ignition YAMAHA VX110 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 244 of 347

7-17

E

–+ELEC

NOTE:

To crank the engine, connect the engine shut-

off cord (lanyard) to the engine shut-off switch,

and then press the start switch and engine

stop switch simultaneously.

4. Measure:

Rectifier/regulator output voltage

Below specification →

Replace the recti-

fier/regulator.

NOTE:

Do not use the peak voltage adapter to mea-

sure the output voltage.

Disconnect the output lead of the tester har-

ness.

Test harness (6 pins):

YB-06848

Test harness FSW-6A (6 pins):

90890-06848

Rectifier/regulator output

voltage:

Red (R) – Black (B)

r/minUnloaded

3,500

V 13.0

BATTERY

Refer to “ELECTRICAL” in Chapter 3.

FUSE

Refer to “STARTING SYSTEM”.

SPARK PLUGS

Refer to “POWER UNIT” in Chapter 3.

IGNITION SYSTEM

ProCarManuals.com

Page 245 of 347

7-18

E

–+ELEC

IGNITION COIL

1. Measure:

Primary coil resistance

Out of specification →

Replace.

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measurement

cannot be obtained because of the tester’s

internal resistance.

Refer to “Low resistance measurement”.

Primary coil resistance:

1.19–1.61

Ω at 20 °C (68 °F)

2. Measure:

Secondary coil resistance

Out of specification →

Replace.

Secondary coil resistance:

8.5–11.5 k

Ω at 20 °C (68 °F)

ENGINE STOP SWITCH

1. Check:

Engine stop switch continuity

Out of specification →

Replace.

Engine stop switch continuity

(black coupler)

Clip PositionLead color

White Black

InstalledFree

Push

RemovedFree

Push

IGNITION SYSTEM

ProCarManuals.com

Page 246 of 347

7-19

E

–+ELECIGNITION SYSTEM

ENGINE TEMPERATURE SENSOR

1. Measure:

Engine temperature sensor resistance

(at the specified temperature)

Out of specification →

Replace.

Engine temperature sensor

resistance:

20 °C (68 °F): 54.2–69.0 k

Ω

100 °C (212 °F): 3.12–3.48 k

Ω

Measurement steps:

Suspend the engine temperature sensor

in a container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the resistance when the speci-

fied temperature is reached.

SENSOR ASSEMBLY

1. Check:

Intake air temperature sensor

Out of specification →

Replace the sen-

sor assembly.

Checking steps:

Measure the ambient temperature.

Connect a computer to the watercraft and

use the Yamaha Diagnostic System to

display the intake air temperature.

If the ambient temperature and the dis-

played intake air temperature differ by

more than ±

5 °C (±

9 °F), replace the

sensor assembly.

ProCarManuals.com

Page 247 of 347

7-20

E

–+ELECIGNITION SYSTEM

THERMOSWITCH (ENGINE)

1. Check:

Thermoswitch (engine) continuity

(at the specified temperature)

Out of specification →

Replace.

1 No continuity

È Temperature

2 Continuity

É Time

NOTE:

The thermoswitch (engine) connector is blue.

Thermoswitch (engine) continuity

temperature:

a 84–90 °C (183–194 °F)

b 70–84 °C (158–183 °F)

Checking steps:

Suspend the thermoswitch (engine) in a

container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the continuity when the speci-

fied temperature is reached.

