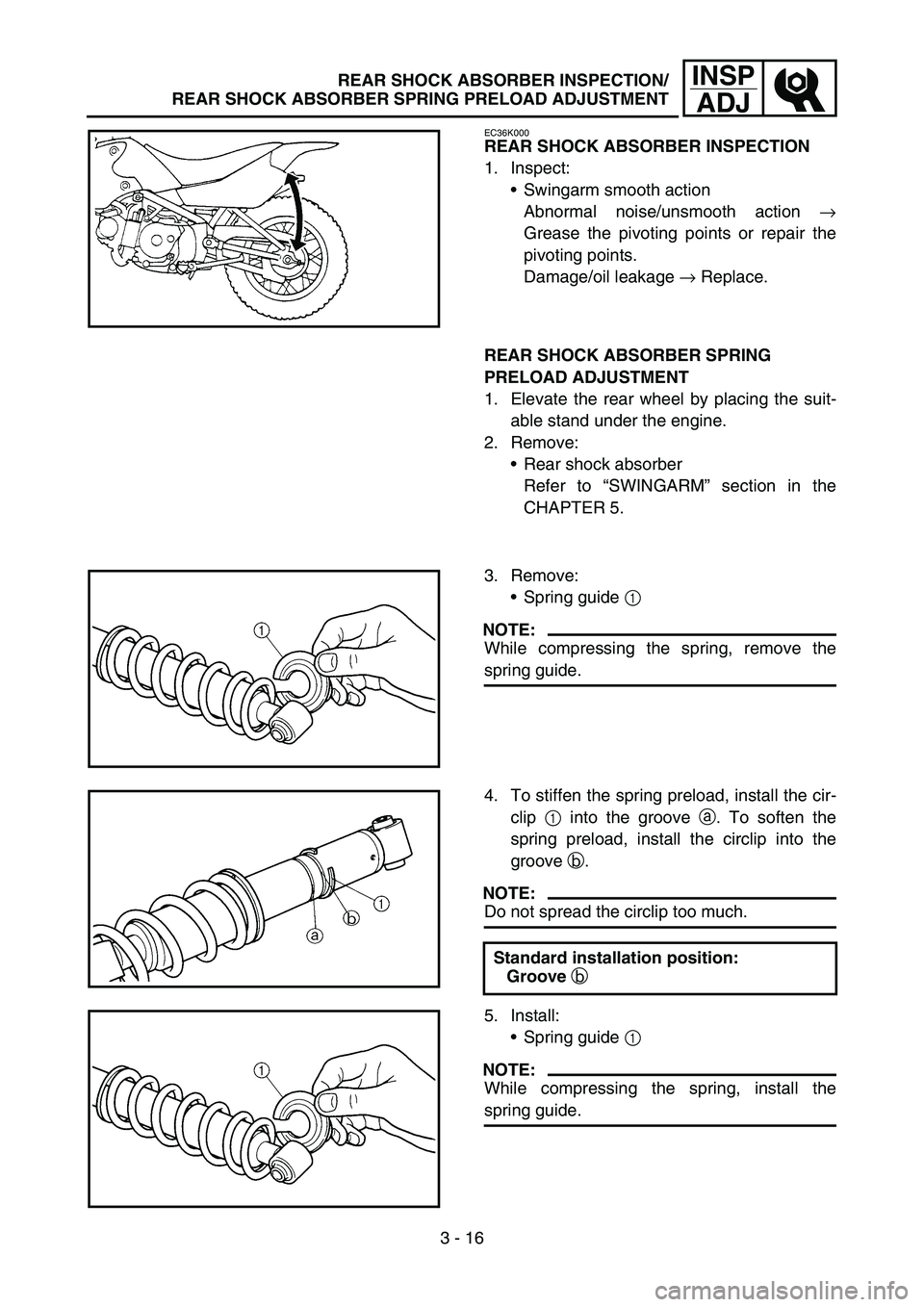

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

Swingarm smooth action

Abnormal noise/unsmooth action →

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage → Replace.

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Remove:

Rear shock absorber

Refer to “SWINGARM” section in the

CHAPTER 5.

3. Remove:

Spring guide 1

NOTE:

While compressing the spring, remove the

spring guide.

4. To stiffen the spring preload, install the cir-

clip 1 into the groove a. To soften the

spring preload, install the circlip into the

groove b.

NOTE:

Do not spread the circlip too much.

Standard installation position:

Groove b

5. Install:

Spring guide 1

NOTE:

While compressing the spring, install the

spring guide.

