ignition YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 105 of 347

5-6

EPOWRENGINE UNIT

7. Install:

Ignition coils

T R..

Ignition coils bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

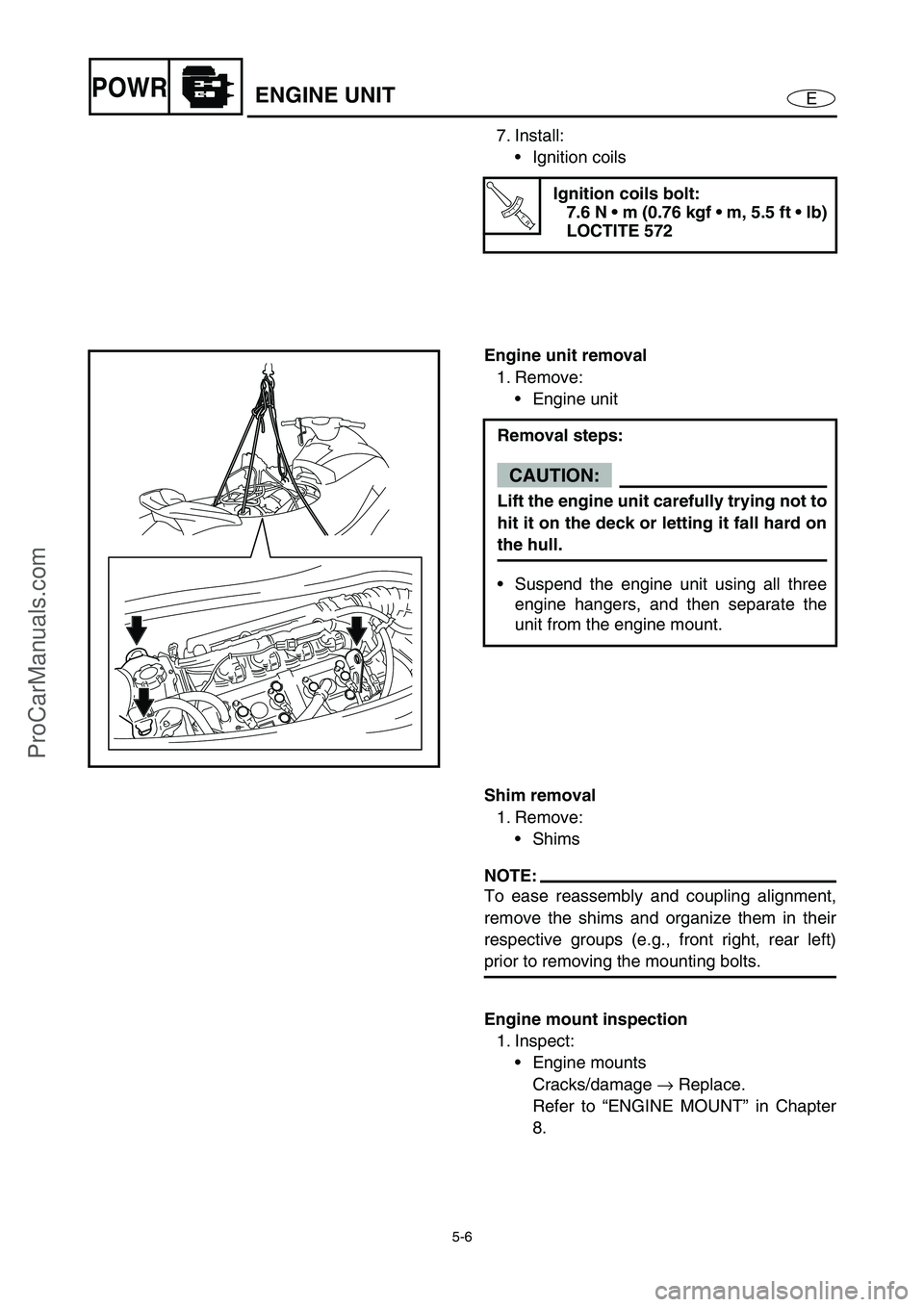

Engine unit removal

1. Remove:

Engine unit

Removal steps:

CAUTION:

Lift the engine unit carefully trying not to

hit it on the deck or letting it fall hard on

the hull.