ProCarManuals.com

Page 248 of 347

7-21

E

–+ELEC

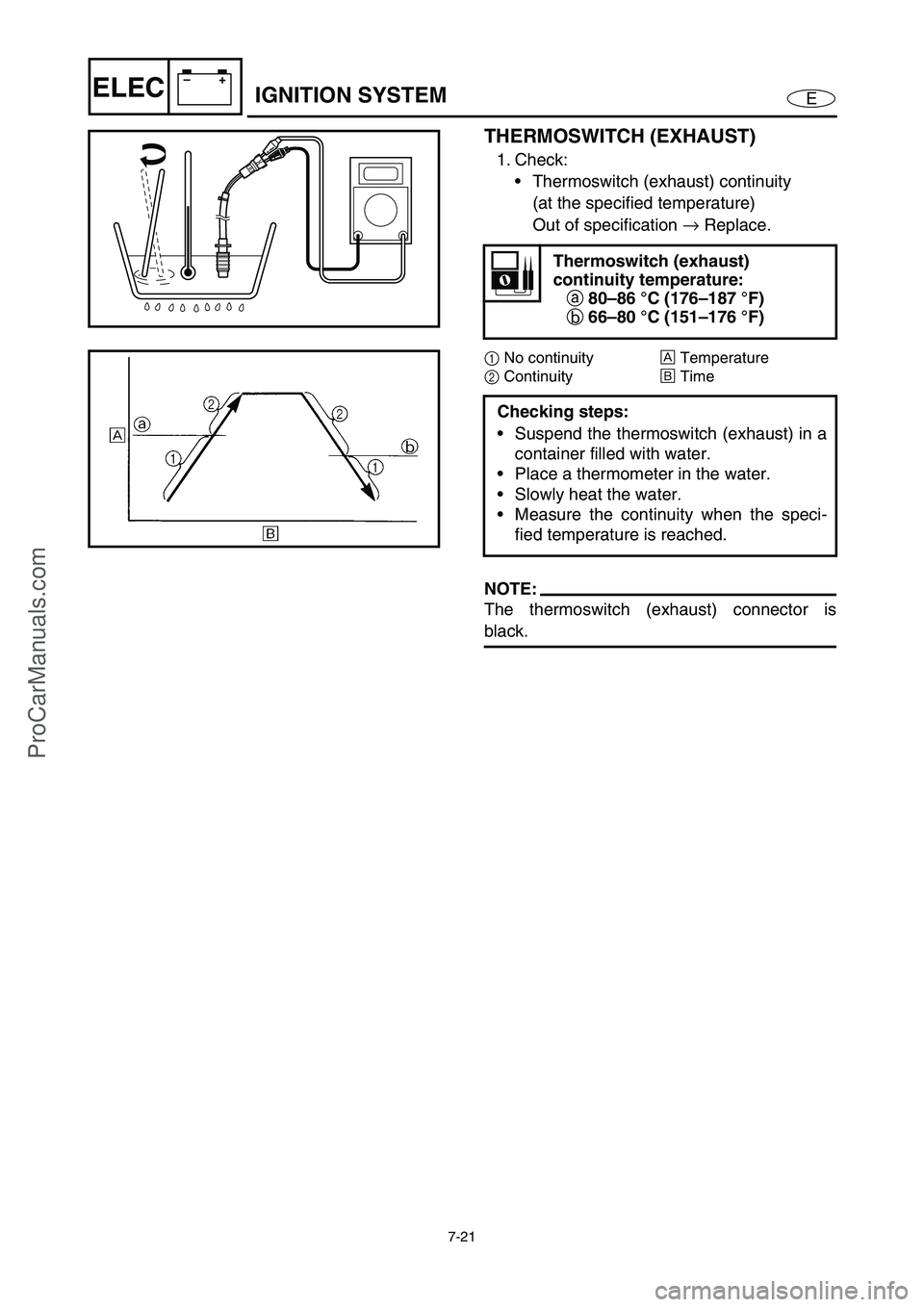

THERMOSWITCH (EXHAUST)

1. Check:

Thermoswitch (exhaust) continuity

(at the specified temperature)

Out of specification →

Replace.

1 No continuity

È Temperature

2 Continuity

É Time

NOTE:

The thermoswitch (exhaust) connector is

black.

Thermoswitch (exhaust)

continuity temperature:

a 80–86 °C (176–187 °F)

b 66–80 °C (151–176 °F)

Checking steps:

Suspend the thermoswitch (exhaust) in a

container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the continuity when the speci-

fied temperature is reached.

