engine YAMAHA TTR90 2006 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 196 of 390

4 - 1

ENG

ENGINE

CARBURETOR

Extent of removal:

1 Carburetor removal

Extent of removal Order Part name Q’ty Remarks

CARBURETOR REMOVAL

Preparation for removal Fuel tank

1 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

2 Carburetor heater lead 1

3 Air vent hose 1

4 Fuel hose 1

5Bolt 2

6 Carburetor assembly 1

7O-ring 2

8Spacer 1

9 Carburetor top 1

10 Starter plunger assembly 1

1

CARBURETOR

Page 216 of 390

4 - 11

ENGCYLINDER HEAD

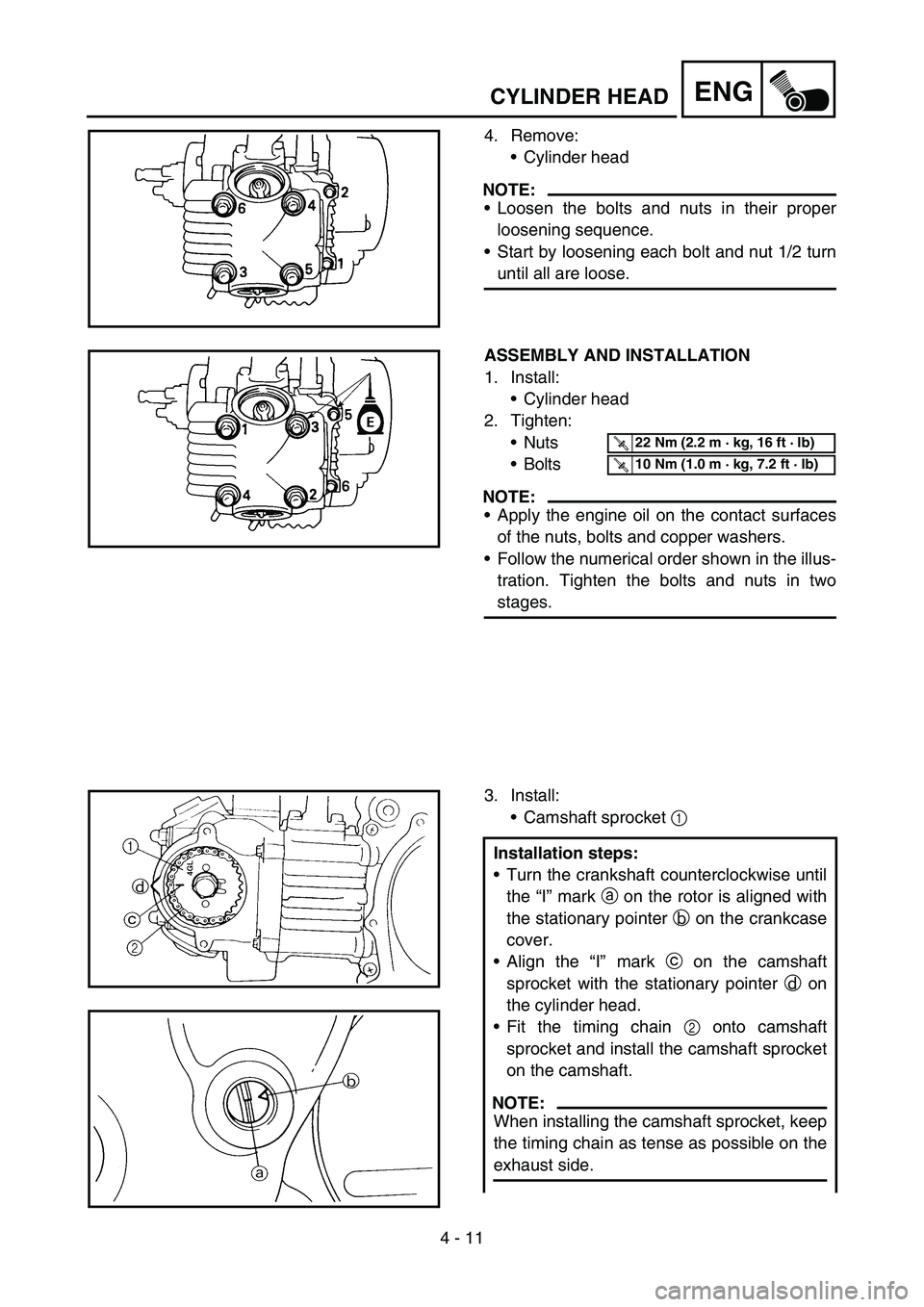

4. Remove:

Cylinder head

NOTE:

Loosen the bolts and nuts in their proper

loosening sequence.