Suspend the engine unit using all three

engine hangers, and then separate the

unit from the engine mount.

Shim removal

1. Remove:

Shims

NOTE:

To ease reassembly and coupling alignment,

remove the shims and organize them in their

respective groups (e.g., front right, rear left)

prior to removing the mounting bolts.

Engine mount inspection

1. Inspect:

Engine mounts

Cracks/damage →

Replace.

Refer to “ENGINE MOUNT” in Chapter

8.

ProCarManuals.com

Page 140 of 347

5-41

EPOWRCAMSHAFTS

CAMSHAFTS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD COVER

REMOVALFollow the left “Step” for removal.

1Bolt 4

2 Ignition coil 4

3 Spark plug 4

4 Clamp/breather hose 1/1È

To oil tank

Paint mark a

5Bolt 1

6 Cam position sensor 1

7 Clamp/cooling water hose 1/1É

To transom plate

8 Rubber seal 1

E

4

65

7 8

10

11

12

13 9

LT

572

LT

14

16

15

3

13 N

m (1.3 kgf m, 9.4 ft Ib)

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 16 mm 6 × 16 mm

2nd 7.6 N m (0.76 kgf

m, 5.5 ft

Ib) 1st 3.7 N m (0.37 kgf

m, 2.7 ft

Ib)

12 N

m (1.2 kgf m, 8.7 ft Ib)

6 × 22 mm

aÈ

É

1

2

7.6 N

m (0.76 kgf m, 5.5 ft Ib)

6 × 16 mm

LT

572

LTAA

1280B

1280B

ProCarManuals.com

Page 225 of 347

E

–+ELEC

1

2

3

4

5

6

7

8

9

CHAPTER 7

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS........................................................................ 7-1

FUSE BOX ....................................................................................................... 7-2

EXPLODED DIAGRAM ............................................................................. 7-2

REMOVAL AND INSTALLATION CHART ................................................ 7-2

ECM AND RECTIFIER/REGULATOR............................................................. 7-7

EXPLODED DIAGRAM ............................................................................. 7-7

REMOVAL AND INSTALLATION CHART ................................................ 7-7

ELECTRICAL ANALYSIS ............................................................................... 7-9

INSPECTION............................................................................................. 7-9

Digital tester ........................................................................................ 7-9

Low resistance measurement ........................................................... 7-10

Peak voltage measurement .............................................................. 7-10

Peak voltage adapter ........................................................................ 7-11

Test harness .................................................................................... 7-11

