service YAMAHA VX110 2005 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 142 of 347

5-43

EPOWRCAMSHAFTS

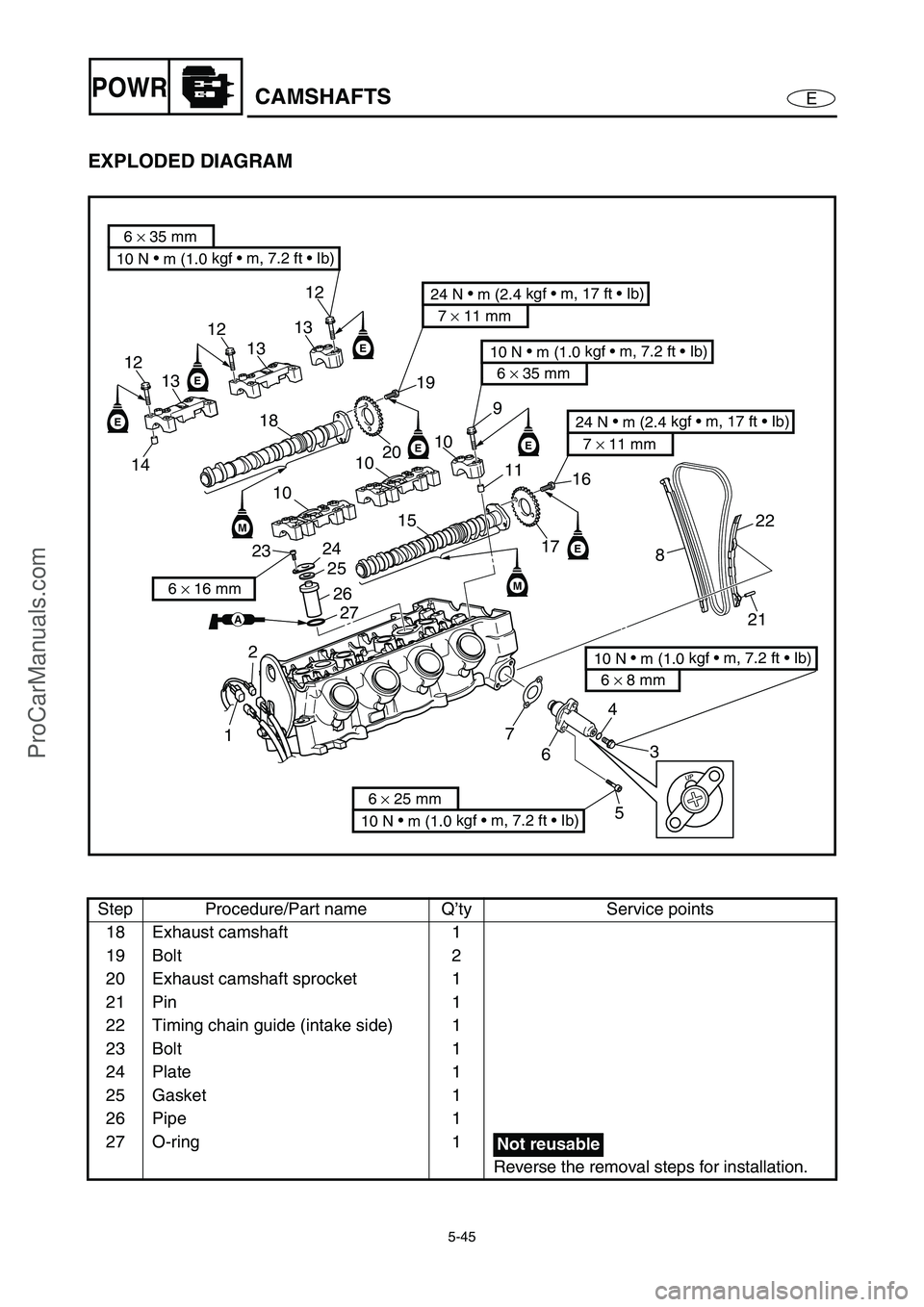

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CAMSHAFT REMOVAL

Follow the left “Step” for removal.

Cylinder head cover

Reduction drive gear case Refer to “REDUCTION DRIVE GEAR”.

NOTE:

When removing camshafts it is not neces-

sary to remove the reduction drive gear

case.