IGNITION SYSTEM

ProCarManuals.com

Page 249 of 347

7-22

E

–+ELECIGNITION SYSTEM

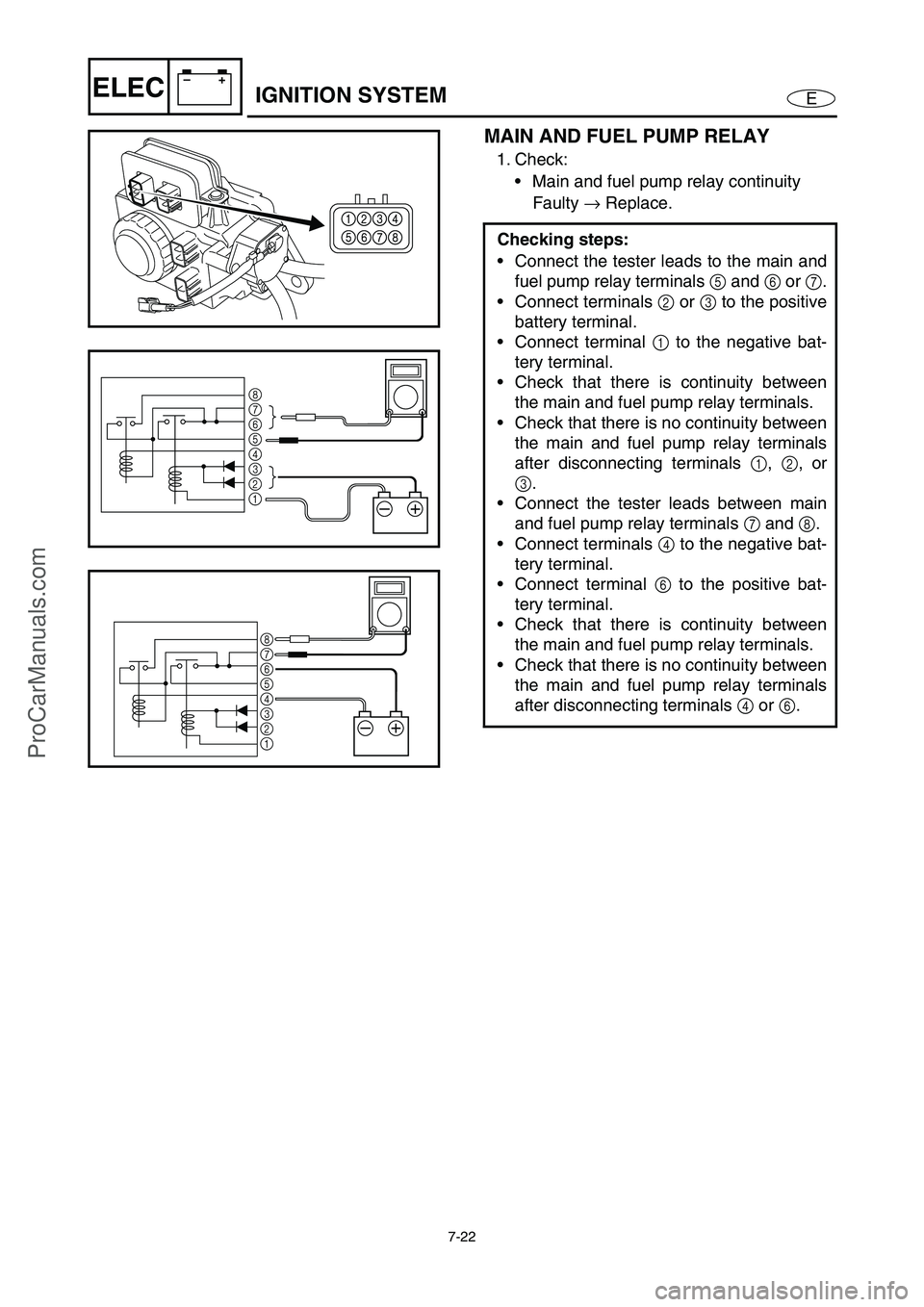

MAIN AND FUEL PUMP RELAY

1. Check:

• Main and fuel pump relay continuity

Faulty → Replace.

Checking steps:

Connect the tester leads to the main and

fuel pump relay terminals 5 and 6 or 7.

Connect terminals 2 or 3 to the positive

battery terminal.

Connect terminal 1 to the negative bat-

tery terminal.

Check that there is continuity between

the main and fuel pump relay terminals.

Check that there is no continuity between

the main and fuel pump relay terminals

after disconnecting terminals 1, 2, or

3.

Connect the tester leads between main

and fuel pump relay terminals 7 and 8.

Connect terminals 4 to the negative bat-

tery terminal.

Connect terminal 6 to the positive bat-

tery terminal.

Check that there is continuity between

the main and fuel pump relay terminals.

Check that there is no continuity between

the main and fuel pump relay terminals

after disconnecting terminals 4 or 6.