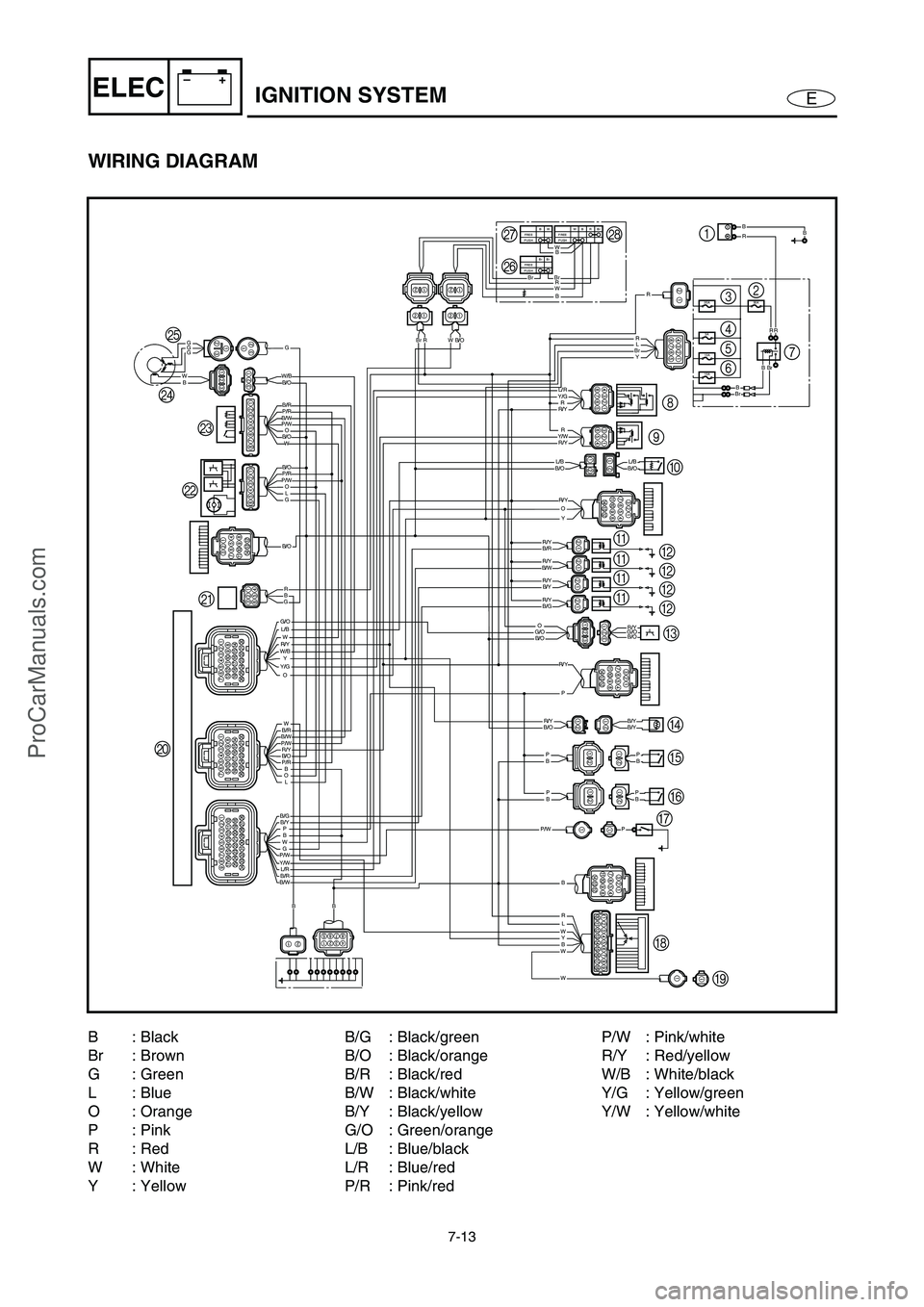

IGNITION SYSTEM ....................................................................................... 7-12

WIRING DIAGRAM ................................................................................. 7-12

IGNITION SPARK ................................................................................... 7-14

IGNITION SYSTEM PEAK VOLTAGE .................................................... 7-15

BATTERY ................................................................................................ 7-17

FUSE ....................................................................................................... 7-17

SPARK PLUGS ....................................................................................... 7-17

IGNITION COIL ....................................................................................... 7-18

ENGINE STOP SWITCH ......................................................................... 7-18

ENGINE TEMPERATURE SENSOR ...................................................... 7-19

SENSOR ASSEMBLY ............................................................................. 7-19

THERMOSWITCH (ENGINE).................................................................. 7-20

THERMOSWITCH (EXHAUST) .............................................................. 7-21

MAIN AND FUEL PUMP RELAY............................................................. 7-22

ELECTRONIC CONTROL THROTTLE VALVE RELAY ......................... 7-23

THROTTLE POSITION SENSOR ........................................................... 7-24

ACCELERATOR POSITION SENSOR ................................................... 7-26

CAM POSITION SENSOR ...................................................................... 7-29

SLANT DETECTION SWITCH ................................................................ 7-30

ProCarManuals.com

Page 228 of 347

7-1

E

–+ELECELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

0

91

2

3

4

5

6

7

8

1Thermoswitch (engine)

2Fuse box

3Slant detection switch

4Starter motor

5Engine temperature sensor

6Spark plugs and ignition coils

7Cam position sensor

8Battery

9Speed sensor

0Sensor assembly (intake air

pressure and intake air tem-

perature)AOil pressure switch

BFuel injectors

CThermoswitch (exhaust)

DRectifier/regulator

EECM

FThrottle body assembly

GLighting coil and pickup coil

HEngine stop switch, engine

shut-off switch, and start

switch

ISteering sensor

JBuzzerKAccelerator position sensor

LElectric fuel pump

MFuel sender

NMultifunction meter

ORemote control unit (Deluxe

model only)

ProCarManuals.com

Page 237 of 347

7-10

E

–+ELECELECTRICAL ANALYSIS

Low resistance measurement

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measure-

ment cannot be obtained because of the

tester’s internal resistance.