Start by loosening each bolt and nut 1/2 turn

until all are loose.

ASSEMBLY AND INSTALLATION

1. Install:

Cylinder head

2. Tighten:

Nuts

Bolts

NOTE:

Apply the engine oil on the contact surfaces

of the nuts, bolts and copper washers.

Follow the numerical order shown in the illus-

tration. Tighten the bolts and nuts in two

stages.

T R..22 Nm (2.2 m · kg, 16 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

3. Install:

Camshaft sprocket 1

Installation steps:

Turn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

Align the “I” mark c on the camshaft

sprocket with the stationary pointer d on

the cylinder head.

Fit the timing chain 2 onto camshaft

sprocket and install the camshaft sprocket

on the camshaft.

NOTE:

When installing the camshaft sprocket, keep

the timing chain as tense as possible on the

exhaust side.

Page 222 of 390

4 - 14

ENGCAMSHAFT AND ROCKER ARMS

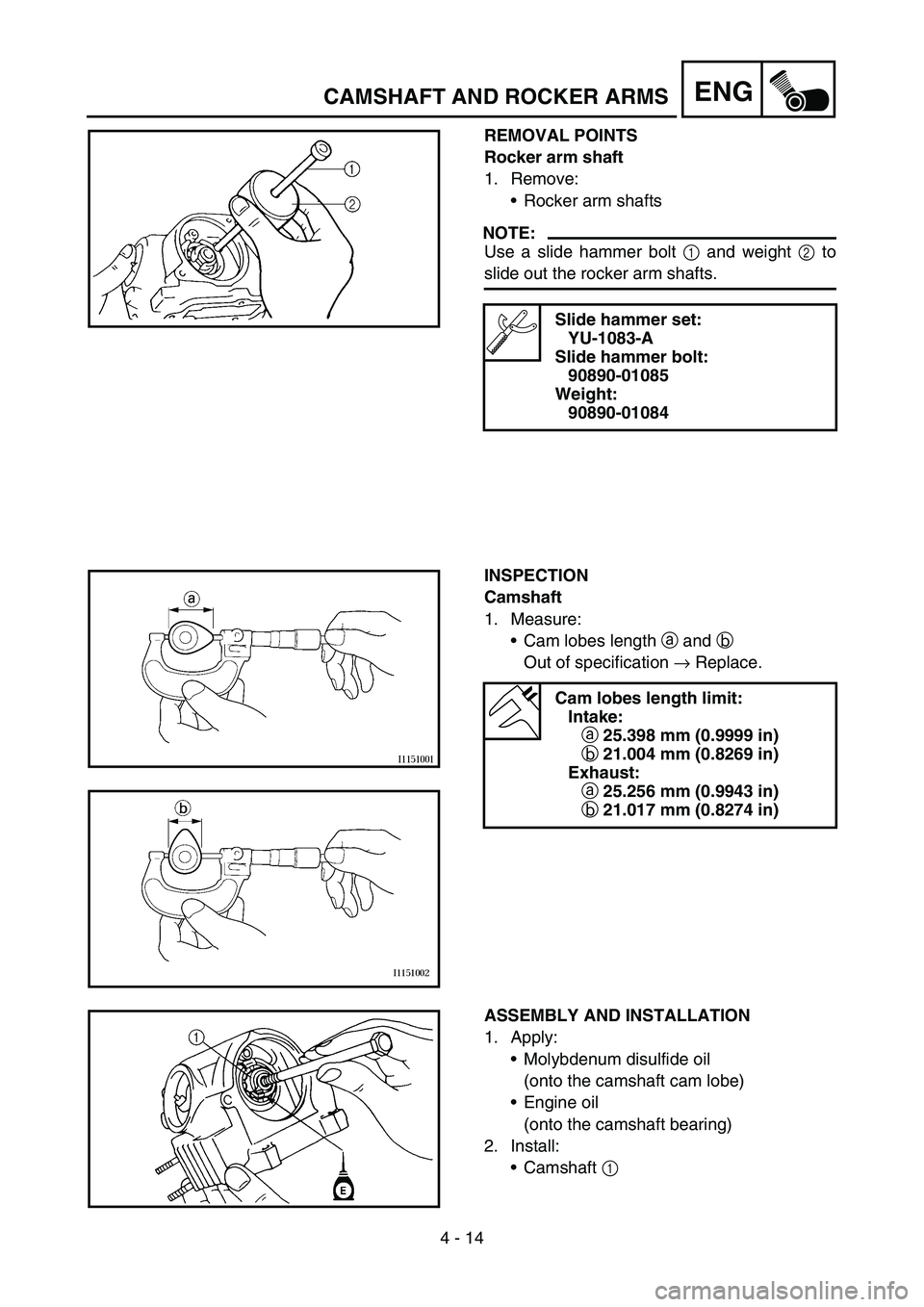

REMOVAL POINTS

Rocker arm shaft

1. Remove:

Rocker arm shafts

NOTE:

Use a slide hammer bolt 1 and weight 2 to

slide out the rocker arm shafts.