–+

8

7

6

5

4

3

2

1

–+

8

7

6

5

4

3

2

1

ProCarManuals.com

Page 250 of 347

7-23

E

–+ELEC

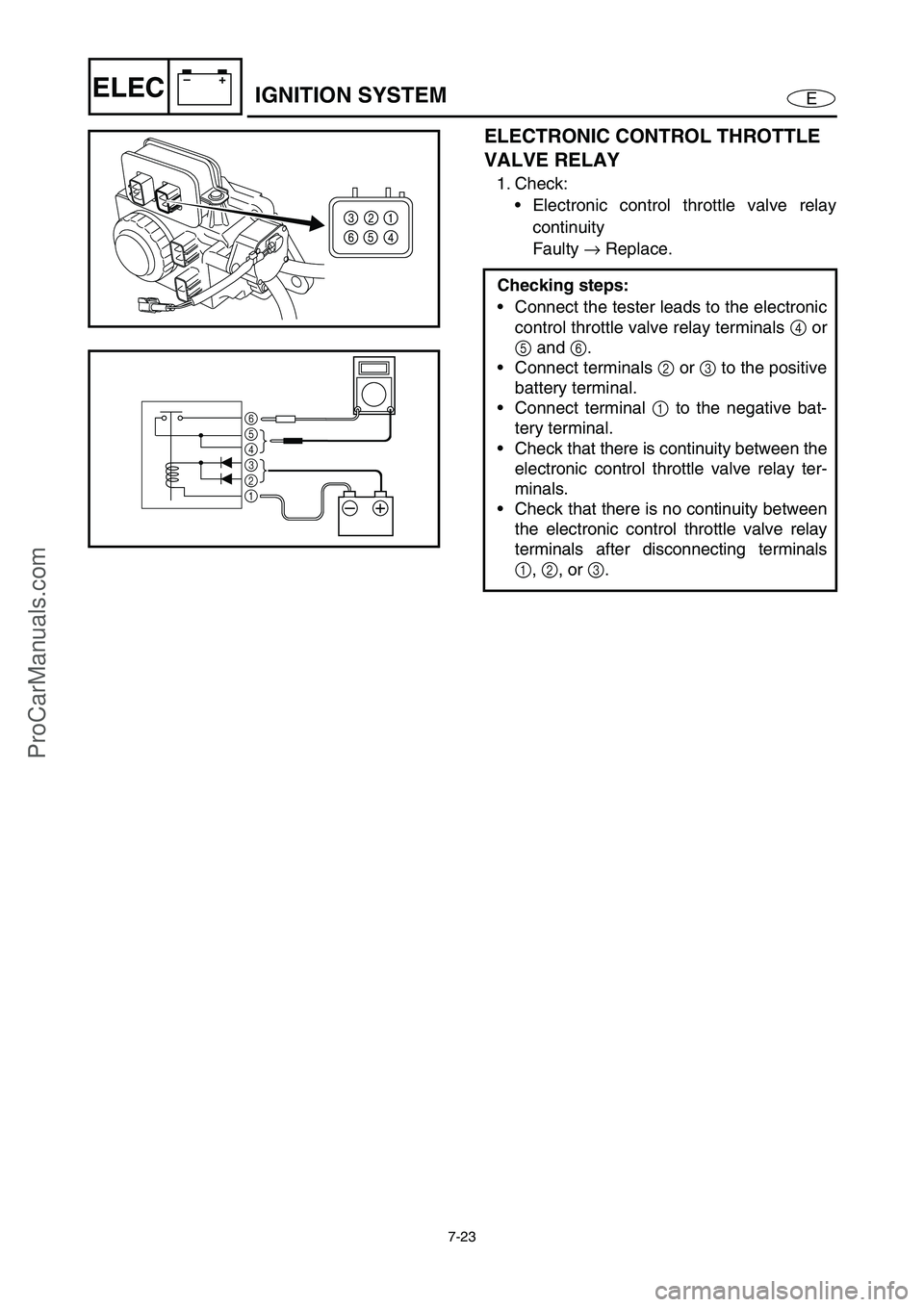

ELECTRONIC CONTROL THROTTLE

VALVE RELAY

1. Check:

Electronic control throttle valve relay

continuity

Faulty →

Replace.

Checking steps:

Connect the tester leads to the electronic

control throttle valve relay terminals 4

or

5

and 6

.