1 Thermoswitch (engine) coupler 1

2 Engine temperature sensor coupler 1

3 Cap bolt 1

4Gasket 1

5Bolt 2

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 143 of 347

5-44

EPOWRCAMSHAFTS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

6 Timing chain tensioner 1

7 Timing chain tensioner gasket 1

8 Timing chain guide (exhaust side) 1

9Bolt 18

10 Intake camshaft cap 3

11 Dowel pin 6

12 Bolt 10

13 Exhaust camshaft cap 3

14 Dowel pin 6

15 Intake camshaft 1

16 Bolt 2

17 Intake camshaft sprocket 1

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N •

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 144 of 347

5-45

EPOWRCAMSHAFTS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

18 Exhaust camshaft 1

19 Bolt 2

20 Exhaust camshaft sprocket 1

21 Pin 1

22 Timing chain guide (intake side) 1

23 Bolt 1

24 Plate 1

25 Gasket 1

26 Pipe 1

27 O-ring 1

Reverse the removal steps for installation.

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 145 of 347

5-46

EPOWRCAMSHAFTS

SERVICE POINTS

Camshaft removal

1. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

2. Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

NOTE:

TDC on the compression stroke can be found

when the camshaft lobes are turned away from

each other.

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-01252

2

1

INEX

3. Make the alignment marks a on the timing

chain and camshaft sprockets.