Slide hammer set:

YU-1083-A

Slide hammer bolt:

90890-01085

Weight:

90890-01084

INSPECTION

Camshaft

1. Measure:

Cam lobes length a and b

Out of specification → Replace.

Cam lobes length limit:

Intake:

a 25.398 mm (0.9999 in)

b 21.004 mm (0.8269 in)

Exhaust:

a 25.256 mm (0.9943 in)

b 21.017 mm (0.8274 in)

ASSEMBLY AND INSTALLATION

1. Apply:

Molybdenum disulfide oil

(onto the camshaft cam lobe)

Engine oil

(onto the camshaft bearing)

2. Install:

Camshaft 1

Page 244 of 390

4 - 25

ENGCYLINDER AND PISTON

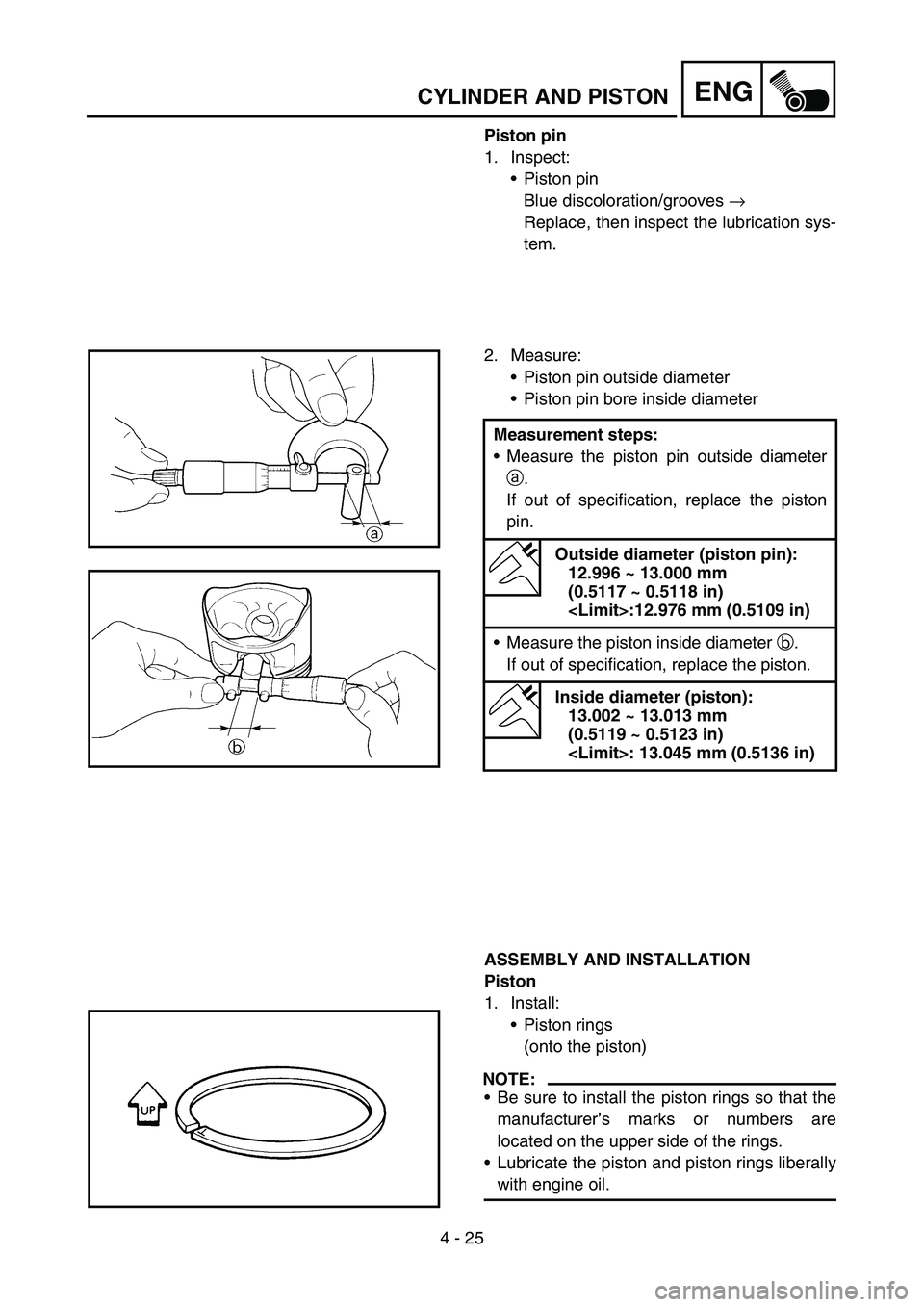

Piston pin

1. Inspect:

Piston pin

Blue discoloration/grooves →

Replace, then inspect the lubrication sys-

tem.

2. Measure:

Piston pin outside diameter

Piston pin bore inside diameter

ASSEMBLY AND INSTALLATION

Piston

1. Install:

Piston rings

(onto the piston)

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers are

located on the upper side of the rings.

Lubricate the piston and piston rings liberally

with engine oil. Measurement steps:

Measure the piston pin outside diameter

a.

If out of specification, replace the piston

pin.

Outside diameter (piston pin):

12.996 ~ 13.000 mm

(0.5117 ~ 0.5118 in)

Measure the piston inside diameter b.

If out of specification, replace the piston.

Inside diameter (piston):

13.002 ~ 13.013 mm

(0.5119 ~ 0.5123 in)