To obtain the correct value, subtract the

internal resistance from the displayed mea-

surement.

The internal resistance of the tester can be

obtained by connecting both of its terminals.

Correct value =

Displayed measurement –

Internal resistance

Peak voltage measurement

NOTE:

When checking the condition of the ignition

system it is vital to know the peak voltage.

Cranking speed is dependant on many fac-

tors (e.g., fouled or weak spark plugs, a

weak battery). If one of these is defective,

the peak voltage will be lower than specifica-

tion.

If the peak voltage measurement is not

within specification the engine will not oper-

ate properly.

A low peak voltage will also cause compo-

nents to prematurely wear.

ProCarManuals.com

Page 239 of 347

7-12

E

–+ELECIGNITION SYSTEM

IGNITION SYSTEM

WIRING DIAGRAM

10A

10A

3A

30A20A

WBrBRFREE

PUSHBWFREE

PUSH

Br BrFREE

PUSH

BW

W

BrBrBrBrR

W

B/W

B/O

B/O

B/O

B/R

P/R

P/R

W/B

P/W

P/W

B/O

L/B

B/WB/R

B/OP/W

P/R

W

W

WLR

Y

G

O

O

W

GG

BW

GG

O

OLG

W

Y

W

G/O

W/BR/Y

Y/G

BL

PBWP/W

B/GB/Y

Y/WL/RB/RB/W

B

B

BBP

P

P

BBP

RR

BBR

R/Y

B/OL/BB/OL/B

B/G

G/OB/OG/O

P/W

B/OB/YB/YR/Y

R/Y

R/Y

R/YB/YR/Y

R/Y

B/O

B/RR/Y

R/Y

R/YY/W

Y/GL/R

Y

P

P

O

O R

R

R

BB

BrRB/O

BBr

B/W

Y BrL R B

R

GB

R/YBBr

4

0 98

B

B B

B

H

I JK LM NOQ

PR

3

5

67 2 1

A

A A

A

C

D

E

F

G

1Battery

2Fuse (30 A)

3Fuse (20 A)

4Fuse (3 A)

5Fuse (10 A)

6Fuse (10 A)

7Starter relay

8Main and fuel pump

relay9Electronic control

throttle valve relay

0Slant detection switch

AIgnition coil

BSpark plug

CCam position sensor

DEngine temperature

sensor

EThermoswitch

(engine)FThermoswitch

(exhaust)

GOil pressure switch

HRemote control unit

(Deluxe model only)

IAntenna

(Deluxe model only)