a

4. Remove:

Timing chain tensioner 1

Gasket

1

ProCarManuals.com

Page 146 of 347

5-47

EPOWRCAMSHAFTS

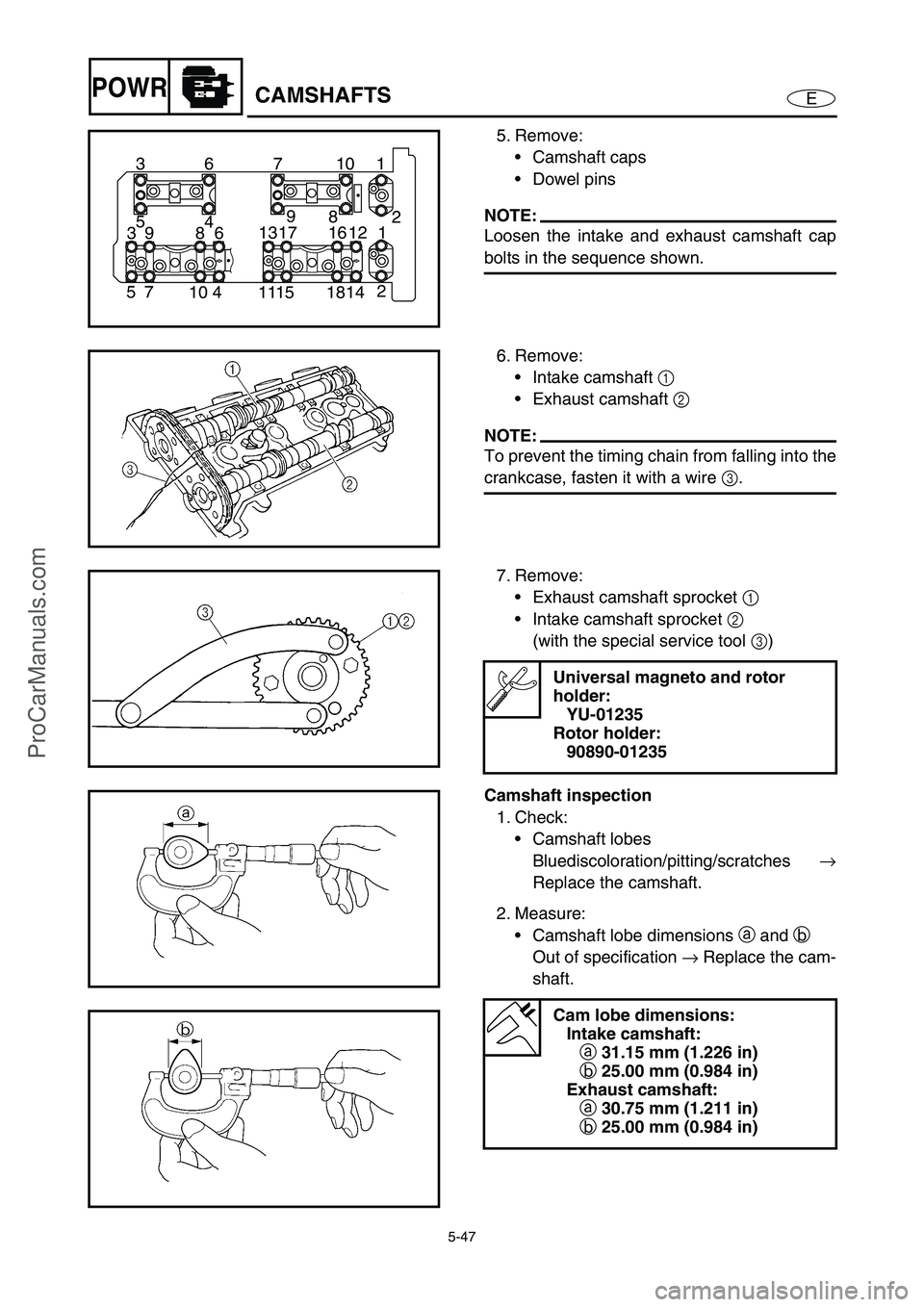

5. Remove:

Camshaft caps

Dowel pins

NOTE:

Loosen the intake and exhaust camshaft cap

bolts in the sequence shown.

1 10 7 6 3

2

14 18 15 11 4 10 7 52 8 9

4 5

1 12 16 17 13

6 8 9 3

6. Remove:

Intake camshaft 1

Exhaust camshaft 2

NOTE:

To prevent the timing chain from falling into the

crankcase, fasten it with a wire 3

.

7. Remove:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

Camshaft inspection

1. Check:

Camshaft lobes

Bluediscoloration/pitting/scratches →

Replace the camshaft.

2. Measure:

Camshaft lobe dimensions a

and b

Out of specification →

Replace the cam-

shaft.

Cam lobe dimensions:

Intake camshaft:

a 31.15 mm (1.226 in)

b 25.00 mm (0.984 in)

Exhaust camshaft:

a 30.75 mm (1.211 in)

b 25.00 mm (0.984 in)

ProCarManuals.com

Page 149 of 347

5-50

EPOWRCAMSHAFTS

Camshaft installation

1. Install:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

NOTE:

Install the camshaft sprocket with the punch

mark a

facing outside.

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

T R..

Camshaft sprocket bolt:

24 N m (2.4 kgf m, 17 ft lb)

2. Install:

Exhaust camshaft

Intake camshaft

Exhaust camshaft caps

Intake camshaft caps

Installation steps:

Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

Install the timing chain onto both cam-

shaft sprockets, and then install the cam-

shaft.

CAUTION:

Do not turn the crankshaft when install-

ing the camshaft to avoid damage or

improper valve timing.

NOTE:

Make sure that the punch marks a

on the

camshafts face up.

Be sure to align the alignment marks b

made during removal to install the timing

chain and camshaft sprockets.