Page 246 of 390

4 - 26

ENGCYLINDER AND PISTON

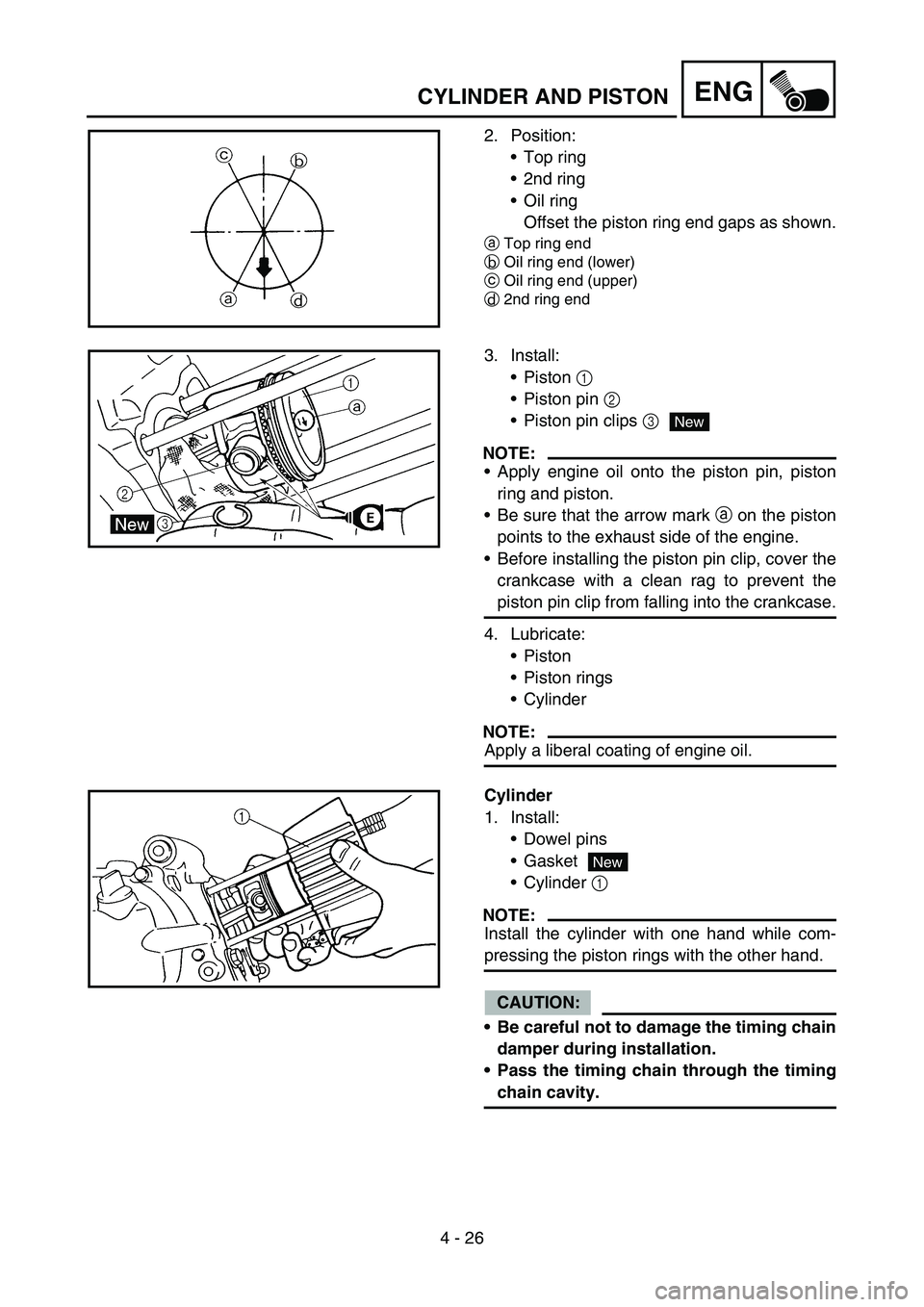

2. Position:

Top ring

2nd ring

Oil ring

Offset the piston ring end gaps as shown.

aTop ring end

bOil ring end (lower)

cOil ring end (upper)

d2nd ring end

3. Install:

Piston 1

Piston pin 2

Piston pin clips 3

NOTE:

Apply engine oil onto the piston pin, piston

ring and piston.

Be sure that the arrow mark

a on the piston

points to the exhaust side of the engine.

Before installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

4. Lubricate:

Piston

Piston rings

Cylinder

NOTE:

Apply a liberal coating of engine oil.

New

Cylinder

1. Install:

Dowel pins

Gasket

Cylinder 1

NOTE:

Install the cylinder with one hand while com-

pressing the piston rings with the other hand.

CAUTION:

Be careful not to damage the timing chain

damper during installation.

Pass the timing chain through the timing

chain cavity.