Connect terminals 2

or 3

to the positive

battery terminal.

Connect terminal 1

to the negative bat-

tery terminal.

Check that there is continuity between the

electronic control throttle valve relay ter-

minals.

Check that there is no continuity between

the electronic control throttle valve relay

terminals after disconnecting terminals

1

, 2

, or 3

.

–+

6

5

4

3

2

1

IGNITION SYSTEM

ProCarManuals.com

Page 251 of 347

7-24

E

–+ELECIGNITION SYSTEM

THROTTLE POSITION SENSOR

1. Measure:

Throttle position sensor output voltage

Out of specification →

Replace the

throttle body assembly.

Checking steps:

CAUTION:

Do not loosen the throttle stop screw nut

and do not turn the throttle stop screw.

Connect a computer to the watercraft and

use the Yamaha Diagnostic System to

display the “throttle position sensor 1 out-

put voltage”, “throttle valve opening

angle”, and “throttle position sensor 2

output voltage”.

Release the throttle lever to the fully

closed position.

Check the output voltage of throttle posi-

tion sensor 1 and the throttle valve open-

ing angle.

1Throttle position sensor 1

2Throttle position sensor 2

ÈThrottle position sensor output voltage

ÉThrottle valve opening angle

ÊFully closed

ËFully open

NOTE:

The actual throttle position sensor output

voltage and throttle valve opening angle

may vary according to environmental condi-

tions.

Throttle position sensor 1 output

voltage with throttle lever fully

closed:

0.45–0.95 V (reference data)

Throttle valve opening angle with

throttle lever fully closed:

–1.1–9.4° (reference data)

2 ± 0.1 V

0.5 ± 0.05 V 4.65

± 0.05 V

(4.5 V)

(10˚)

É

ÊË È1 2

ProCarManuals.com

Page 252 of 347

7-25

E

–+ELECIGNITION SYSTEM

Squeeze the throttle lever to the fully

open position and hold it.

Check the output voltage of throttle posi-

tion sensor 2 and the throttle valve open-

ing angle.

Throttle position sensor 2 output

voltage with throttle lever fully

open:

4.60–4.70 V

Throttle valve opening angle with

throttle lever fully open:

above 80° (reference data)

Release the throttle lever from the fully

open position to the fully closed position

slowly and check the output voltage of

throttle position sensor 2 and the throttle

valve opening angle.

Hold the throttle lever when the output

voltage of throttle position sensor 2 is

below 4.5 V and the throttle valve open-

ing angle is above 10°.

Calculate the difference of the output

voltage of throttle position sensor 1 and

the output voltage of throttle position sen-

sor 2.

Throttle position sensor 2 output

voltage – throttle position sensor

1 output voltage = 1.9–2.1 V

Example:

If the output voltage of throttle position sen-

sor 1 is 2.5 V and the output voltage of

throttle position sensor 2 is 4.5 V, then

4.5 – 2.5 = 2.0 V

Operate the throttle lever and check that

the output voltage of throttle position sen-

sors 1 and 2 changes continuously.

NOTE:

The maximum output voltage of throttle

position sensor 2 is 4.65 ±

0.05 V at the half

open position.

ProCarManuals.com

Page 253 of 347

7-26

E

–+ELECIGNITION SYSTEM

ACCELERATOR POSITION SENSOR

1. Measure:

Accelerator position sensor output volt-

age

Out of specification →

Replace the

accelerator position sensor.

Checking steps:

Connect a computer to the watercraft and

use the Yamaha Diagnostic System to

display the “accelerator position sensor

1” and “accelerator position sensor 2”.

Release the throttle lever to the fully

closed position.

Check that the accelerator position sen-

sor 1 and 2 output voltage.

NOTE:

The actual accelerator position sensor out-

put voltage and throttle valve opening angle

may vary according to environmental condi-

tions.

Accelerator position sensor 1

output voltage at throttle lever

fully closed position:

0.50–0.90 V

Accelerator position sensor 2

output voltage at throttle lever

fully closed position:

0.35–1.05 V

Throttle valve opening angle at

throttle lever fully closed

position:

2.7–4.8°

Squeeze the throttle lever to the fully

open position and hold it.

Check that the accelerator position sen-

sor 1 and 2 output voltage.

ProCarManuals.com