b

ProCarManuals.com

Page 153 of 347

5-54

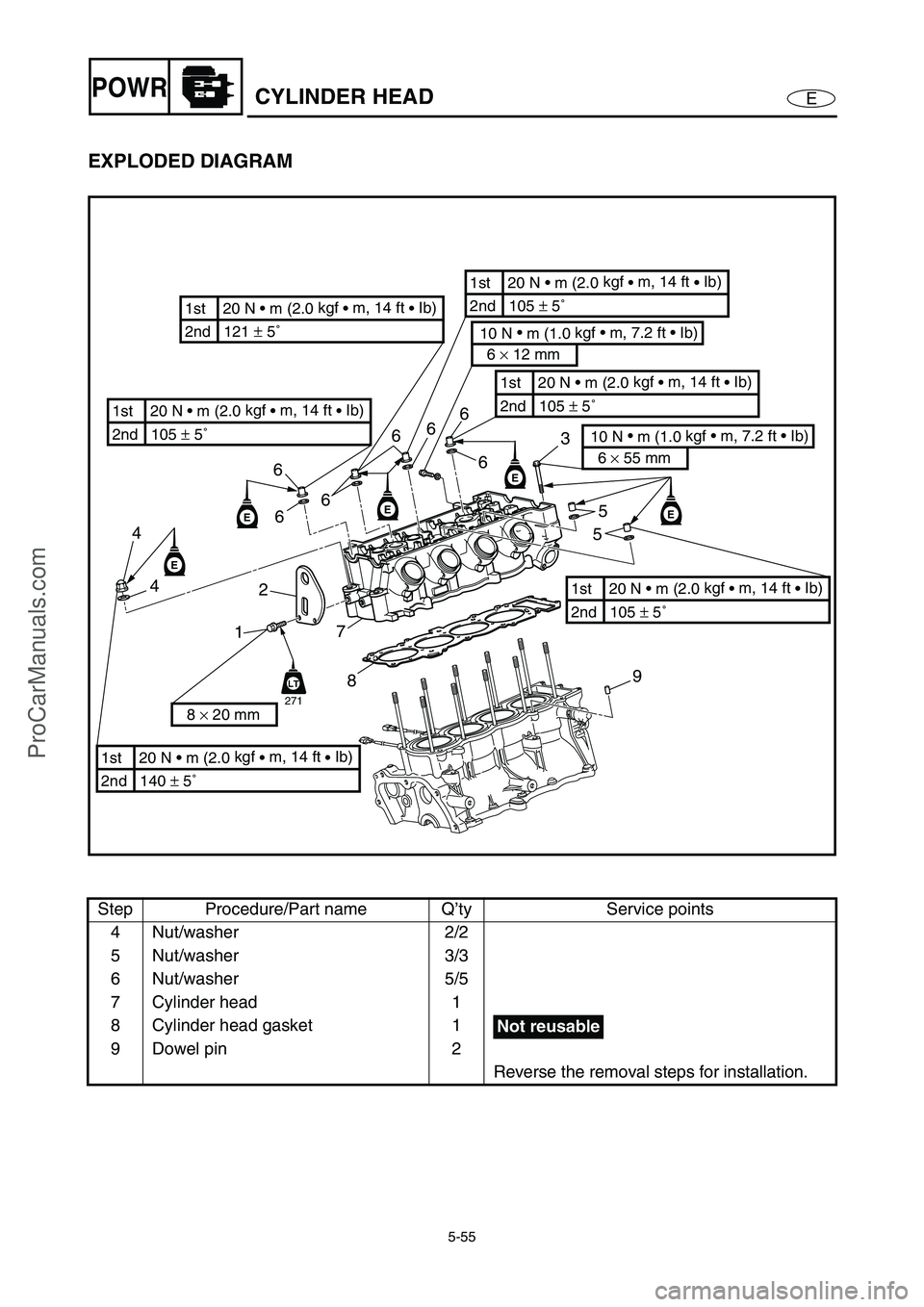

EPOWRCYLINDER HEAD

CYLINDER HEAD

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD REMOVAL

Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

Oil tank Refer to “OIL TANK”.

Intake and exhaust camshaft Refer to “CAMSHAFTS”.

1Bolt 2

2 Hunger 1

3Bolt 3

EEE

E

2 4

1

855

7

9 3 6

6

LT

271

2nd 121 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 140 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 12 mm

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 55 mm

8 × 20 mm

6

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

E6

4

66

6

ProCarManuals.com

Page 154 of 347

5-55

EPOWRCYLINDER HEAD

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

4 Nut/washer 2/2

5 Nut/washer 3/3

6 Nut/washer 5/5

7 Cylinder head 1

8 Cylinder head gasket 1

9 Dowel pin 2

Reverse the removal steps for installation.

EEE

E

2 4

1

855

7

9 3 6

6

LT

271

2nd 121 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 140 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 12 mm

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 55 mm

8 × 20 mm

6

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

E6

4

66

6

Not reusable

ProCarManuals.com

Page 155 of 347

5-56

EPOWRCYLINDER HEAD

SERVICE POINTS

Cylinder head removal

1. Remove:

Cylinder head bolts 1

2. Remove:

Cylinder head nuts

NOTE:

Loosen the cylinder head nuts in the sequence

shown.

Cylinder head inspection

1. Eliminate:

Combustion chamber carbon deposits

(with a rounded scraper)

NOTE:

Do not use a sharp instrument to avoid damag-

ing or scratching:

spark plug bore threads

valve seats

2. Check:

Cylinder head

Damage/scratches →

Replace.

Cylinder head water jacket

Mineral deposits/rust →

Eliminate.