New

Page 248 of 390

4 - 27

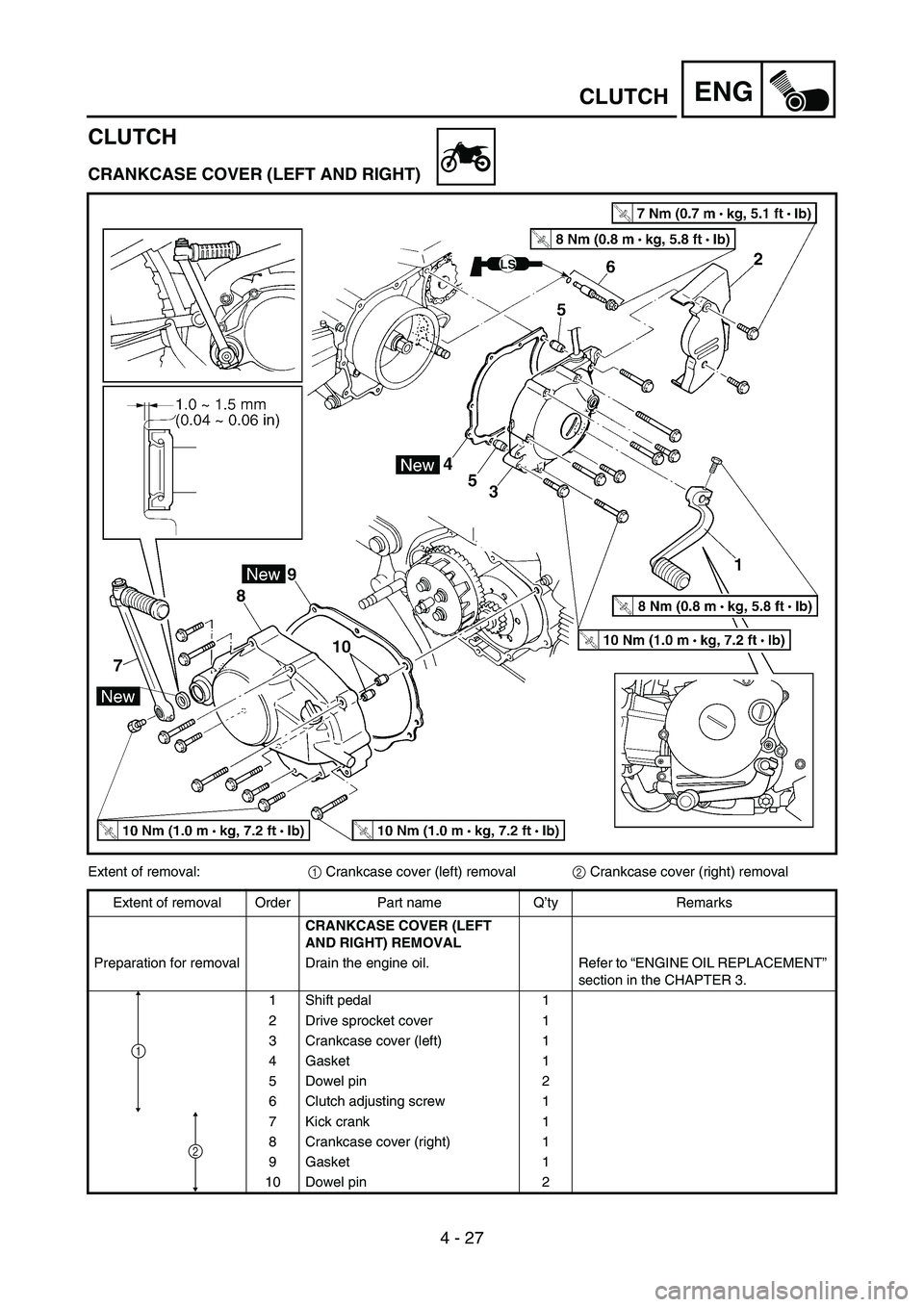

ENGCLUTCH

CLUTCH

CRANKCASE COVER (LEFT AND RIGHT)

Extent of removal:

1 Crankcase cover (left) removal

2 Crankcase cover (right) removal

Extent of removal Order Part name Q’ty Remarks

CRANKCASE COVER (LEFT

AND RIGHT) REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

1 Shift pedal 1

2 Drive sprocket cover 1

3 Crankcase cover (left) 1

4 Gasket 1

5 Dowel pin 2

6 Clutch adjusting screw 1

7 Kick crank 1

8 Crankcase cover (right) 1

9 Gasket 1

10 Dowel pin 2

2

1

Page 282 of 390

4 - 44

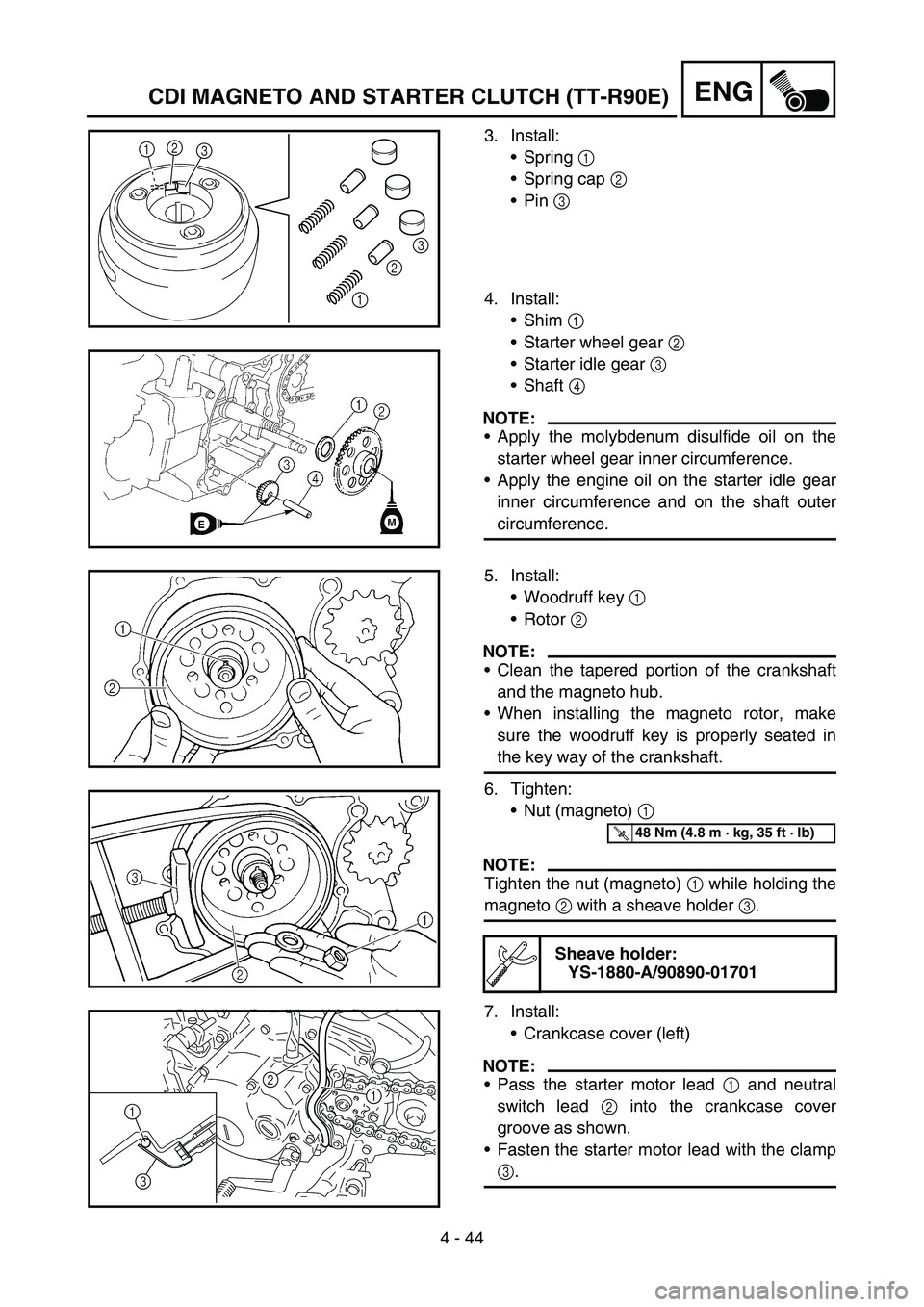

ENGCDI MAGNETO AND STARTER CLUTCH (TT-R90E)

3. Install:

Spring 1

Spring cap 2

Pin 3

4. Install:

Shim 1

Starter wheel gear 2

Starter idle gear 3

Shaft 4

NOTE:

Apply the molybdenum disulfide oil on the

starter wheel gear inner circumference.

Apply the engine oil on the starter idle gear

inner circumference and on the shaft outer

circumference.

12

3

123

5. Install:

Woodruff key 1

Rotor 2

NOTE:

Clean the tapered portion of the crankshaft

and the magneto hub.

When installing the magneto rotor, make

sure the woodruff key is properly seated in

the key way of the crankshaft.

6. Tighten:

Nut (magneto) 1

NOTE:

Tighten the nut (magneto) 1 while holding the

magneto 2 with a sheave holder 3.

7. Install:

Crankcase cover (left)

NOTE:

Pass the starter motor lead 1 and neutral

switch lead 2 into the crankcase cover

groove as shown.

Fasten the starter motor lead with the clamp

3.

Sheave holder:

YS-1880-A/90890-01701

T R..48 Nm (4.8 m · kg, 35 ft · lb)

2

1

1

3

Page 284 of 390

4 - 45

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

CRANKCASE SEPARATION

AND CRANKSHAFT REMOVAL

Preparation for removal Seat, fuel tank and rear fender

Exhaust pipe

Air filter case

Carburetor Refer to “CARBURETOR” section.

Drain the engine oil Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Engine guard and drive sprocket

Engine assembly From the chassis.

Cylinder head Refer to “CYLINDER HEAD” section.

Cylinder and piston Refer to “CYLINDER AND PISTON” sec-

tion.

Clutch housing and clutch carrier Refer to “CLUTCH” section.

Kick axle assembly Refer to “KICK AXLE” section.