JECM

KRectifier/regulatorLThrottle body assem-

bly

MAccelerator position

sensor

NPickup coil

OLighting coil

PStart switch

QEngine stop switch

REngine shut-off switch

ProCarManuals.com

Page 240 of 347

7-13

E

–+ELECIGNITION SYSTEM

WIRING DIAGRAM

10A

10A

3A

30A20A

WBrBRFREE

PUSHBWFREE

PUSH

Br BrFREE

PUSH

BW

W

BrBrBrBrR

W

B/W

B/O

B/O

B/O

B/R

P/R

P/R

W/B

P/W

P/W

B/O

L/B

B/WB/R

B/OP/W

P/R

W

W

WLR

Y

G

O

O

W

GG

BW

GG

O

OLG

W

Y

W

G/O

W/BR/Y

Y/G

BL

PBWP/W

B/GB/Y

Y/WL/RB/RB/W

B

B

BBP

P

P

BBP

RR

BBR

R/Y

B/OL/BB/OL/B

B/G

G/OB/OG/O

P/W

B/OB/YB/YR/Y

R/Y

R/Y

R/YB/YR/Y

R/Y

B/O

B/RR/Y

R/Y

R/YY/W

Y/GL/R

Y

P

P

O

O R

R

R

BB

BrRB/O

BBr

B/W

Y BrL R B

R

GB

R/YBBr

4

0 98

B

B B

B

H

I JK LM NOQ

PR

3

5

67 2 1

A

A A

A

C

D

E

F

G

B: Black

Br : Brown

G: Green

L: Blue

O : Orange

P: Pink

R: Red

W: White

Y : YellowB/G : Black/green

B/O : Black/orange

B/R : Black/red

B/W : Black/white

B/Y : Black/yellow

G/O : Green/orange

L/B : Blue/black

L/R : Blue/red

P/R : Pink/redP/W : Pink/white

R/Y : Red/yellow

W/B : White/black

Y/G : Yellow/green

Y/W : Yellow/white

ProCarManuals.com

Page 241 of 347

7-14

E

–+ELECIGNITION SYSTEM

IGNITION SPARK

WARNING

When checking the spark gap, do not

touch any of the connections of the spark

checker/ignition tester lead wires.

When performing the spark gap test, take

special care not to let sparks leak out of

the removed spark plug cap.

When performing the spark gap check,

keep flammable gas or liquids away,

since this test can produce sparks.

1. Check:

Ignition spark

Weak →

Check the ECM output peak

voltage.

Check the ignition coil for resistance.

Checking steps:

Connect the spark plug cap to the special

service tool.

Spark checker:

YM-34487

Ignition tester:

90890-06754

Crank the engine and observe the igni-

tion system spark through the discharge

window.

OK

ProCarManuals.com

Page 242 of 347

7-15

E

–+ELECIGNITION SYSTEM

IGNITION SYSTEM PEAK VOLTAGE

WARNING

When checking the electrical components,

do not touch any of the connections of the

digital tester lead wires.

NOTE:

If there is no spark, or the spark is weak,

continue with the ignition system test.

If a good spark is obtained, the problem is

not with the ignition system, but possibly with

the spark plug(s) or another component.

1. Measure:

ECM output peak voltage

Below specification →

Measure the

pickup coil output peak voltage.

NOTE:

When measuring the ECM output peak volt-

age while cranking the engine, disconnect

the ignition coil couplers for all cylinders

except for the cylinder being measured.

To crank the engine, connect the engine

shut-off cord (lanyard) to the engine shut-off

switch, and then press the start switch.

Test harness (2 pins):

New: YB-06867

Current: YB-06767

Test harness FWY-2 (2 pins):

New: 90890-06867

Current: 90890-06767

ECM output peak voltage:

Black/red (B/R) –

Red/yellow (R/Y)

Black/white (B/W) –

Red/yellow (R/Y)

Black/yellow (B/Y) –

Red/yellow (R/Y)

Black/green (B/G) –

Red/yellow (R/Y)

r/minLoaded

Cranking 2,000 3,500

V 90 130 140

ProCarManuals.com

Page 243 of 347

7-16

E

–+ELECIGNITION SYSTEM

2. Measure:

Pickup coil output peak voltage

Below specification →

Replace the

pickup coil.

Above specification →

Replace the

ECM.

NOTE:

To crank the engine, connect the engine shut-

off cord (lanyard) to the engine shut-off switch,

and then press the start switch and engine

stop switch simultaneously.

Test harness (3 pins):

New: YB-06877

Current: YB-06777

Test harness HM090-3 (3 pins):

New: 90890-06877

Current: 90890-06777

Pickup coil output peak voltage:

White/black (W/B) –

Black/orange (B/O)

r/minUnloaded Loaded

Cranking 2,000 3,500

V 8.0 6.9 19.4 25.1

3. Measure:

Lighting coil output peak voltage

Below specification →

Replace the light-

ing coil.

Test harness (3 pins):

New: YB-06870

Current: YB-06770

Test harness SMT250-3 (3 pins):

New: 90890-06870

Current: 90890-06770

Lighting coil output peak voltage:

Green (G) – Green (G)

r/minUnloaded

Cranking 2,000 3,500

V 7.8 24.5 41.6

ProCarManuals.com