ProCarManuals.com

Page 158 of 347

5-59

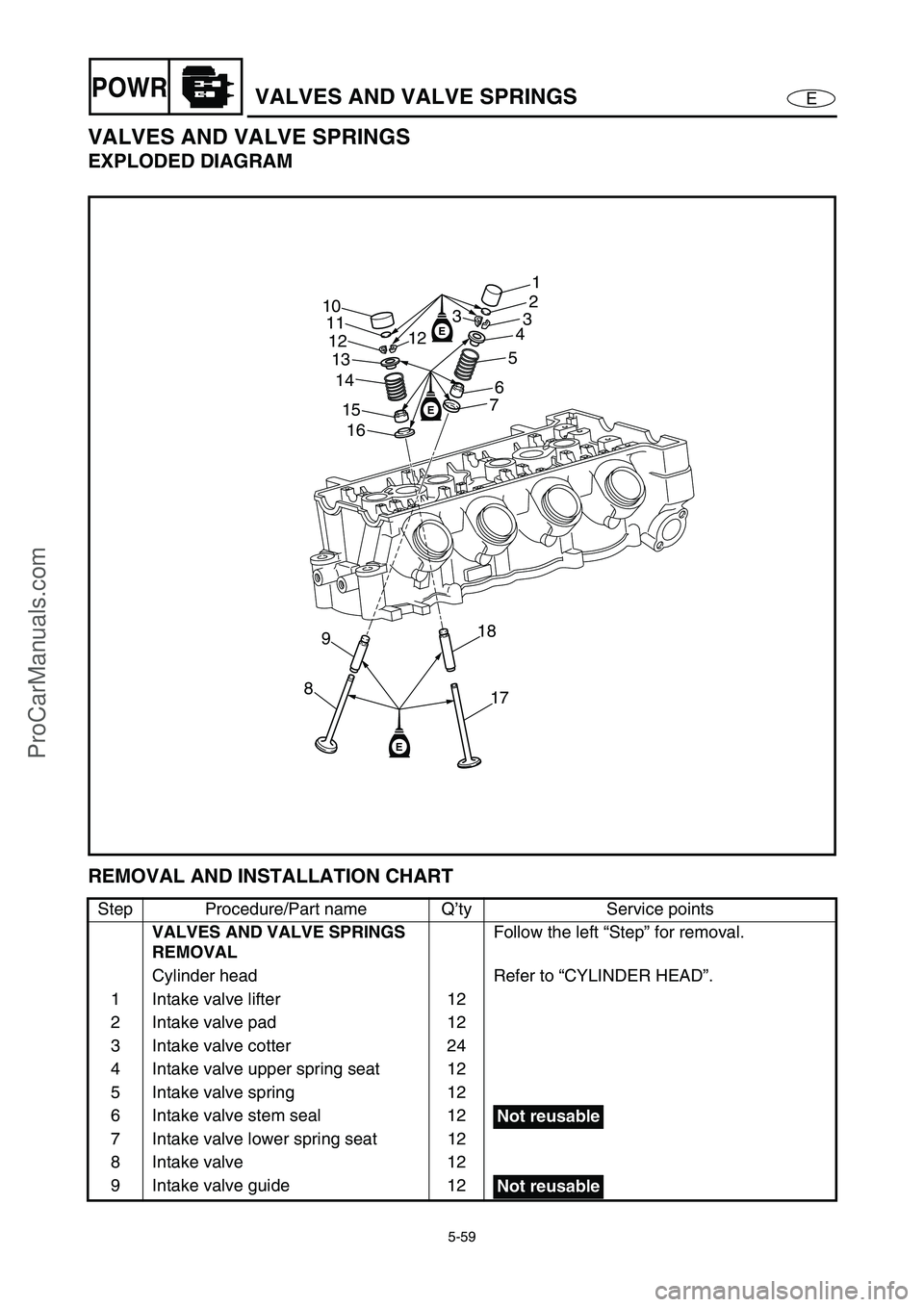

EPOWRVALVES AND VALVE SPRINGS

VALVES AND VALVE SPRINGS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

VALVES AND VALVE SPRINGS

REMOVALFollow the left “Step” for removal.

Cylinder head Refer to “CYLINDER HEAD”.

1 Intake valve lifter 12

2 Intake valve pad 12

3 Intake valve cotter 24

4 Intake valve upper spring seat 12

5 Intake valve spring 12

6 Intake valve stem seal 12

7 Intake valve lower spring seat 12

8 Intake valve 12

9 Intake valve guide 12

E

E

E

89

17 18 16 15 14 13 10

11

121

2

3

4

5

6

7 3

12

Not reusable

Not reusable

ProCarManuals.com