Page 290 of 390

4 - 48

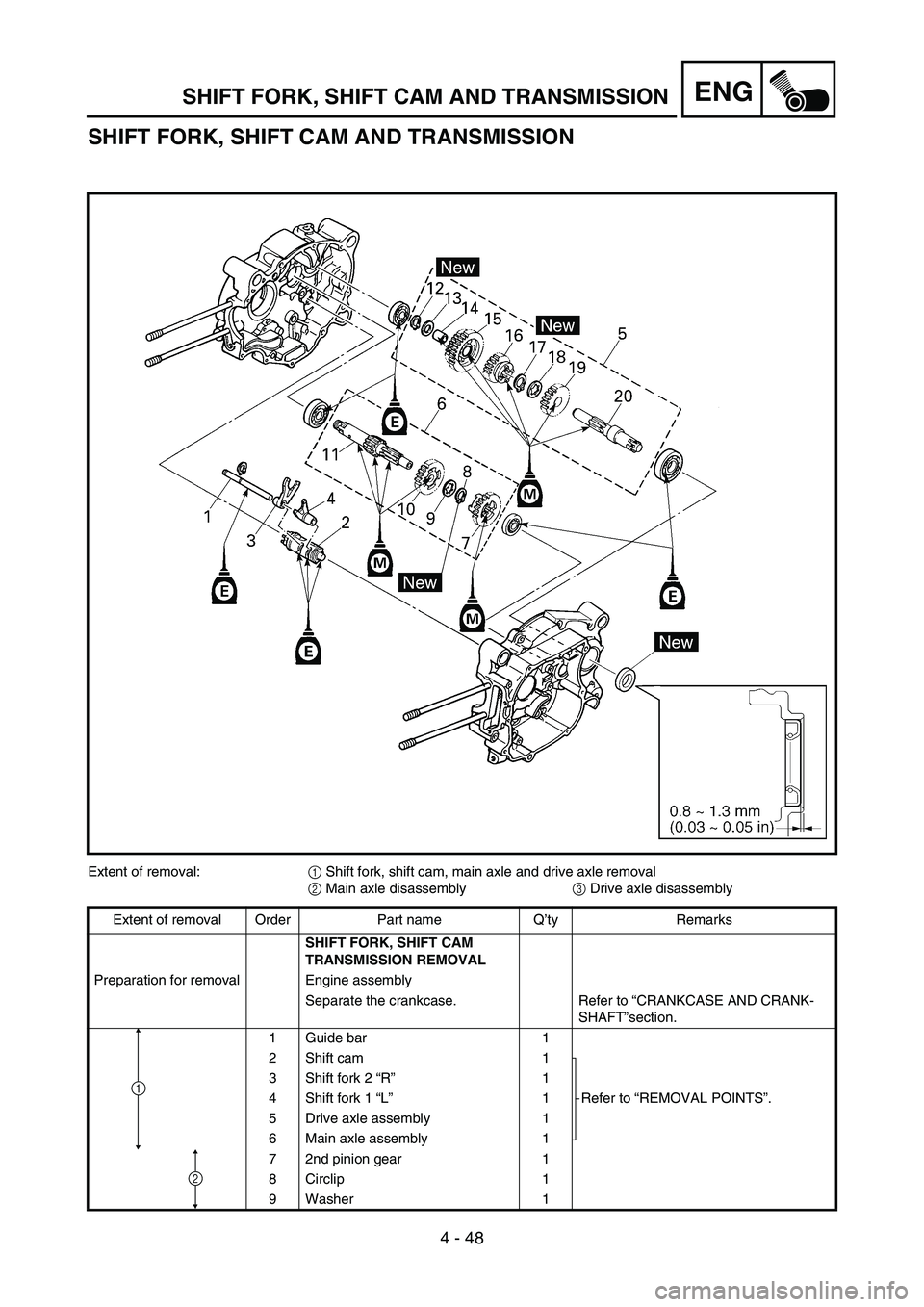

ENGSHIFT FORK, SHIFT CAM AND TRANSMISSION

SHIFT FORK, SHIFT CAM AND TRANSMISSION

Extent of removal:

1 Shift fork, shift cam, main axle and drive axle removal

2 Main axle disassembly

3 Drive axle disassembly

Extent of removal Order Part name Q’ty Remarks

SHIFT FORK, SHIFT CAM

TRANSMISSION REMOVAL

Preparation for removal Engine assembly

Separate the crankcase. Refer to “CRANKCASE AND CRANK-

SHAFT”section.

1 Guide bar 1

2Shift cam 1

Refer to “REMOVAL POINTS”. 3 Shift fork 2 “R”1

4 Shift fork 1 “L”1

5 Drive axle assembly 1

6 Main axle assembly 1

7 2nd pinion gear 1

8 Circlip 1

9 Washer 1

2

1

Page 294 of 390

4 - 50

ENGSHIFT FORK, SHIFT CAM AND TRANSMISSION

EC4H3000

REMOVAL POINTS

Shift fork, shift cam and transmission

1. Remove:

Shift forks

Shift cam

Drive axle assembly

Main axle assembly

NOTE:

Tap lightly on the transmission drive axle and

shift cam with a soft hammer to remove.

Remove assembly carefully. Note the posi-

tion of each part. Pay particular attention to

the location and direction of shift forks.

ASSEMBLY AND INSTALLATION

Transmission, shift cam shift fork

1. Install:

Main axle assembly 1

Drive axle assembly 2

2. Install:

Shift fork 1 “L” 1

Shift fork 2 “R” 2

Shift cam 3

Guide bar 4

NOTE:

The embossed marks on the shift forks should

face towards the right side of the engine and

be in the following sequence: “R”, “L”.

3. Check:

Shifter operation

Transmission operation

Unsmooth operation → Repair.