Page 166 of 390

3 - 18

INSP

ADJWHEEL INSPECTION/

STEERING HEAD INSPECTION AND ADJUSTMENT

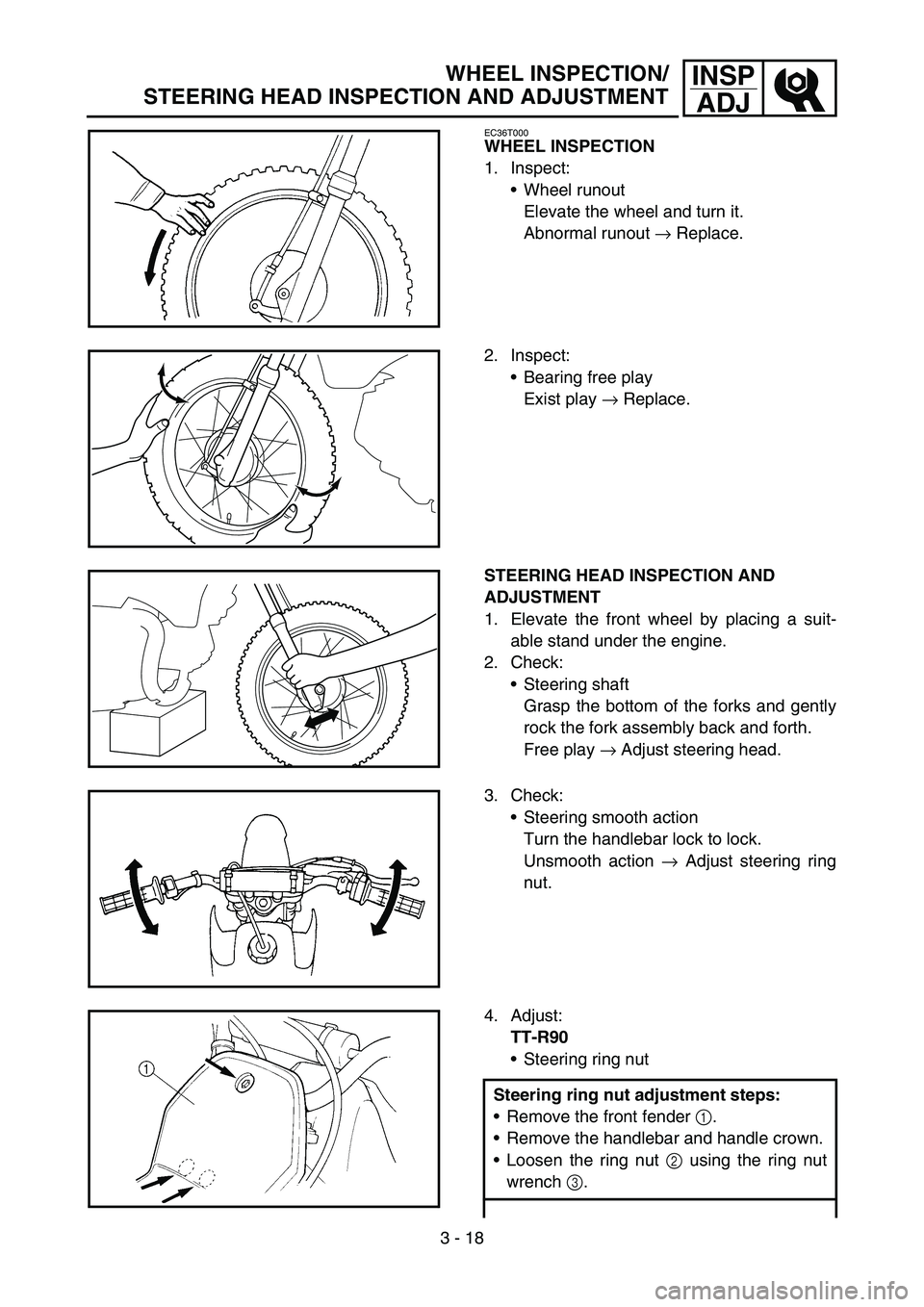

EC36T000

WHEEL INSPECTION

1. Inspect:

Wheel runout

Elevate the wheel and turn it.

Abnormal runout → Replace.

2. Inspect:

Bearing free play

Exist play → Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

Steering shaft

Grasp the bottom of the forks and gently

rock the fork assembly back and forth.

Free play → Adjust steering head.

3. Check:

Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action → Adjust steering ring

nut.

4. Adjust:

TT-R90

Steering ring nut

Steering ring nut adjustment steps:

Remove the front fender 1.

Remove the handlebar and handle crown.

Loosen the ring nut 2 using the ring nut

wrench 3.

Page 176 of 390

3 - 23

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode 1

Wear/damage → Replace.

Insulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color → Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

4. Clean the plug with a spark plug cleaner if

necessary.

Spark plug gap:

0.6 ~ 0.7 mm (0.02 ~ 0.03 in)

Standard spark plug:

CR6HSA (NGK)

U20FSR-U (DENSO)

5. Tighten:

Spark plug

NOTE:

Before installing a spark plug, clean the gas-

ket surface and plug surface.

Finger-tighten a the spark plug before torqu-

ing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)